Nutrient transfer and transformation mechanism of biochar-based infiltrated urea fertilizer from different raw materials

-

摘要:目的

研究对比不同原材料生物炭基渗融尿素肥(Biochar-based infiltrated urea fertilizer,BIUF)的成肥及养分释放特性,探讨渗融法制肥中生物质种类、热解温度、表面官能团含量对肥料颗粒释放机制的影响,为BIUF缓释性能的进一步优化提供理论指导。

方法以稻壳炭(Husk biochar,HB)、松子壳炭(Pine nut biochar,PNB)、油茶壳炭(Oil-tea biochar,OTB)、花生壳炭(Peanut biochar,PB)和尿素颗粒为原料,采用渗融法制备BIUF,利用万能压力试验机、扫描电子显微镜、热重分析仪和傅里叶红外光谱仪对其成型特性和养分迁移机制进行研究。

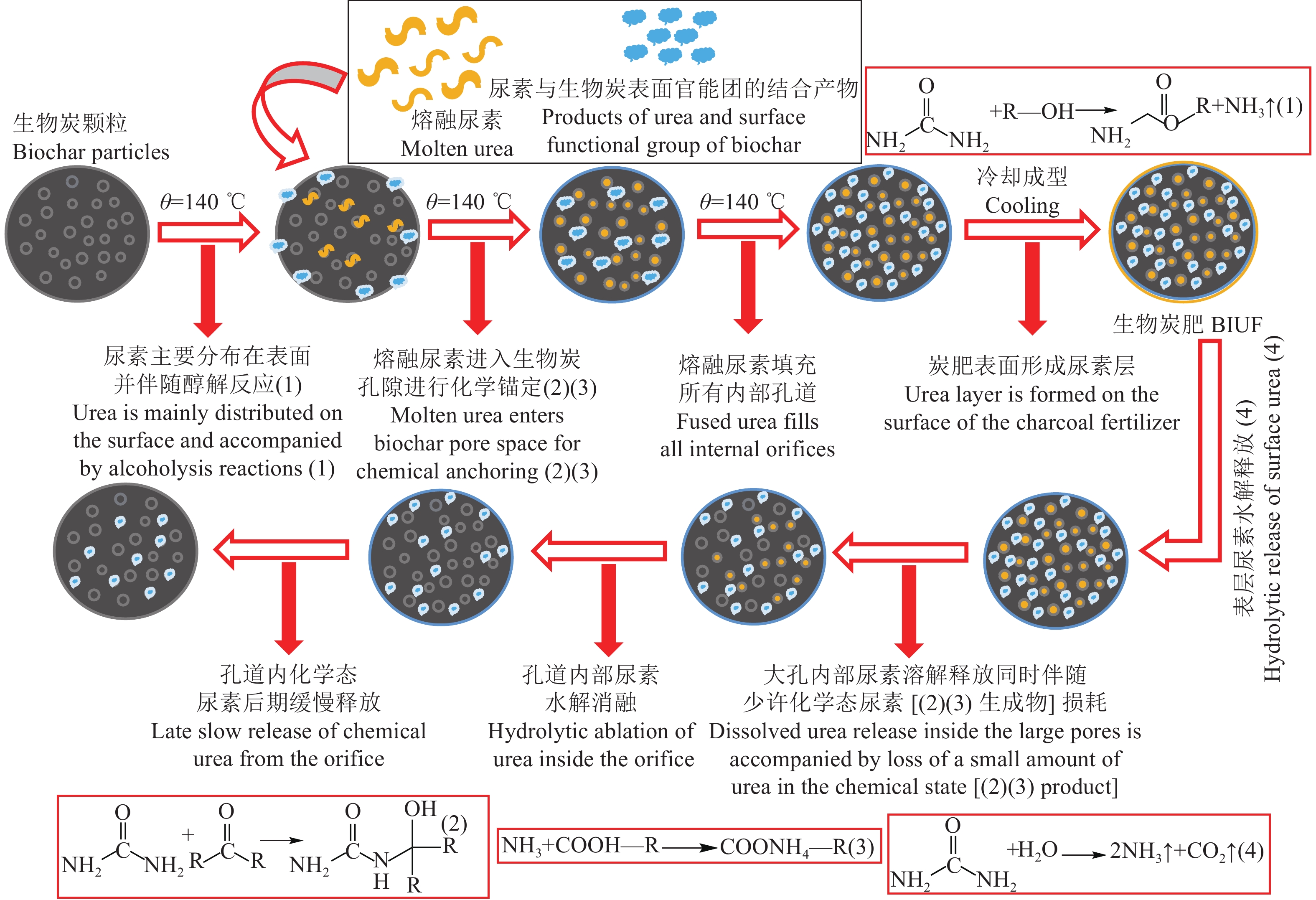

结果生物炭颗粒的表观形貌及孔壁厚度影响BIUF的物理性能,与易碎薄片化的生物炭颗粒相比,蜂窝状的生物炭颗粒结构更利于提高BIUF的物理机械性能,抗破碎性能提升1.7~2.3倍。生物炭表面的官能团含量影响BIUF的缓释性能,炭表面的—COOH、—C=O和—OH等官能团与尿素生成稳固的化学态尿素,而链式脂肪醇上的—OH与尿素发生醇解反应,造成BIUF肥力下降,释放周期缩短40%~50%。蜂窝状的稻壳炭孔隙结构复杂、含氧官能团丰富以及链式脂肪醇含量低,所制备的花生壳炭基渗融尿素肥具备优异的抗破碎性能,养分释放周期延长90%以上,具备良好的释放性能。

结论不同生物炭独特的理化性质具备良好的养分吸附性,通过提高热解温度、延长热解时间可提升生物质材料的炭化程度,所制备的BIUF具备优异的物理性能以及一定的缓释性能,对农业的可持续发展具有积极影响。

Abstract:ObjectiveTo study and compare the fertilizer formation and nutrient release characteristics of biochar-based infiltrated urea fertilizer (BIUF) from different raw materials, explore the effects of biomass type, pyrolysis temperature and surface functional group content on the release mechanism of fertilizer granules in fertilizer production by percolation method, and provide a theoretical guidance for further optimization of the slow release performance of BIUF.

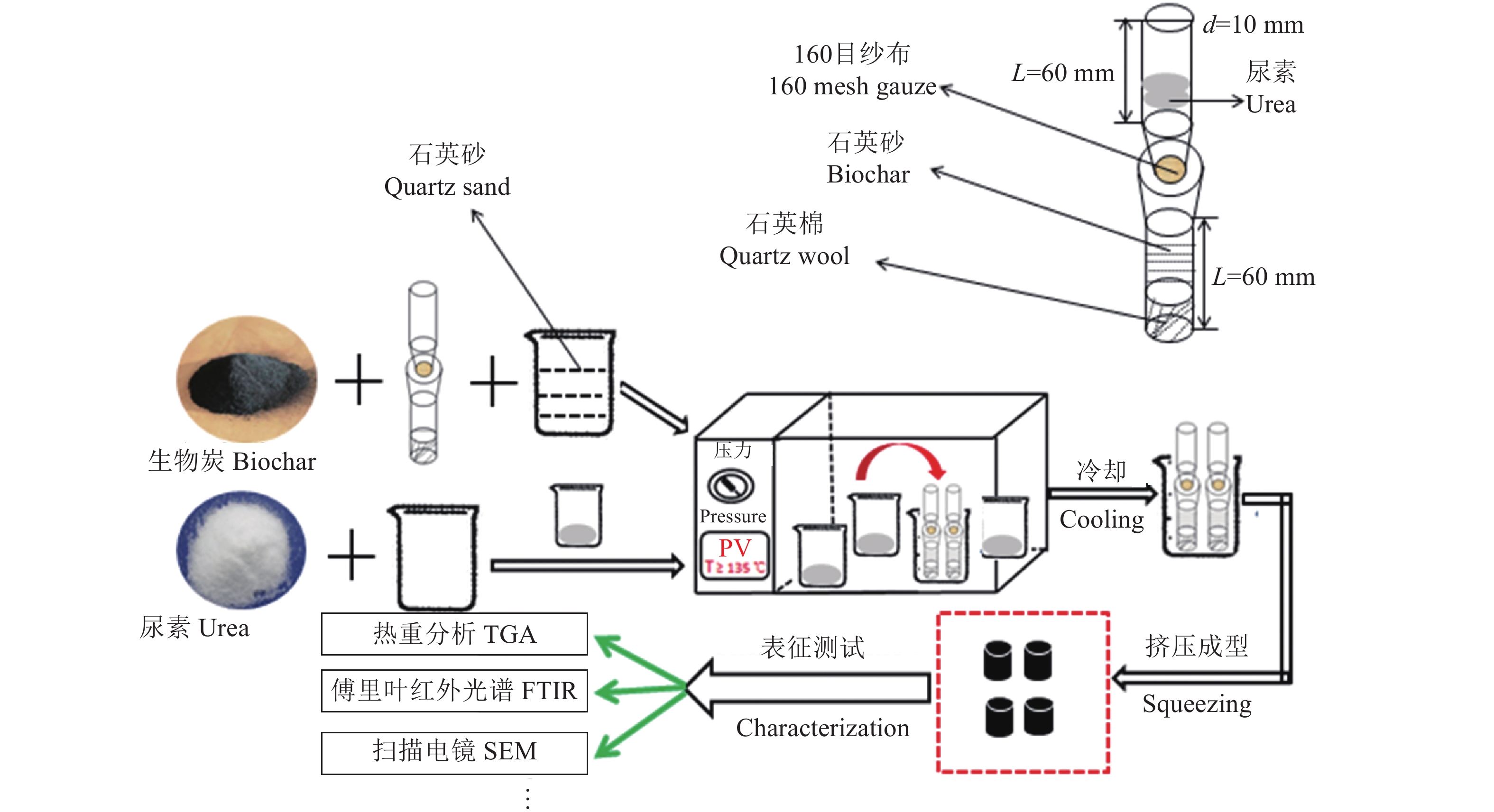

MethodBIUF was prepared by the infiltration method using rice husk bichar (HB), pine nut biochar (PNB), oil-tea biochar (OTB), peanut biochar (PB) and urea pellets as raw materials, and its molding characteristics and nutrient migration mechanism were investigated using a universal pressure tester, scanning electron microscope, thermogravimetric analyzer and Fourier infrared spectrometer.

ResultThe apparent morphology and pore wall thickness of biochar particles influenced the physical properties of BIUF. Compared with fragile and flaky biochar particles, the structure of honeycomb-shaped biochar particles was more conducive to improve the physical and mechanical properties of BIUF, and the resistance to fragmentation increased by 1.7−2.3 times. The content of functional groups on the surface of the biochar affects the slow release performance of BIUF. Functional groups such as —COOH, —C=O and —OH on the charcoal surface produced a solid chemical state urea with urea, while —OH on chain fatty alcohols reacted in an alcoholysis reaction with urea, resulting in reduced fertility of BIUF and a 40% to 50% shorter release cycle. Due to the complex pore structure of the honeycomb husk biochar, the abundant oxygen-containing functional groups and the low content of chain fatty alcohols, the prepared peanut BIUF possessed excellent fragmentation resistance, while the nutrient release cycle was prolonged by more than 90%, with good release performance.

ConclusionThe unique physicochemical properties of different biochars have good nutrient adsorption properties. By increasing the pyrolysis temperature and extending the pyrolysis time, the charring degree of biomass materials can be enhanced, and the prepared BIUF has excellent physical properties and certain slow-release properties, which have a positive impact on the sustainable development of agriculture.

-

-

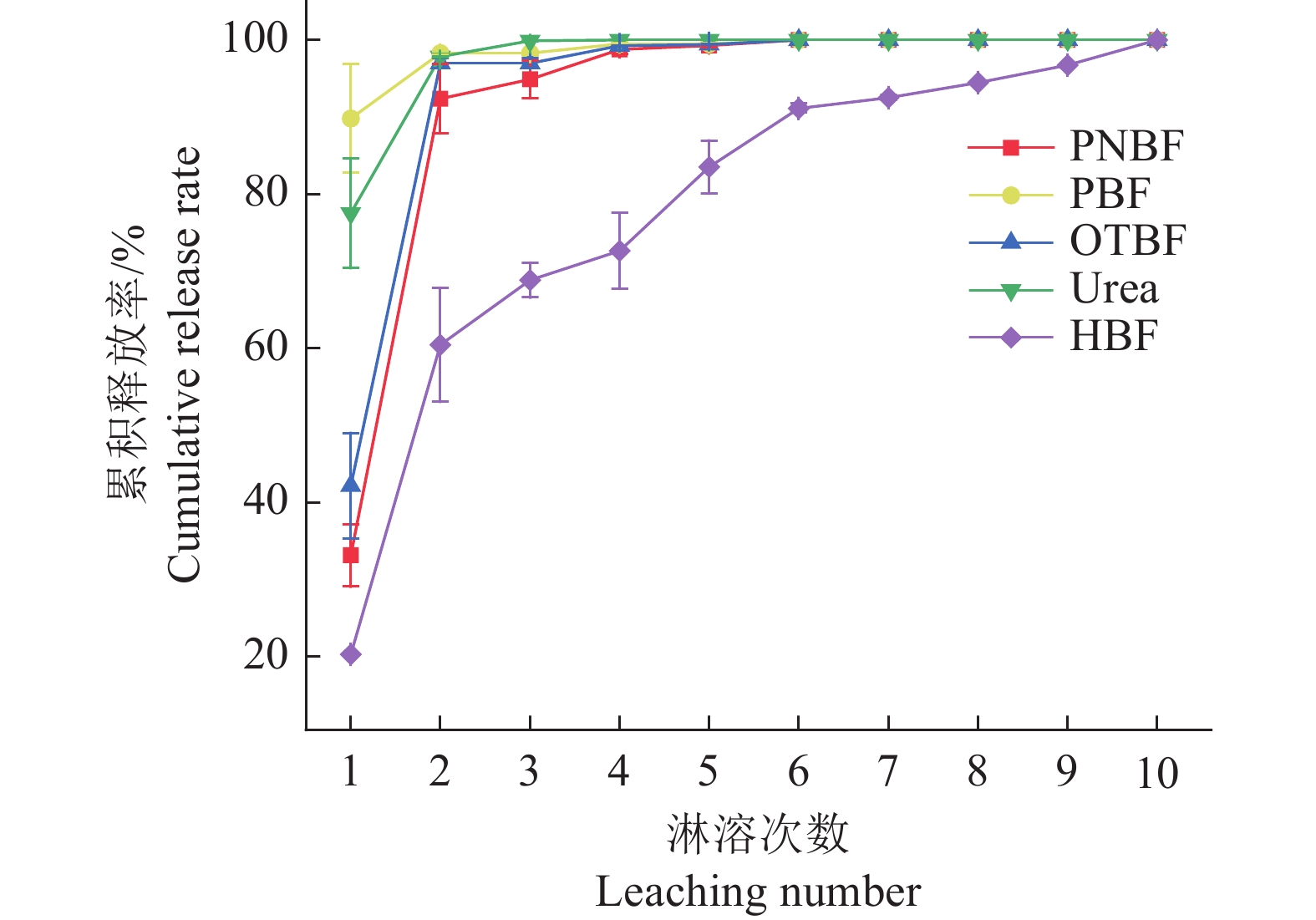

图 2 生物炭基渗融尿素肥(BIUF)与尿素的缓释性能

PNBF:松子壳炭基渗融尿素肥;PBF:花生壳炭基渗融尿素肥;OTBF:油茶壳炭基渗融尿素肥;Urea:纯尿素颗粒;HBF:稻壳炭基渗融尿素肥

Figure 2. The slow-release performances of biochar-based infiltrated urea fertilizer (BIUF) and urea

PNBF: Pine nut biochar-based infiltrated urea fertilizer; PBF: Peanut biochar-based infiltrated urea fertilizer; OTBF: Oil-tea biochar-based infiltrated urea fertilizer; Urea: Pure urea particles; HBF: Husk biochar-based infiltrated urea fertilizer

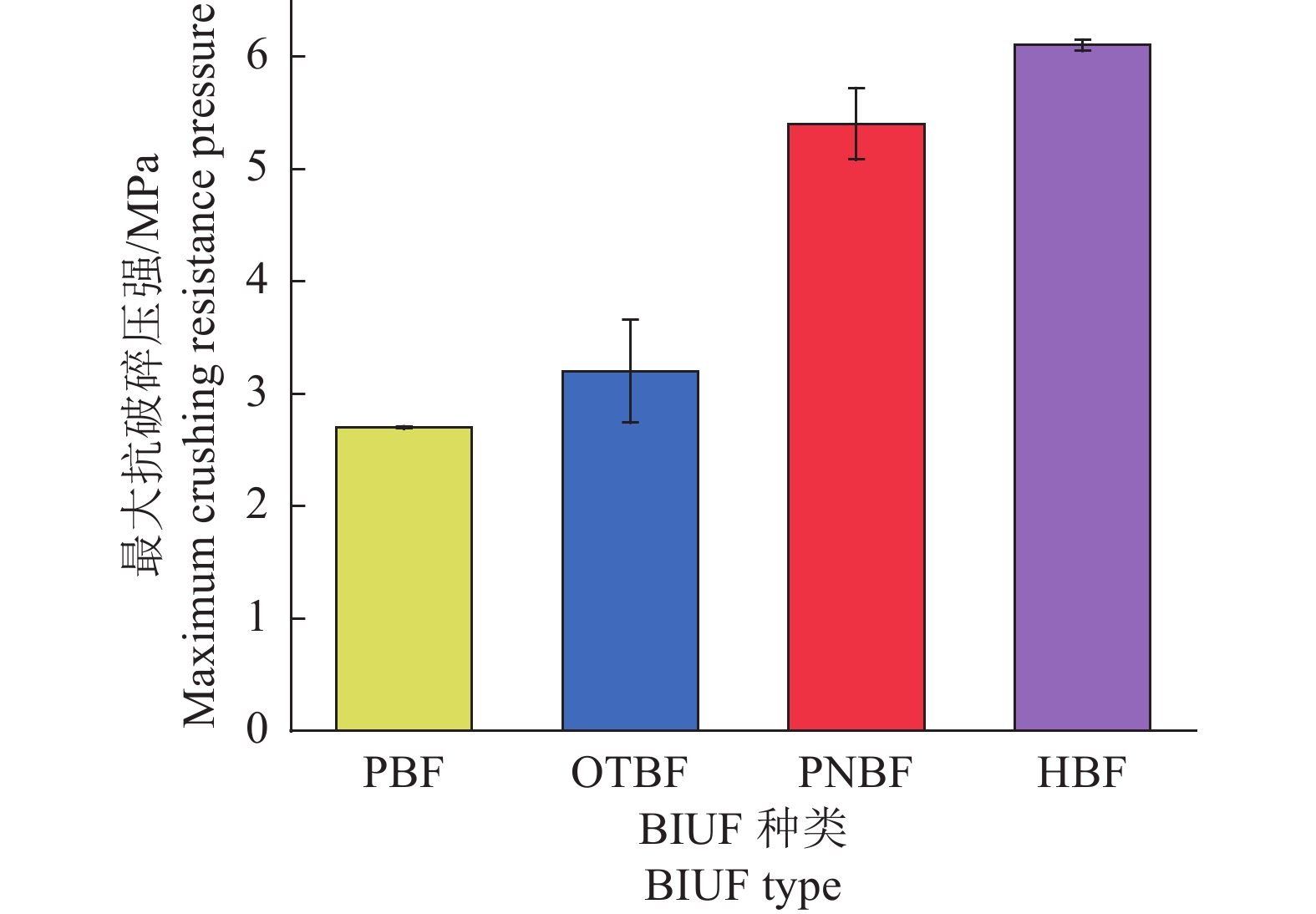

图 3 生物炭基渗融尿素肥(BIUF)的抗破碎性能

PBF:花生壳炭基渗融尿素肥;OTBF:油茶壳炭基渗融尿素肥;PNBF:松子壳炭基渗融尿素肥;HBF:稻壳炭基渗融尿素肥

Figure 3. Crushing resistance of biochar-based infiltrated urea fertilizer (BIUF)

PBF: Peanut biochar-based infiltrated urea fertilizer; OTBF: Oil-tea biochar-based infiltrated urea fertilizer; PNBF: Pine nut biochar-based infiltrated urea fertilizer; HBF: Husk biochar-based infiltrated urea fertilizer

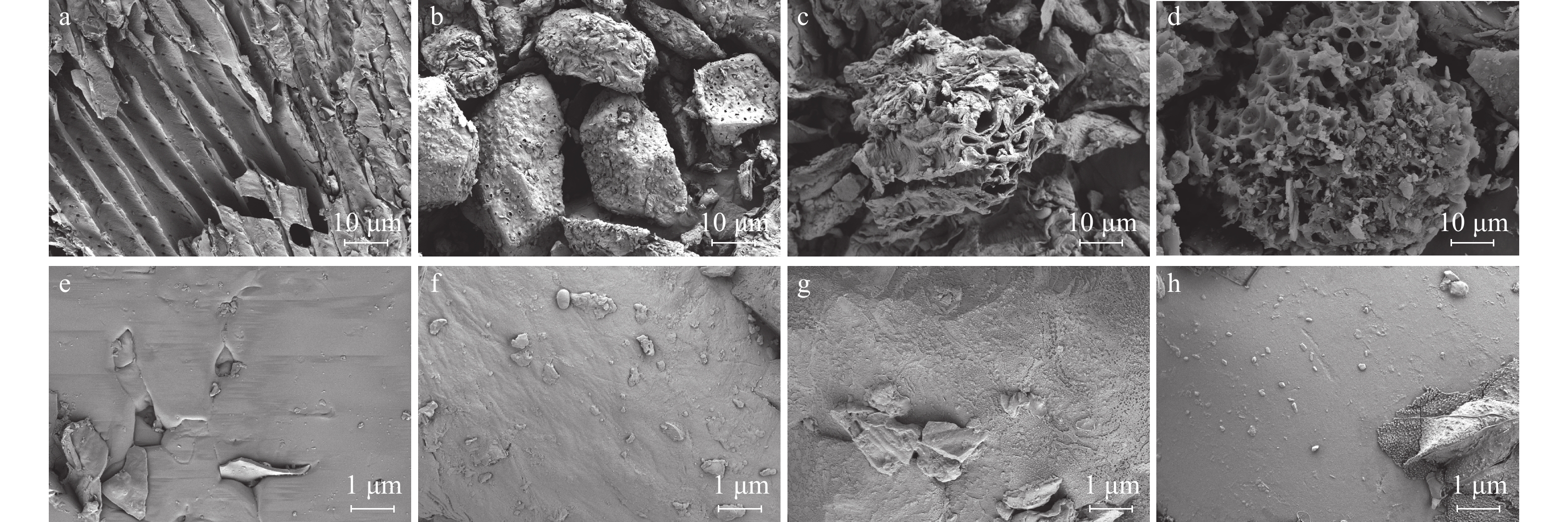

图 4 生物炭和生物炭基渗融尿素肥的表观形貌

a:花生壳炭(PB);b:松子壳炭(PNB);c:油茶壳炭(OTB);d:稻壳炭(HB);e:花生壳炭基渗融尿素肥(PBF);f:松子壳炭基渗融尿素肥(PNBF);g:油茶壳炭基渗融尿素肥(OTBF);h:稻壳炭基渗融尿素肥(HBF)

Figure 4. The apparent morphology of biochar and biochar-based infiltrated urea fertilizer

a: Peanut biochar (PB); b: Pine nut biochar (PNB); c: Oil-tea biochar (OTB); d: Husk biochar (HB); e: Peanut biochar-based infiltrated urea fertilizer (PBF); f: Pine nut biochar-based infiltraed urea fertilizer (PNBF); g: Oil-tea biochar-based infiltrated urea fertilizer (OTBF); h: Husk biochar-based infiltrated urea fertilizer (HBF)

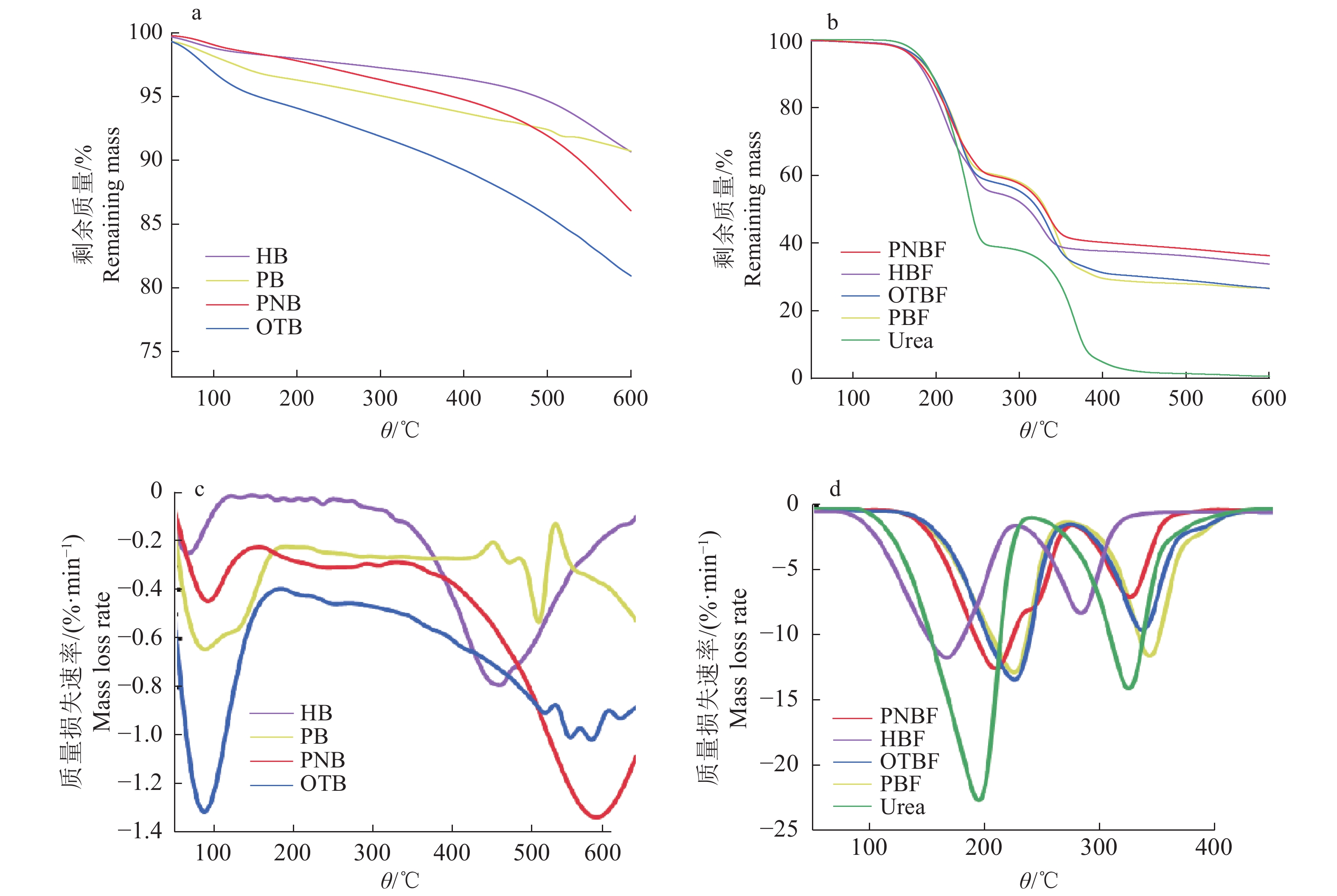

图 5 生物炭(a、c)和生物炭基渗融尿素肥(b、d)的热稳定性分析

图a、c中,HB:稻壳炭,PB:花生壳炭,PNB:松子壳炭,OTB:油茶壳炭;图b、d中,PNBF:松子壳炭基渗融尿素肥,HBF:稻壳炭基渗融尿素肥,OTBF:油茶壳炭基渗融尿素肥,PBF:花生壳炭基渗融尿素肥,Urea:纯尿素颗粒

Figure 5. The thermal stability analyses of biochar (a, c) and biochar-based infiltrated urea fertilizer (b, d)

In figure a and c, HB: Husk biochar, PB: Peanut biocharr, PNB: Pine nut biochar, OTB: Oil-tea biochar; In figure b and d, PNBF: Pine nut biochar-based infiltrated urea fertilizer, HBF: Husk biochar-based infiltrated urea fertilizer, OTBF: Oil-tea biochar-based infiltrated urea fertilizer, PBF: Peanut biochar-based infiltrated urea fertilizer; Urea: Pure urea particles

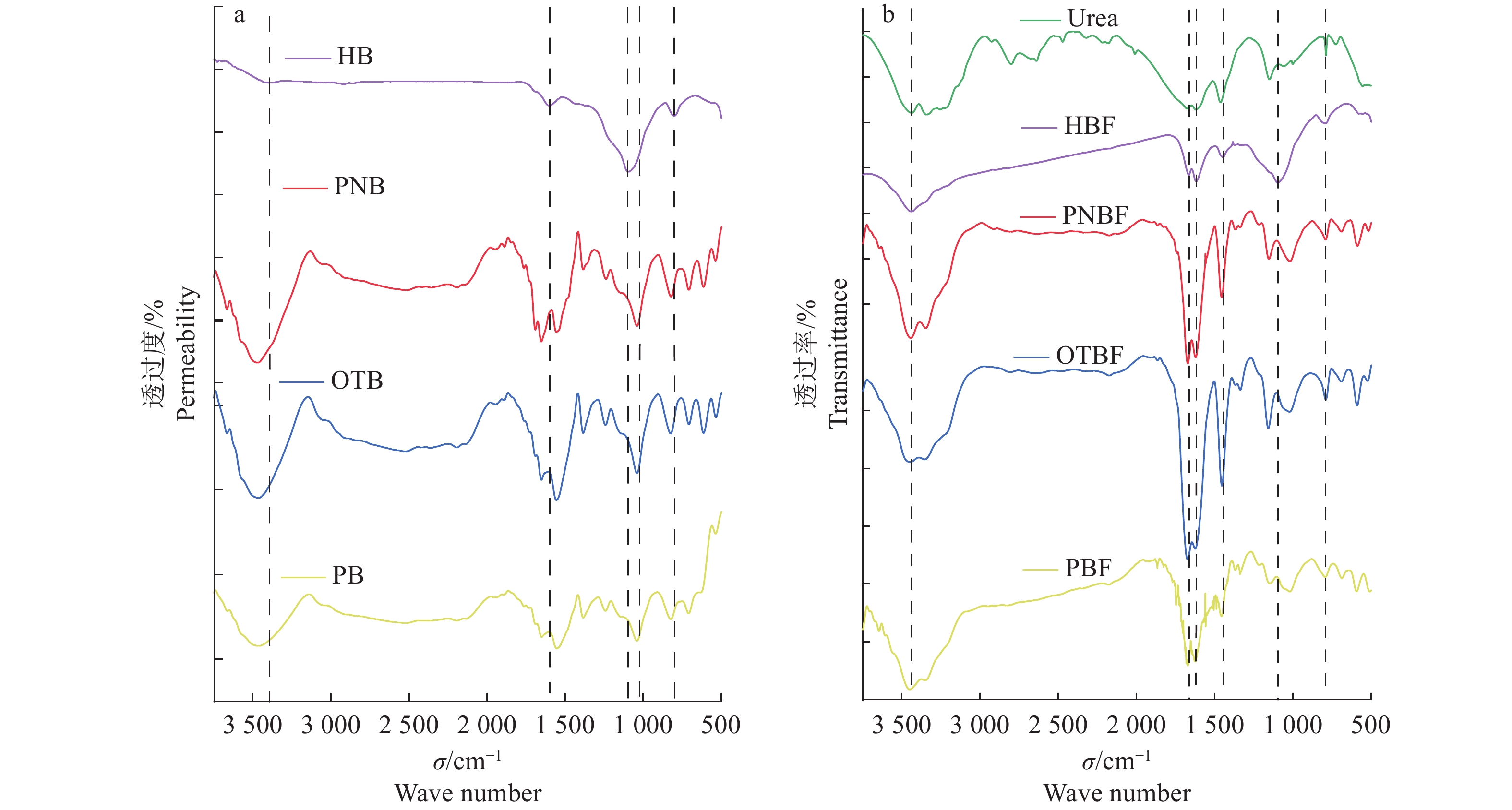

图 6 生物炭(a)和生物炭基渗融尿素肥(b)的红外分析

图a中,HB:稻壳炭,PNB:松子壳炭,OTB:油茶壳炭,PB:花生壳炭;图b中,Urea:纯尿素颗粒,HBF:稻壳炭基渗融尿素肥,PNBF:松子壳炭基渗融尿素肥,OTBF:油茶壳炭基渗融尿素肥,PBF:花生壳炭基渗融尿素肥

Figure 6. The FTIR analyses of biochar (a) and biochar-based infiltrated urea fertilizer (b)

In figure a, HB: Husk biochar, PNB: Pine nut biochar, OTB: Oil-tea biochar, PB: Peanut biocharr; In figure b, Urea: Pure urea particles, HBF: Husk biochar-based infiltrated urea fertilize, PNBF: Pine nut biochar-based infiltrated urea fertilizer, OTBF: Oil-tea biochar-based infiltrated urea fertilizer, PBF: Peanut biochar-based infiltrated urea fertilizer

-

[1] HEFFER P, PRUD'HOMME M, 茹铁军. 肥料展望2016—2020年(摘要报告)[J]. 磷肥与复肥, 2016, 31(10): 49-52. [2] LIU J L, YANG Y C, GAO B, et al. Bio-based elastic polyurethane for controlled-release urea fertilizer: Fabrication, properties, swelling and nitrogen release characteristics[J]. Journal of Cleaner Production, 2019, 209: 528-537. doi: 10.1016/j.jclepro.2018.10.263

[3] ZHENG J F, HAN J M, LIU Z W, et al. Biochar compound fertilizer increases nitrogen productivity and economic benefits but decreases carbon emission of maize production[J]. Agriculture Ecosystems and Environment, 2017, 241: 70-78. doi: 10.1016/j.agee.2017.02.034

[4] 李永华, 武雪萍, 何刚, 等. 我国麦田有机肥替代化学氮肥的产量及经济环境效应[J]. 中国农业科学, 2020, 53(23): 4879-4890. [5] WANG C Q, LUO D, ZHANG X, et al. Biochar-based slow-release of fertilizers for sustainable agriculture: A mini review[J]. Environmental Science and Ecotechnology, 2022, 10: 100167. doi: 10.1016/j.ese.2022.100167.

[6] GONZÁLEZ-CENCERRADO A, RANZ J P, TERESA LÓPEZ-FRANCO JIMÉNEZ M, et al. Assessing the environmental benefit of a new fertilizer based on activated biochar applied to cereal crops[J]. Science of the Total Environment, 2020, 711(4): 134668. doi: 10.1016/j.scitotenv.2019.134668.

[7] SAHA A, BASAK B B, GAJBHIYE N A, et al. Sustainable fertilization through co-application of biochar and chemical fertilizers improves yield, quality of Andrographis paniculata and soil health[J]. Industrial Crops and Products, 2019, 140: 111607. doi: 10.1016/j.indcrop.2019.111607.

[8] 王微, 王明峰, 姜洋, 等. 稻壳炭基肥的制备及其释放特性和机理探讨[J]. 可再生能源, 2020, 38(10): 1288-1294. [9] 王剑, 张砚铭, 邹洪涛, 等. 生物质炭包裹缓释肥料的制备及养分释放特性[J]. 土壤, 2013, 45(1): 186-189. doi: 10.3969/j.issn.0253-9829.2013.01.029 [10] 原鲁明, 赵立欣, 沈玉君, 等. 我国生物炭基肥生产工艺与设备研究进展[J]. 中国农业科技导报, 2015, 17(4): 107-113. [11] 曹兵, 黄志浩, 吴广利, 等. 控释掺混肥一次性减量施用对夏玉米产量、氮肥利用和叶片氮代谢酶活性的影响[J]. 中国土壤与肥料, 2021, 293(3): 127-133. doi: 10.11838/sfsc.1673-6257.20238 [12] 牛智有, 刘鸣, 牛文娟, 等. 炭肥比和膨润土粘结剂对炭基肥颗粒理化及缓释特性的影响[J]. 农业工程学报, 2020, 36(2): 219-227. doi: 10.11975/j.issn.1002-6819.2020.02.026 [13] 沈秀丽, 柳思远, 沈玉君, 等. 不同粒径生物炭包膜尿素缓释肥性能及缓释效果[J]. 农业工程学报, 2020, 36(15): 159-166. doi: 10.11975/j.issn.1002-6819.2020.15.020 [14] NOORDIN N, GHAZALI S, ADNAN N. Impact of sap-biochar incorporation on controlled release water retention fertilizer (CRWR) towards growth of okras (Abelmoschus esculentus)[J]. Materials Today: Proceedings, 2018, 5(10): 21911-21918. doi: 10.1016/j.matpr.2018.07.050

[15] LI H, XU H, ZHOU S, et al. Distribution and transformation of lead in rice plants grown in contaminated soil amended with biochar and lime[J]. Ecotoxicology and Environmental Safety, 2018, 165: 589-596. doi: 10.1016/j.ecoenv.2018.09.039

[16] XIANG A H, QI R Y, WANG M F, et al. Study on the infiltration mechanism of molten urea and biochar for a novel fertilizer preparation[J]. Industrial Crops and Products, 2020, 153: 112558. doi: 10.1016/j.indcrop.2020.112558.

[17] 蒋恩臣, 张伟, 秦丽元, 等. 粒状生物质炭基尿素肥料制备及其性能研究[J]. 东北农业大学学报, 2014, 45(11): 89-94. doi: 10.3969/j.issn.1005-9369.2014.11.014 [18] 钟旋. 稻壳炭基尿素肥的制备及其特性研究[D]. 广州: 华南农业大学, 2019. [19] 刘海林, 蔡隽, 杨红竹, 等. 成型压力对棒状复合肥料抗压性能及氮钾养分淋溶特性的影响[J]. 中国土壤与肥料, 2021(6): 276-281. doi: 10.11838/sfsc.1673-6257.20508 [20] WANG M F, XIANG A H, GAO Z N, et al. Study on the nitrogen-releasing characteristics and mechanism of biochar-based urea infiltration fertilizer[J]. Biomass Conversion and Biorefinery, 2021: 1-11. Doi: 10.1007/s13399-021-01848-5.

[21] 廖芬, 杨柳, 李强, 等. 不同生物质来源生物炭品质的因子分析与综合评价[J]. 华南农业大学学报, 2019, 40(3): 29-37. [22] WANG D H, DONG N, SHUI S E, et al. Analysis of urea pyrolysis in 132.5-190 ℃[J]. Fuel, 2019, 242: 62-67. doi: 10.1016/j.fuel.2019.01.011

[23] SHI W, JU Y Y, BIAN R J, et al. Biochar bound urea boosts plant growth and reduces nitrogen leaching[J]. Science of the Total Environment, 2020, 701: 134424. doi: 10.1016/j.scitotenv.2019.134424.

[24] LE CROY C, MASIELLO C A, RUDGERS J A, et al. Nitrogen, biochar, and mycorrhizae: Alteration of the symbiosis and oxidation of the char surface[J]. Soil Biology and Biochemistry, 2013, 58: 248-254. doi: 10.1016/j.soilbio.2012.11.023

[25] 安华良, 曲雅琪, 刘震, 等. 以1, 2–丙二醇为循环剂的尿素醇解合成碳酸二甲酯催化反应精馏研究[J]. 洁净煤技术, 2022, 28(1): 122-128. [26] BEDADE D K, SUTAR Y B, SINGHAL R S. Chitosan coated calcium alginate beads for covalent immobilization of acrylamidase: Process parameters and removal of acrylamide from coffee[J]. Food Chemistry, 2019, 275: 95-104. doi: 10.1016/j.foodchem.2018.09.090

[27] 钟旋, 蒋恩臣, 卢璐璎, 等. 稻壳炭的制备及其对尿素态氮的吸附特性[J]. 农业环境科学学报, 2021, 40(10): 2150-2158. doi: 10.11654/jaes.2021-0308 [28] CHEN Z, WANG M, JIANG E, et al. Pyrolysis of torrefied biomass[J]. Trends in Biotechnology, 2018, 36(12): 1287-1298. doi: 10.1016/j.tibtech.2018.07.005

[29] 于正国, 袁亮, 赵秉强, 等. 腐植酸与尿素结合工艺对尿素在潮土中转化的影响[J]. 中国土壤与肥料, 2022(1): 206-212.

下载:

下载: