Effect of UV-C treatment on chilling injury and flavor quality of Solanum muricatum fruit during storage

-

摘要:目的

研究UV-C处理对人参果Solanum muricatum贮藏期间冷害及风味变化的影响,以期为人参果的采后贮藏保鲜及防止低温冷害提供新的技术手段及理论依据。

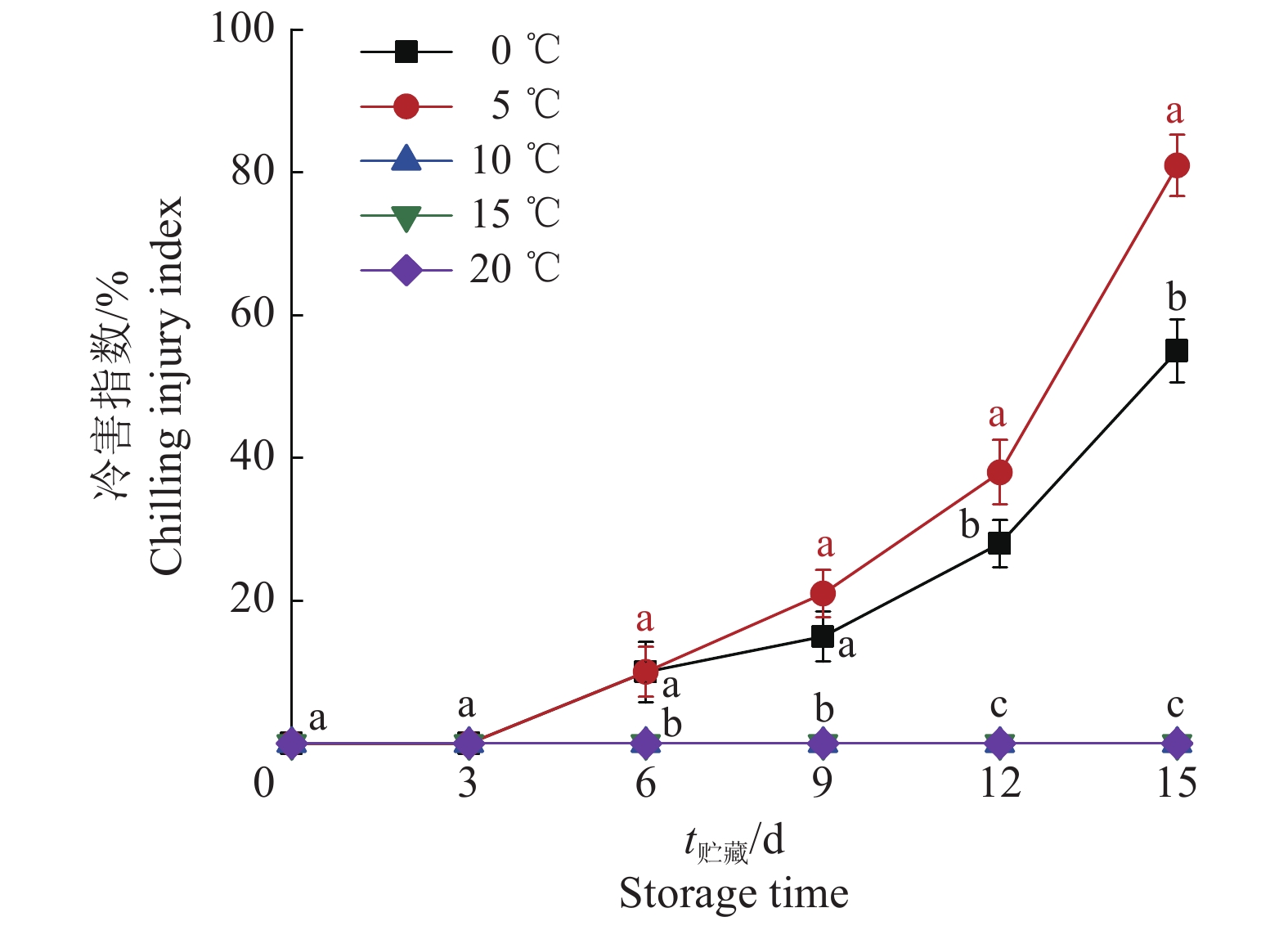

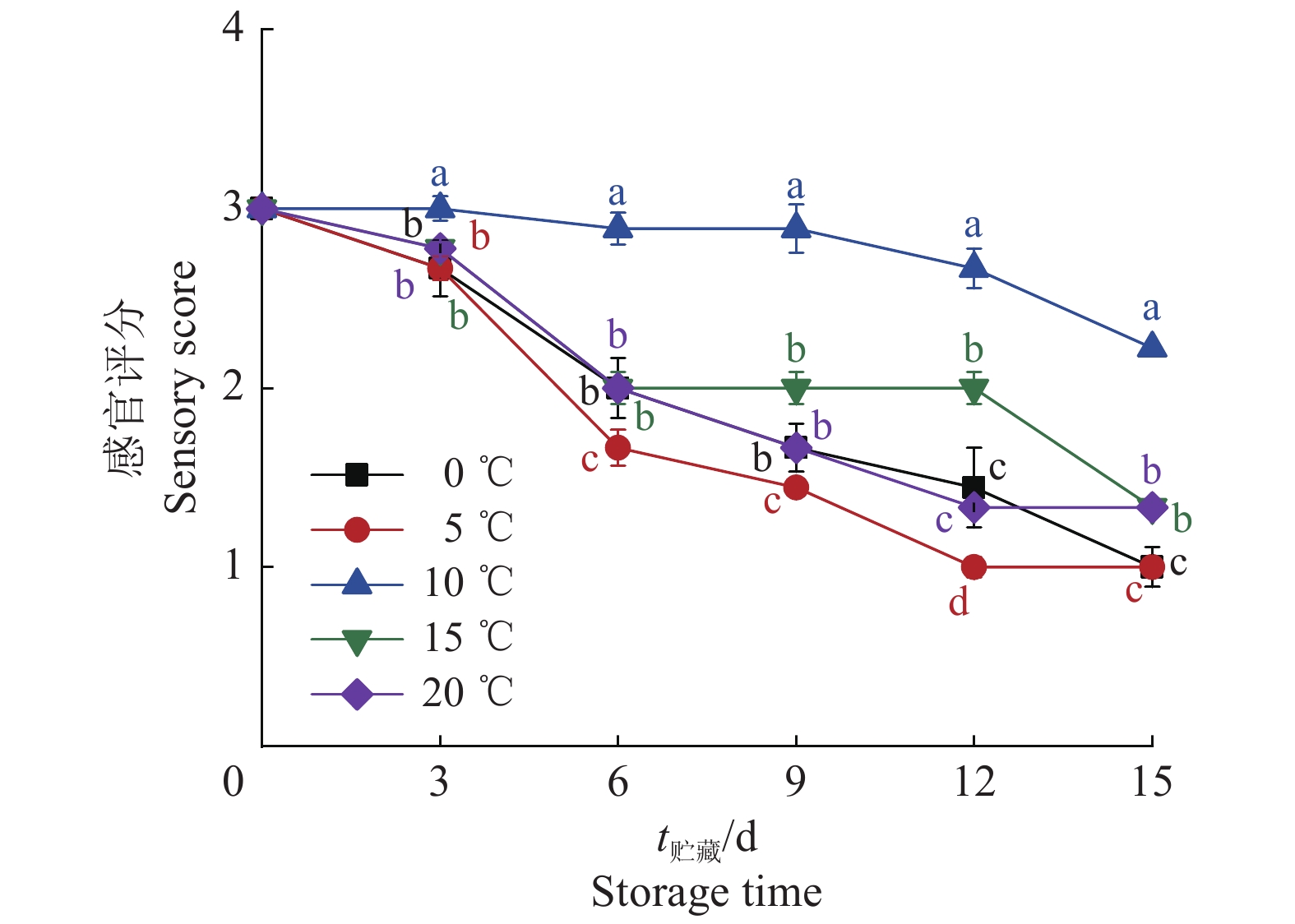

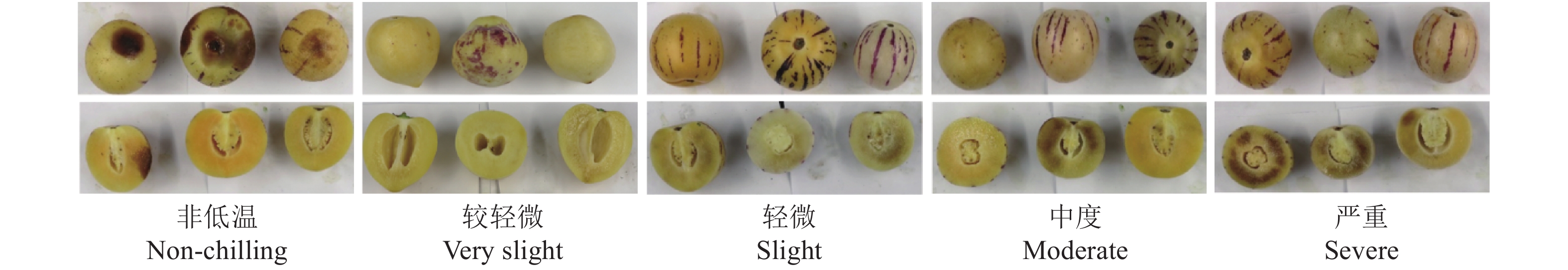

方法将人参果置于不同温度(0、5、10、15、20 ℃)下贮藏15 d,通过测定贮藏期间的冷害指数、感官品质、呼吸强度和乙烯释放量的变化,验证人参果在5 ℃及以下贮藏会发生冷害。采用0.25、0.50和1.00 kJ·m−2剂量的UV-C处理人参果,在5 ℃冷库中贮藏15 d,测定贮藏期间其冷害及风味品质的变化,并结合电子鼻测定风味物质的变化情况。

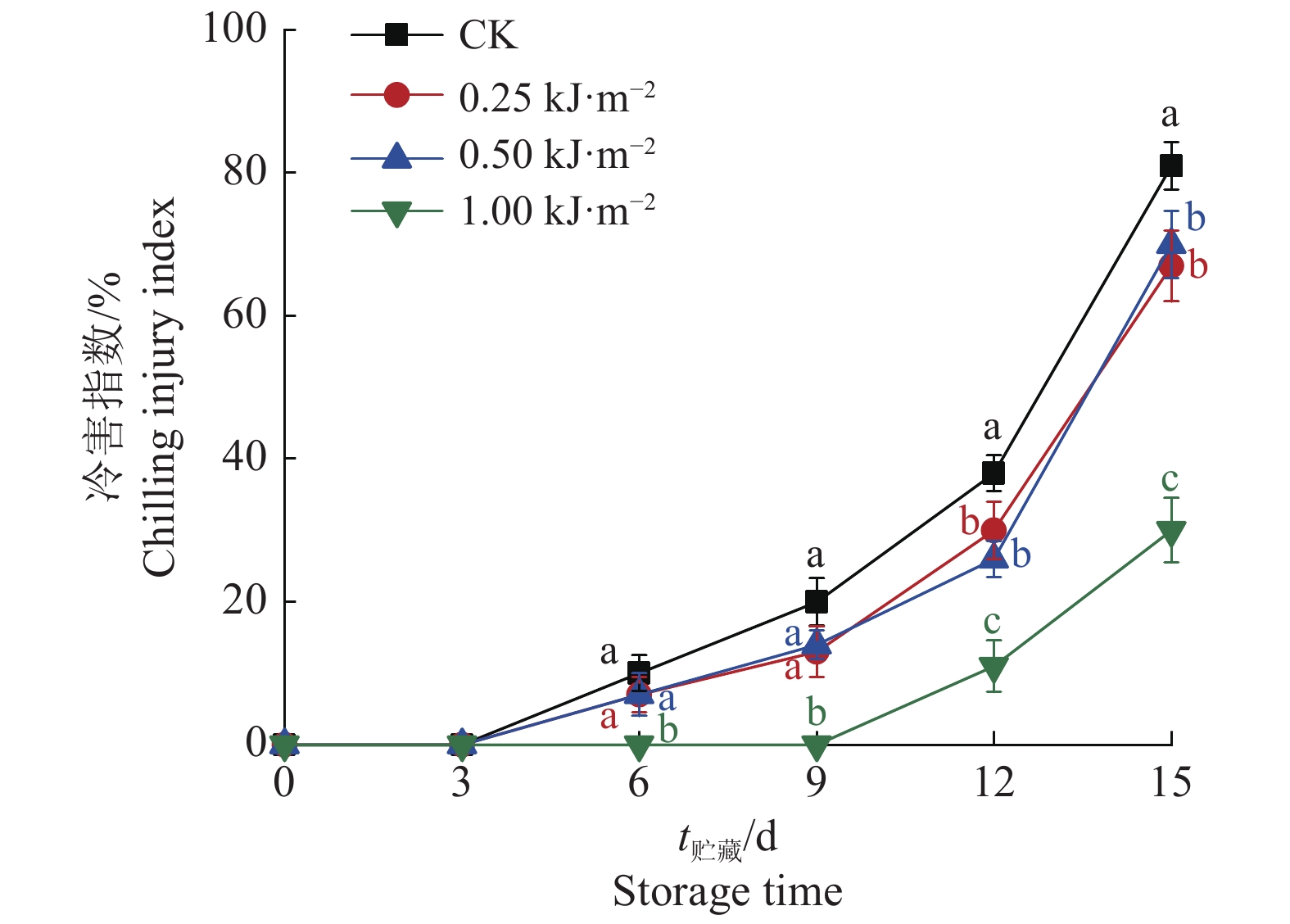

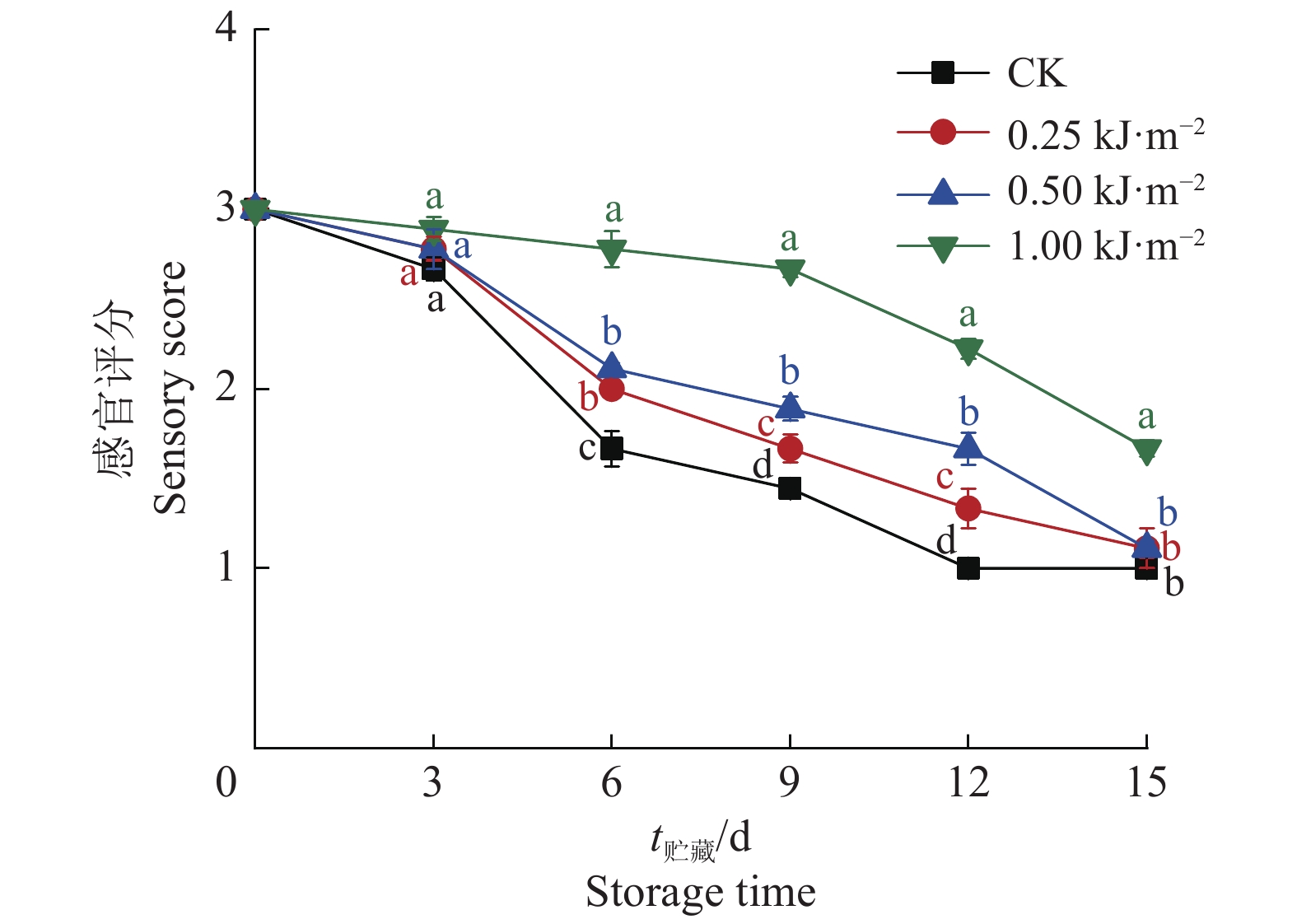

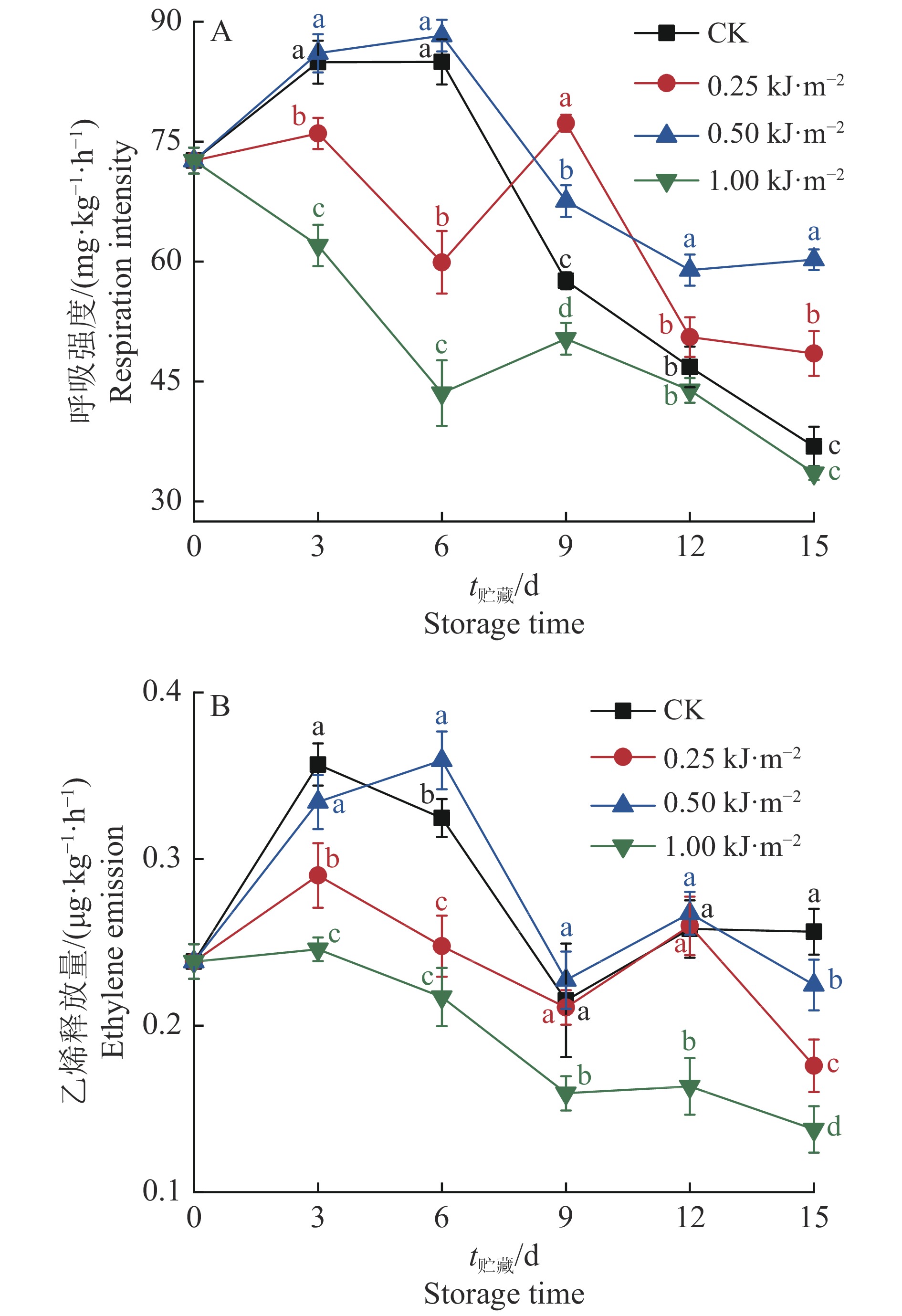

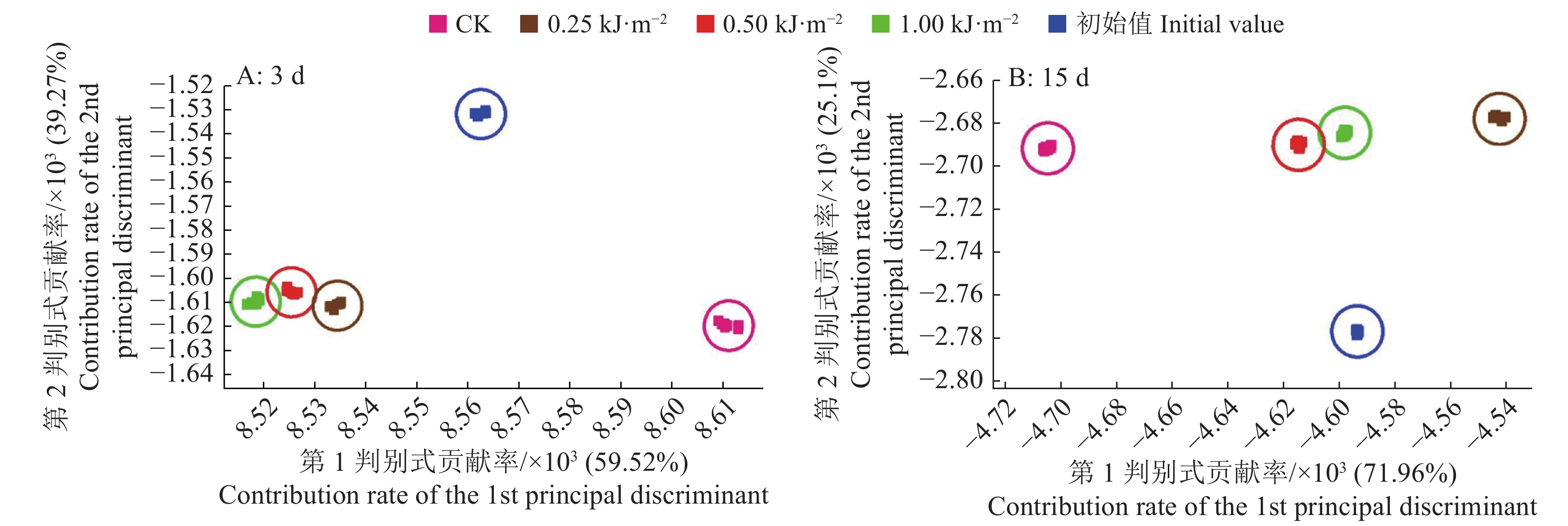

结果在5 ℃冷胁迫下,不同剂量的UV-C处理均有效地保持了人参果的风味品质,减轻了人参果的冷害症状,抑制了人参果在低温下的呼吸强度和乙烯释放量。在贮藏第15天,1.00 kJ·m−2UV-C处理组乙烯释放量比对照组低46%,1.00、0.50和0.25 kJ·m−2 UV-C处理组的冷害指数分别为30%、70%和67%,均显著低于对照组(81%),且1.00 kJ·m−2 UV-C处理将冷害的发生时间推迟了6 d。通过线性判别法和雷达图分析发现,不同剂量的UV-C处理均保持人参果较好的挥发性香气成分。

结论在冷胁迫下,不同剂量的UV-C处理均明显减轻人参果的冷害症状,不同程度地保持了人参果贮藏期的风味品质,延缓衰老;与其他处理相比,1.00 kJ·m−2 UV-C处理的人参果在贮藏期间冷害指数较低,处理效果最佳。

Abstract:ObjectiveTo study the effects of UV-C treatment on chilling injury and flavor changes of pepino (Solanum muricatum) fruit during storage, and provide a new technique and theoretical basis for postharvest storage and chilling injury prevention of pepino fruit.

MethodPepino fruits were stored at different temperatures (0, 5, 10, 15, 20 ℃) for 15 days, and the changes in chilling injury index, sensory quality, respiration intensity, and ethylene production during storage were measured to verify pepino fruits would have chilling injury when stored at 5 ℃ and below. Further pepino fruits were treated with UV-C at doses of 0.25, 0.50 and 1.00 kJ·m−2 respectively, and stored at 5 ℃ for 15 days. The changes in chilling injury and flavor quality during storage were measured, combining with measurement of the changes of flavor substances using the electronic nose.

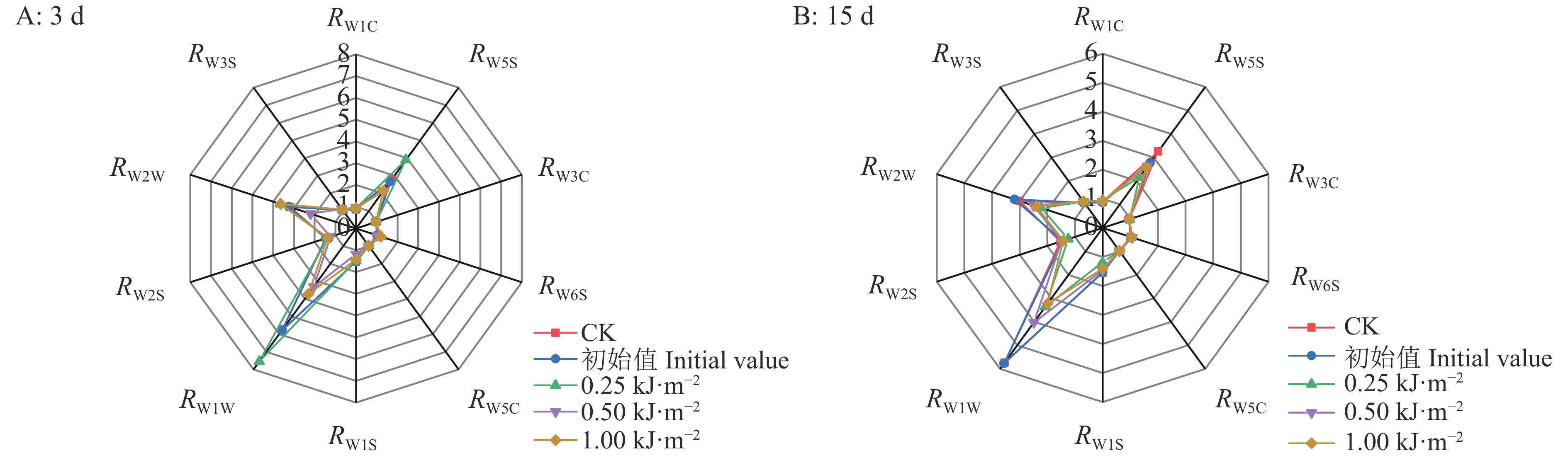

ResultUnder 5 ℃ cold stress, the different doses of UV-C treatment effectively maintained the flavor quality, alleviated the symptoms of chilling injury and inhibited the respiration intensity and ethylene production at low temperature of pepino fruits. The ethylene production of 1.00 kJ·m−2 UV-C treatment was 46% lower than that of the control group on the 15th day of storage, and the chilling injury index of 1.00, 0.50 and 0.25 kJ·m−2 UV-C treatments were 30%, 70% and 67% respectively, which were significantly lower than that of the control group (81%). The 1.00 kJ·m−2 UV-C treatment could significantly delay the onset of chilling injury for six days. Through linear discriminant analysis and radar analysis, it was found that the different doses of UV-C treatment kept the volatile aroma components of pepino fruits well.

ConclusionUnder cold stress, the different doses of UV-C treatment could significantly decrease the symptoms of chilling injury, maintain the flavor quality during storage to varying degrees, and delay the senescence of pepino fruits. Compared with other treatments, pepino fruits treated with 1.00 kJ·m−2 UV-C have lower chilling injury index during storage and the treatment effect is the best.

-

Keywords:

- pepino fruit /

- UV-C irradiation /

- chilling injury /

- ethylene /

- electronic nose

-

-

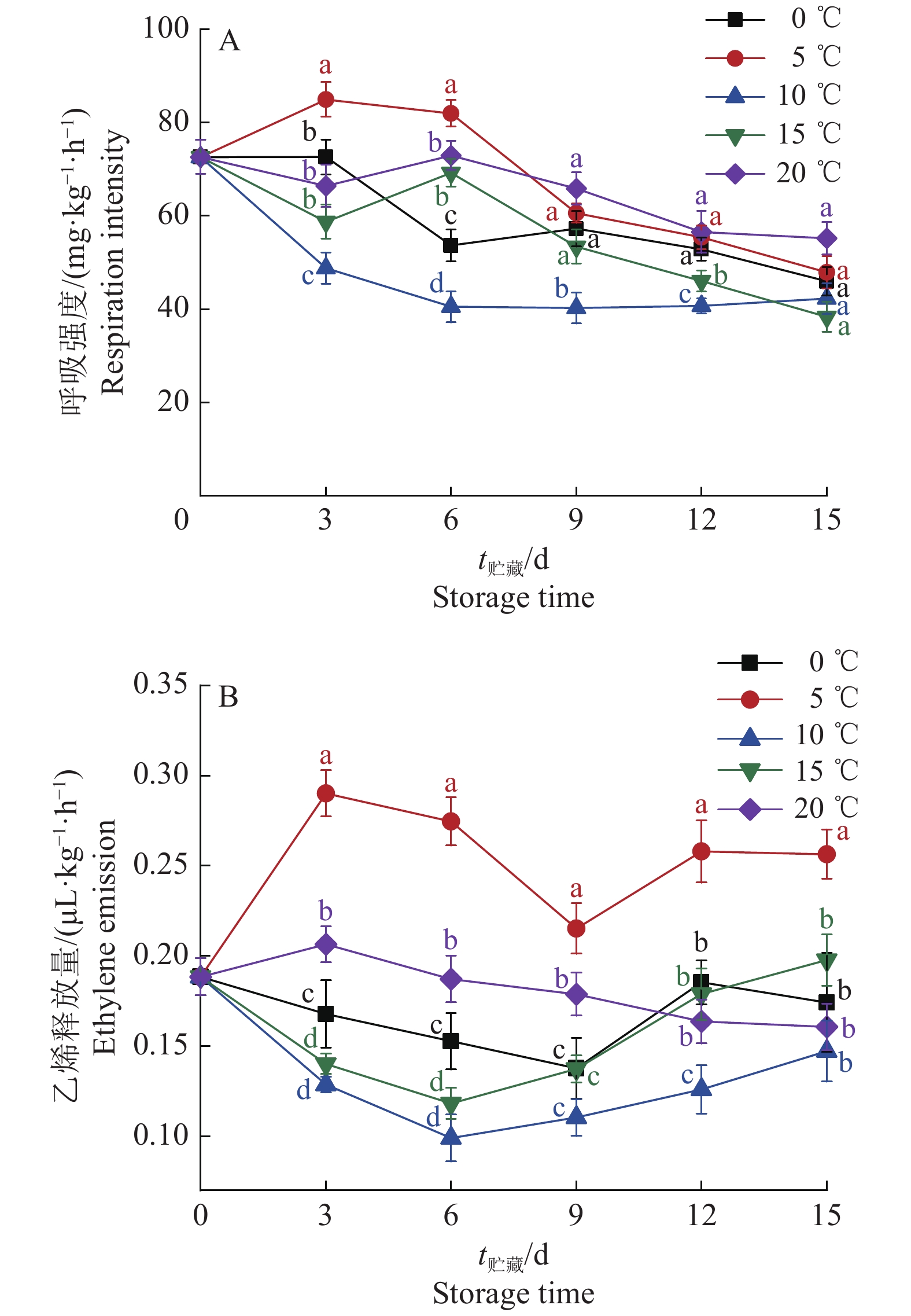

图 5 不同贮藏温度下的人参果电子鼻数据分析

A:传感器对UV-C处理前人参果香气的响应图,B:传感器载荷分析,C:贮藏第15天传感器响应值的雷达图分析,D:相关性分析图;R:对应传感器的相对电阻率,Rr:呼吸强度,EP:乙烯释放量,CI:冷害指数; “*”和“**”分别表示在0.05和0.01水平显著相关

Figure 5. Analysis of electronic nose data for pepino fruits under different storage temperatures

A: The sensor response graph of pepino fruits before UV-C treatment, B: Sensor load analysis, C: Radar graph of sensor response on the 15th day of storage, D: Correlation analysis diagram; R: Relative resistance of the corresponding sensor, Rr: Respiration intensity, EP: Ethylene production, CI: Chilling injury index; “*”and“**”indicate significant correlation at 0.05 and 0.01 levels respectively

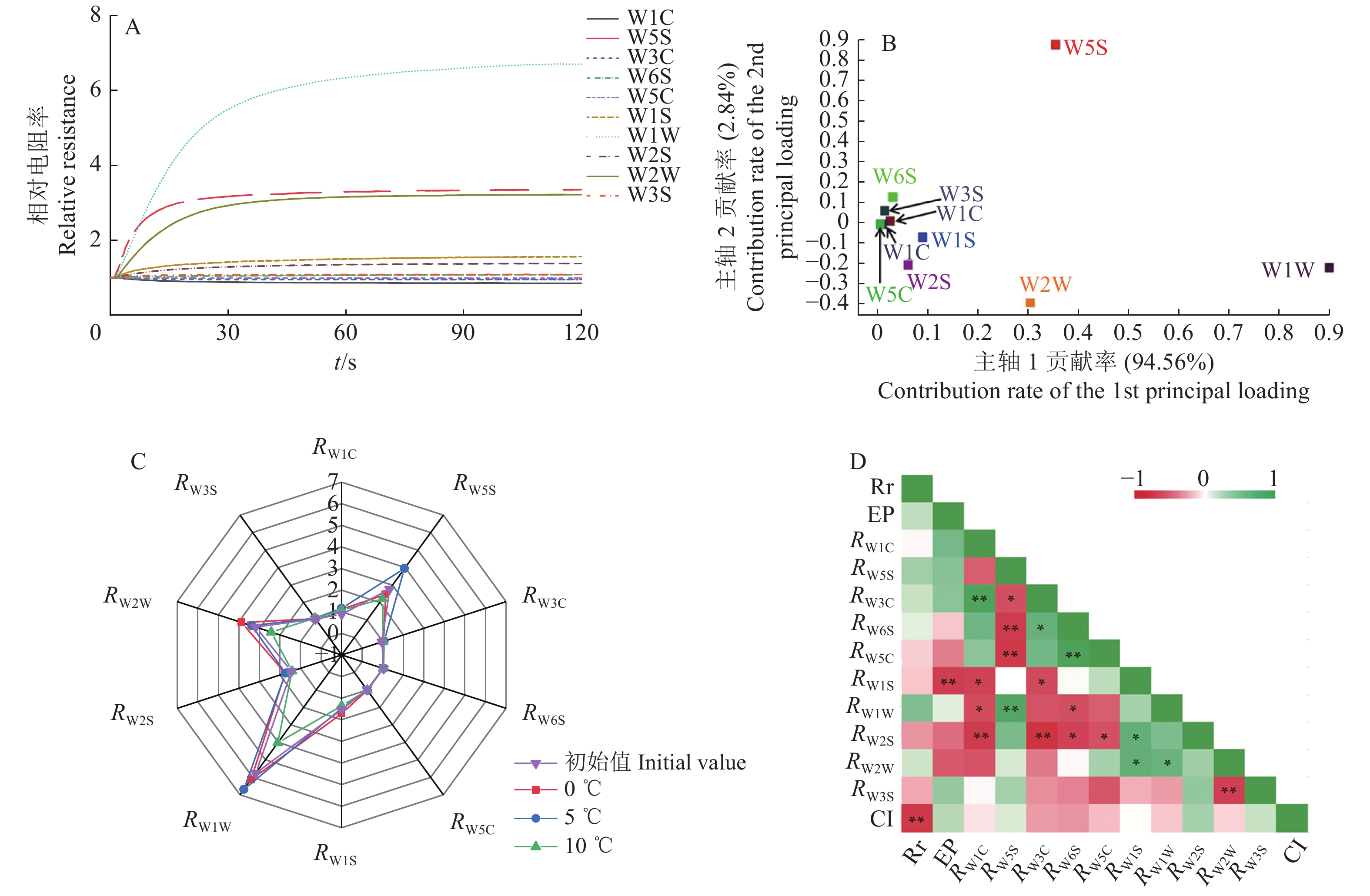

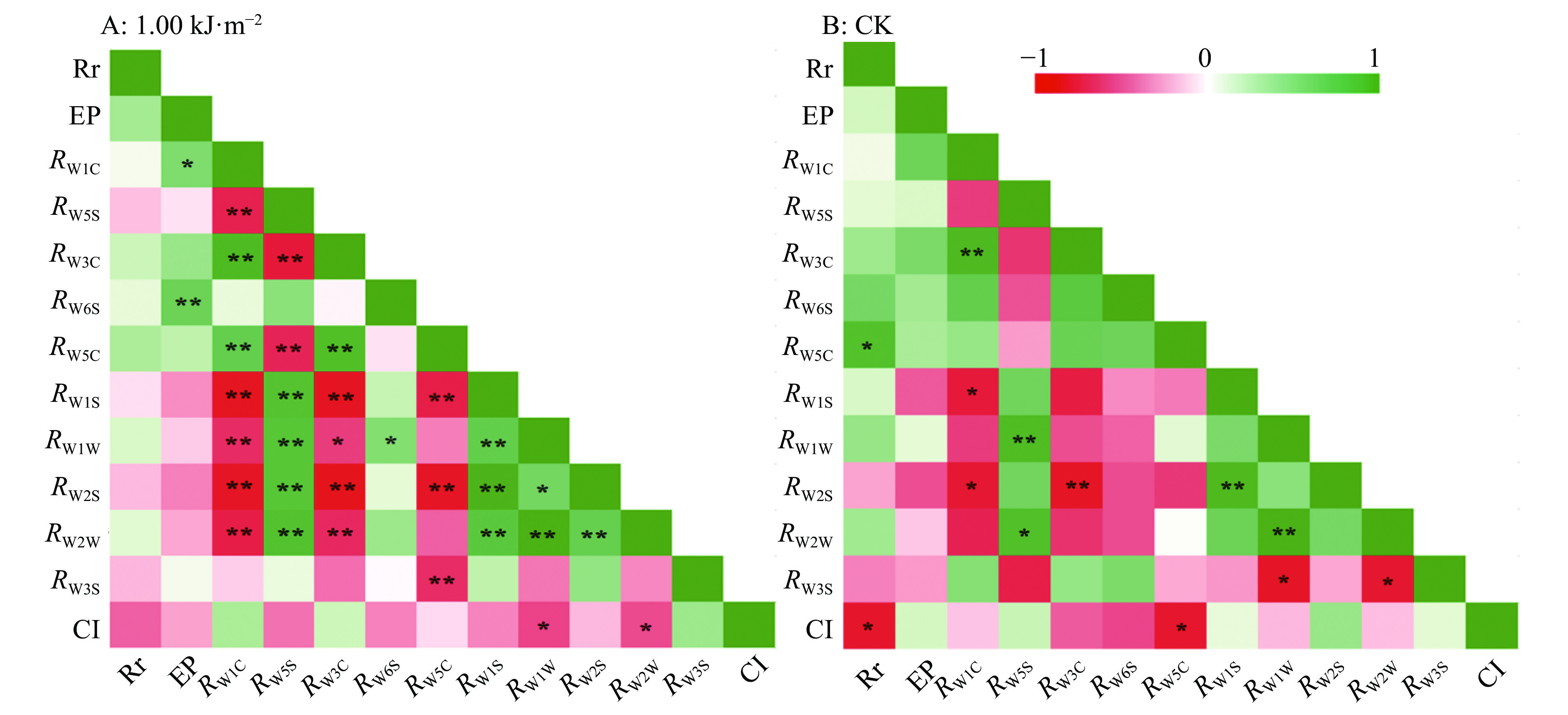

图 11 1.00 kJ·m−2 UV-C和对照处理人参果在贮藏期间测量指标之间的相关性分析

Rr:呼吸强度;EP:乙烯释放量;CI:冷害指数;R:对应传感器的相对电阻率;“*”和“**”分别表示在0.05和0.01水平显著相关

Figure 11. Analysis of correlation between the measurement data of pepino fruits from 1.00 kJ·m−2 UV-C and control treatments during storage

Rr: Respiration intensity; EP: Ethylene production; CI: Chilling injury index; R: Relative resistance of the corresponding sensor; “*”and“**”indicate significant correlation at 0.05 and 0.01 levels respectively

表 1 PEN3型便携式电子鼻标准传感器阵列与性能

Table 1 Standard sensor arrays and performance of PEN3 electronic nose

传感器编号 Sensor number 传感器名称 Sensor name 主要敏感化合物 Major sensitive compounds S1 W1C 芳香族有机化合物 Aromatic organic compounds S2 W5S 氮氧化合物 Nitrogen oxides S3 W3C 氨类、芳香成分 Ammonia, aromatic compounds S4 W6S 氢化物 Hydrogen S5 W5C 短链烷烃、芳香成分 Short chain alkanes, aromatic compounds S6 W1S 甲基类化合物 Methyl compounds S7 W1W 无机硫化物 Inorganic sulfide S8 W2S 醇类 Alcohols S9 W2W 有机硫化物、芳香成分 Organic sulfide, aromatic compounds S10 W3S 长链烷烃 Long chain alkanes -

[1] 杨世鹏, 蒋晓婷, 许盼盼, 等. 人参果营养成分、采后生理及贮藏保鲜方式研究进展[J]. 西北农业学报, 2020, 29(10): 1447-1456. [2] KOLA O, SIMSEK M, DURAN H, et al. HPLC determination of carotenoid, organic acid, and sugar content in pepino (Solanum muricatum) fruit during the ripening period[J]. Chemistry of Natural Compounds, 2015, 51(1): 132-136. doi: 10.1007/s10600-015-1219-6

[3] REDGWELL R J, TURNER N A. Pepino (Solanum muricatum): Chemical composition of ripe fruit[J]. Journal of the Science of Food and Agriculture, 1986, 37(12): 1217-1222. doi: 10.1002/jsfa.2740371211

[4] SHIOTA H, YOUNG H, PATERSON V, et al. Volatile aroma constituents of pepino fruit[J]. Journal of the Science of Food and Agriculture, 2010, 43(4): 343-354.

[5] CONTRERAS C, SCHWAB W, MAYERSHOFER M, et al. Study of physiological and quality parameters during development and ripening of pepino (Solanum muricatum Aiton) fruit[J]. Chilean Journal of Agricultural Research, 2019, 79(3): 385-395. doi: 10.4067/S0718-58392019000300385

[6] SANCHEZ M, CAMARA M, PROHENS J, et al. Variation in carbohydrate content during ripening in two clones of pepino[J]. Journal of the Science of Food and Agriculture, 2000, 80(13): 1985-1991. doi: 10.1002/1097-0010(200010)80:13<1985::AID-JSFA744>3.0.CO;2-K

[7] 陵军成. 化肥减量和增施生物有机肥对人参果产量、品质和耐贮性的影响[J]. 保鲜与加工, 2020, 20(4): 77-82. doi: 10.3969/j.issn.1009-6221.2020.04.012 [8] 朱娜, 潘磊庆, 邬慧颖, 等. 基于电子鼻检测“霞晖5号”桃果实的冷害[J]. 食品科学, 2014, 35(4): 95-100. doi: 10.7506/spkx1002-6630-201404020 [9] LIZANA L, LEVANO B. Caracterizacion y comportamiento de post-cosecha del pepino dulce, Solanum muricatum,Ait[J]. Proceedings of the American Society for Horticultural Science, 1977, 21: 11-15.

[10] 姚昕, 涂勇. 壳聚糖涂膜对人参果贮藏保鲜效果的研究[J]. 农产品加工(学刊), 2012(12): 56-58. [11] El-ZEFTAWI B M, BROHIER L, DOOLEY L, et al. Some maturity indices for tamarillo and pepino fruits[J]. Journal of the Science of Food and Agriculture, 1988, 63(1): 163-169.

[12] SUSANNE H, HERU W, LÜDDERS P, et al. Postharvest quality of pepino (Solanum muricatum Ait.) fruit in controlled atmosphere storage[J]. Journal of Food Engineering, 2006, 77(3): 628-634. doi: 10.1016/j.jfoodeng.2005.07.028

[13] 马丽丽, 左进华, 王清, 等. UV-C处理对青椒色泽和生理品质的影响[J]. 食品科学, 2021, 42(3): 281-288. doi: 10.7506/spkx1002-6630-20200216-165 [14] 李玉娟. 采后短波紫外线处理对苹果抗病性及品质的影响[D]. 杨凌: 西北农林科技大学, 2015. [15] 徐艳群. 短波紫外光(UV-C)采前辐照调控草莓果实品质和植株抗病性机理研究[D]. 杭州: 浙江大学, 2019. [16] SAMPEDRO F, PHILLIPS J, FAN X T. Use of response surface methodology to study the combined effects of UV-C and thermal processing on vegetable oxidative enzymes[J]. LWT - Food Science and Technology, 2014, 55(1): 189-196. doi: 10.1016/j.lwt.2013.07.010

[17] 尹建云. UV-C结合热处理调控黄瓜冷害机理研究[D]. 杭州: 浙江农林大学, 2013. [18] 王涛, 郝利平, 李月圆, 等. 壳聚糖及UV-C处理对长山药冷害和品质的影响[J]. 核农学报, 2019, 33(4): 732-738. doi: 10.11869/j.issn.100-8551.2019.04.0732 [19] 陈奕兆, 刚成诚, 王亦佳, 等. UV-C处理对水蜜桃果实冷害及贮藏品质的影响[J]. 中国南方果树, 2013, 42(1): 16-21. [20] WILSON A D, BAIETTO M. Applications and advances in electronic-nose technologies[J]. Sensors, 2009, 9(7): 5099-5148. doi: 10.3390/s90705099

[21] NAHID A, MOHAMMAD J D, ADIEH A. Detection of ripeness grades of berries using an electronic nose[J]. Food Science & Nutrition, 2020, 8(9): 4919-4928.

[22] YANG Y Q, HUA J, DENG Y L, et al. Aroma dynamic characteristics during the process of variable-temperature final firing of Congou black tea by electronic nose and comprehensive two-dimensional gas chromatography coupled to time-of-flight mass spectrometry[J]. Food Research International, 2020, 137: 109656. doi: 10.1016/j.foodres.2020.109656

[23] JIA W, LIANG G, JIANG Z, et al. Advances in electronic nose development for application to agricultural products[J]. Food Analytical Methods, 2019, 12(10): 2226-2240. doi: 10.1007/s12161-019-01552-1

[24] 葛东颖, 李华佳, 杨成聪, 等. 不同处理工艺对猕猴桃果酒品质的影响[J]. 中国酿造, 2019, 38(4): 70-74. doi: 10.11882/j.issn.0254-5071.2019.04.014 [25] BEGHI R, BURATTI S, GIOVENZANA V, et al. Electronic nose and visible-near infrared spectroscopy in fruit and vegetable monitoring[J]. Reviews in Analytical Chemistry, 2017, 36(4). doi: 10.1515/revac-2016-0016.

[26] DOMINGO M, SERRRANO M, VALERO D. Physiological changes in pepino (Solanum muricatum Ait.) fruit stored at chilling and non-chilling temperatures[J]. Postharvest Biology and Technology, 2003, 30(2): 177-186. doi: 10.1016/S0925-5214(03)00106-6

[27] PLUDA D, RABINOWITCH H D, KAFKAI U. Pepino dulce (Solanum muricatum Ait.) quality characteristics respond to nitrogen nutrition and salinity[J]. Journal of the American Society for Horticultural Science, 1993, 118(1): 86-91. doi: 10.21273/JASHS.118.1.86

[28] 刘泽松, 史君彦, 左进华, 等. UV-C和LED红光复合处理对西兰花贮运品质的影响[J]. 食品科学, 2019, 41(17): 1-14. doi: 10.7506/spkx1002-6630-20180910-092 [29] 范林林, 王清, 左进华, 等. 外源NO处理对茄子贮藏品质的影响[J]. 中国食品学报, 2017, 17(1): 186-192. [30] 刘瑶, 徐冬颖, 刘婧, 等. 基于电子鼻的运输振动蔬菜气味品质检测[J]. 北方园艺, 2019(18): 100-109. [31] 陈辰, 鲁晓翔, 张鹏, 等. 基于电子鼻技术的玫瑰香葡萄贮藏期快速判别[J]. 食品与机械, 2015, 31(6): 137-141. [32] 千春录, 朱芹, 高姗, 等. 外源褪黑素处理对采后水蜜桃冷藏品质及冷害发生的影响[J]. 江苏农业学报, 2020, 36(3): 702-708. doi: 10.3969/j.issn.1000-4440.2020.03.024 [33] 郭雨萱, 郝利平, 卢银洁. 不同处理对茄子采后冷害及相关酶活性的影响[J]. 山西农业大学学报(自然科学版), 2016, 36(9): 668-672. [34] 金鹏, 王静, 朱虹, 等. 果蔬采后冷害控制技术及机制研究进展[J]. 南京农业大学学报, 2012, 35(5): 167-174. [35] 邵青旭, 高湘荃, 时晓雪, 等. 低温贮藏对薄皮甜瓜果实风味品质的影响[J]. 沈阳农业大学学报, 2020, 51(1): 62-69. [36] MAUL F, SARGENT S A, SIMS C A, et al. Tomato flavor and aroma quality as affected by storage temperature[J]. Journal of Food Science, 2000, 65(7): 1228-1237. doi: 10.1111/j.1365-2621.2000.tb10270.x

[37] ZHANG B, TIEMAN D M, JIAO C, et al. Chilling-induced tomato flavor loss is associated with altered volatile synthesis and transient changes in DNA methylation[J]. Proceedings of the National Academy of Sciences of the United States of America, 2016, 113(44): 12580-12585. doi: 10.1073/pnas.1613910113

[38] 唐国冬, 廖欣怡, 郑雅轩, 等. 低温对赤霞珠葡萄香气和单体酚含量的影响[J]. 食品科学, 2017, 38(20): 48-54. [39] 任伟, 郝利平. UV-C处理对贡橘冷害的影响[J]. 核农学报, 2016, 30(6): 1111-1116. doi: 10.11869/j.issn.100-8551.2016.06.1111

下载:

下载: