Design and experiment of real-time monitoring system for cotton sowing quality

-

摘要:目的

针对新疆地区使用的棉花穴播机作业过程中,驾驶员无法及时发现穴播器漏播、重播的问题,设计了一套棉花播种质量实时监测系统。

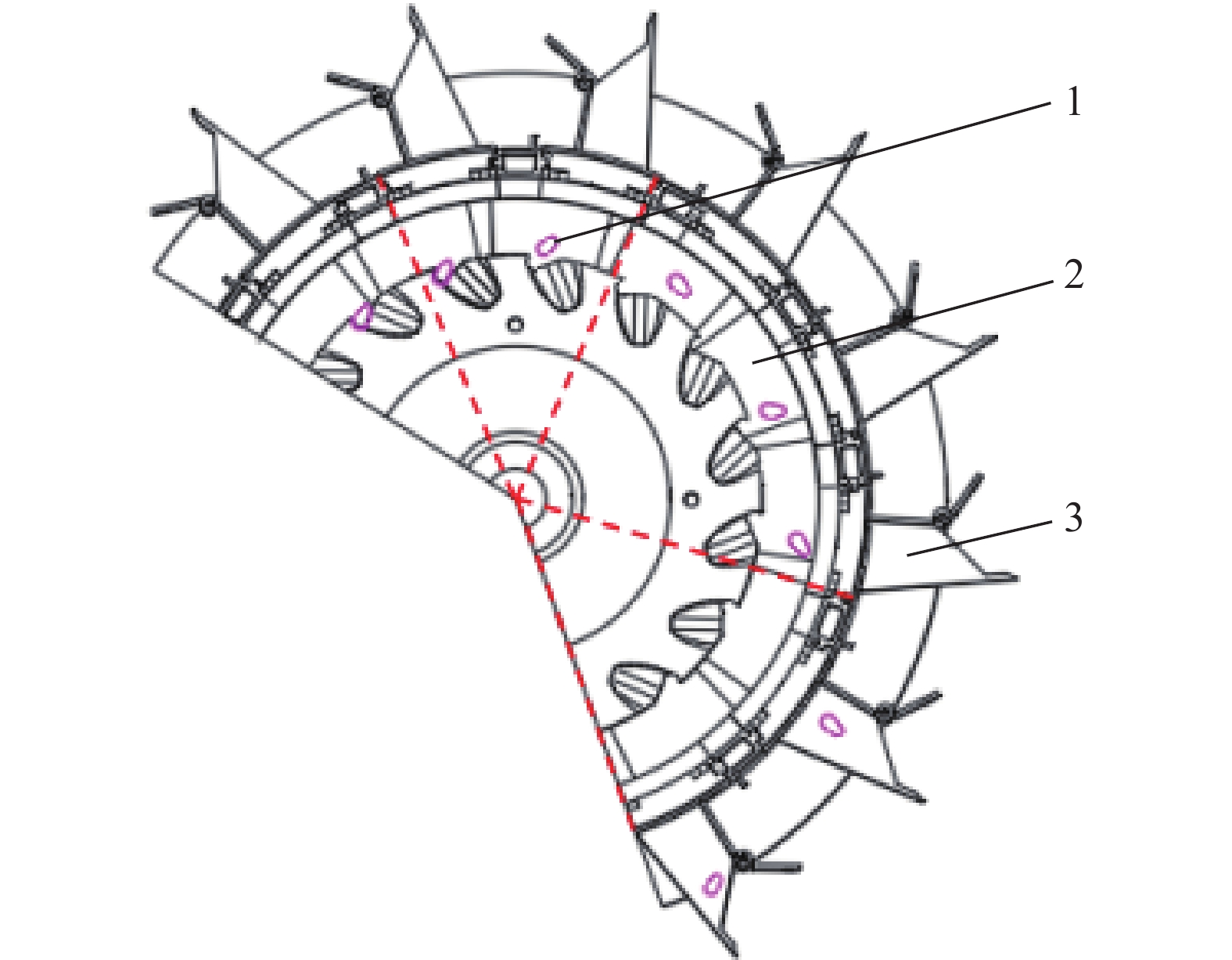

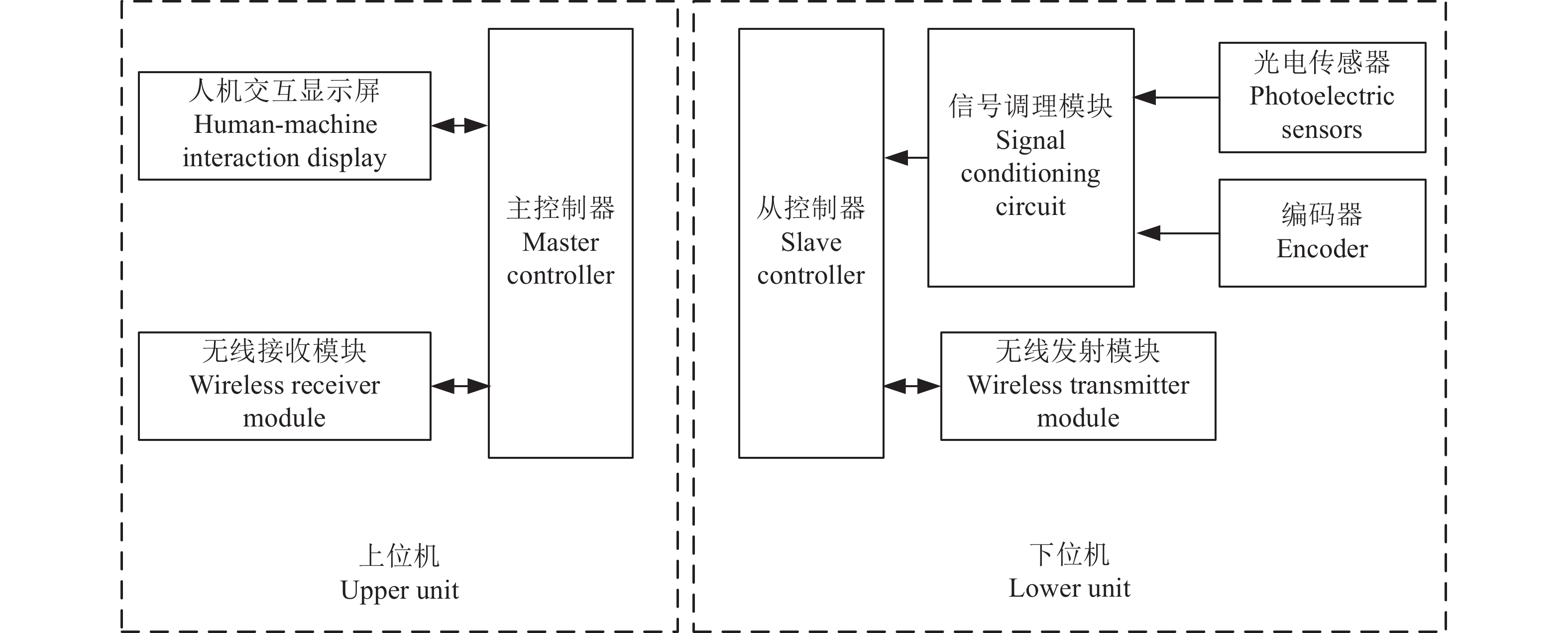

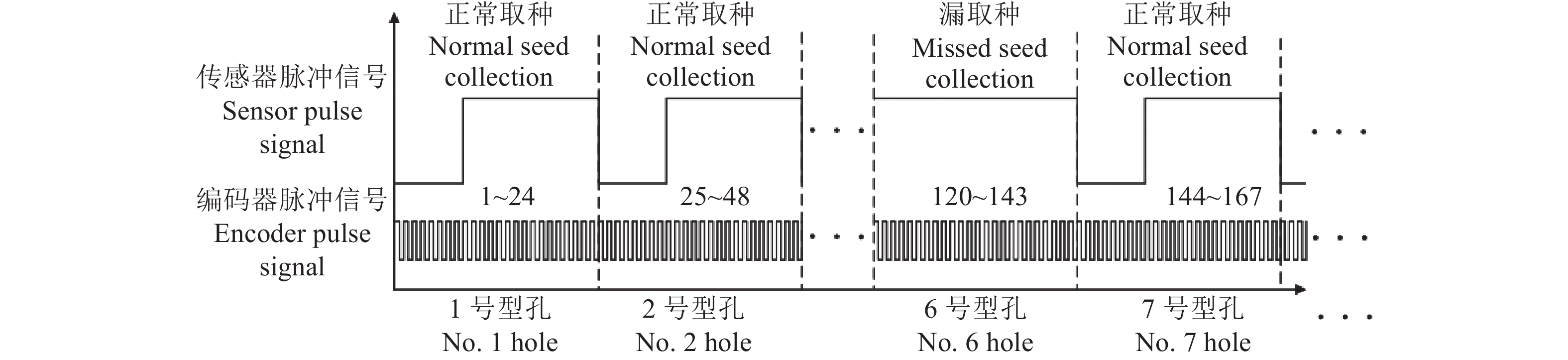

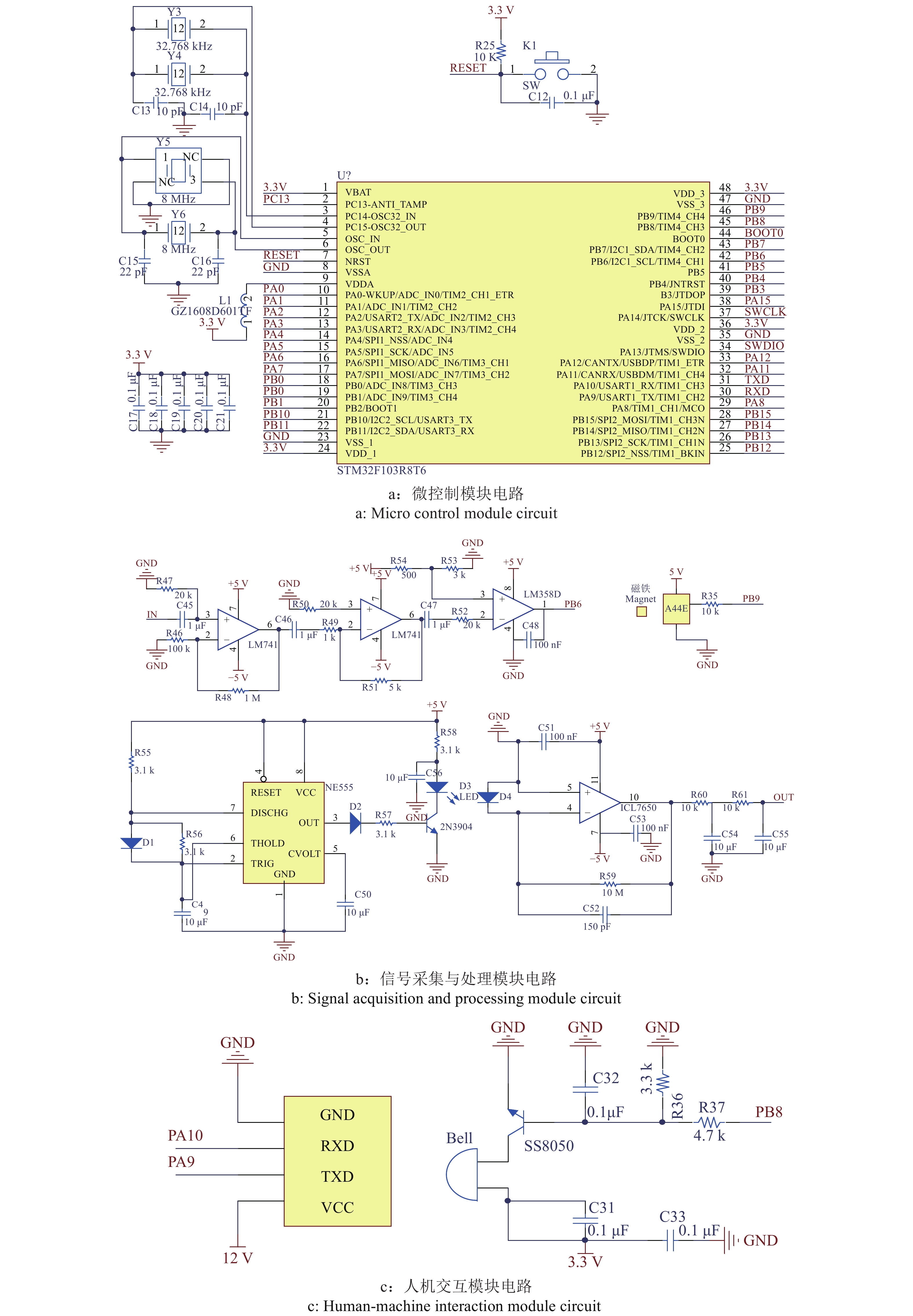

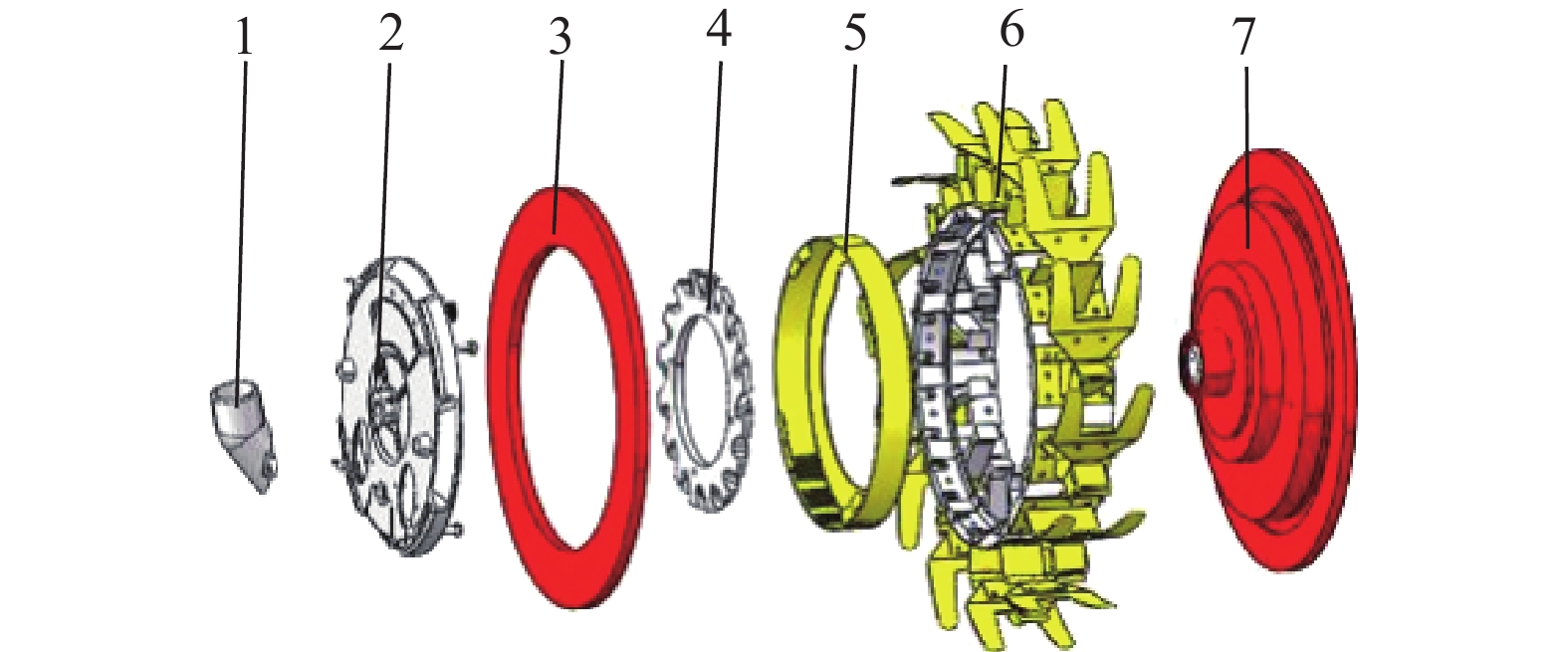

方法该监测系统以STM32F103C8T6微控制器硬件系统为下位机,通过安装在穴播器存种圈上的对射式光电传感器和光电编码器分别获取棉花种子漏播、重播信息,判断棉花播种状况,并通过nRF24L01模块将播种信息传输至DWIN触摸屏上位机人机交互界面实时显示。搭建棉花播种质量监测系统试验台,通过田间试验验证监测系统的准确性。

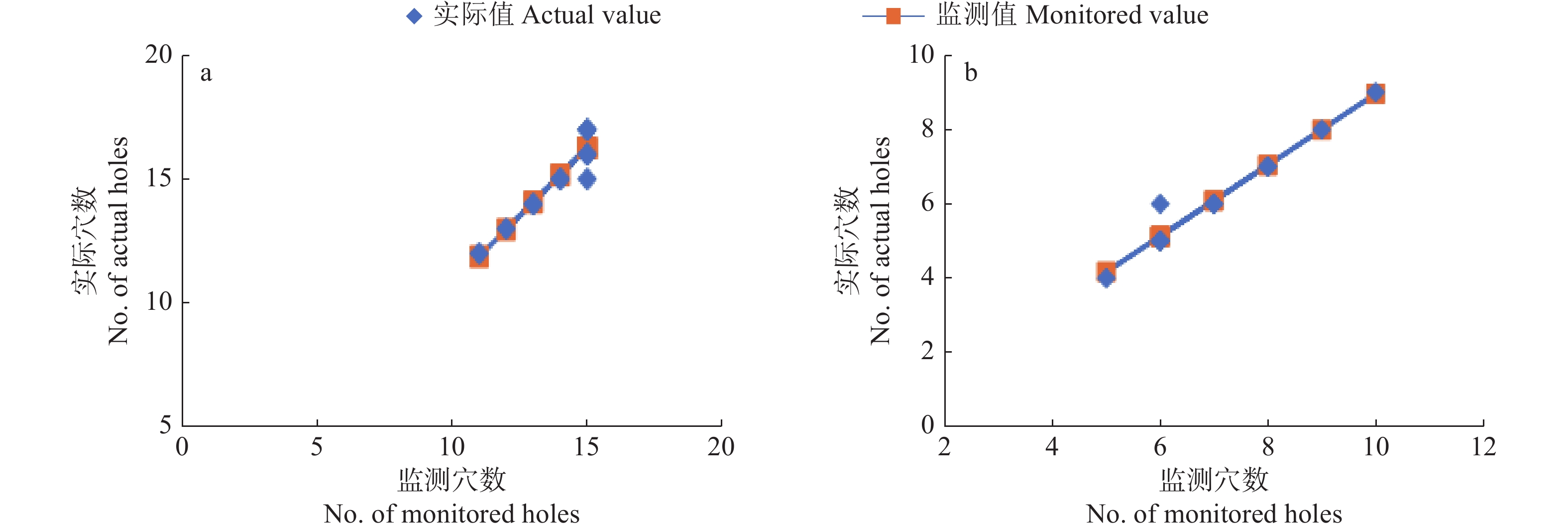

结果台架试验结果表明:当穴播器转速为30 r/min时,系统的合格播种、漏播和重播监测精度最高,分别为96.65%、94.59%和92.00%。当穴播器转速高于30 r/min时,监测精度明显下降。田间试验验证结果表明:系统对合格播种、漏播和重播平均监测精度分别为94.51%、92.38%和86.55%。利用SPSS软件对田间试验数据进行分析,结果显示试验数据具有统计意义,采用监测系统获得的棉花播种质量数据与人工实测数据具有较高的相关性,实际值可以由系统监测值反映出来。

结论该系统满足田间作业对棉花播种质量监测的需求,对实现棉花种植提质增效具有重要意义。

Abstract:ObjectiveThere are problems of missed seeding and reseeding during the operation of cotton hole sowing machine used in Xinjiang region, which the driver could not find in time. A real-time monitoring system for cotton sowing quality was designed to solve these problems.

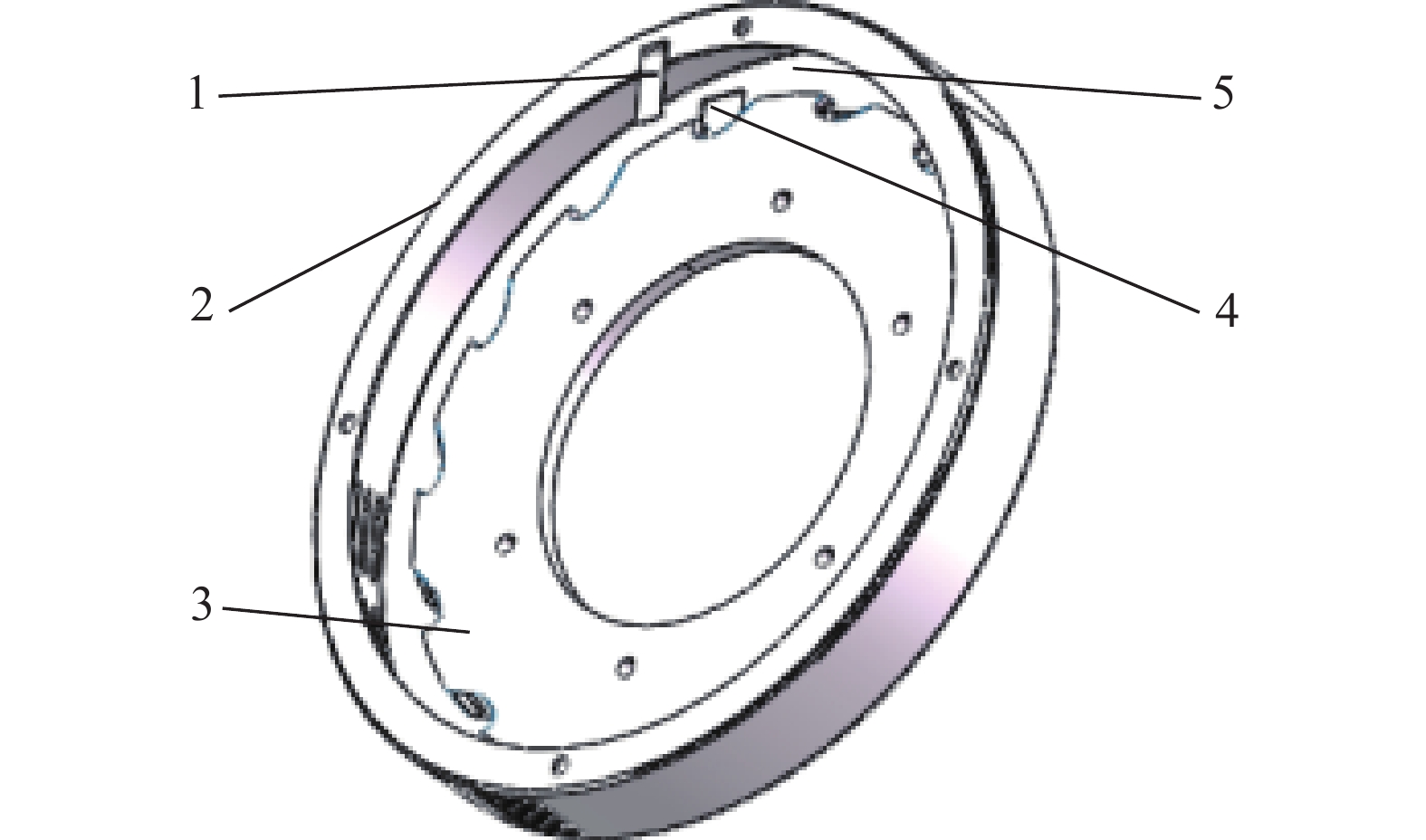

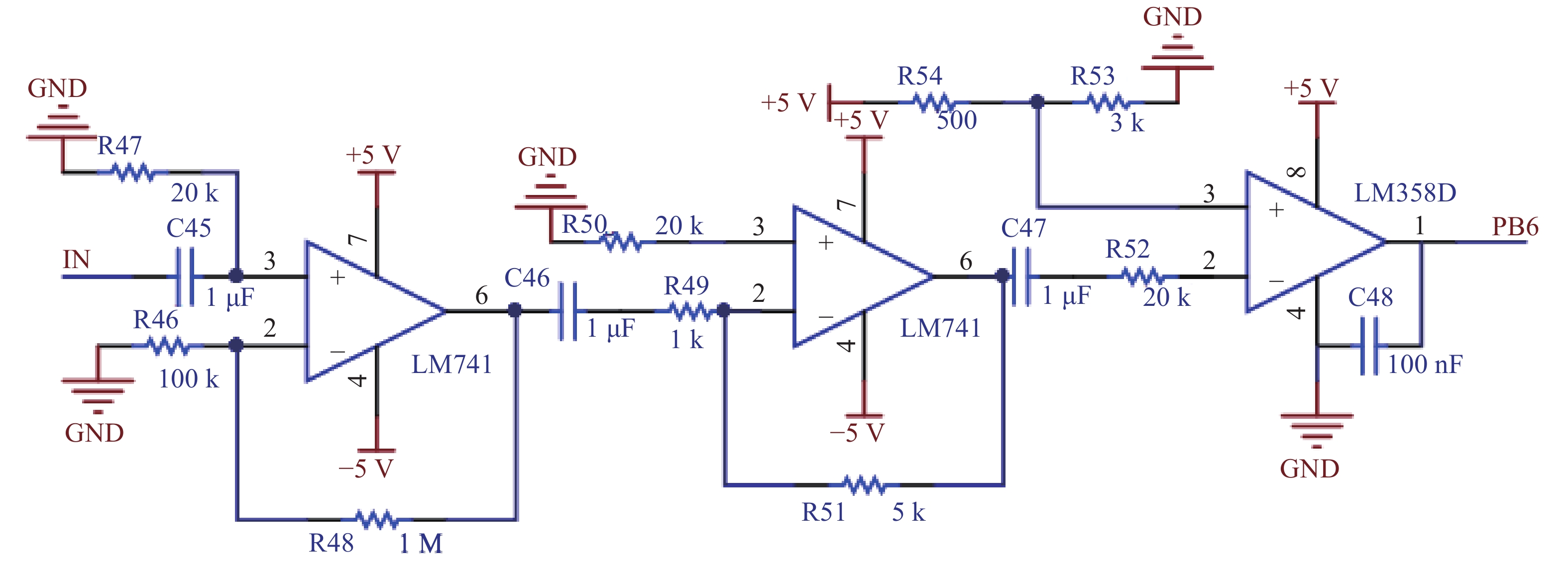

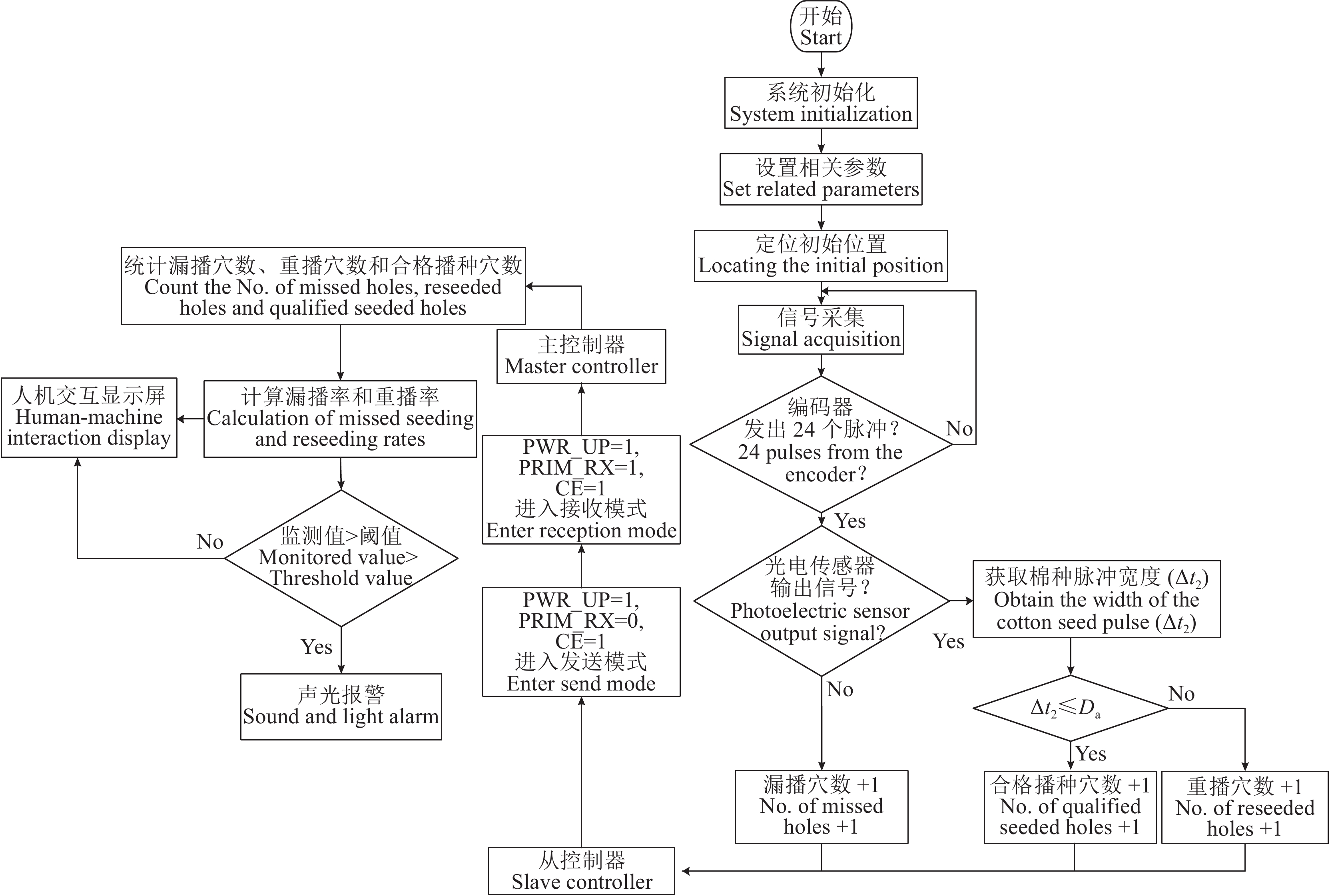

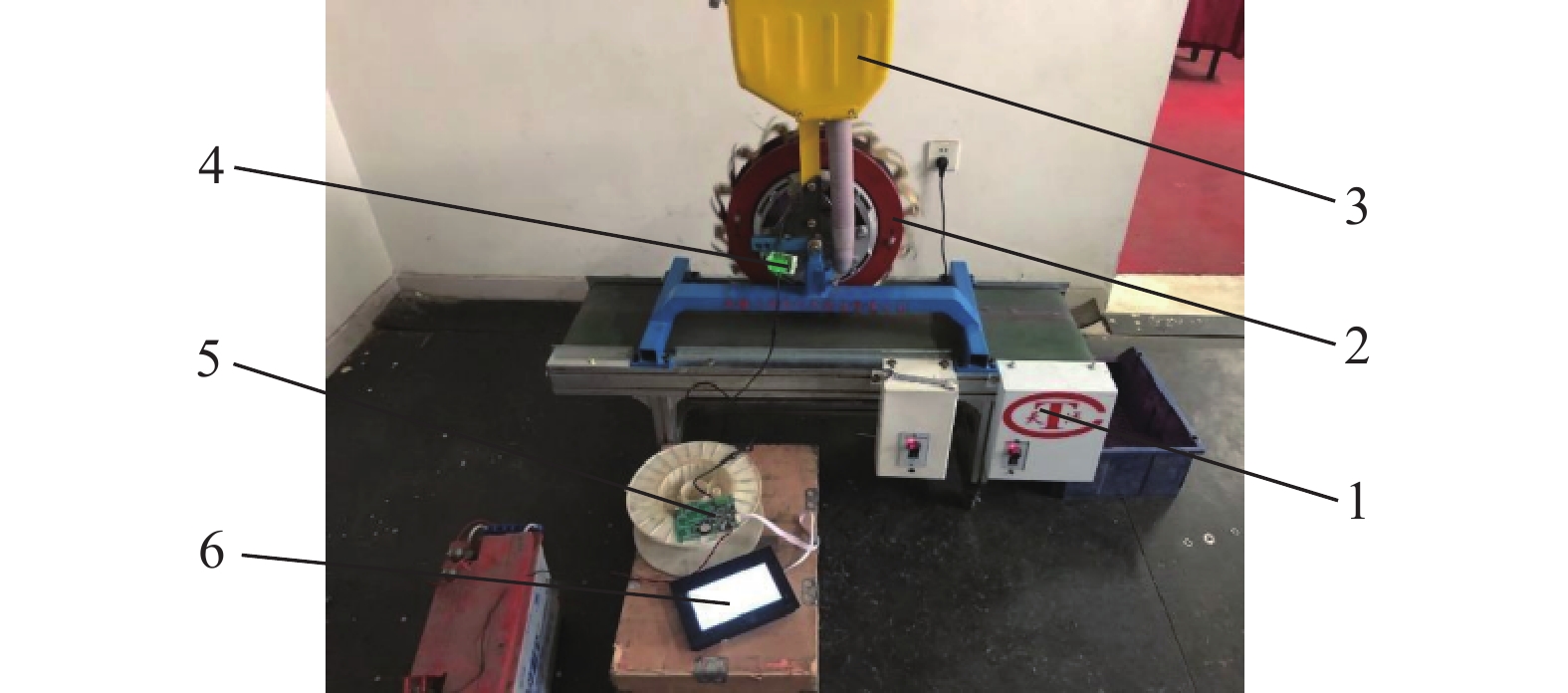

MethodThe monitoring system uses the STM32F103C8T6 microcontroller hardware system as the lower computer, obtains the information of missed seeding and reseeding of cotton seeds through the counter-light photoelectric sensor and photoelectric encoder installed on the seed storage ring of the hole sower, and determines the quality of cotton sowing. The cotton sowing information is transmitted to the human-machine interface of the DWIN touch screen through the nRF24L01 module for real-time display. A test bed of cotton sowing quality monitoring system was built to verify the accuracy of the monitoring system through field tests.

ResultThe results of the bench test showed that the system had the highest monitoring accuracies of 96.65%, 94.59% and 92.00% respectively for qualified seeding, missed seeding and reseeding when the speed of the hole sower was 30 r/min. When the speed of the hole sower was higher than 30 r/min, the monitoring accuracy decreased obviously. The results of field trial validation showed that the average monitoring accuracies of the system were 94.51%, 92.38% and 86.55% respectively for qualified seeding, missed seeding and reseeding. The analysis of the field trial data using SPSS software concluded that the trial data were statistically significant, and the cotton sowing quality data obtained by the monitoring system had a high correlation with the manually measured data, and the actual values could be reflected by the system monitoring values.

ConclusionThe system meets the demand for monitoring the quality of cotton sowing in field operation, and is of great significance for realizing the improvement of quality and efficiency of cotton planting.

-

Keywords:

- Cotton /

- Hole sower /

- Seeding quality /

- Monitoring system /

- Monitoring accuracy

-

-

表 1 监测系统精度试验结果

Table 1 Monitoring system accuracy test results

穴播器转速/ (r·min−1) Rotary speed of hole sower 应播穴数 No. of sowable holes 合格播种 Qualified seeding 漏播 Missed seeding 重播 Reseeding 实际穴数 Actual No. of holes 监测穴数 No. of monitored holes 监测精度/% Monitoring accuracy 实际穴数 Actual No. of holes 监测穴数 No. of monitored holes 监测精度/% Monitoring accuracy 实际穴数 Actual No. of holes 监测穴数 No. of monitored holes 监测精度/% Monitoring accuracy 30 600 538 520 96.65 37 35 94.59 25 23 92.00 35 600 539 519 96.29 37 35 94.59 24 22 91.67 40 600 538 517 96.09 38 35 92.11 24 22 91.67 45 600 538 516 95.91 39 36 92.30 23 21 91.30 表 2 棉花播种田间试验结果

Table 2 Field test results of cotton sowing

穴播器编号 Hole sower number 应播穴数 No. of sowable holes 合格播种 Qualified seeding 漏播 Missed seeding 重播 Reseeding 实际穴数 Actual No. of holes 监测穴数 No. of monitored holes 监测精度/% Monitoring accuracy 实际穴数 Actual No. of holes 监测穴数 No. of monitored holes 监测精度/% Monitoring accuracy 实际穴数 Actual No. of holes 监测穴数 No. of monitored holes 监测精度/% Monitoring accuracy 1 1000 980 931 95.00 12 11 91.67 8 7 87.50 2 1000 978 927 94.79 15 14 93.33 7 6 85.71 3 1000 975 925 94.87 17 15 88.24 8 7 87.50 4 1000 977 924 94.58 17 15 88.24 6 5 83.33 5 1000 975 923 94.67 16 15 93.75 9 8 88.89 6 1000 976 922 94.47 14 13 92.86 10 9 90.00 7 1000 981 931 94.90 13 12 92.31 6 5 83.33 8 1000 980 925 94.69 14 13 92.86 6 6 100.00 9 1000 979 920 93.97 15 15 100.00 6 5 83.33 10 1000 977 920 94.17 16 15 93.75 7 6 85.71 11 1000 978 919 93.97 17 15 88.24 5 4 80.00 12 1000 979 921 94.08 15 14 93.33 6 5 83.33 $\bar x $ 1000 978 924 94.51 15.08 13.90 92.38 7 6.08 86.55 表 3 指标监测值和实际值单因素线性回归分析结果

Table 3 Results of univariate linear regression analysis of monitored and actual values of indicators

指标 Indicator 模型 Model 相关系数(r) Correlation coefficient 拟合优度(r2) Goodness of fit 调整r2Ajusted r2 标准估计误差 Standard estimation error 漏播穴数 No. of missed holes 1 0.94 0.88 0.87 0.59 重播穴数 No. of reseeded holes 1 0.98 0.96 0.96 0.30 表 4 指标监测值和实际值方差分析结果

Table 4 Results of trial ANOVA of monitored and actual values of indicators

指标 Indicator 模型 Model 自由度 DF 平方和 SS 均方 MS F P 漏播穴数 No. of missed holes 回归 Return 1 25.47 25.47 74.01 0.00 残差 Residual 10 3.44 0.34 总计 Total 11 28.91 重播穴数 No. of reseeded holes 回归 Return 1 23.08 23.08 251.91 0.00 残差 Residual 10 0.92 0.09 总计 Total 11 24.00 表 5 指标监测值和实际值系数

Table 5 Indicator monitoring value and actual value coefficient

指标 Indicator 模型 Model 非标准化系数 Non-standardized coefficient 标准化系数 Standardization coefficient t P 系数B Coefficient B 标准误差 Standard error 漏播穴数 No. of missed holes 常量 Constant −0.28 1.79 0.94 −0.15 0.21 实际值 Actual value 1.10 0.13 8.60 0.00 重播穴数 No. of reseeded holes 常量 Constant 0.90 0.39 0.98 2.27 0.04 实际值 Actual value 1.00 0.06 15.87 0.00 -

[1] 贾小凡. 国家棉花市场监测系统报告[R]. 北京: 中储棉花信息中心有限公司, 2020. [2] 闫建峰. 新疆维吾尔自治区棉花生产现状及发展对策[J]. 乡村科技, 2020, 11(22): 47-48. doi: 10.3969/j.issn.1674-7909.2020.22.023 [3] 曹叶, 王旭峰, 王龙, 等. 精量穴播器排种性能检测方法研究分析及展望[J]. 新疆农机化, 2020(6): 19-24. [4] 戈天剑, 赵斌, 衣淑娟, 等. 气吸式玉米播种机排种监测系统研究[J]. 农机化研究, 2017, 39(8): 82-85. doi: 10.3969/j.issn.1003-188X.2017.08.017 [5] 丁幼春, 王凯阳, 刘晓东, 等. 中小粒径种子播种检测技术研究进展[J]. 农业工程学报, 2021, 37(8): 30-41. doi: 10.11975/j.issn.1002-6819.2021.08.004 [6] 林相峰, 邹林, 叶明宇. 约翰迪尔1820型气力式免耕变量播种机[J]. 现代化农业, 2005(8): 26. doi: 10.3969/j.issn.1001-0254.2005.08.034 [7] Precision Planting. WaveVision[EB/OL]. (2014-07-15) [2019-08-22]. https://www.precisionplanting.com/products/product/wavevision.

[8] BORJA A A, AMONGO R M C, SUMINISTRADO D C, et al. A machine vision assisted mechatronic seed meter for precision planting of corn[C]// IEEE. 2018 3rd International Conference on Control and Robotics Engineering (ICCRE). Nagoya: IEEE, 2018: 183-187

[9] MARRION C C, FOSTER N J, LIU L, et al. System and method for three-dimensional alignment of objects using machine vision: US8442304B2[P/OL]. [2022-01-03]. https://www.researchgate.net/publication/302633414_System_and_method_for_three-dimensional_alignment_of_objects_using_machine_vision.

[10] 丁幼春, 王雪玲, 廖庆喜. 基于时变窗口的油菜精量排种器漏播实时检测方法[J]. 农业工程学报, 2014, 30(24): 11-21. doi: 10.3969/j.issn.1002-6819.2014.24.002 [11] 丁幼春, 朱凯, 王凯阳, 等. 薄面激光−硅光电池中小粒径种子流监测装置研制[J]. 农业工程学报, 2019, 35(8): 12-20. doi: 10.11975/j.issn.1002-6819.2019.08.002 [12] 李明, 刘晓辉, 丁幼春, 等. 基于排种频率的油菜气力式精量排种器漏播检测技术与装置[C]// 中国农业工程学会. 中国农业工程学会2011年学术年会论文集. 重庆: 中国农业工程学会, 2011: 299-304. [13] 谭穗妍, 马旭, 董文浩, 等. 基于嵌入式机器视觉的水稻秧盘育秧图像无线传输系统[J]. 农业机械学报, 2017, 48(4): 22-28. doi: 10.6041/j.issn.1000-1298.2017.04.002 [14] 谭穗妍, 马旭, 吴露露, 等. 基于机器视觉和BP神经网络的超级杂交稻穴播量检测[J]. 农业工程学报, 2014, 30(21): 201-208. doi: 10.3969/j.issn.1002-6819.2014.21.024 [15] 杨硕, 王秀, 高原源, 等. 玉米精密播种粒距在线监测与漏播预警系统设计[J]. 农业机械学报, 2021, 52(3): 17-24. doi: 10.6041/j.issn.1000-1298.2021.03.002 [16] 黄东岩, 朱龙图, 贾洪雷, 等. 基于GPS和GPRS的远程玉米排种质量监测系统[J]. 农业工程学报, 2016, 32(6): 162-168. doi: 10.11975/j.issn.1002-6819.2016.06.022 [17] 王金武, 张曌, 王菲, 等. 基于压电冲击法的水稻穴直播监测系统设计与试验[J]. 农业机械学报, 2019, 50(6): 74-84. doi: 10.6041/j.issn.1000-1298.2019.06.008 [18] 姚建真. 迪文DGUS与Modbus协议的基本应用[J]. 电子技术应用, 2013, 39(1): 2. doi: 10.3969/j.issn.0258-7998.2013.01.002 [19] 中国国家标准化管理委员会. 单粒(精密)播种机试验方法: GB/T 6973—2005[S]. 北京: 中国农业出版社, 2005. [20] 董万城, 张立新, 李文春, 等. 新疆棉花播种机械应用现状及发展趋势[J]. 新疆农机化, 2021(2): 11-15. [21] 中国国家标准化管理委员会. 铺膜穴播机作业质量: NY/T 987— 2006[S]. 北京: 中国农业出版社, 2006.

下载:

下载: