Design and experiment of automatic feeding seedling mechanism and control system for rice pot seedlings

-

摘要:目的

提高水稻钵苗有序抛秧机中自动输送进给钵苗行的输送精度及可靠性,减少送秧环节的漏秧问题。

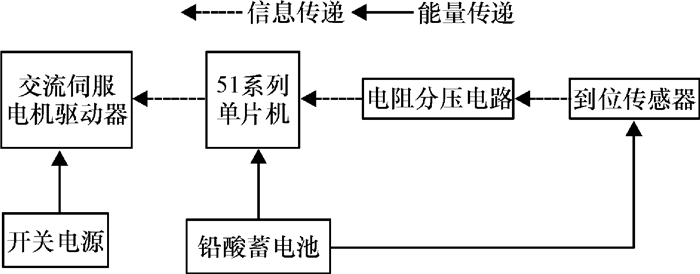

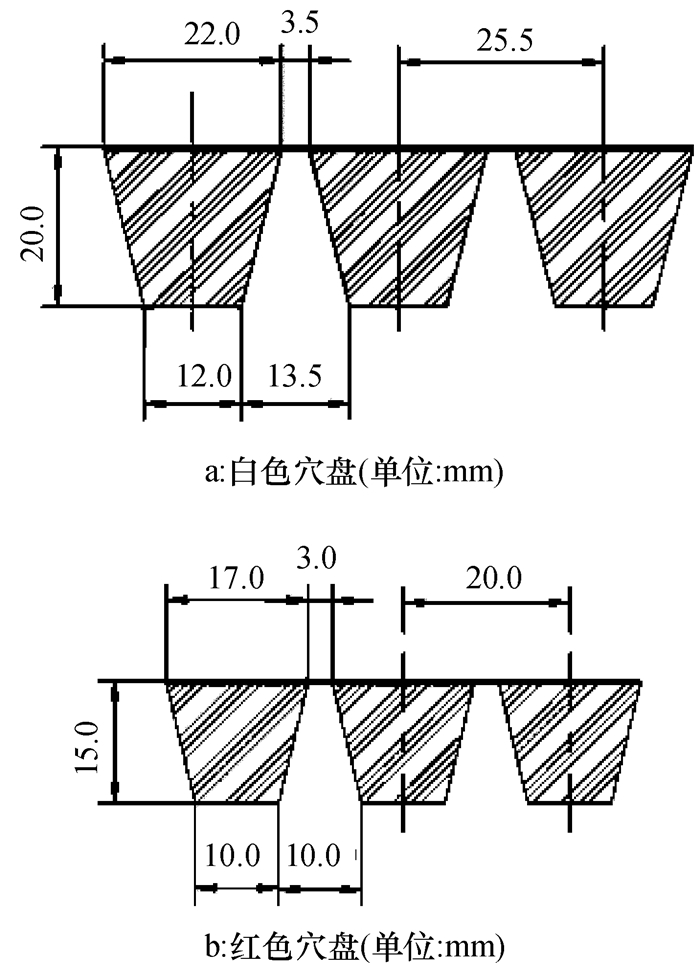

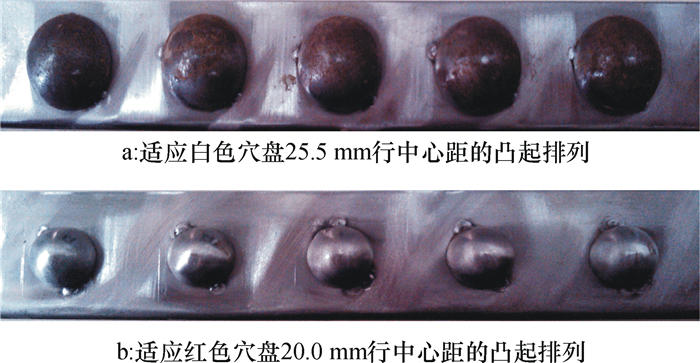

方法提出了钵苗行到位自动检测方案和程序实现方法,通过样机试验,分别获得基于直接在线检测秧苗茎秆、穴盘钵体和铁盘磁性凸起3种表征钵苗行到位的特征信号,概括出钵苗行到位信号的综合测量属性,确立钵苗行到位较佳的监测方案及其控制电路;设计集钵苗行到位检测及输送进给一体的皮带式自动送秧机构及控制系统。

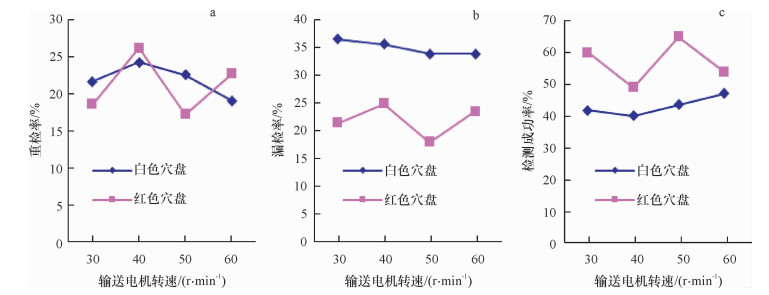

结果选用塑料穴盘钵体为检测对象时,皮带式自动送秧机构送秧到位检测成功率最高,为99.78%;铁盘磁性凸起的次之,为96.64%;秧苗茎秆最差。以塑料穴盘钵体和铁盘磁性凸起为检测对象时,穴盘类型对钵苗行到位检测成功率的影响不显著(P>0.05);但以秧苗茎秆为检测对象时,则影响极显著(P < 0.01)。在3种钵苗行到位检测方案中,输送电机转速在30~60 r·min-1范围内变动时,对钵苗行到位检测效果的影响均不显著(P>0.05)。

结论所设计的皮带式自动送秧机构及其钵苗行到位的自动检测控制系统能够满足钵苗有序自动抛秧机对钵苗行输送进给的性能要求。

Abstract:ObjectiveTo improve the accuracy and reliability of automatic feeding rice seedlings in the orderly throwing transplanter, and reduce the seedling loss in the seedling feeding link.

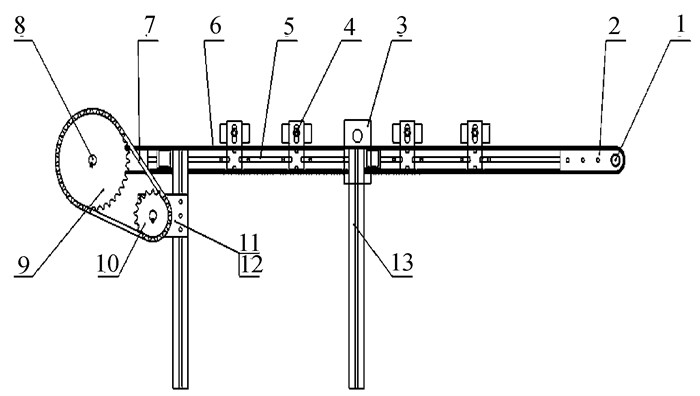

MethodA rice seedling-row-in-position detecting scheme and its practical program method were proposed, while a belt-type automatic seedling feeding mechanism (BASFM) and related control system were developed. Through prototype test, three kinds of characteristic signals representing the plug-seedling-row-in-position status were received based on direct-on-line detection of seedling stalk, plastic tray and magnetic bulge of ferric tray respectively. The synthetical measure attribute of plug-seedling-row-in-position signal was summarized. An optimal scheme to monitor plug-seedling-row-in-position and associated control circuit was established. The BASFM with functions of detecting seedling-row, transporting and feeding seedling was designed.

ResultWhen body of plastic tray was chosen as a detected target, the success-detect rate was the highest (99.78%), magnetic bulges aside ferric tray was higher (96.64%) and seedling stalk was the lowest. When plastic tray or magnetic bulge of ferric tray was chosen as a row detected target, tray type showed no significant effect on success-detect rate, but significant while seedling stalk was chosen as a row detected target. For three seedling-row-in-position detecting schemes, the variance of transport motor speed also showed no significant impact on the seedling-row-in-position detecting performance between 30-60 r·min-1.

ConclusionThis design of BASFM and affiliated seedling-row-in-position automatic detecting and control system can meet the performance requirements for pot-seedling-row transporting and feeding in the rice seedling orderly throwing transplanter.

-

-

表 1 秧苗茎秆行检测评价指标的两因素方差分析

Table 1 Two-way ANOVA of evaluation indexes based on direct-on-line detection of seedling stalk

表 2 铁盘磁性凸起检测试验结果

Table 2 Results of detecting magnetic bulges aside ferric tray

表 3 铁盘磁性凸起检测评价指标的两因素方差分析结果

Table 3 Two-way ANOVA of evaluate indexes based on detection of magnetic bulge of ferric tray

-

[1] 周海波, 马旭, 姚亚利.水稻秧盘育秧播种技术与装备的研究现状及发展趋势[J].农业工程学报, 2008, 24(4):301-306. doi: 10.3321/j.issn:1002-6819.2008.04.060 [2] 闫凤宇, 于凤阁.水稻抛秧应用现状及技术要点[J].现代农业科技, 2011(3):99. doi: 10.3969/j.issn.1007-5739.2011.03.054 [3] 马瑞峻, 区颖刚, 王玉兴, 等.穴盘水稻秧苗机械抛栽的农艺要求[J].华中农业大学学报, 2003, 22(1):55-59. doi: 10.3321/j.issn:1000-2421.2003.01.013 [4] 张冬梅, 汪春.水稻钵育机械化栽培技术研究现状及发展趋势[J].长春理工大学学报(高教版), 2009, 4(7):175-176. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK200902481286 [5] 夏俊芳, 王树才, 许绮川.水稻抛秧机械的现状与发展趋势[J].农业机械, 2001(11):35-36. http://d.old.wanfangdata.com.cn/Periodical/nyjx200111016 [6] 李建桥, 张国凤, 陈建能, 等.钵苗有序移栽机构的研究进展及应用展望[J].农机化研究, 2008(2):1-5. doi: 10.3969/j.issn.1003-188X.2008.02.001 [7] 杨坚, 阳潮声, 陈兆耀, 等.2ZB-8电磁振动式小型水稻钵苗移栽机的研究[J].农业工程学报, 2002, 18(6):84-87. doi: 10.3321/j.issn:1002-6819.2002.06.022 [8] 陈风. 钵苗移栽机输送、分苗系统的研究[D]. 石河子: 石河子大学, 2005. [9] 陈恒高, 宋来田, 田金和, 等.水稻机制钵苗抛秧机的研究[J].农业机械学报, 1996, 27(3):47-51. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK199600778246 [10] 陈恒高, 田金和, 宋来田, 等.机械手式水稻抛秧机的研究[J].农业机械学报, 1998, 29(3):48-52. http://d.old.wanfangdata.com.cn/Periodical/nyjxxb199803010 [11] 王瑞丽, 李宝筏.水稻钵苗有序移栽试验装置的研究[J].农机化研究, 2007(9):116-118. doi: 10.3969/j.issn.1003-188X.2007.09.036 [12] 原新斌, 张国凤, 陈建能, 等.顶出式水稻钵苗有序移栽机的研究[J].浙江理工大学学报, 2011, 28(5):749-752. doi: 10.3969/j.issn.1673-3851.2011.05.020 [13] 韩长杰, 杨宛章, 张学军, 等.穴盘苗移栽机自动取喂系统的设计与试验[J].农业工程学报, 2013, 29(8):51-61. http://d.old.wanfangdata.com.cn/Periodical/nygcxb201308008 [14] 包春江, 李宝筏, 包文育, 等.水稻钵苗空气整根气吸式有序移栽机的研究[J].农业工程学报, 2003, 19(6):130-134. doi: 10.3321/j.issn:1002-6819.2003.06.031 [15] 高英武, 任述光, 汤兴初, 等.步进式水稻钵苗摆植机送秧机构的研究[J].农业机械学报, 2003, 34(2):37-39. doi: 10.3969/j.issn.1000-1298.2003.02.012 [16] 杜立恒, 俞高红, 张国凤, 等.高速插秧机钵体毯状苗纵向送秧装置的设计与试验[J].农业工程学报, 2014, 30(14):17-25. doi: 10.3969/j.issn.1002-6819.2014.14.003 [17] 成永芳.日本RX-6型水稻钵苗移栽机引进试验简报[J].粮油加工与食品机械, 1999(3):28-32. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK199901027111 [18] KUMAR G V P, RAHEMAN H. Automatic feeding mechanism of a vegetable transplanter[J]. IJABE, 2012, 5(2): 20-27. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=nygcxb201715003

[19] SATPATHY S K, GARG I K. Effect of selected parameters on the performance of a semi-automatic vegetable transplanter[J]. AMA-Agr Mech Asia, Af, 2008, 39(2): 47-51. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=JJ026464972

[20] 吴俭敏, 颜华, 金鑫, 等.移栽机送盘装置与定位控制系统研究[J].农业机械学报, 2013, 44(S1):14-18. http://d.old.wanfangdata.com.cn/Periodical/nyjxxb2013z1003 [21] 田素博, 王荣华, 邱立春.温室穴盘苗自动移栽输送系统设计[J].沈阳农业大学学报, 2009, 40(5):620-622. doi: 10.3969/j.issn.1000-1700.2009.05.023 [22] RYU K H, KIM G, HAN J S. AE:Automation and emerging technologies: Development of a robotic transplanter for bedding plants[J]. J Agr Eng Res, 2001, 78(2): 141-146. http://d.old.wanfangdata.com.cn/Periodical/zgnykx200106002

[23] 马瑞峻, 区颖刚, 赵祚喜, 等.水稻钵苗机械手取秧有序移栽机的改进[J].农业工程学报, 2003, 19(1):113-116. doi: 10.3321/j.issn:1002-6819.2003.01.029 [24] 汤平波.单片机系统的电平转换技术[J].计算技术与自动化, 1996, 15(4):71-74. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK199600296635 [25] 郞春, 郎小飞, 郎明飞. 水稻钵体育苗摆栽机专用育秧盘: CN200920099436. 5[P]. 2010-03-03. [26] 张小鸣.单片机系统设计与开发[M].北京:清华大学出版社, 2014. [27] 王幸之, 王雷, 钟爱琴, 等.单片机应用系统电磁干扰与抗干扰技术[M].北京:北京航空航天大学出版社, 2006. [28] 顾永红.综述单片机应用系统的抗干扰设计[J].计算机自动测量与控制, 2000, 8(1):51-53. http://d.old.wanfangdata.com.cn/Periodical/jsjzdclykz200001018 [29] 秦臻, 田宏伟.单片机应用系统电磁干扰技术研究[J].机械管理开发, 2011(5): 67-68. doi: 10.3969/j.issn.1003-773X.2011.05.035

下载:

下载: