Design and experiment of precision seeder with double seed filling type hole roller for hybrid rice seedling raising

-

摘要:目的

为满足杂交稻钵苗育秧低播量精密播种的农艺要求,解决型孔滚筒式育秧播种器作业过程中稻种在充种室流动性差、充种可靠性低、漏播指数高以及型孔易堵塞等问题,设计一种双充种型孔滚筒式杂交稻育秧精密播种器。

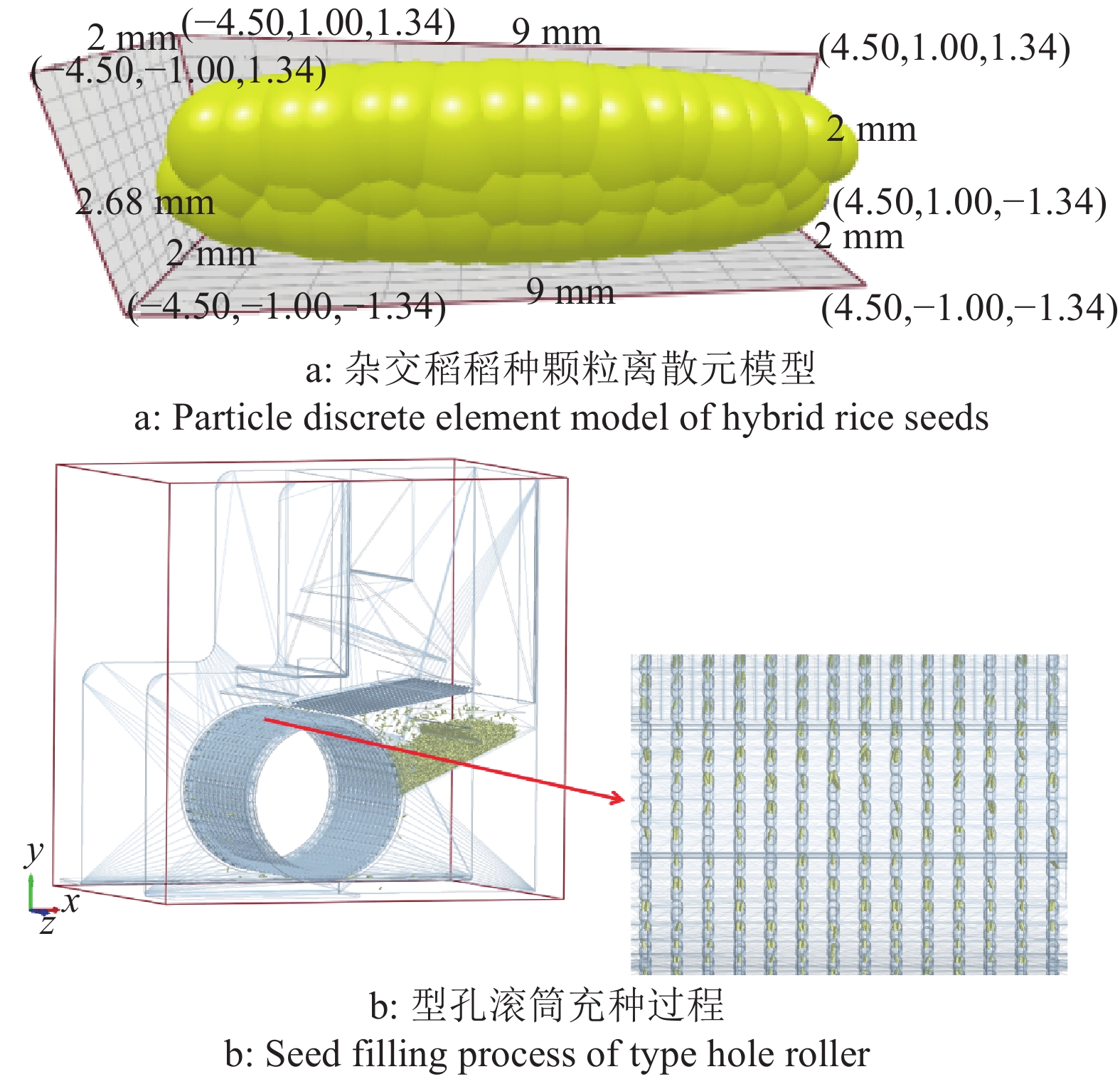

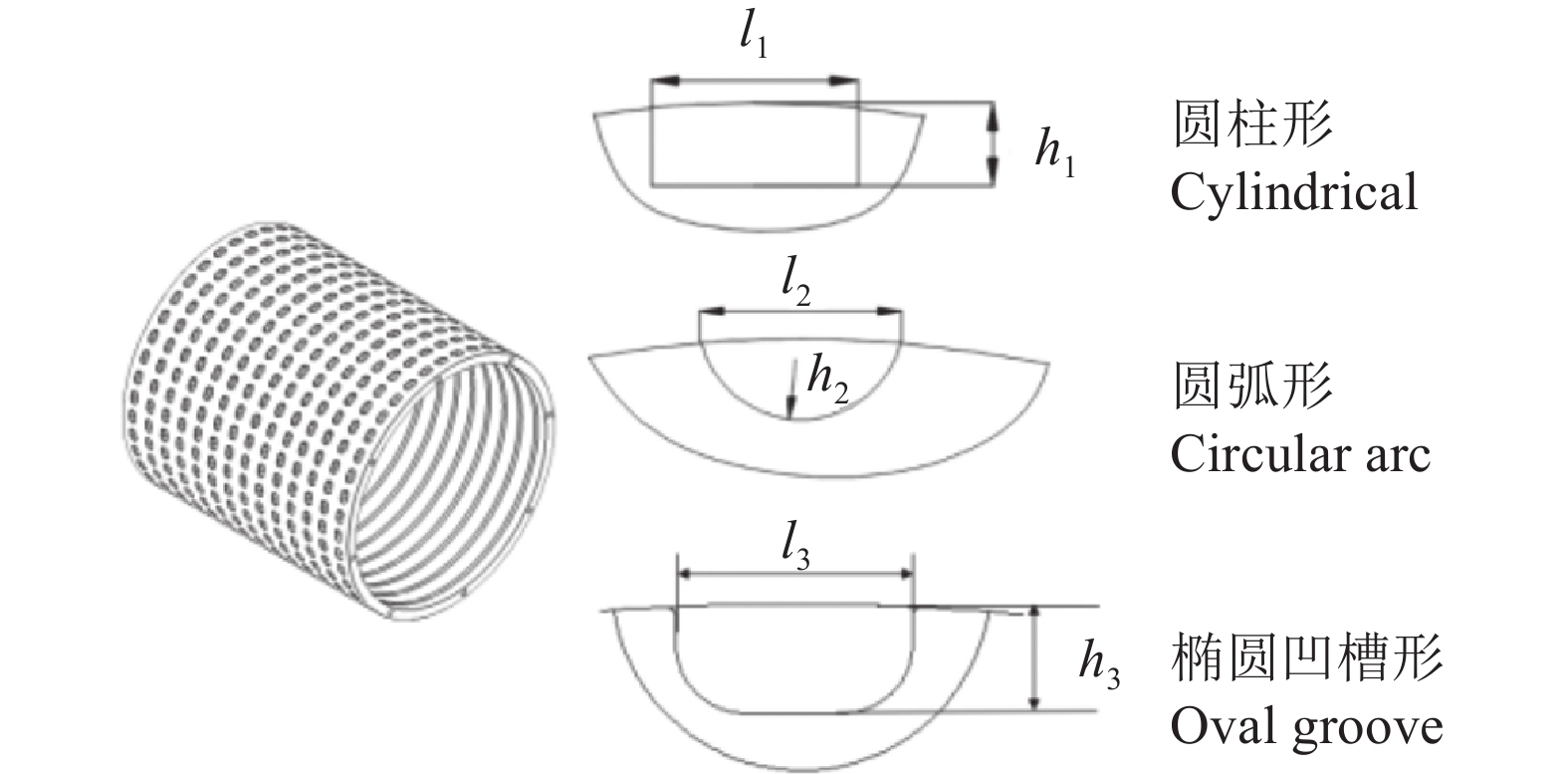

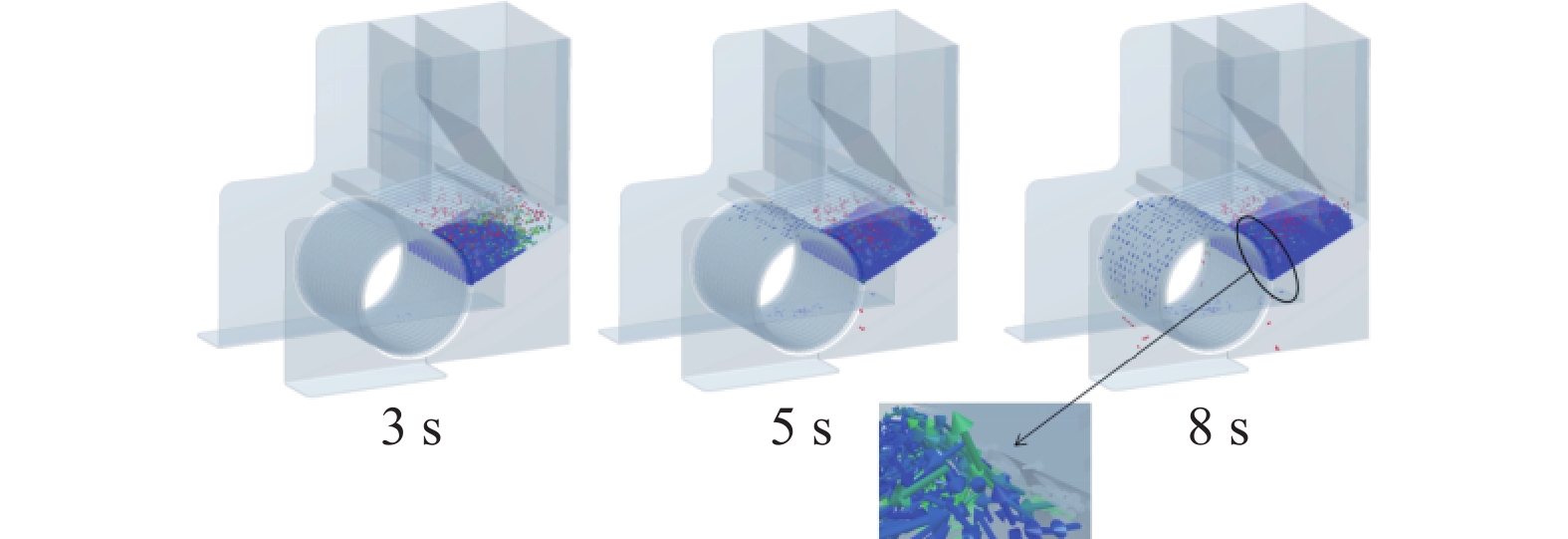

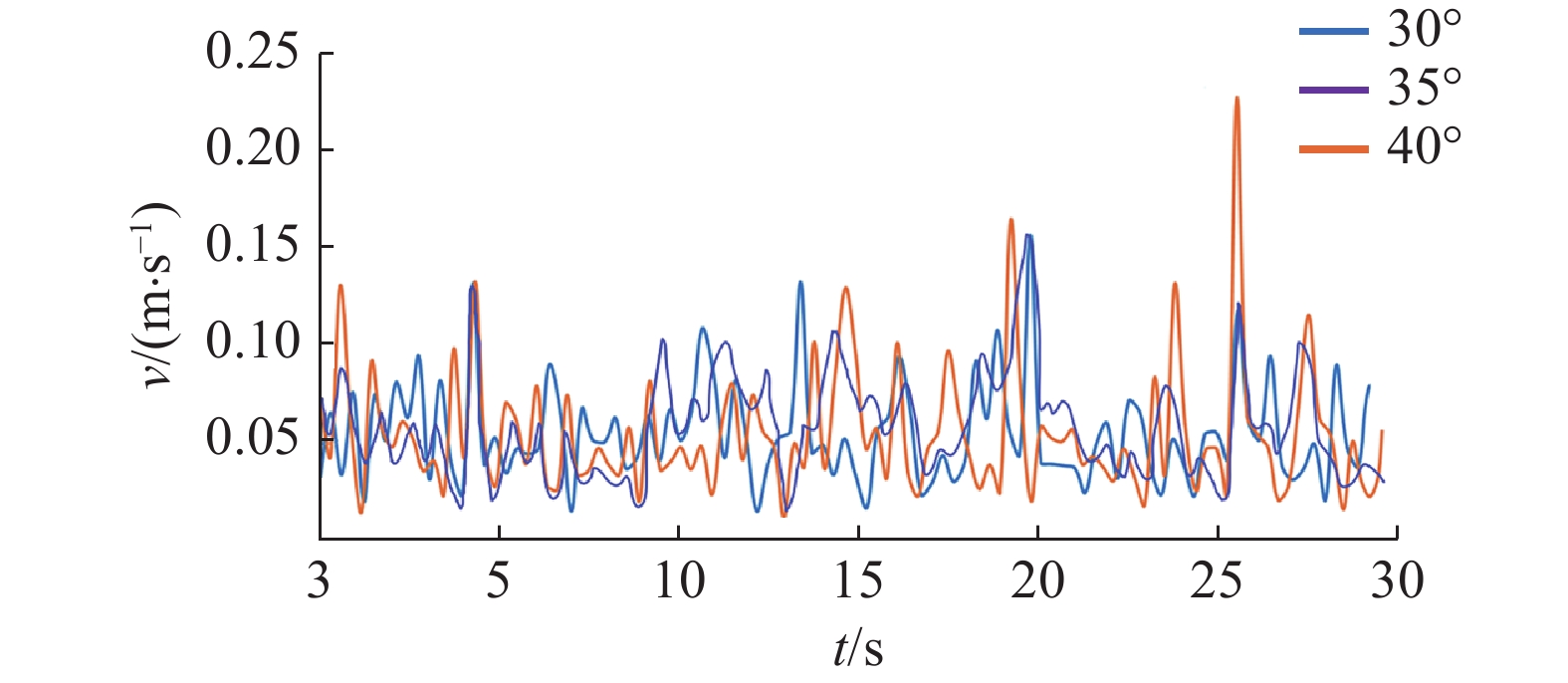

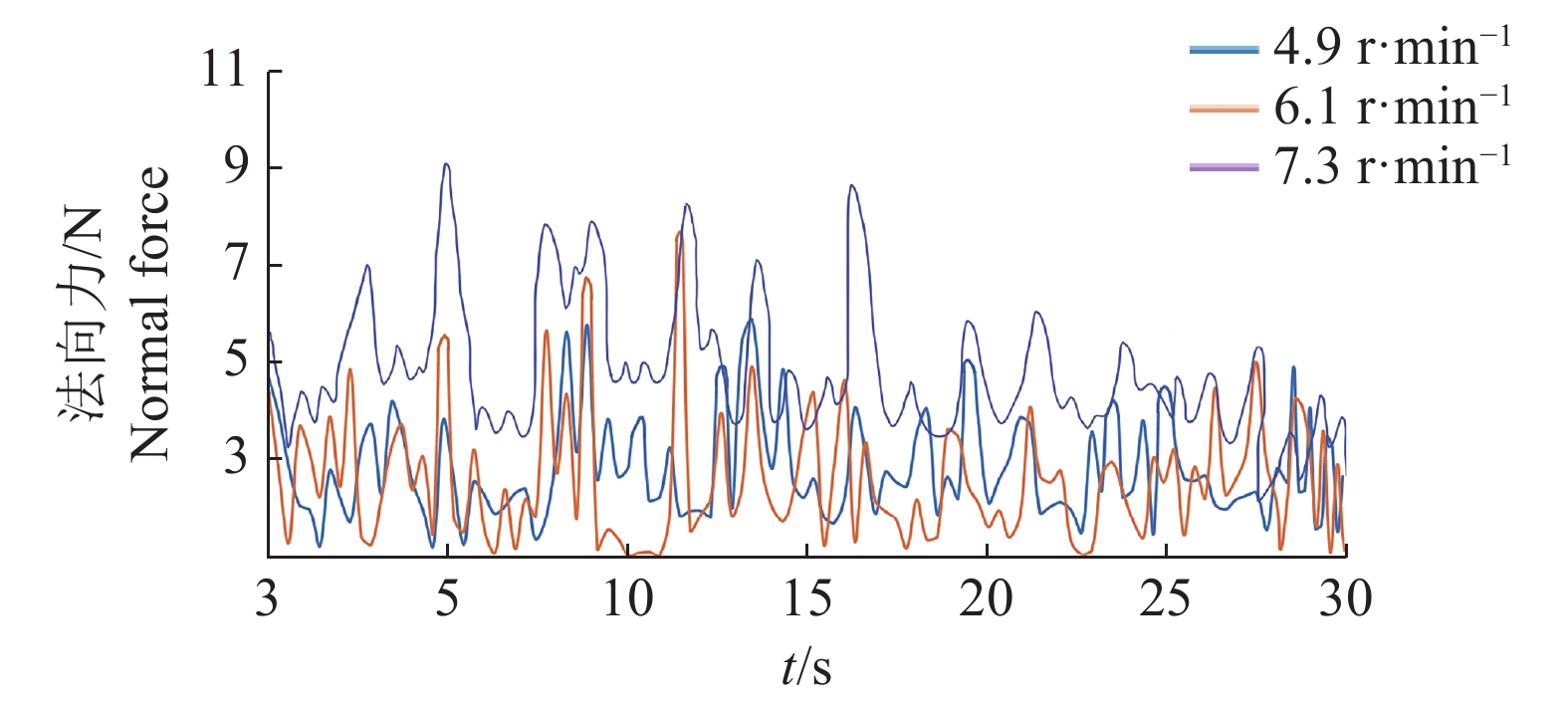

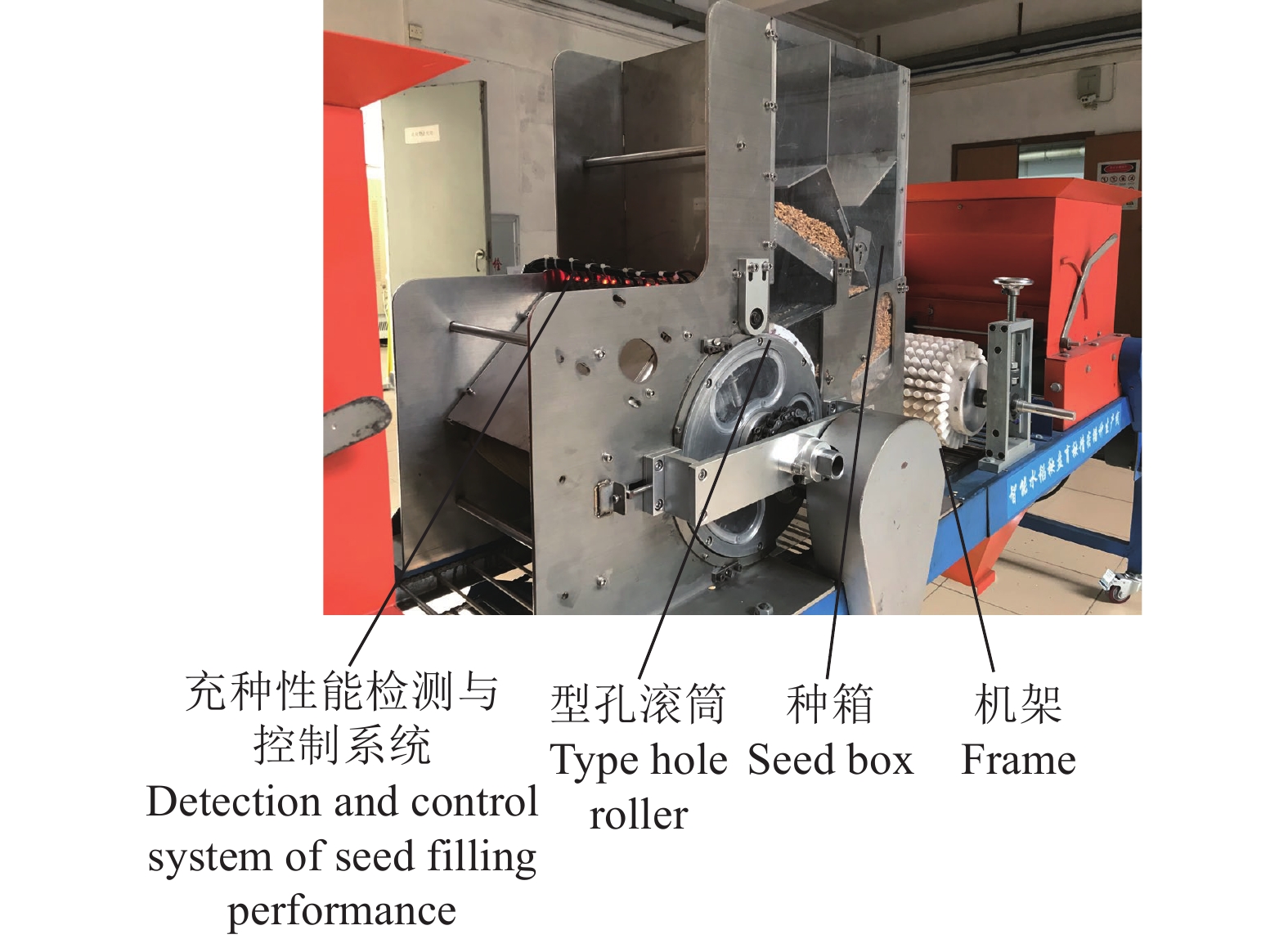

方法基于PLC控制技术,搭建型孔充种性能检测与控制系统,对播种器的关键部件进行设计,并通过EDEM离散元软件开展不同型孔形状、第一充种室充种位置角及生产率对充种性能影响的仿真试验,对第一充种区的型孔滚筒工作参数进行优化。研制试验样机并进行性能试验,试验材料为‘培杂泰丰’杂交稻。试验分2步:第1步,第二充种机构不动作,采用三因素三水平正交试验,研究型孔深度、生产率和第一充种室充种位置角对试验指标的影响,验证仿真准确性;第2步,启动第二充种机构,研究进行双充种作用下的不同振动频率对试验指标的影响,探明设计第二充种机构后播种性能。

结果第1步试验结果表明,影响播种合格指数与重播指数的因素主次顺序为型孔深度>生产率>第一充种室充种位置角;影响漏播指数的因素主次顺序为生产率>型孔深度>第一充种室充种位置角。第2步试验结果表明,当型孔形状为椭圆凹槽形,第一充种室的充种位置角为35°、第二充种室振动频率为27 Hz、生产率在400~600盘/h,播种合格指数均大于90%,漏播指数均小于3%,试验结果满足杂交稻低播量精密播种的农艺要求。

结论采用双充种的填充方式改善了播种器每穴的填充性能,减少了漏播指数,本研究结果为轻简型杂交稻钵苗育秧精密播种机的开发提供了理论依据。

Abstract:ObjectiveIn order to meet the agronomic requirements of low sowing rate and precision sowing of hybrid rice potted-seedling raising, and solve the problems of poor fluidity of rice seeds in the seed filling chamber, low seed filling reliability, high missing sowing index and easy blockage of type holes during the operation of seedling raising seeder with type hole roller, a precision seeder with double seed filling type hole roller for hybrid rice seedling raising was designed.

MethodBased on PLC control technology, a detection and control system for type hole seed filling performance was built, and the key components were analyzed and designed. The simulation tests of the influences of the seed filling performance of different type hole shapes, the seed filling position angle of the first seed filling chamber, and the productivity on seed filling performance were carried out through EDEM discrete element software, to optimize the working parameters of the type hole roller in the first seed filling area. The experimental prototype was developed for post performance test, and rice variety was ‘Peizataifeng’ hybrid rice. The test was divided into two steps. In the first step, the second seed filling mechanism did not act, a three-factor-three-level orthogonal test was adopted to study the effects of type hole depth, productivity and seed filling position angle of the first seed filling chamber on the test indexes, and verify the accuracy of the simulation research. The second step was through the action of the second seed filling mechanism to study the effects of different vibration frequencies on the test indexes under double seed filling, and prove the sowing performance after designing the second seed filling mechanism.

ResultThe results of the first step showed that the order of factors affecting qualified index and replay sowing index was type hole depth > productivity > seed filling position angle of the first filling chamber; The order of the factors affecting the missing sowing index was productivity > type hole depth > seed filling position angle of the first filling chamber. The results of the second step showed that when the type hole shape was oval groove, the seed filling position angle of the first seed filling chamber was 35°, the vibration frequency of the second seed filling chamber was 27 Hz and the productivity was 400−600 discs/h, the qualified index of sowing was above 90%, and the missing sowing index was below 3%. The test results met the agronomic requirements of low sowing rate and precision sowing of hybrid rice.

ConclusionThe double seed filling method improves the filling performance of each hole of the seeder and reduces the missing sowing index. The results of this study provide references for developing the light and simple precision seeder for hybrid rice potted-seedling raising.

-

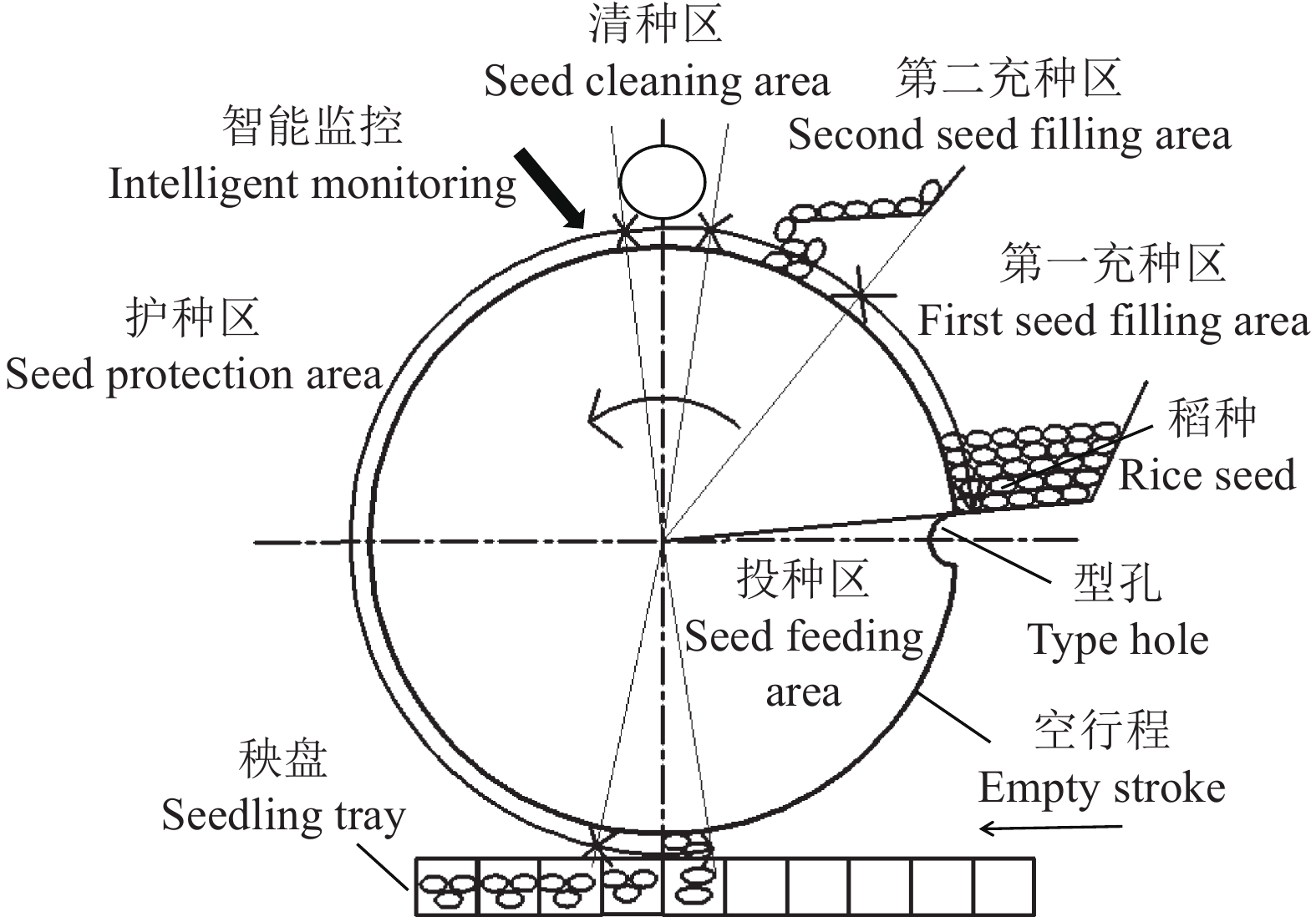

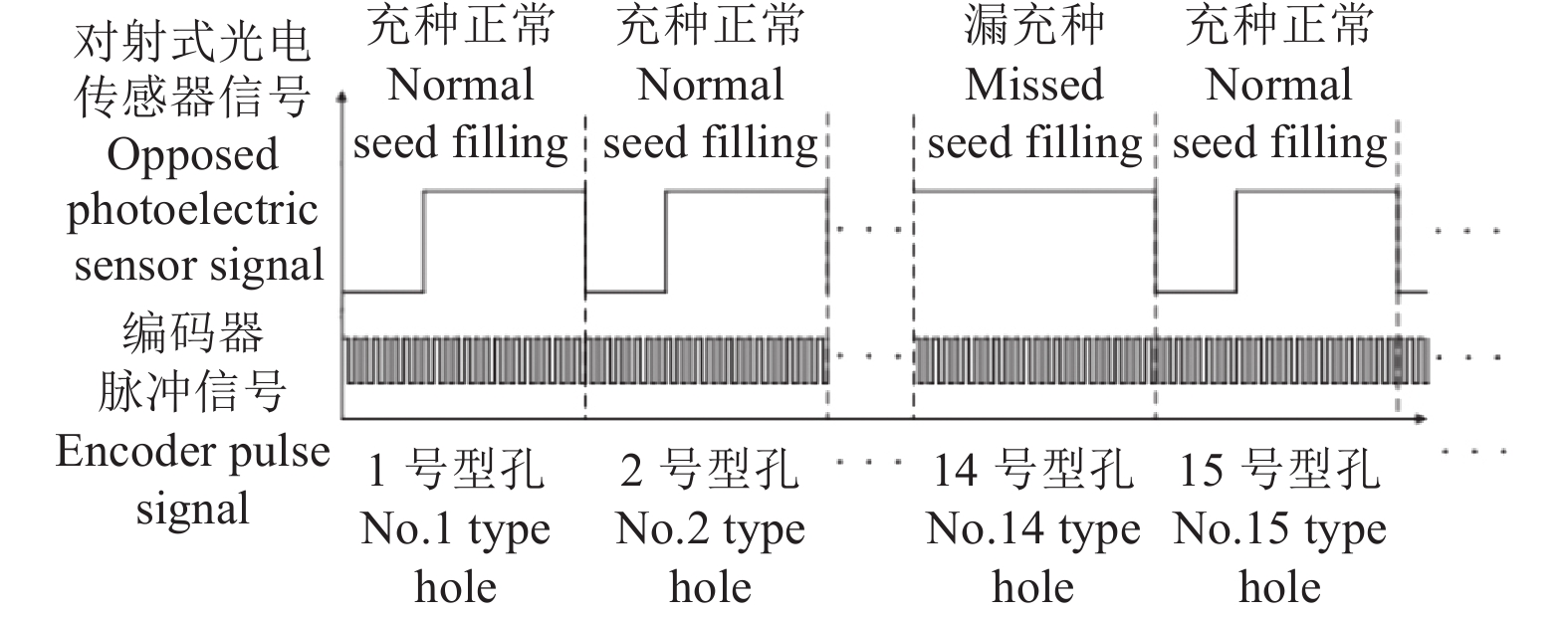

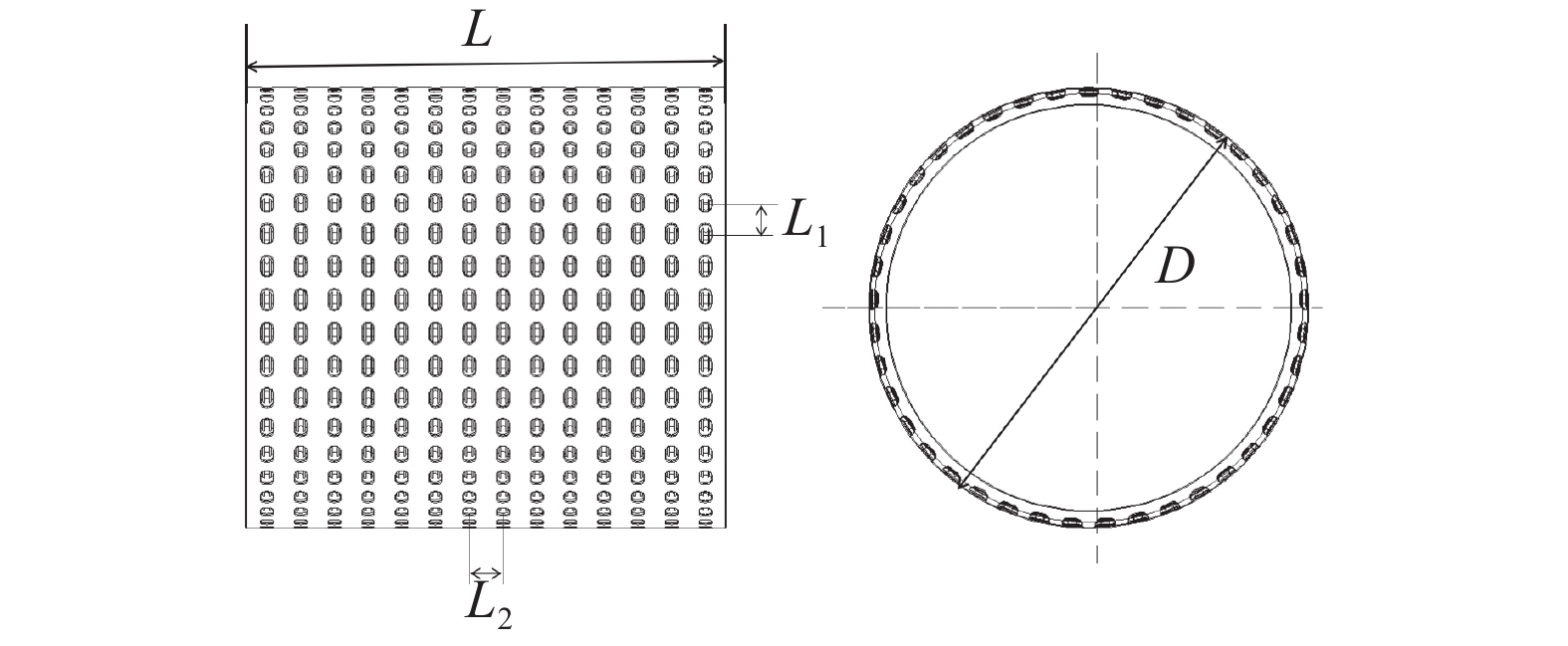

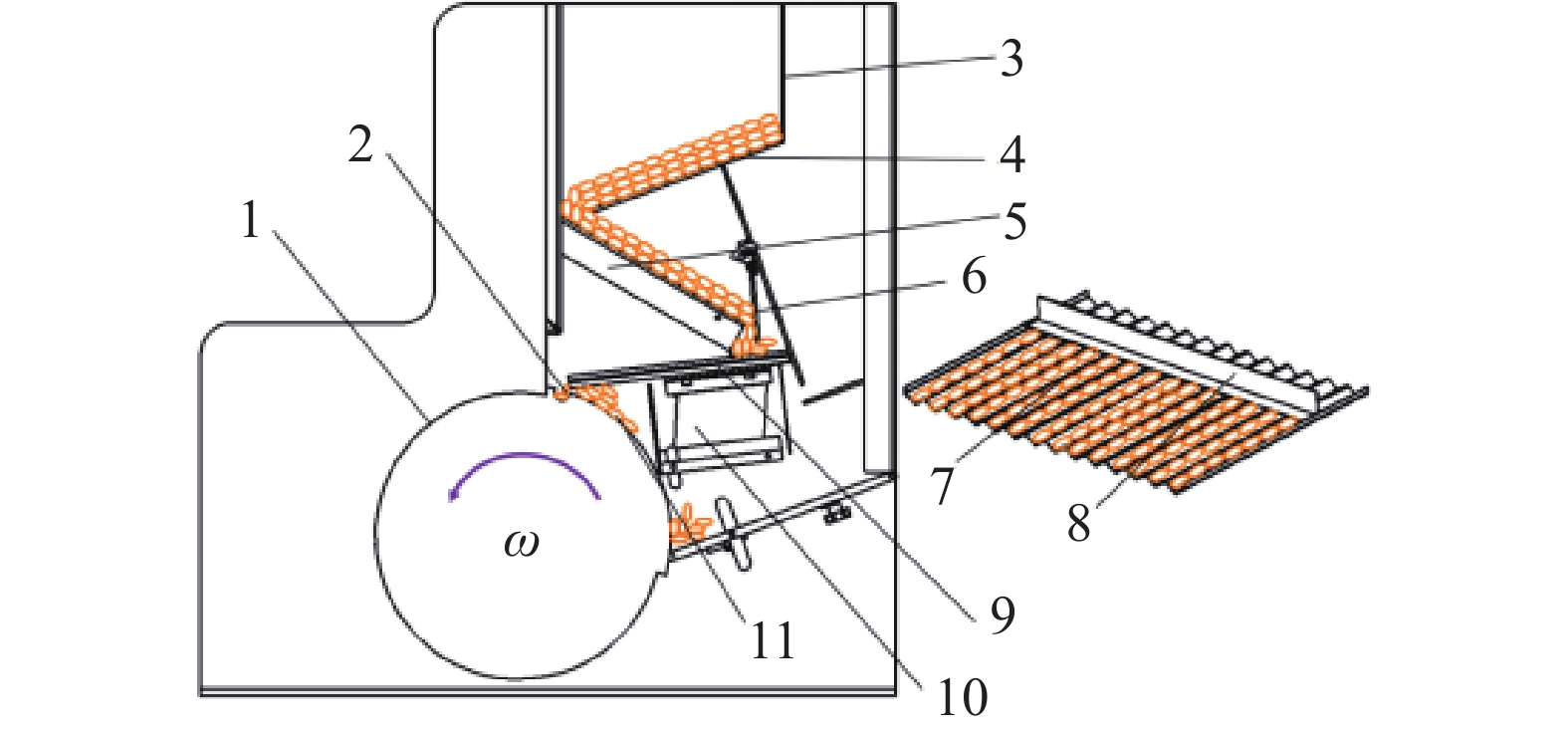

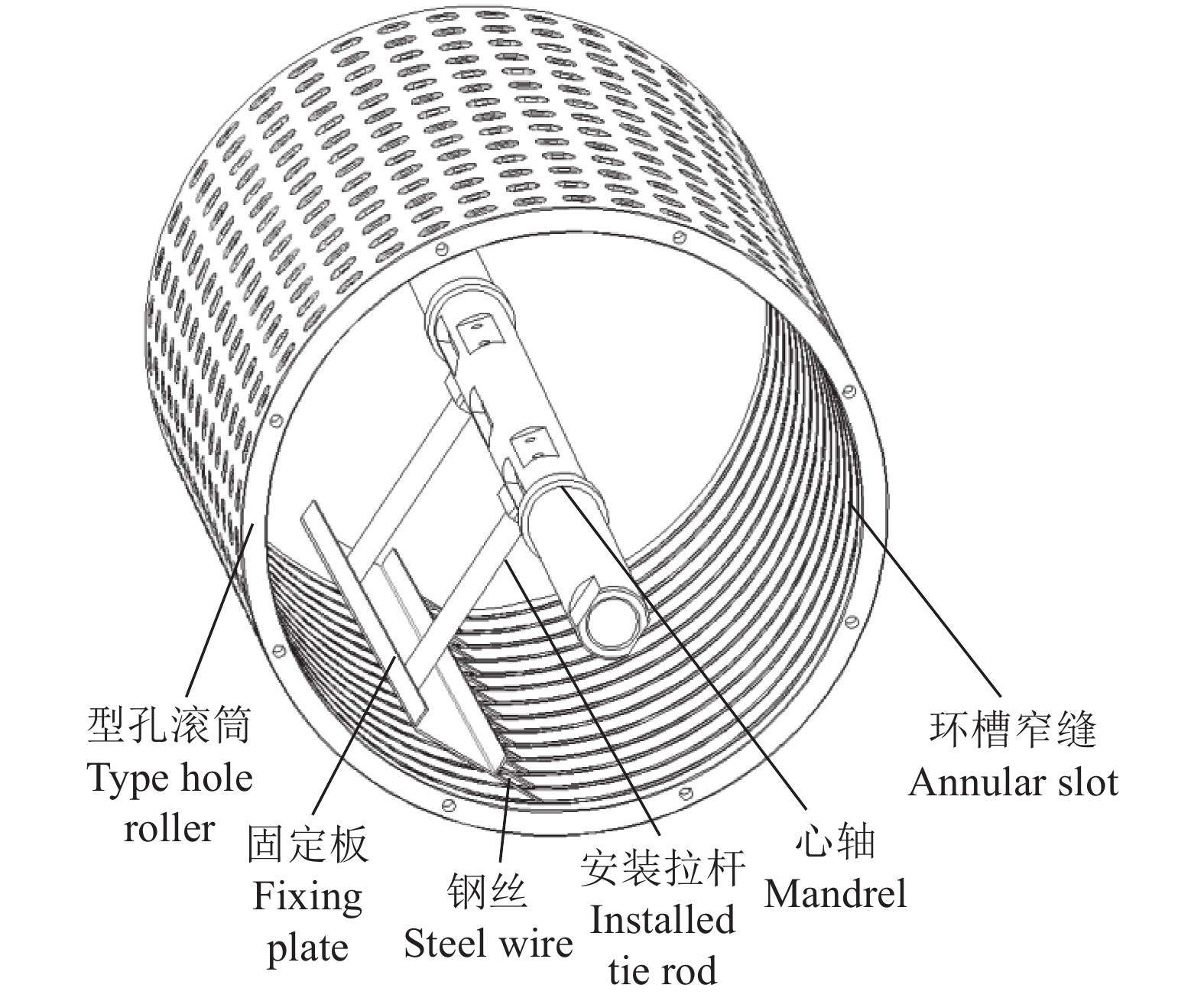

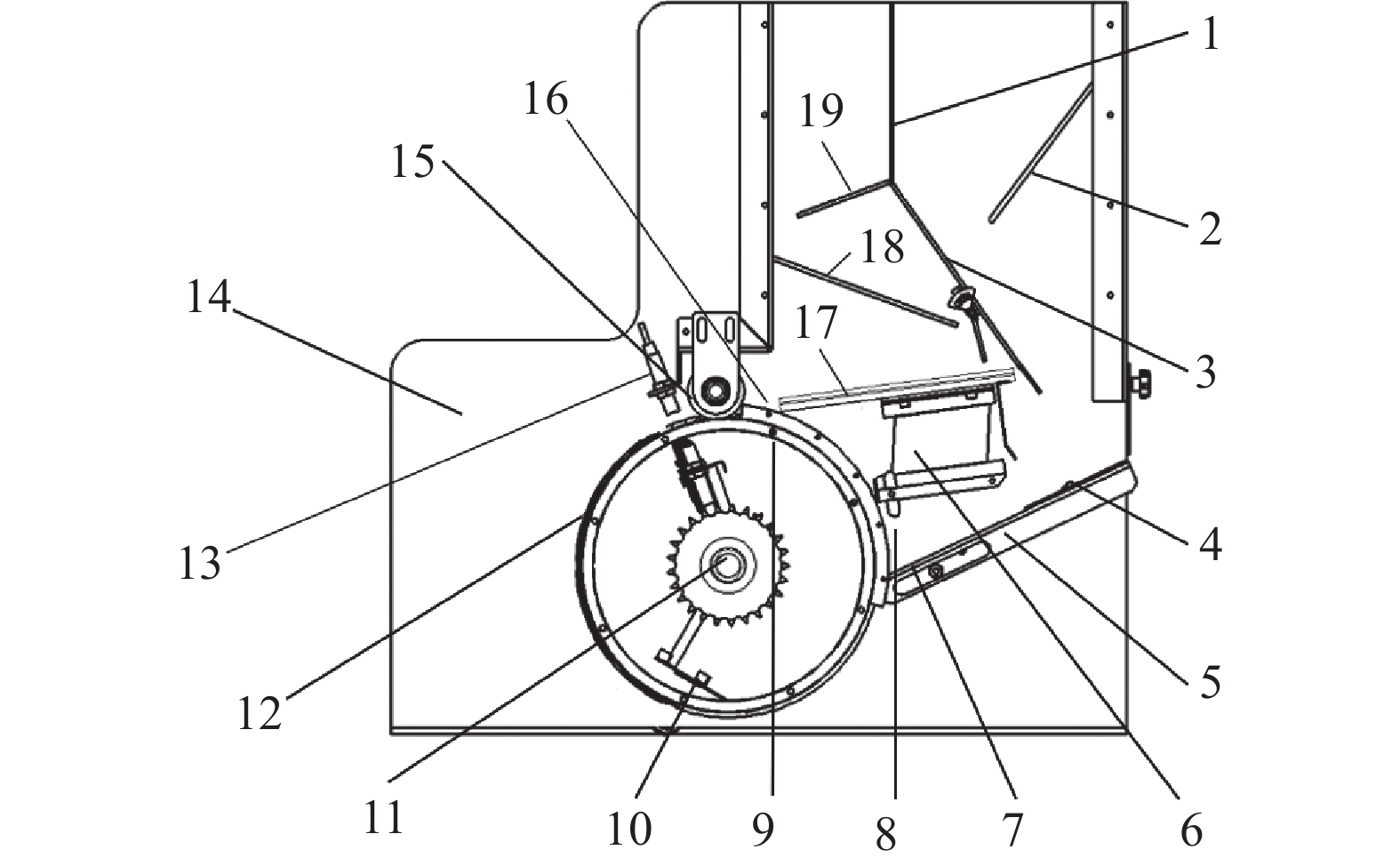

图 1 双充种型孔滚筒式杂交稻育秧精密播种器结构图

1:隔板;2:导种板Ⅰ;3:导种板Ⅱ;4:充种角调节机构;5:导种板Ⅲ;6:电磁振动器;7:卸种板;8:第一充种区;9:型孔滚筒;10:钢丝推种机构;11:心轴;12:护种机构;13:对射式光电传感器;14:侧板;15:清种轮;16:第二充种区;17:V型槽板;18:滑种板Ⅰ;19:滑种板Ⅱ

Figure 1. Structural schematic diagram of precision seeder with double seed filling type hole roller for hybrid rice seedling raising

1: Clapboard; 2: Seed guiding plate I; 3: Seed guiding plate II; 4: Seed filling angle adjusting mechanism; 5: Seed guiding plate III; 6: Electromagnetic vibrator; 7: Seed unloading plate; 8: First seed filling area; 9: Type hole roller; 10: Steel wire seed pushing mechanism; 11: Spindle; 12: Seed protection mechanism; 13: Opposed photoelectric sensor; 14: Side plate; 15: Seed cleaning wheel; 16: Second seed filling area; 17: V-shaped groove plate; 18: Seed sliding plate I; 19: Seed sliding plate II

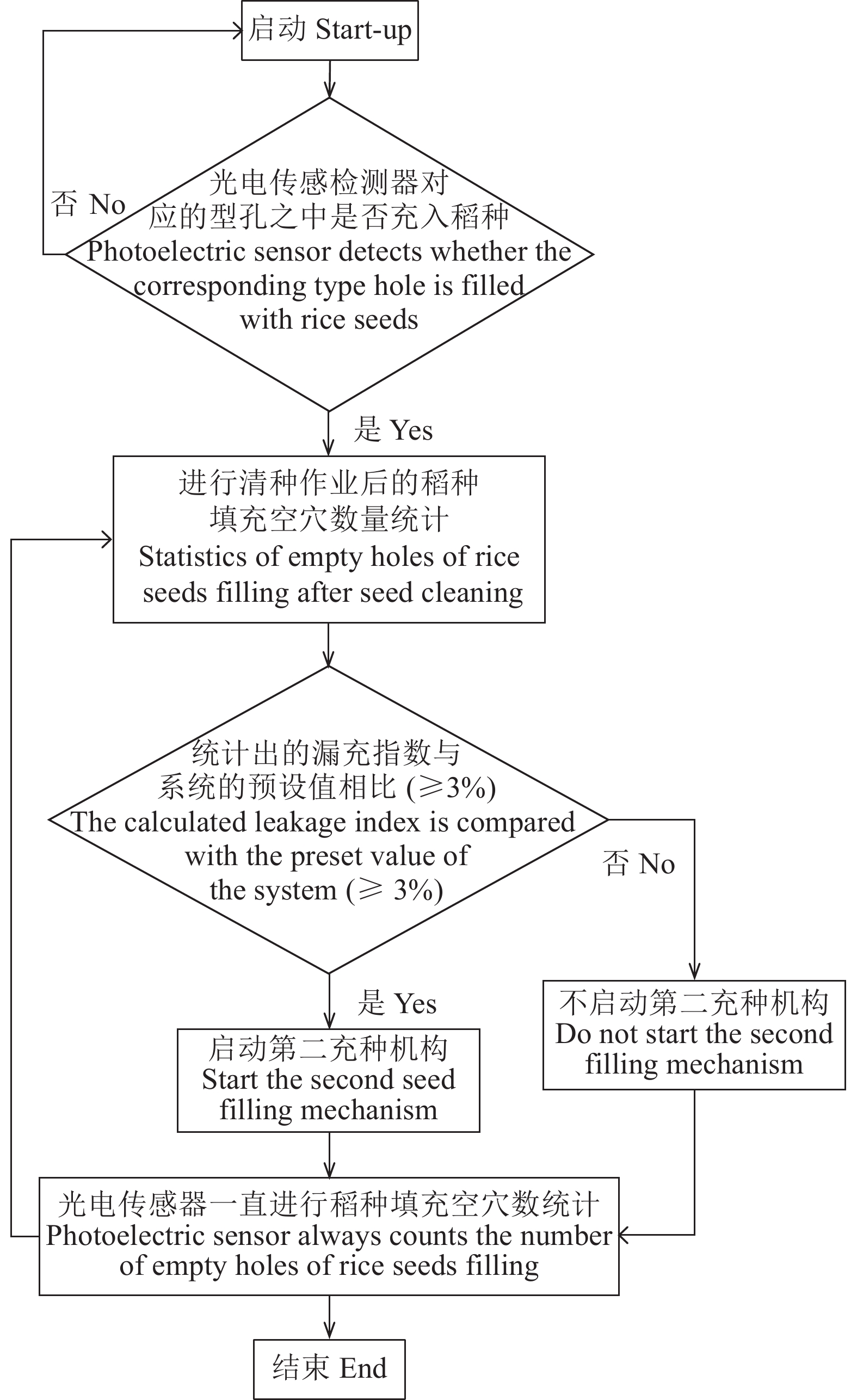

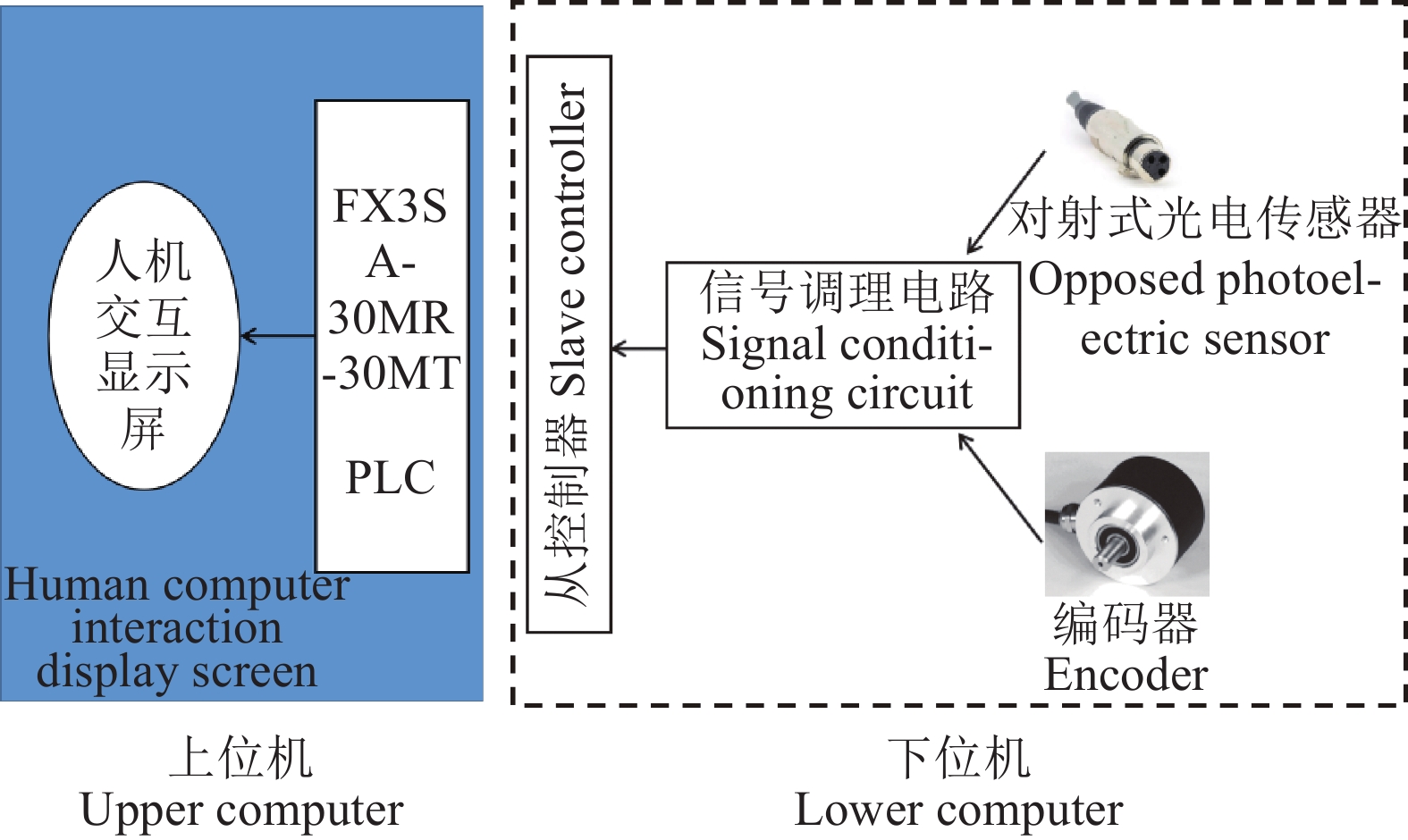

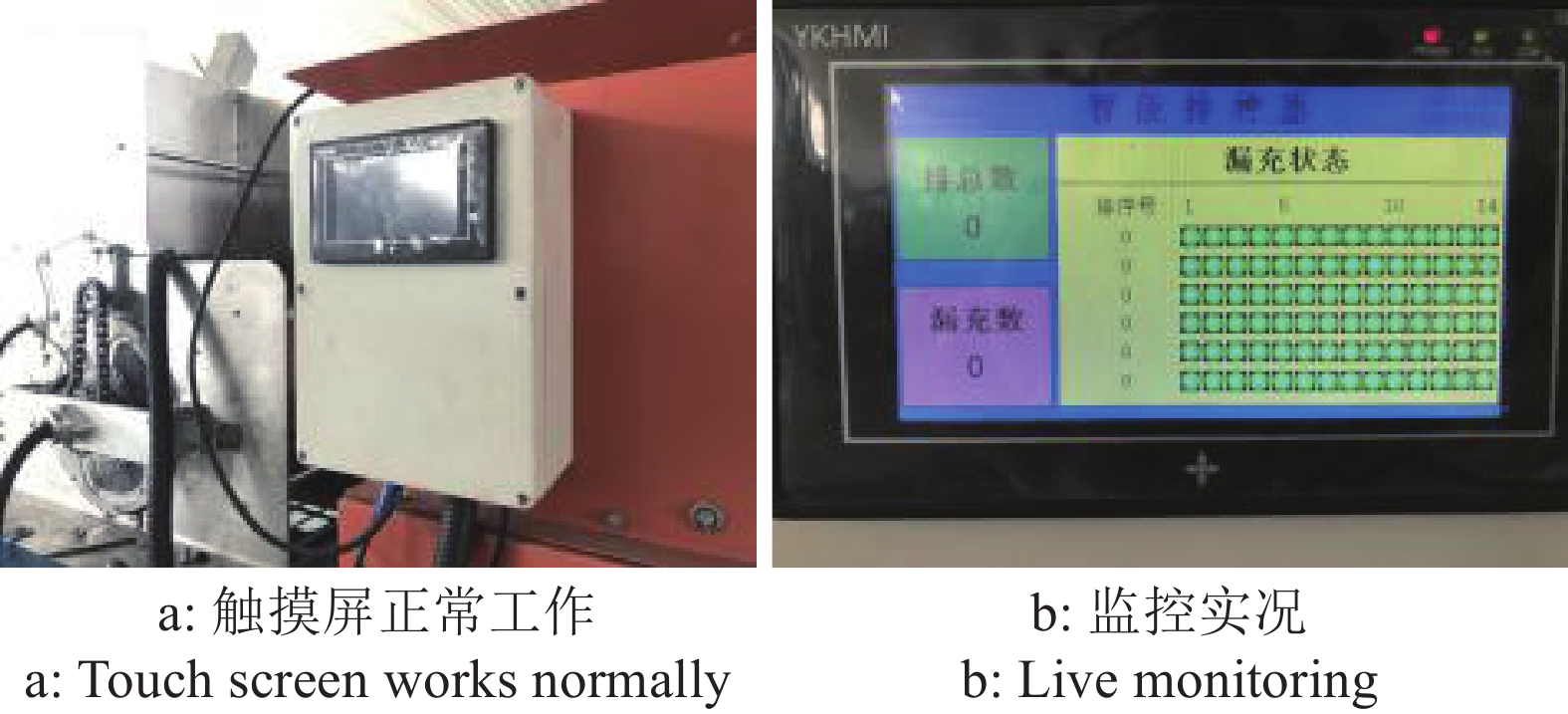

图 8 第二充种机构结构示意图

1:型孔滚筒;2:稻种;3:隔板;4:滑种板Ⅰ;5:滑种板Ⅱ;6:种量调节板;7:V型槽板;8:刮种片;9:安装板;10:电磁直振器;11:回流稻种

Figure 8. Structural sketch of the second seed filling mechanism

1: Type hole roller; 2: Rice seed; 3: Clapboard; 4: Seed sliding plate I; 5: Seed sliding plate II; 6: Seed quantity adjusting plate; 7: V-shaped groove plate; 8: Seed scraper; 9: Mounting plate; 10: Electromagnetic vibrator; 11: Reflux rice seed

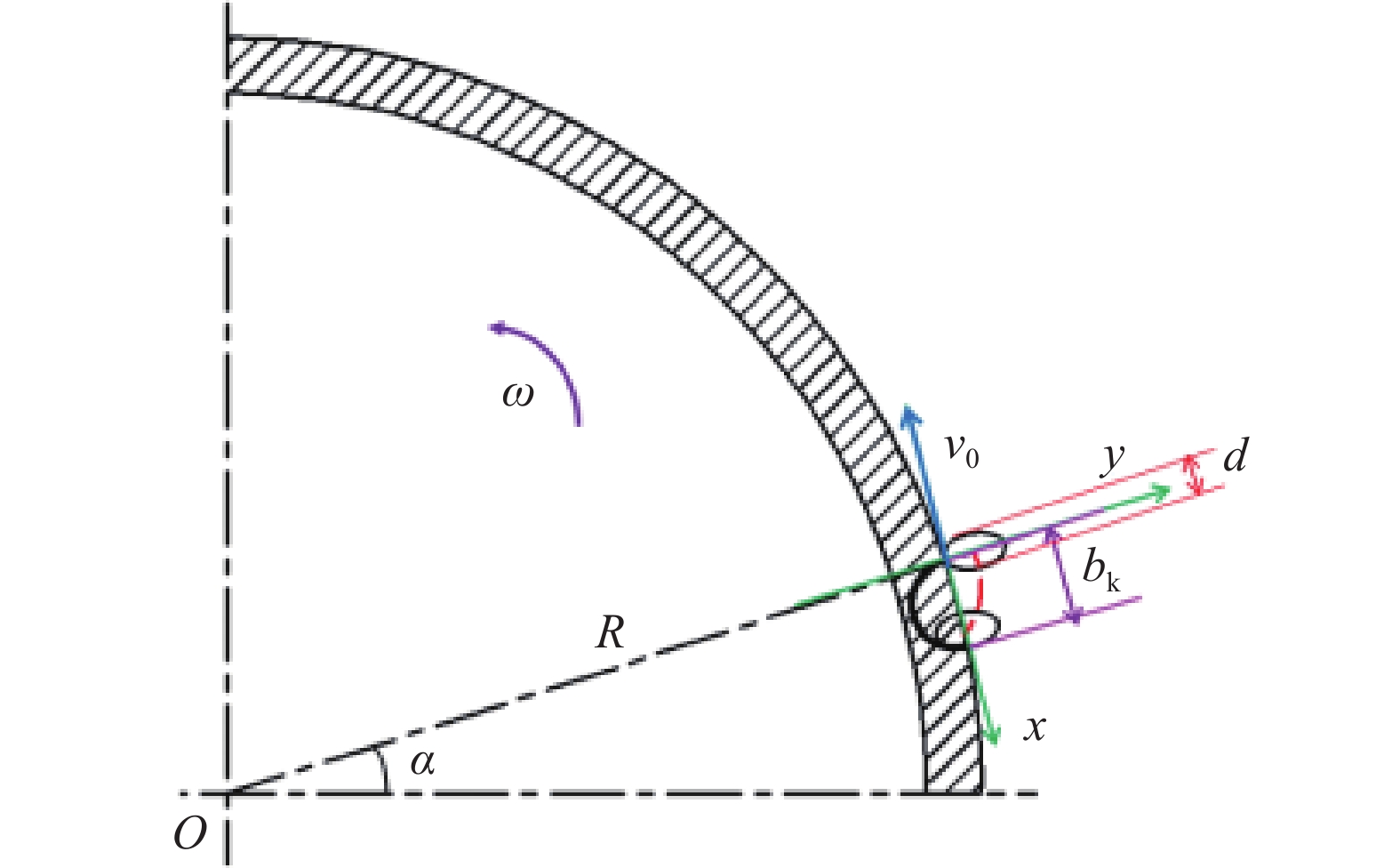

图 10 稻种充入型孔运动学分析

v0:滚筒边缘线速度;bk:型孔宽度;α:第一充种区充种位置角;d:稻种短轴当量直径;$\omega $:滚筒角速度;R:滚筒半径

Figure 10. Kinematics analysis of rice seeds filling type holes

v0: Linear speed of the roller edge; bk: Width of the type hole; α: Seed filling position angle of the first seed filling area; d: Equivalent diameter of short axis of rice seed; $\omega $: Angular speed of the roller; R: Roller radius

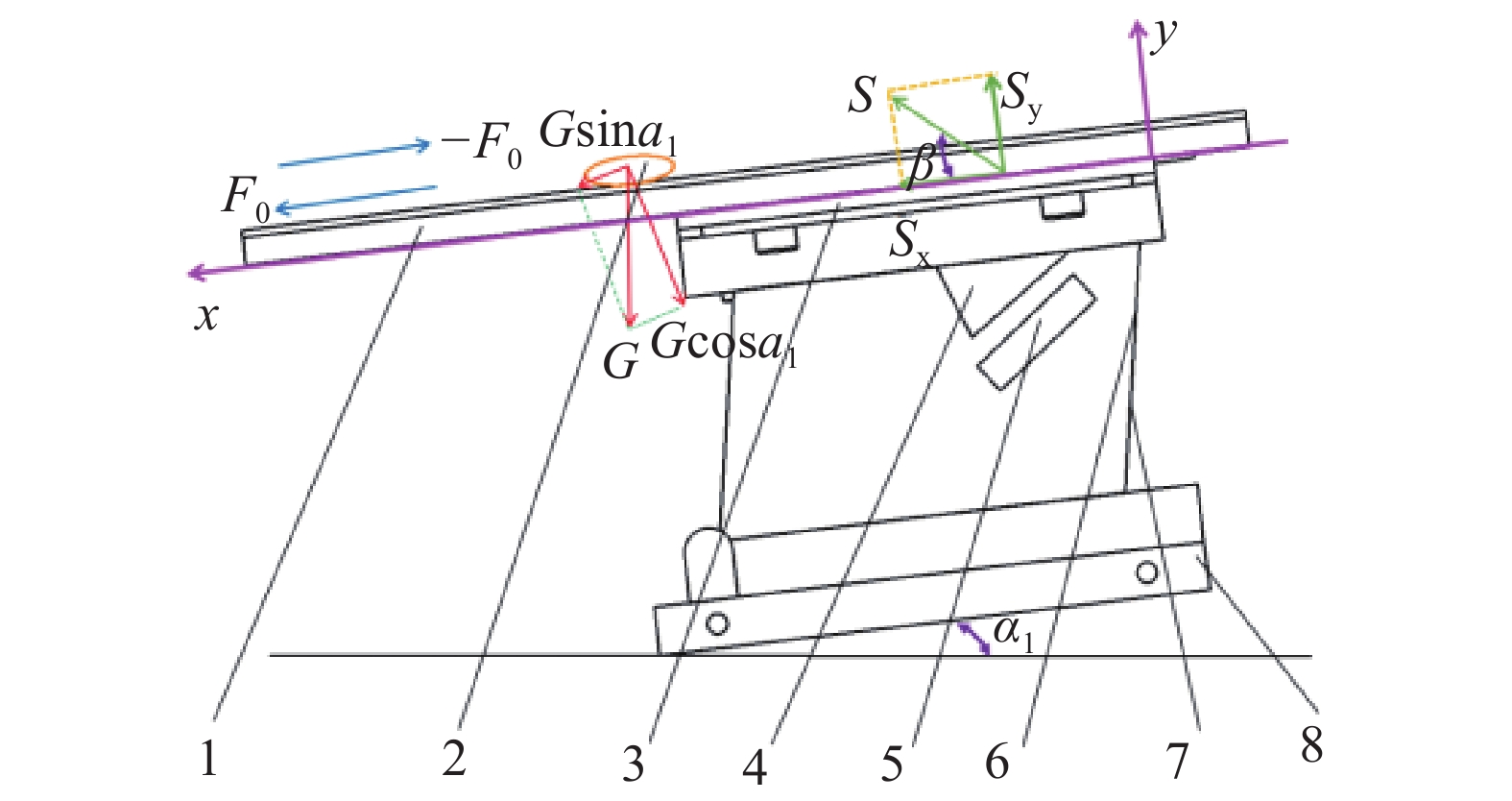

图 11 第二充种机构原理及稻种运动分析

1:V型槽;2:稻种;3:安装板;4:电磁铁;5:衔铁;6:激振线圈;7:主板簧;8:底座;α1:电磁直振器安装倾角;F0:稻种受到的摩擦力;G:稻种重力;S:激振力方向;β:振动方向角

Figure 11. Principle of the second seed filling mechanism and motion analysis of rice seeds

1: V-groove; 2: Rice seed; 3: Mounting plate; 4: Electromagnet; 5: Armature; 6: Exciting coil; 7: Main board spring; 8: Base; α1: Installation angle of electromagnetic vibrator; F0: Friction force of rice seed; G: Gravity of rice seed; S: Direction of exciting force; β: Vibration direction angle

表 1 不同稻种姿态概率比较

Table 1 Probability comparison of different posture of rice seeds

品种

Cultivar长/mm

Length宽/mm

Width高/mm

Height概率/% Probability 排序

Ranking平躺Lie flat(PL)

侧卧Lie on side(PS) 竖立Erect(PE) 培杂泰丰 Peizataifeng 9.01 2.68 2.00 50.5 37.8 11.7 PL>PS>PE 国稻1号 Guodao No. 1 10.02 2.09 2.54 49.2 40.5 10.3 PL>PS>PE 华航38号 Huahang No. 38 9.94 2.11 2.46 48.3 41.4 10.3 PL>PS>PE 表 2 3种形状型孔尺寸参数及充种性能仿真结果1)

Table 2 Size parameters and seed filling simulation results for three shapes of type hole

型孔形状

Type hole shape长度/mm

Length深度/mm

HeightY1/% Y2/% Y3/% 圆柱形

Cylindrical12.0 4.5 84.1 11.7 4.2 14.0 5.0 83.9 9.8 6.3 16.0 5.5 83.8 7.8 8.4 圆弧形

Circular arc12.0 4.5 88.0 7.4 4.6 14.0 5.0 87.2 5.9 6.9 16.0 5.5 86.8 4.7 8.5 椭圆凹槽形

Oval groove12.0 4.5 90.5 6.4 3.1 14.0 5.0 90.3 5.2 4.5 16.0 5.5 89.9 4.7 5.4 1)Y1:合格指数;Y2:漏播指数;Y3:重播指数

1) Y1: Qualified index; Y2: Missing sowing index; Y3: Replay sowing index表 3 不同充种位置角充种性能仿真结果1)

Table 3 Simulation results of seed filling performance at different seed filling position angles

% 充种位置角/(°)

Seed filling position angleY1 Y2 Y3 30 90.5 6.4 3.1 35 91.6 5.5 2.9 40 90.4 5.9 3.7 1)Y1:合格指数;Y2:漏播指数;Y3:重播指数

1) Y1: Qualified index; Y2: Missing sowing index; Y3: Replay sowing index表 4 不同生产率下的充种性能仿真结果1)

Table 4 Simulation results of seed filling performance at different productivity

% 生产率/(盘·h−1)

ProductivityY1 Y2 Y3 400 92.5 4.2 3.3 500 91.6 5.5 2.9 600 89.8 6.7 3.5 1)Y1:合格指数;Y2:漏播指数;Y3:重播指数

1) Y1: Qualified index; Y2: Missing sowing index; Y3: Replay sowing index表 5 试验因素与水平

Table 5 Factors and levels of test

水平

Level型孔

深度/mm

Type

hole depth生产率/

(盘·h−1)

Productivity充种

位置角/(°)

Seed filling

position angle振动

频率/Hz

Vibration

frequency1 4.5 400 30 23 2 5.0 500 35 25 3 5.5 600 40 27 表 6 第二充种机构不动作试验方案及结果

Table 6 Design and results of the second seed filling mechanism non-action

% 试验序号

Test number水平 Level 合格指数(Y1)

Qualified

index漏播指数(Y2)

Missing sowing

index重播指数(Y3)

Replay sowing

index型孔深度(A)

Hole depth生产率(B)

Productivity充种位置角(C)

Seed filling position angle1 1 1 1 92.5 4.8 2.7 2 1 2 2 92.4 5.4 2.2 3 1 3 3 91.7 6.3 2.0 4 2 1 2 90.4 4.7 4.9 5 2 2 3 90.3 5.4 4.3 6 2 3 1 90.2 5.8 4.0 7 3 1 3 89.7 3.9 6.4 8 3 2 1 89.4 4.4 6.2 9 3 3 2 88.8 5.3 5.9 指数 Index 因素 Factor k1 k2 k3 R Y1 A 92.2 90.3 89.3 2.9 B 90.9 90.7 90.2 0.7 C 90.7 90.5 90.6 0.2 Y2 A 5.5 5.3 4.5 1.0 B 4.5 5.0 5.8 1.3 C 5.0 5.1 5.2 0.2 Y3 A 2.3 4.4 6.2 3.9 B 4.7 4.2 4.0 0.7 C 4.3 4.3 4.2 0.1 表 7 不同振动频率下性能试验结果1)

Table 7 Performance test results under different vibration frequencies

% 生产率/(盘·h−1)

Productivity振动频率/Hz

Vibration frequencyY1 Y2 Y3 400 23 92.4 3.1 4.5 25 92.1 2.6 5.3 27 91.9 1.8 6.3 500 23 91.7 3.3 5.0 25 91.4 2.9 5.7 27 91.1 2.7 6.2 600 23 90.9 4.7 4.4 25 90.5 3.4 6.1 27 90.2 2.9 6.9 1)Y1:合格指数,Y2:漏播指数,Y3:重播指数

1) Y1: Qualified index, Y2: Missing sowing index, Y3: Replay sowing index -

[1] 李泽华, 马旭, 李秀昊, 等. 水稻栽植机械化技术研究进展[J]. 农业机械学报, 2018, 49(5): 1-20. doi: 10.6041/j.issn.1000-1298.2018.05.001 [2] SINGH R S, ELYAMANI A E. Technological change in paddy production: A comparative analysis of traditional and direct seeding methods of cultivation[J]. AMA-Agricultural Mechanization in Asia Africa and Latin America, 2012, 43(3): 41-46.

[3] 周海波, 马旭, 姚亚利. 水稻秧盘育秧播种技术与装备的研究现状及发展趋势[J]. 农业工程学报, 2008, 24(4): 301-306. doi: 10.3321/j.issn:1002-6819.2008.04.060 [4] 刘彩玲, 王超, 宋建农, 等. 振动供种型孔轮式非圆种子精密排种器设计与试验[J]. 农业机械学报, 2018, 49(5): 108-115. doi: 10.6041/j.issn.1000-1298.2018.05.012 [5] 刘彩玲, 王亚丽, 都鑫, 等. 摩擦复充种型孔带式水稻精量排种器充种性能分析与验证[J]. 农业工程学报, 2019, 35(4): 29-36. doi: 10.11975/j.issn.1002-6819.2019.04.004 [6] 左彦军, 马旭, 玉大略, 等. 水稻芽种窝眼窄缝式气吸滚筒排种器流场模拟与试验[J]. 农业机械学报, 2011, 42(2): 58-62. [7] 韩豹, 杨亚楠, 孟繁超, 等. 气吸滚筒式自动清堵粳稻排种器的改进设计与性能试验[J]. 农业工程学报, 2016, 32(19): 18-25. doi: 10.11975/j.issn.1002-6819.2016.19.003 [8] 鹿芳媛, 马旭, 齐龙, 等. 振动式水稻精密播种装置机理分析与试验[J]. 农业机械学报, 2018, 49(6): 119-128. doi: 10.6041/j.issn.1000-1298.2018.06.014 [9] 刘彩玲, 魏丹, 都鑫, 等. 宽苗带勾型窝眼轮式小麦精量排种器设计与试验[J]. 农业机械学报, 2019, 50(1): 75-84. doi: 10.6041/j.issn.1000-1298.2019.01.008 [10] 邢赫, 臧英, 王在满, 等. 水稻气力式排种器分层充种室设计与试验[J]. 农业工程学报, 2015, 31(4): 42-48. doi: 10.3969/j.issn.1002-6819.2015.04.006 [11] 陈立东, 马淑英, 何堤, 等. 气吸式排种器充种室种面调节装置的设计[J]. 河北科技师范学院学报, 2007, 21(3): 59-62. doi: 10.3969/j.issn.1672-7983.2007.03.016 [12] 王在满, 黄逸春, 王宝龙, 等. 播量无级调节水稻精量排种装置设计与试验[J]. 农业工程学报, 2018, 34(11): 9-16. doi: 10.11975/j.issn.1002-6819.2018.11.002 [13] 张明华, 王在满, 罗锡文, 等. 组合型孔排种器双充种室结构对充种性能的影响[J]. 农业工程学报, 2018, 34(12): 8-15. doi: 10.11975/j.issn.1002-6819.2018.12.002 [14] 齐龙, 谭祖庭, 马旭, 等. 气动振动式匀种装置工作参数的优化及试验[J]. 吉林大学学报(工学版), 2014, 44(6): 1684-1691. [15] 赵金辉, 刘立晶, 杨学军, 等. 基于PLC的苔麸播种机设计与试验[J]. 农业机械学报, 2016, 47(S1): 84-89. [16] 陈林涛, 马旭, 李泽华, 等. 水稻秧盘形变测度方法与等级评价研究[J]. 农业机械学报, 2018, 49(6): 159-166. doi: 10.6041/j.issn.1000-1298.2018.06.018 [17] 张波屏. 播种机械设计原理[M]. 北京: 机械工业出版社, 1982. [18] 罗锡文, 刘涛, 蒋恩臣, 等. 水稻精量穴直播排种轮的设计与试验[J]. 农业工程学报, 2007, 23(3): 108-112. doi: 10.3321/j.issn:1002-6819.2007.03.022 [19] 田立权. 弹射式耳勺型水稻芽种播种装置机理分析与试验研究[D]. 哈尔滨: 东北农业大学, 2018. [20] 李兆东, 王晴晴, 张亚兰, 等. 倾斜抛物线型孔轮式小麦供种装置设计与试验[J]. 农业机械学报, 2018, 49(5): 116-124. doi: 10.6041/j.issn.1000-1298.2018.05.013 [21] FU W, ZHANG Z, ZANG Y, et al. Development and experiment of rice hill-drop drilling machine for dry land based on proportional speed regulation[J]. International Journal of Agricultural and Biological Engineering, 2017, 10(4): 77-86. doi: 10.25165/j.ijabe.20171004.3125

[22] HUANG M, SHAN S L, XIE X B, et al. Why high grain yield can be achieved in single seedling machine-transplanted hybrid rice under dense planting conditions[J]. Journal of Integrative Agriculture, 2018, 17(6): 1299-1306. doi: 10.1016/S2095-3119(17)61771-4

[23] 袁昊, 刘彩玲, 宋建农, 等. 超级杂交稻穴盘育苗精量排种器压电振动供种装置研究[J]. 农业机械学报, 2020, 51(S2): 31-40. doi: 10.6041/j.issn.1000-1298.2020.S2.004 [24] 鹿芳媛, 马旭, 齐龙, 等. 基于离散元法的杂交稻振动匀种装置参数优化与试验[J]. 农业工程学报, 2016, 32(10): 17-25. doi: 10.11975/j.issn.1002-6819.2016.10.003 [25] 曾令超, 马旭, 陈林涛, 等. 基于离散元的交叉导流式穴播装置仿真与试验[J]. 农机化研究, 2019, 41(10): 20-24. doi: 10.3969/j.issn.1003-188X.2019.10.004 [26] 国家质量监督检验检疫总局. 单粒(精密)播种机试验方法: GB/T 6973—2005[S]. 北京: 中国标准出版社, 2006. [27] CHEN L T, MA X, WANG C, et al. Design and test of soft-pot-tray automatic embedding system for light-economical pot seedling nursery machine[J]. International Journal of Agricultural and Biological Engineering, 2020, 13(1): 91-100. doi: 10.25165/j.ijabe.20201301.4726

[28] 马旭, 陈林涛, 黄冠, 等. 水稻秧盘育秧播种生产线电控式软硬秧盘自动供盘装置[J]. 农业机械学报, 2017, 48(6): 41-49. doi: 10.6041/j.issn.1000-1298.2017.06.005 [29] 马旭, 谭永炘, 齐龙, 等. 水稻秧盘育秧精密播种流水线软硬秧盘自动叠放装置[J]. 农业机械学报, 2016, 47(3): 29-36. doi: 10.6041/j.issn.1000-1298.2016.03.005 [30] 陈林涛, 马旭, 曹秀龙, 等. 基于主成分分析的杂交稻芽种物理特性评价研究[J]. 农业工程学报, 2019, 35(16): 334-342. doi: 10.11975/j.issn.1002-6819.2019.16.037

下载:

下载: