Optimization design and test of seed protecting structure of combined type-hole metering device

-

摘要:目的

解决水稻精量穴直播机组合型孔排种器在实际应用过程中护种带容易跑偏、打滑,导致护种带磨损严重、伤种率偏高的问题。

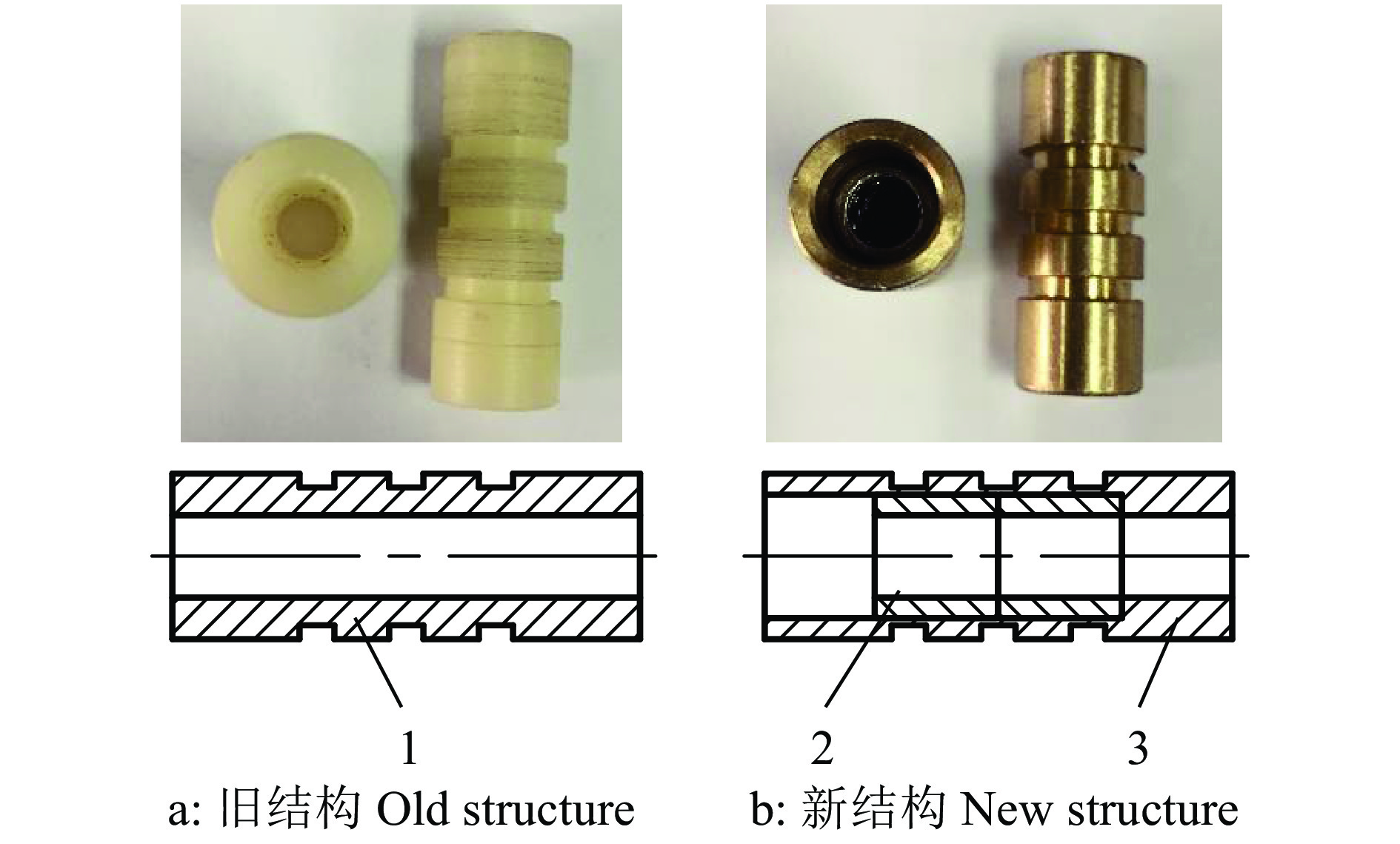

方法对护种机构同步原理进行分析,优化设计了轴套结构(A)和护种带硬度(B)。以水稻品种‘培杂泰丰’和 ‘秀水134’ 种子为试验材料,设计了以不同轴套结构[尼龙轴套结构(A1)和滚针轴承&铜套结构(A2)]和不同护种带硬度[40(B1)、45(B2)、50(B3)、55(B4)和60 HA(B5)]为变量的双因素试验。

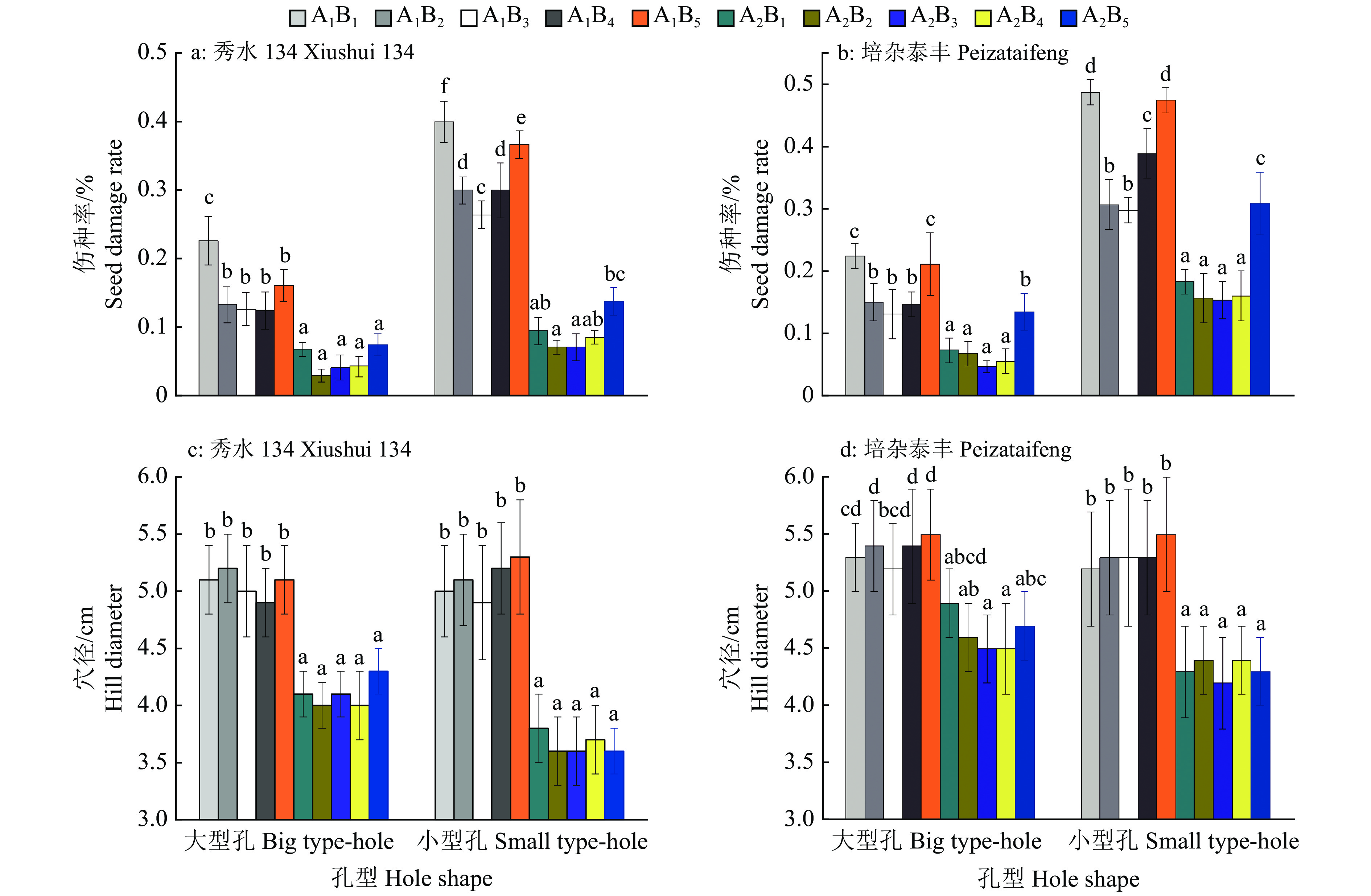

结果A和B对水稻种子伤种率影响极显著(P<0.01),且A与B之间存在显著交互作用(P < 0.05);A 2B2和A2B3对伤种率影响最小;A1与A2之间差异极显著,且A2组的伤种率明显小于A1组,说明A2优于A1;B2与B3差异不显著,但与其他试验组差异显著。A对穴径影响显著,B对穴径无显著影响,且A2B2、A2B3和A2B4对穴径影响较小;A1、A2对穴径的影响差异极显著,且A2明显优于A1。工作100 h后,试验组A2B3、A2B4和A2B5的护种带磨损量较小;试验组A2B3最优,其护种带磨损体积为72.6×10−3 mm3,伤种率为0.04%,成穴性最好、播种效果最佳。

结论优化设计的滚针轴承&铜套的轴套结构合理,可以显著减小轴套与转轴之间的摩擦系数,且更耐高温、更耐磨;有效地提高了护种带的同步性,显著地提升了排种器的可靠性和播种质量。

Abstract:ObjectiveIn order to solve the problems that the seed guard belt is easy to deviate and slip in application of the combined type-hole metering device of rice precision hole seeder, which leads to serious wear of the seed guard belt and high rate of seed damage.

MethodThe synchronization principle of seed protection mechanism was analyzed, and the shaft sleeve structure(A) and the hardness of seed guard belt(B) were optimized. A two-factor experiment with different bushing structures (A1 as nylon bushing structure, A2 as needle bearing & copper bushing structure) and hardness of seed guard belt (B 1, B2, B3, B4 and B5 represented the hardness of 40, 45, 50, 55 and 60 HA, respectively) was designed using rice variety ‘Peizataifeng’ and ‘Xiushui134’ seeds as test materials.

ResultThe experimental groups of A and B had the highly significant effect on the damage rate of rice seeds (P < 0.01), and there was a significant interaction between A and B ( P < 0.05). A 2B2 and A2B3 had the least effect on seed damage rate. There was a highly significant difference between A1 and A2, and seed damage rate of A2 was significantly lower than that of A1, indicating that A2 was better than A1. There was no significant difference between B2 and B3, but B2 and B3 had significant difference with other groups. The experimental group A had a significant effect on hill diameter, B had no significant effect on hill diameter, and the groups of A2B2, A2B3 and A2B4 had the less effect on hill diameter. There was a significant difference between A1 and A2, and A2 was significantly better than A1.The results of test showed that the wear of seed guard belt of A2B3, A2B4 and A2B5 were less after working for 100 hour. The grouo A2B3 was the optimal with the wearing volume of 72.6×10−3 mm3 and seed injury rate of 0.04%, and the hole forming ability and sowing effect were both the best.

ConclusionThe optimized design of needle bearing & copper bushing shaft sleeve structure is reasonable. It can significantly reduce the friction coefficient between sleeve and shaft, is more resistant to high temperature and wear resistance, effectively improves the synchronization of seed guard belt, and significantly improves the reliability and sowing quality of seed platter.

-

-

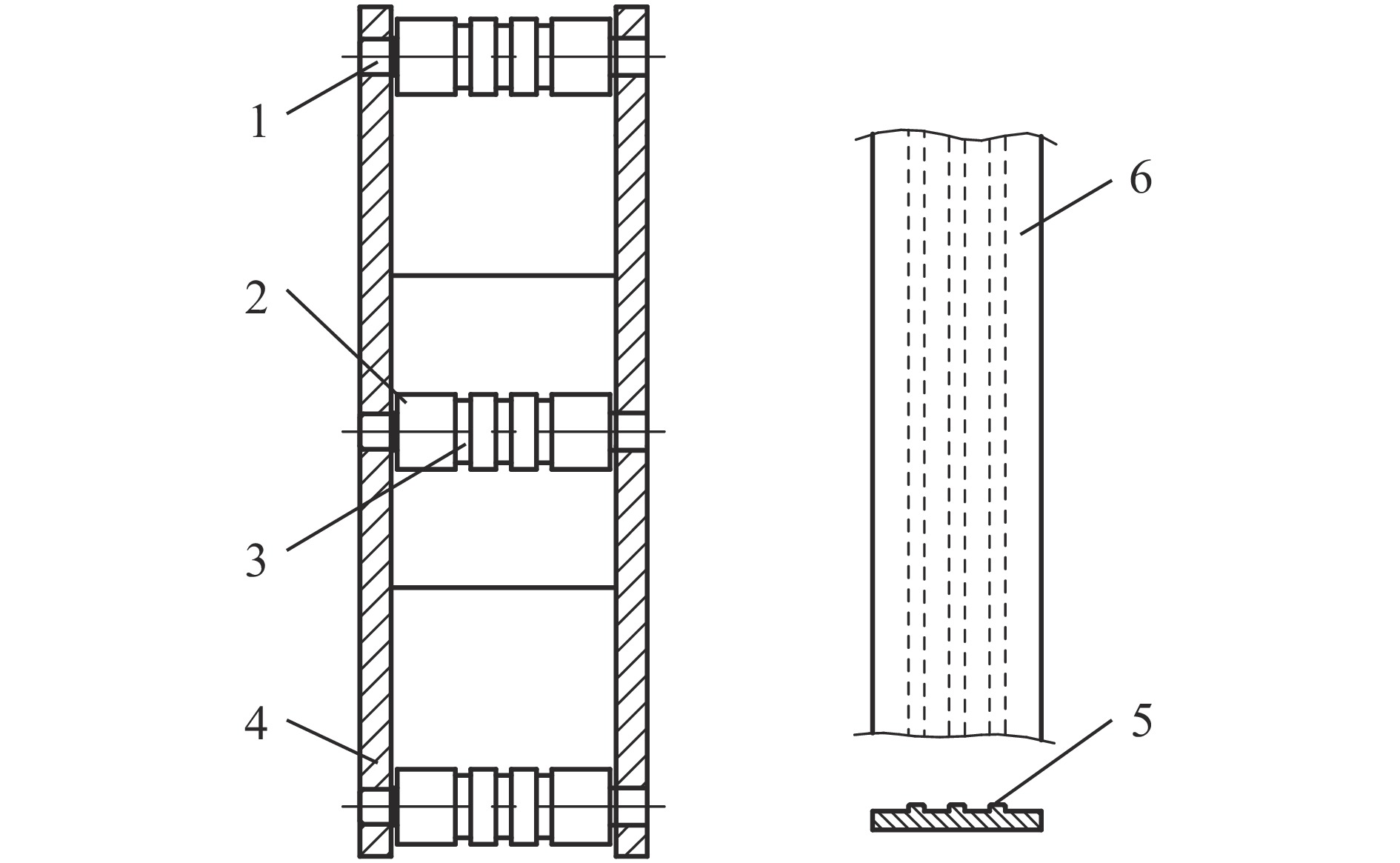

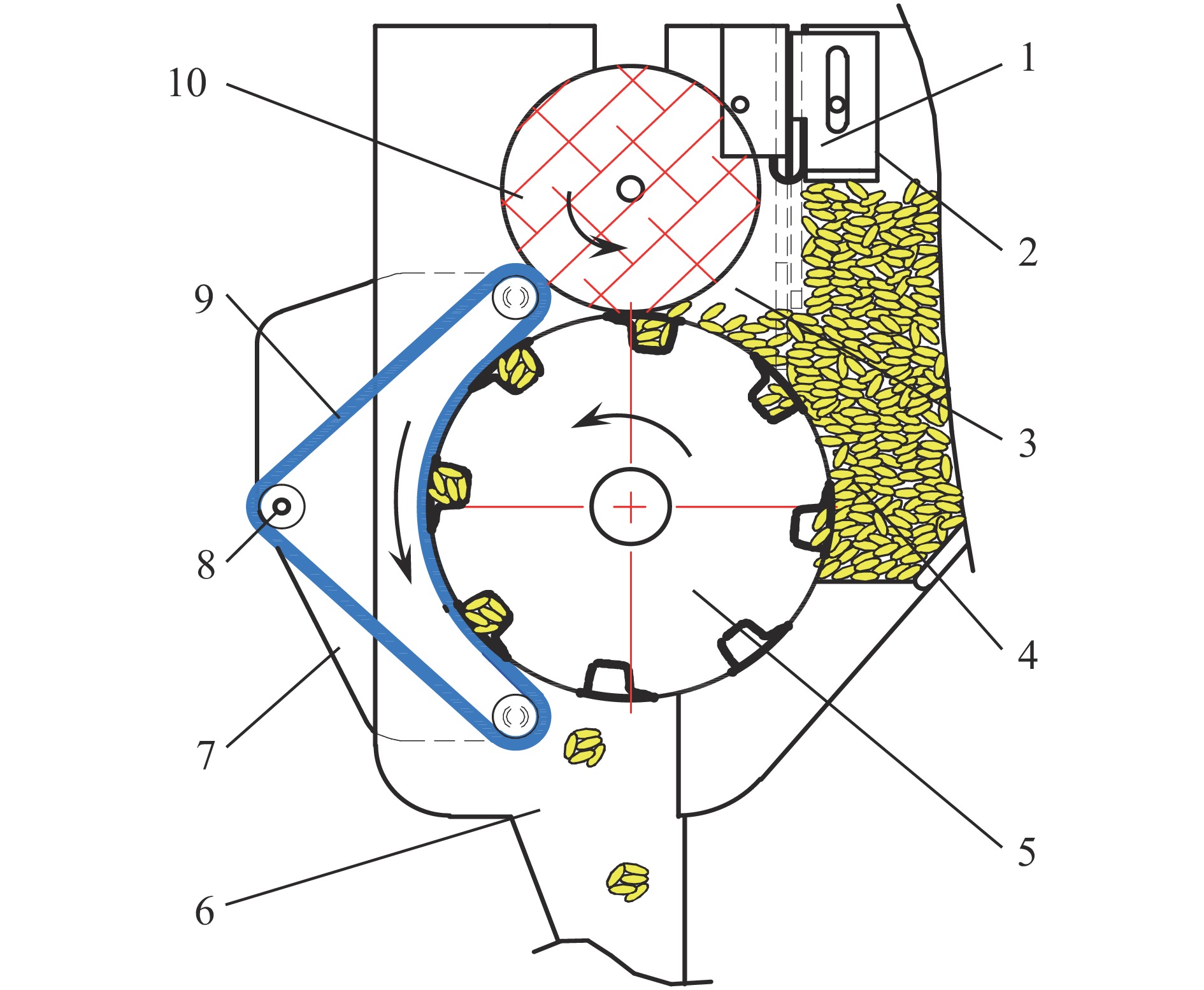

图 1 排种器工作原理图

1:限种机构;2:第1充种室;3:第2充种室;4:种子;5:排种轮;6:排种管;7:护种带架子;8:轴套;9:护种带;10:清种机构

Figure 1. Schematic diagram of seed metering device

1: Flow adjusting device; 2: The first filling chamber; 3: The second filling chamber; 4: Seed; 5: Hole-type roller; 6: Seed metering tube; 7: Protecting device; 8: Axle sleeve; 9: Guard belt; 10: Cleaning device

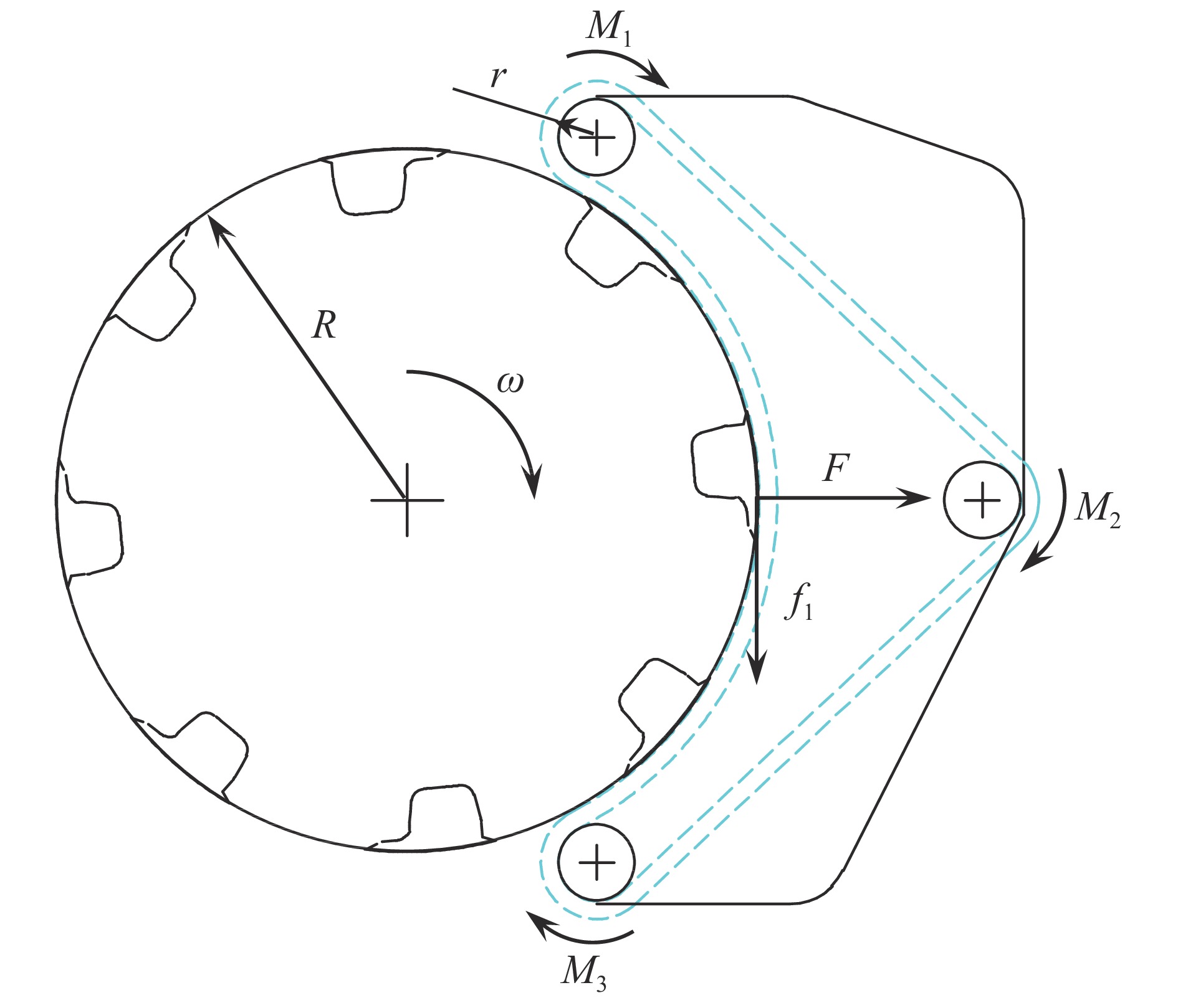

图 3 护种机构同步力学分析

M1~M3:对应转轴的摩擦力矩,N·m;F:排种轮作用在护种带上压力的合力,N;f1 :排种轮与护种带之间的最大静摩擦力,N;R:排种轮半径,m;r:转轴半径,m;ω:排种轮角速度,rad/s

Figure 3. Mechanics analysis of synchronization for seed protecting device

M1−M3: Friction torque of corresponding shaft, N·m; F: Resultant force of pressure exerted by the seed metering wheel on the seed guard belt, N; f1: Maximum static friction between seed metering wheel and guard belt, N; R: Radius of seed metering wheel, m; r: Radius of shaft, m; ω: Angular velocity of seed metering wheel, rad/s

图 6 不同孔型护种机构对不同水稻品种伤种率和穴径的影响

A1:尼龙轴套结构;A2:滚针轴承&铜套结构;B1~B5代表护种带硬度分别为40、45、50、55和60 HA。各图中,相同护种机构柱子上不同小写字母表示差异显著(P<0.05,Duncan’s 法)

Figure 6. Effect of different protecting structure on hill diameter and seed damage rate of different rice variety

A1:Nylon bushing structure;A2:Needle bearing & copper bushing structure;B1, B2, B3, B4 and B5 represented the hardness of 40, 45, 50, 55 and 60 HA, respectively. Different lowercase letters on bars of the same seed protecting device indicated significant differences (P<0.05, Duncan’s test)

表 1 试验因素和水平

Table 1 Factors and levels in experiments

水平

Level轴套结构

Bush structure (A)护种带硬度/HA

Hardness of guard belt (B)1 尼龙轴套 40 2 滚针轴承&铜套结构 45 3 50 4 55 5 60 表 2 不同轴套结构不同工作时间对护种带打滑率的影响1)

Table 2 Effects of different structure of axle sleeves on slip rate of guard belt at different working time

% 试验组

Test group0 h 25 h 50 h 75 h 100 h A1B1 32.40±0.10f 21.28±0.15g 79.82±0.20h 68.81±0.2g 75.30±0.22e A1B2 2.30±0.01e 4.80±0.09e 5.41±0.10f 6.60±0.13e 6.21±0.14c A1B3 1.01±0.05d 3.40±0.11d 4.32±0.09e 5.52±0.14d 6.42±0.15c A1B4 0.97±0.02c 2.82±0.07c 4.27±0.01e 5.12±0.11c 6.35±0.12c A1B5 8.61±0.02c 9.80±0.10f 8.92±0.11g 10.21±0.18f 11.45±0.18d A2B1 0.10±0.01a 0.50±0.04b 1.20±0.03d 1.82±0.08b 1.81±0.08b A2B2 0.27±0.02b 0.45±0.03b 0.53±0.04b 0.62±0.05a 0.62±0.05a A2B3 0.16±0.01b 0.26±0.02a 0.25±0.02a 0.60±0.03a 0.52±0.03a A2B4 0.19±0.08b 0.57±0.03b 0.79±0.06c 0.71±0.02a 0.63±0.023a A2B5 0.25±0.01b 0.46±0.04b 0.43±0.04b 0.64±0.04a 0.64±0.035a 1) A1:尼龙轴套结构;A2:滚针轴承&铜套结构;B1~B5代表护种带硬度分别为40、45、50、55和60 HA。同列数据后不同小写字母表示差异显著(P<0.05,Duncan’s 法)

1) A1: Nylon bushing structure; A2: Needle bearing & copper bushing structure; B 1, B2, B3, B4 and B5 represented the hardness of 40, 45, 50, 55 and 60 HA, respectively. Different lowercase letters of data in the same column indicated significant differences (P<0.05, Duncan’s test)表 3 不同工作时间护种带磨损试验的磨损体积1)

Table 3 The wear volume of guard belt in wear test at different working time

×10−3 mm3 t/h A1B1 A1B2 A1B3 A1B4 A1B5 A2B1 A2B2 A2B3 A2B4 A2B5 0 2.5±0.2a 2.5±0.2a 2.6±0.3a 2.6±0.3a 2.4±0.3a 2.5±0.3a 2.5±0.2a 2.5±0.3a 2.4±0.2a 2.5±0.2a 100 205.6±14.6e 195.6±15.7e 170.1±9.7d 136.4±12.9c 98.7±8.9b 102.4±5.7b 98.7±4.7b 72.6±6.8a 70.5±5.4a 69.4±5.1a 1) A1:尼龙轴套结构;A2:滚针轴承&铜套结构;B1~B5代表护种带硬度分别为40、45、50、55和60 HA。同行数据的不同小写字母表示差异显著(P<0.05,Duncan’s 法)

1) A1: Nylon bushing structure; A2: Needle bearing & copper bushing structure; B 1, B2, B3, B4 and B5 represented the hardness of 40, 45, 50, 55 and 60 HA, respectively. Different lowercase letters of data in the same line indicated significant differences (P<0.05, Duncan’s test) -

[1] 罗锡文, 欧洲, 蒋恩臣, 等. 抛掷成穴式水稻精量直播排种器试验[J]. 农业机械学报, 2005, 36(9): 37-40. doi: 10.3969/j.issn.1000-1298.2005.09.010 [2] CHOSA T, FURUHATA M, OMINE M, et al. Development of air-assisted strip seeding for direct seeding in flooded paddy fields: Seeding machine and effect of air assistance[J]. Farm Work Research: Journal of Farm Work Society of Japan, 2009, 141: 211-218.

[3] FURUHATA M, CHOSA T, SHIOYA Y, et al. Developing direct seeding cultivation using an air-assisted strip seeder[J]. Japan Agricultural Research Quarterly, 2015, 49(3): 227-233. doi: 10.6090/jarq.49.227

[4] 罗锡文, 刘涛, 蒋恩臣, 等. 水稻精量穴直播排种轮的设计与试验[J]. 农业工程学报, 2007, 23(3): 108-112. doi: 10.3321/j.issn:1002-6819.2007.03.022 [5] 张明华, 罗锡文, 王在满, 等. 水稻直播机组合型孔排种器设计与试验[J]. 农业机械学报, 2016, 47(9): 29-36. [6] 张明华, 王在满, 罗锡文, 等. 组合型孔排种器双充种室结构对充种性能的影响[J]. 农业工程学报, 2018, 34(12): 8-15. doi: 10.11975/j.issn.1002-6819.2018.12.002 [7] 张明华. 水稻精量穴直播机的优化设计与试验[D]. 广州: 华南农业大学, 2017. [8] 罗锡文, 王在满, 蒋恩臣, 等. 型孔轮式排种器弹性随动护种带装置设计[J]. 农业机械学报, 2008, 39(12): 60-63. [9] 王冲, 宋建农, 王继承, 等. 机械式排种器同步柔性皮带护种器的设计[J]. 农业工程学报, 2009, 25(10): 107-111. doi: 10.3969/j.issn.1002-6819.2009.10.019 [10] 于建群, 马成林, 张格. 组合内窝孔精密排种器护种和投种过程分析[J]. 农业机械学报, 2001, 32(4): 28-30. doi: 10.3969/j.issn.1000-1298.2001.04.009 [11] 中国农业机械化科学研究院. 农业机械设计手册: 上册[M]. 北京: 中国农业科学技术出版社, 2007. [12] 张波屏. 播种机械设计原理[M]. 北京: 机械工业出版社, 1982. [13] 张德文, 李林, 王惠民. 精密播种机械[M]. 北京: 农业出版社, 1982. [14] 罗锡文, 蒋恩臣, 王在满. 一种带有可拆式弹性转动护种装置的谷物排种器: 200810027896.7[P]. 2011-09-14. [15] 宋建农, 王冲, 王继承. 同步柔性皮带护种器: 200720187281.1[P]. 2008-11-05. [16] 廖庆喜, 黄吉星, 刘光, 等. 油菜播种机槽孔轮式精量排种器设计与试验[J]. 农业机械学报, 2011, 42(2): 63-66. [17] 廖庆喜, 李兆东, 廖宜涛, 等. 气压护种式精量集排器: 201410483283. X[P]. 2016-05-11. [18] 张顺, 夏俊芳, 周勇, 等. 气力滚筒式水稻直播精量排种器的设计与试验[J]. 农业工程学报, 2015, 31(1): 11-19. doi: 10.3969/j.issn.1002-6819.2015.01.002 [19] 张顺, 夏俊芳, 周勇, 等. 气力滚筒式水稻直播精量排种器排种性能分析与田间试验[J]. 农业工程学报, 2017, 33(3): 14-23. doi: 10.11975/j.issn.1002-6819.2017.03.003 [20] 李兆东, 雷小龙, 曹秀英, 等. 油菜精量气压式集排器的设计与试验[J]. 农业工程学报, 2015, 31(7): 9-17. [21] 李兆东, 李姗姗, 曹秀英, 等. 油菜精量气压式集排器排种性能试验[J]. 农业工程学报, 2015, 31(18): 17-25. doi: 10.11975/j.issn.1002-6819.2015.18.004 [22] 朱德泉, 李兰兰, 文世昌, 等. 滑片型孔轮式水稻精量排种器排种性能数值模拟与试验[J]. 农业工程学报, 2018, 34(21): 17-26. doi: 10.11975/j.issn.1002-6819.2018.21.003 [23] 张永振. 材料的干摩擦学[M]. 北京: 科学出版社, 2012. [24] 汪久根, 董光能. 摩擦学基础[M]. 西安: 西安电子科技大学出版社, 2018. [25] 侯文英. 摩擦磨损与润滑[M]. 北京: 机械工业出版社, 2012. [26] 王泽鹏, 张义, 徐梦飞. 基于分形理论的橡胶复合材料磨耗表面形貌表征[J]. 橡胶工业, 2018(1): 25-30. doi: 10.3969/j.issn.1000-890X.2018.01.006 [27] 王泽鹏, 李珂, 张义. 基于多重分形的橡胶复合材料磨耗表面形貌特征研究[J]. 北京化工大学学报(自然科学版), 2015, 42(1): 87-91. [28] MUKHOPADHYAY A. SEM study of worn surface morphology of an indigenous ‘EPDM’ rubber[J]. Polymer Testing, 2016, 52: 167-173. doi: 10.1016/j.polymertesting.2016.04.013

[29] KALA A. Thermal characterization and surface morphology of natural rubber (NR)/Nitrile butadiene rubber (NBR) blend[J]. The IUP Journal of Physics, 2009, 2(4): 7-14.

[30] XU S H, GU J, LUO Y F, et al. Influence of nanocrystalline cellulose on structure and properties of natural rubber/silica composites[J]. Polymer Composites, 2015, 36(5): 861-868. doi: 10.1002/pc.23005

[31] SPANO D, PINTUS F, ESPOSITO F, et al. Euphorbia characias latex: Micromorphology of rubber particles and rubber transferase activity[J]. Plant Physiology and Biochemistry, 2015, 87: 26-34. doi: 10.1016/j.plaphy.2014.12.008

[32] 中国国家标准化管理委员会. 单粒(精密)播种机试验方法: GB/T 6973—2005[S]. 北京: 中国标准出版社, 2005.

下载:

下载: