Design and experiment of seed cleaning device of vegetable plug seedling seeder

-

摘要:目的

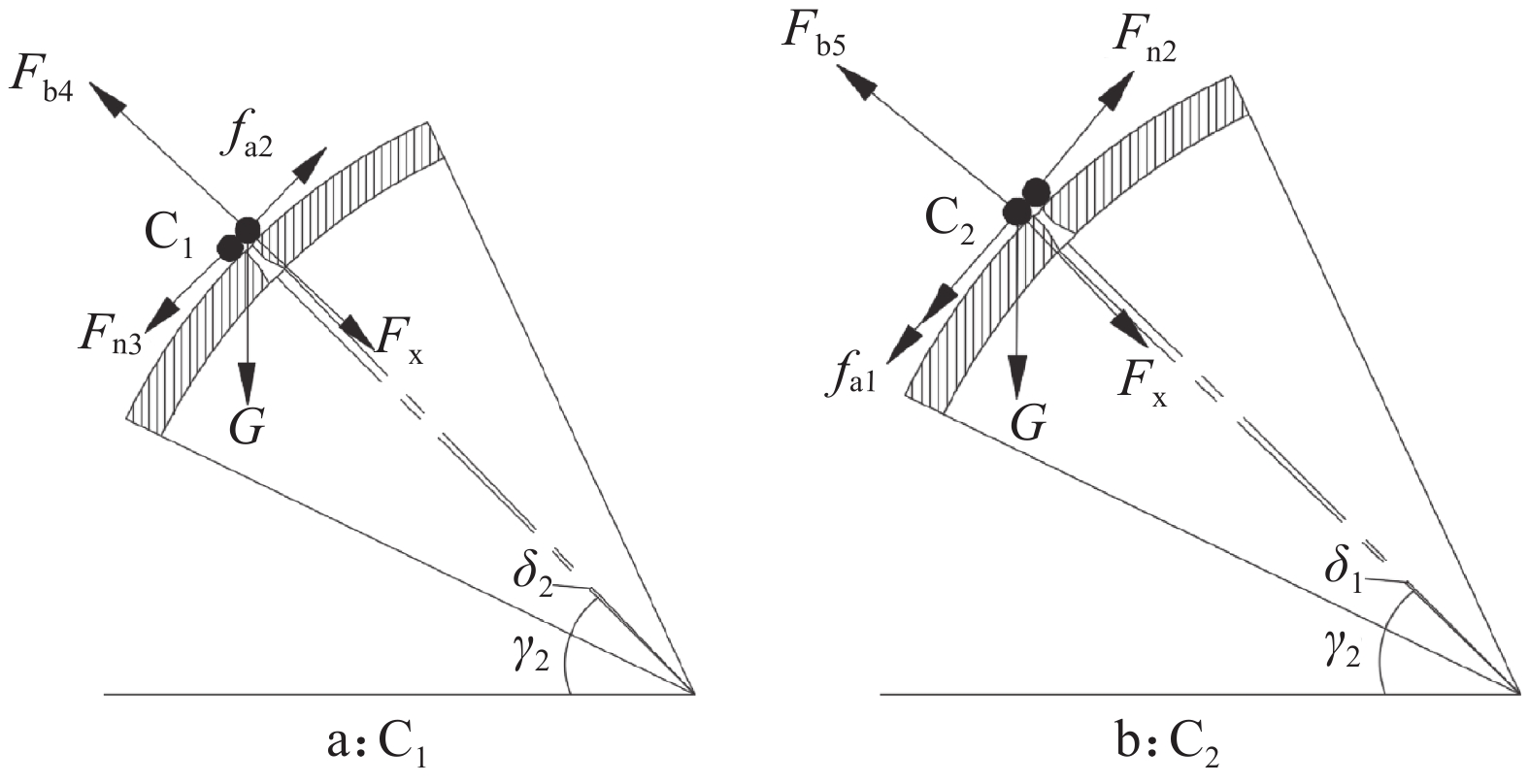

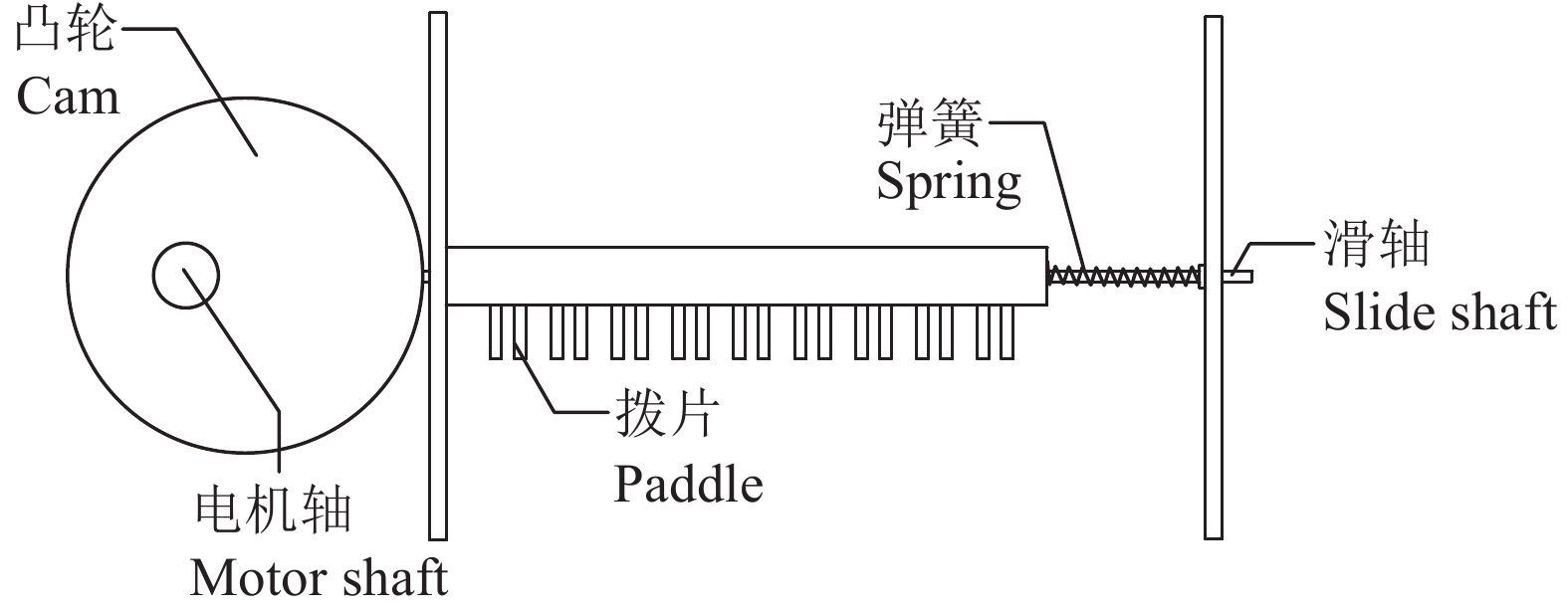

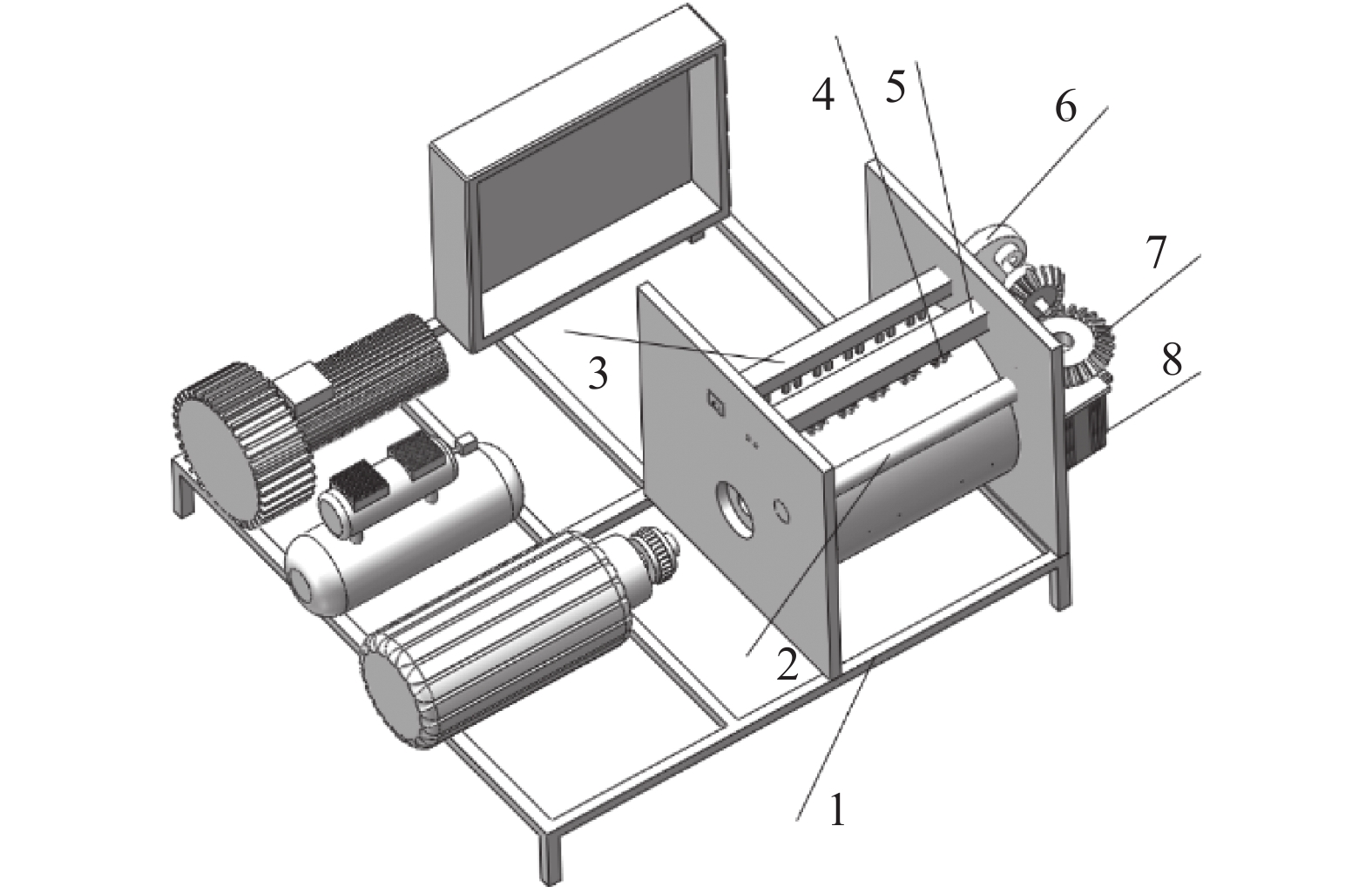

针对蔬菜穴盘育苗播种机现有清种装置清种效果不好,导致的充种合格率低、重播率高问题,设计集机械式、气吹式、电控式为一体的清种装置。

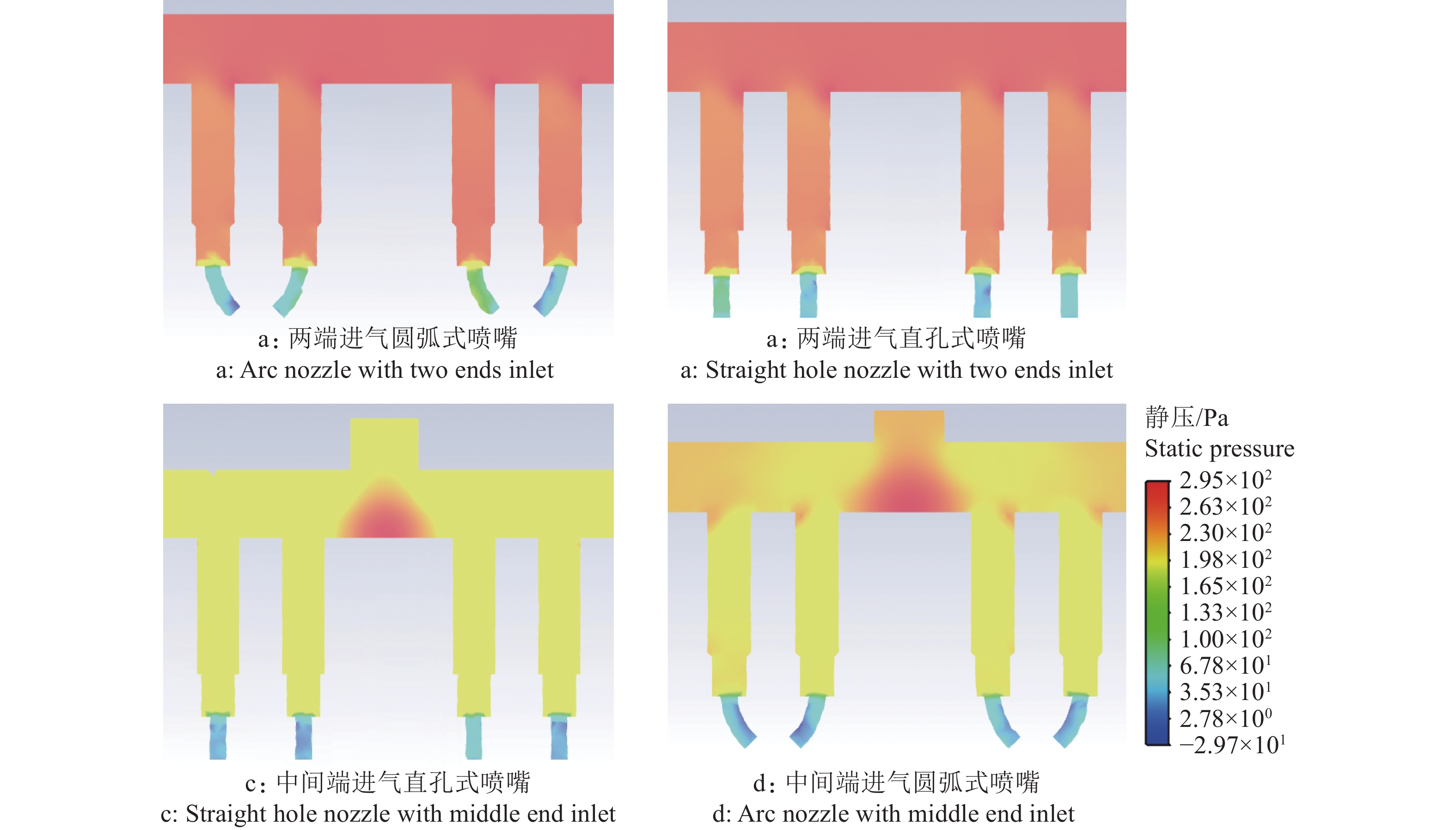

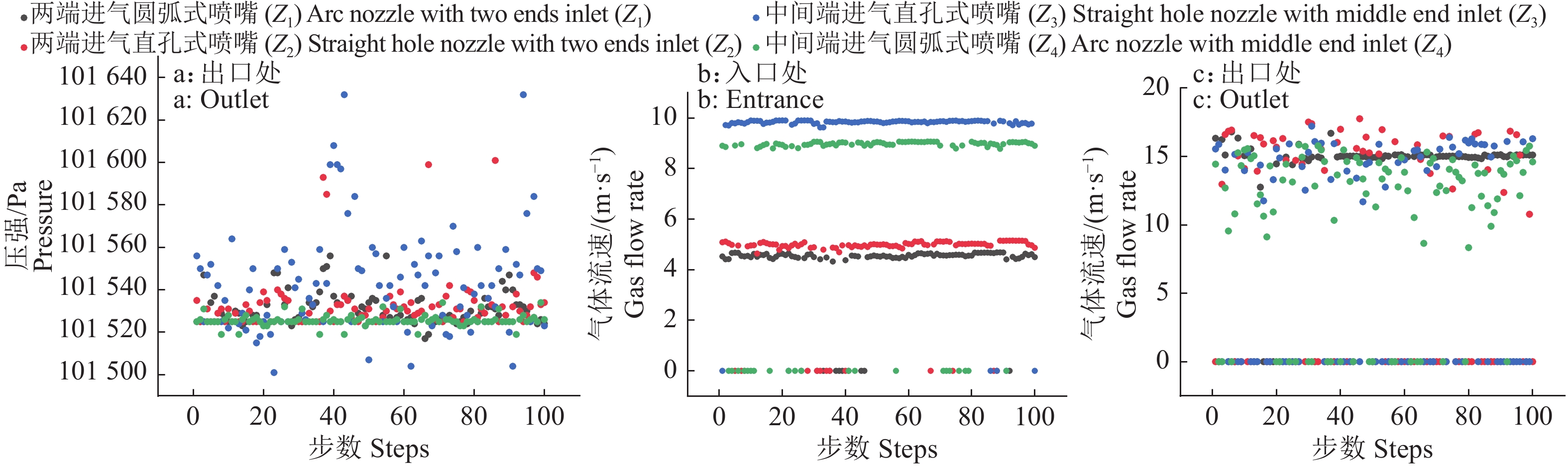

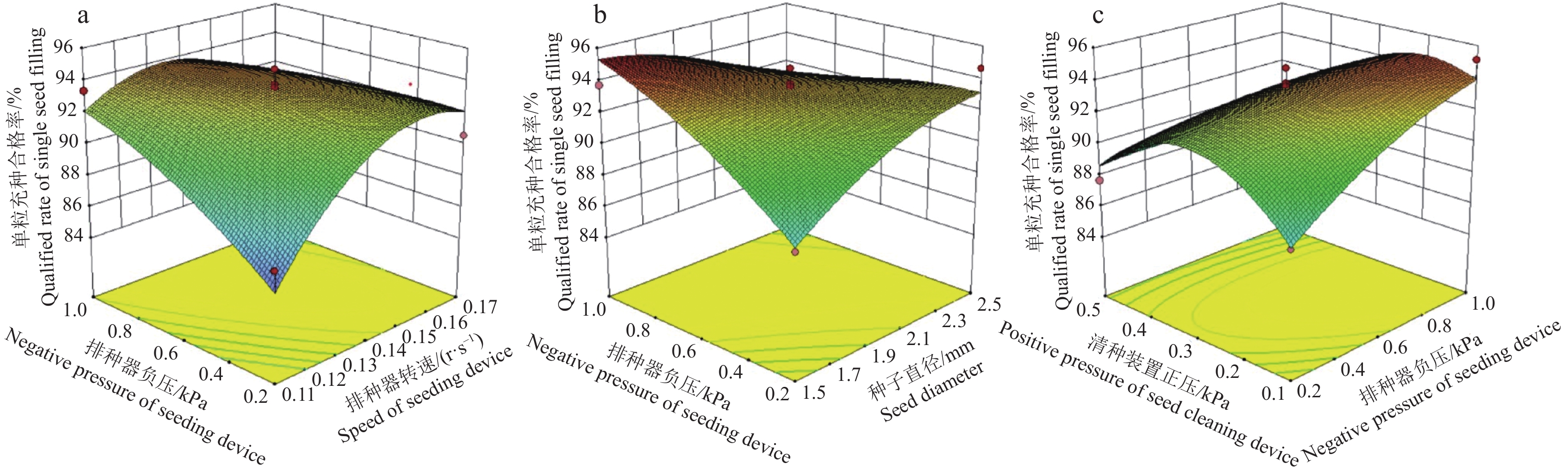

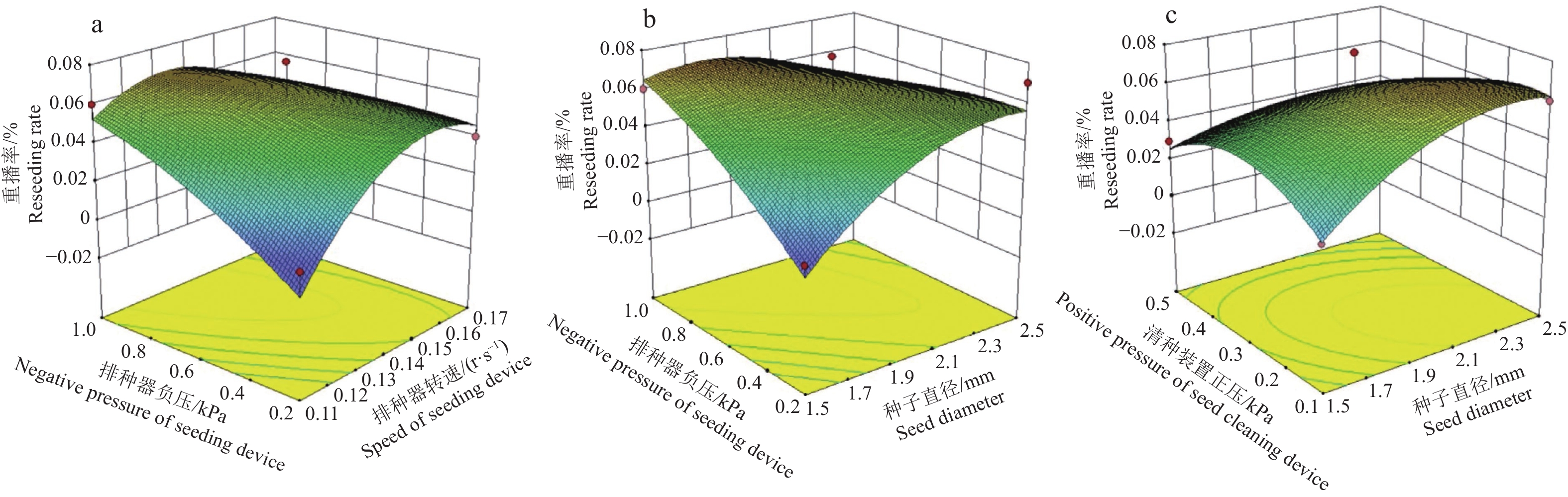

方法结合运动学及动力学理论对三级清种装置的结构进行设计;采用Ansys软件中Fluent模块对气吹式清种装置的不同进气口和出气口结构中的气流稳定性进行分析;在理论分析和仿真分析的基础上选取排种器转速、排种器负压、清种装置正压、种子直径为试验因素,结合农艺要求选取单粒充种合格率、重播率为试验指标开展四因素三水平二次回归正交试验。根据试验数据得出最佳参数组合。

结果由仿真分析得出,中间端进气圆弧式喷嘴气吹式清种结构清种效果最好。由台架试验得到排种最佳参数组合,即在排种器转速为0.17 r/s、种子直径为1.5 mm、排种器负压为0.6 kPa、气吹式清种装置正压为0.3 kPa时,平均单粒充种合格率为95.31%,平均重播率为0.2%。

结论本文设计的清种装置满足了蔬菜播种农艺要求,可以有效提升充种合格率、降低重播率,为生产实际提供理论指导。

Abstract:ObjectiveAiming at the problem that the existing seed cleaning device of the vegetable plug seedling seeder is not effective in cleaning seeds, resulting in low seed filling qualification rate and high reseeding rate, a seed cleaning device integrating mechanical type, air blowing and electric control is designed.

MethodCombined with kinematics and dynamics theory, the structure of the three-stage seed cleaning device was designed. The air flow stability in different air-inlet and air-outlet structures of the air-blown seed cleaning device was analyzed by using the fluent module in Ansys software. On the basis of theoretical analysis and simulation analysis, the speed of seeding device, negative pressure of seeding device, positive pressure of seed cleaning device and seed diameter were selected as the experimental factors. According to the agronomy requirements, qualified rate of single seed filling and reseeding rate were selected as test indexes to carry out four-factor and three-level quadratic regression orthogonal test. The best parameter combination was obtained based on the experimental data.

ResultAccording to the simulation analysis, it is concluded that the air blowing type structure with the air-inlet circular arc nozzle at the middle end had the best seed cleaning effect. The best parameter combination for seed metering was summarized from the bench test. When the speed of the seeding device was 0.17 r/s, and the seed diameter was 1.5 mm, the negative pressure of the seeding device was 0.6 kPa, and the positive pressure of the air blowing seed cleaning device was 0.3 kPa, the average qualified rate of single seed filling was 95.31%, and the average reseeding rate was 0.2%.

ConclusionThe design of the seed cleaning device meets the agronomic requirements of vegetable sowing, which can effectively improve the qualified rate of seed filling and reduce the reseeding rate, and provide theoretical guidance for production practice.

-

Keywords:

- Vegetable /

- Plug seedling /

- Seeder /

- Seed cleaning device /

- Quadratic regression orthogonal test

-

-

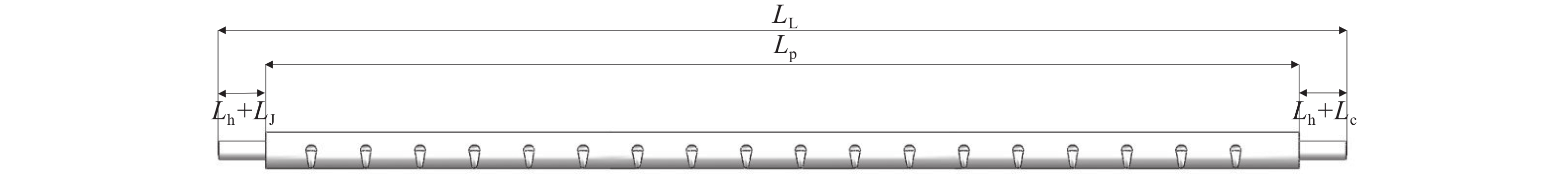

图 3 种子刚吸附时受力平衡图

Fb1:种箱对种子的支持力;Fb2:排种器对种子的支持力;FX:负压吸附力;Fn:种群力;α:休止角;G:单粒种子重力

Figure 3. Force balance map of the seed just adsorbed

Fb1: Supporting force of the seed box on the seed; Fb2: Supporting force of the seeding device on the seed; FX: Negative pressure adsorption force; Fn: Seed group force; α: Angle of repose; G: Gravity of a single seed

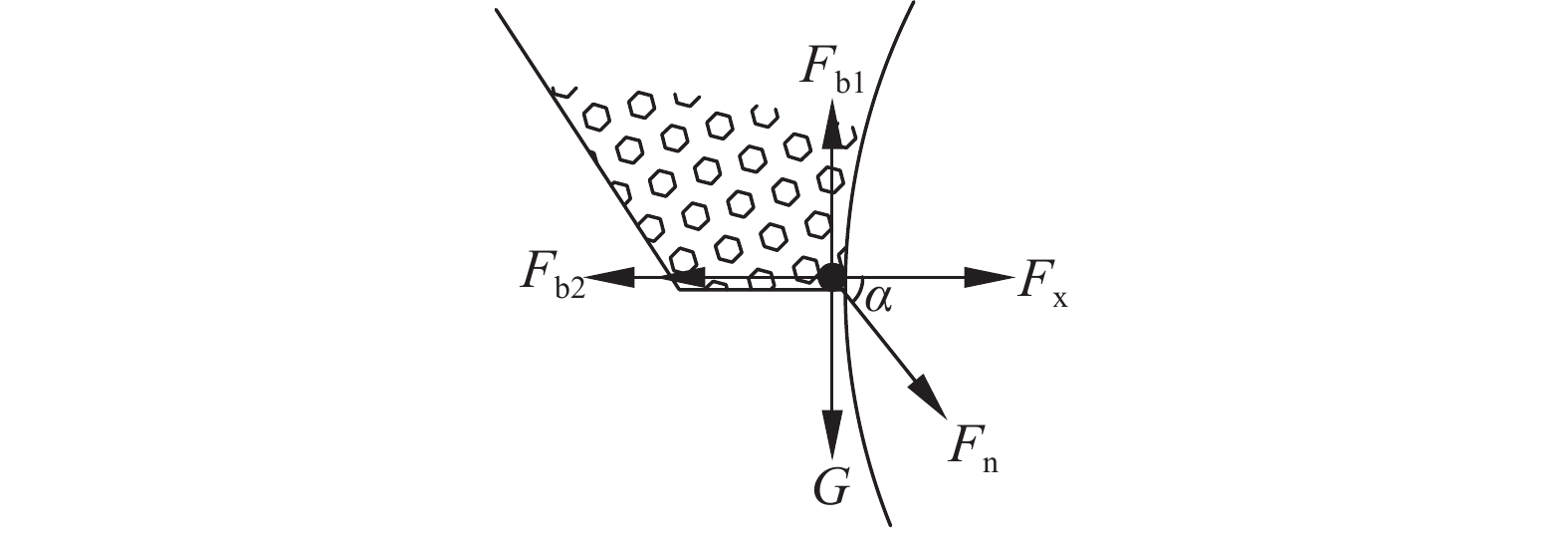

图 4 气吹式清种区左(C1)右(C2)种子受力图

fa2:C1种子抵抗C2种子作用力后与排种器间的摩擦力;Fn3:C1种子对C2种子的作用力;γ2:气吹式清种区起点与水平面的夹角;δ2:C1种子中心与排种器轴线的垂直连线和排种器气孔径间的夹角;Fb4:C1种子的理论支持力;fa1:C2种子抵抗C1种子作用力后与排种器间的摩擦力;Fn2:C2种子对C1种子的作用力;δ1:C2种子中心与排种器轴线的垂直连线和排种器气孔径间的夹角;Fb5:C2种子的理论支持力;FX:负压吸附力

Figure 4. Stress map of left (C1) and right (C2) seeds in air blowing seed cleaning area

fa2: Friction force between C1 seed and seeding device after resisting the force of C2 seed; Fn3: Force of C1 seed on C2 seed; γ2: Angle between the starting point of the gas-blown seed cleaning area and the horizontal plane; δ2: Angle between the vertical line connecting the C1 seed center and the axis of the seeding device and the gas aperture of the seeding device; Fb4: Theoretical support of C1 seed; fa1: Friction force between C2 seed and seeding device after resisting C1 seed force; Fn2: Force of C2 seed on C1 seed; δ1: Angle between the vertical line connecting C2 seed center and the axis of the seeding device and the gas aperture of the seeding device; Fb5: Theoretical support of C2 seed; FX: Negative pressure adsorption force

表 1 清种试验因素水平

Table 1 Factor and level of seed cleaning test

水平

Level排种器转速/(r·s−1)

Speed of seeding

device (A)种子直径/mm

Seed diameter

(B)排种器负压/kPa

Negative pressure of

seeding device (C)清种装置正压/kPa

Positive pressure of seed

cleaning device (D)−1 0.11 1.5 0.2 0.1 0 0.14 2.0 0.6 0.3 1 0.17 2.5 1.0 0.5 表 2 清种试验方案与结果

Table 2 Seed cleaning test design and result

试验方案

Testing

program排种器转速/(r·s−1)

Speed of seeding

device

(A)种子直径/mm

Seed

diameter

(B)排种器负压/kPa

Negative pressure of

seeding device

(C)清种装置正压/kPa

Positive pressure of

seed cleaning device

(D)单粒充种合格率/%

Qualified rate

of single seed filling

(Y1)重播率/%

Reseeding

rate

(Y2)1 0.11 1.5 0.6 0.3 87.04 0.10 2 0.17 1.5 0.6 0.3 95.31 0.20 3 0.11 2.5 0.6 0.3 86.89 0.13 4 0.17 2.5 0.6 0.3 89.70 0.30 5 0.14 2.0 0.2 0.1 87.84 0.20 6 0.14 2.0 1.0 0.1 95.14 0.77 7 0.14 2.0 0.2 0.5 87.70 0.10 8 0.14 2.0 1.0 0.5 87.37 0.20 9 0.11 2.0 0.6 0.1 86.62 0.10 10 0.17 2.0 0.6 0.1 90.76 0.60 11 0.11 2.0 0.6 0.5 86.41 0.10 12 0.17 2.0 0.6 0.5 85.36 0.20 13 0.14 1.5 0.2 0.3 87.74 0.07 14 0.14 2.5 0.2 0.3 94.64 0.70 15 0.14 1.5 1.0 0.3 93.73 0.60 16 0.14 2.5 1.0 0.3 90.27 0.37 17 0.11 2.0 0.2 0.3 86.75 0.07 18 0.17 2.0 0.2 0.3 90.59 0.40 19 0.11 2.0 1.0 0.3 93.38 0.57 20 0.17 2.0 1.0 0.3 88.19 0.20 21 0.14 1.5 0.6 0.1 88.39 0.17 22 0.14 2.5 0.6 0.1 92.21 0.57 23 0.14 1.5 0.6 0.5 88.57 0.30 24 0.14 2.5 0.6 0.5 86.72 0.10 25 0.14 2.0 0.6 0.3 93.76 0.60 26 0.14 2.0 0.6 0.3 92.73 0.60 27 0.14 2.0 0.6 0.3 93.56 0.53 28 0.14 2.0 0.6 0.3 92.97 0.60 29 0.14 2.0 0.6 0.3 94.70 0.83 表 3 清种试验的方差分析1)

Table 3 Analysis of variance of seed filling test

方差来源

Source单粒充种合格率 Qualified rate of single seed filling 重播率 Reseeding rate 平方和 SS 均方 MS F P 平方和 SS 均方 MS F P 模型 Model 247.92 17.71 6.30 0.0007** 1.45 0.10 7.46 0.0003** A 13.70 13.70 4.88 0.0444* 0.06 0.06 4.14 0.0612 B 0.01 0.01 3.63×10−3 0.9528 0.04 0.04 3.20 0.0951 C 13.70 13.70 4.88 0.0444* 0.11 0.11 8.23 0.0124* D 29.55 29.55 10.52 0.0059** 0.17 0.17 11.95 0.0038** A×B 7.45 7.45 2.65 0.1256 1.23×10−3 1.23×10−3 0.09 0.7706 A×C 20.39 20.39 7.26 0.0175* 0.12 0.12 8.84 0.0101* A×D 6.73 6.73 2.40 0.1439 0.04 0.04 2.89 0.1115 B×C 26.83 26.83 9.55 0.0080** 0.18 0.18 13.34 0.0026** B×D 8.04 8.04 2.86 0.1129 0.09 0.09 6.49 0.0232* C×D 14.55 14.55 5.18 0.0391* 0.06 0.06 3.98 0.0658 A2 53.38 53.38 19.00 0.0007** 0.38 0.38 27.28 0.0001** B2 7.74 7.74 2.76 0.1191 0.17 0.17 12.19 0.0036** C2 4.43 4.43 1.58 0.2299 0.04 0.04 3.10 0.1000 D2 73.12 73.12 26.03 0.0002** 0.23 0.23 16.26 0.0012** 残差 Residual 39.33 2.81 0.19 0.01 失拟项 Lack of fit 36.95 3.70 6.22 0.0465* 0.14 0.01 1.07 0.5162 误差 Error 2.38 0.59 0.05 0.01 总和 Total 287.24 1.64 1) A:排种器转速;B:种子直径;C:排种器负压;D:清种装置正压;“*”和“**”分别表示0.05和0.01的显著水平

1) A: Rotation speed of seed feeder; B: Seed diameter; C: Negative pressure of seed feeder; D: Positive pressure of seed cleaning device; “*” and “**” indicate 0.05 and 0.01 significance levels respectively表 4 单级清种装置试验数据表

Table 4 Data sheet for single stage cleaning device test

清种装置类型

Type of seed

cleaning device单圈充种穴数

No. of seed

filling holes per circle单圈单粒充种穴数

No. of single seed

filling holes per circle单粒充种合格率/%

Qualified rate of

single seed filling重播率/%

Reseeding

rate机械式 Mechanical 51.1 48.3 89.50 5.19 气吹式 Air blown 51.3 50.2 92.96 2.10 电控式 Electrically controlled 50.8 49.3 91.23 2.53 表 5 三级清种装置清种性能验证试验结果

Table 5 Validation test result of seed cleaning performance of the three level seed cleaning device

项目

Itern单粒充种合格率/%

Qualified rate of single seed filling重播率/%

Reseeding rate台架试验

Bench test95.31 0.2 最优参数验证试验

Optimal parameter verification test94.86 0.5 误差 Error 0.45 0.3 -

[1] 人民资讯. 云南“牛年”交出“牛气答卷” [EB/OL]. [2022-01-26]. https://baijiahao.baidu.com/s?id=1722859648213784805&wfr=spider& for=pc. [2] 云南省统计局. 2021年云南经济运行情况南省统计局 [EB/OL].(2022-01-26)[2022-08-26]. http://stats.yn.gov.cn/tjsj/jjxx/202201/t20220126_1073014.html. [3] 刘云强, 赵郑斌, 刘立晶, 等. 蔬菜穴盘育苗播种机研究现状及发展趋势[J]. 农业工程, 2018, 8(1): 6-12. [4] 王牧野, 李建平, 李俊杰. 成本收益视角下中国设施蔬菜生产效率研究: 以黄瓜、番茄栽培为例[J]. 中国农业资源与区划, 2021, 42(12): 170-183. [5] 张立舒, 刘燕, 张雄基, 等. 蔬菜工厂化播种育苗技术优势及发展措施探究[J]. 种子科技, 2021, 39(21): 135-136. doi: 10.19904/j.cnki.cn14-1160/s.2021.21.067 [6] 李建忠. 蔬菜工厂化播种育苗技术优势及发展措施探究[J]. 南方农业, 2019, 13(26): 1-2. [7] 李晓冉, 张银平, 刁培松, 等. 我国蔬菜生产概况及精量播种机研究现状[J]. 农机化研究, 2021, 43(5): 263-268. [8] 王计新. 斜面重力清种型孔式小籽粒(谷子)精少量排种器设计研究[J]. 当代农机, 2020(3): 61-64. [9] 许健, 蔡宗寿, 甘义权, 等. 基于EDEM的倾斜圆盘勺式大豆排种器清种过程优化研究[J]. 东北农业大学学报, 2018, 49(10): 79-88. doi: 10.3969/j.issn.1005-9369.2018.10.010 [10] BRAUNACK M V, JOHNSTON D B, PRICE J, et al. Soil temperature and soil water potential under thin oxodegradable plastic film impact on cotton crop establishment and yield[J]. Field Crops Research, 2015, 184: 91-103. doi: 10.1016/j.fcr.2015.09.009

[11] 刘云强, 刘立晶, 赵郑斌, 等. 蔬菜育苗播种机清种装置设计与试验[J]. 农业机械学报, 2018, 49(S1): 83-91. [12] 康施为, 倪向东, 齐庆征, 等. 气吸滚筒式棉花精密排种器的设计与试验[J]. 农机化研究, 2020, 42(6): 136-141. [13] YAZGI A, DEGIRMENCIOGLU A. Optimisation of the seed spacing uniformity performance of a vacuum-type precision seeder using response surface methodology[J]. Biosystems Engineering, 2007, 97(3): 347-356.

[14] 贾洪雷, 陈玉龙, 赵佳乐, 等. 气吸机械复合式大豆精密排种器设计与试验[J]. 农业机械学报, 2018, 49(4): 75-86. [15] 杨铭. 气振精密播种机自适应清种装置设计及试验研究[D]. 镇江: 江苏大学, 2020. [16] 曾山, 文智强, 刘伟健, 等. 气吸式小粒蔬菜种子精量穴播排种器优化设计与试验[J]. 华南农业大学学报, 2021, 42(6): 52-59. [17] 杨文彩, 阚成龙, 张效伟, 等. 气吸式三七育苗播种精密排种器设计与试验[J]. 农业机械学报, 2021, 52(6): 95-105. [18] 佚名. 播种机械设计原理[M]. 张波屏, 编译. 北京: 机械工业出版社, 1982. [19] 谢海军, 李志伟, 张静. 气力滚筒式小粒圆形种子排种器孔口结构仿真分析[J]. 农机化研究, 2018, 40(7): 31-35. [20] 霍增辉, 董成, 俞经虎, 等. 基于FLUENT的三偏心蝶阀数值仿真及结构优化[J]. 轻工机械, 2021, 39(1): 47-51. [21] 秀洲区政府网站. 蔬菜育苗穴盘的选择[EB/OL]. (2022-11-03)[2023-12-08].http://www.xiuzhou.gov.cn/art/2022/11/3/art_1229406499_5020421.html.

下载:

下载: