Fermentation optimization and antioxidant activities of dark beer prepared with the addition of purple potato enzymolysis juice by freeze-thaw process

-

摘要:目的

冻融分离产生的汁液是固液分离法制备紫色马铃薯全粉的副产物,富含碳水化合物和花青素。为提高该汁液的利用价值,将酶解后的汁液作为辅料添加至麦芽汁中发酵制备浓色啤酒。

方法采用单因素结合正交试验优化浓色啤酒的发酵条件,分析其主要抗氧化成分含量及抗氧化能力。

结果添加紫色马铃薯酶解汁液制备浓色啤酒的最佳发酵条件为:马铃薯酶解汁液添加体积分数为25%,初始pH 6.5,接种2%(φ)的M21啤酒酵母,15 ℃条件下发酵10 d。所得啤酒呈琥珀色、晶莹剔透,酒香协调、入口柔顺,感官评分为86.9,酒精度[φ(乙醇)]5.84%,总酸体积分数15.6 mL/L,还原糖质量浓度18.69 mg/mL,色度37.71 EBC,总酚、绿原酸和花青素质量浓度分别为360.2、685.7和208.4 mg/L,每100 mL 啤酒中含啤酒10倍稀释液的总还原能力与0.150 mg/mL 维生素C相当,DPPH自由基清除率为49.9%,与质量浓度为0.043 mg/mL 维生素C相当,ABTS自由基清除率83.9%。

结论紫色马铃薯冻融分离酶解汁液可部分替代麦芽汁发酵高抗氧化活性的浓色啤酒。

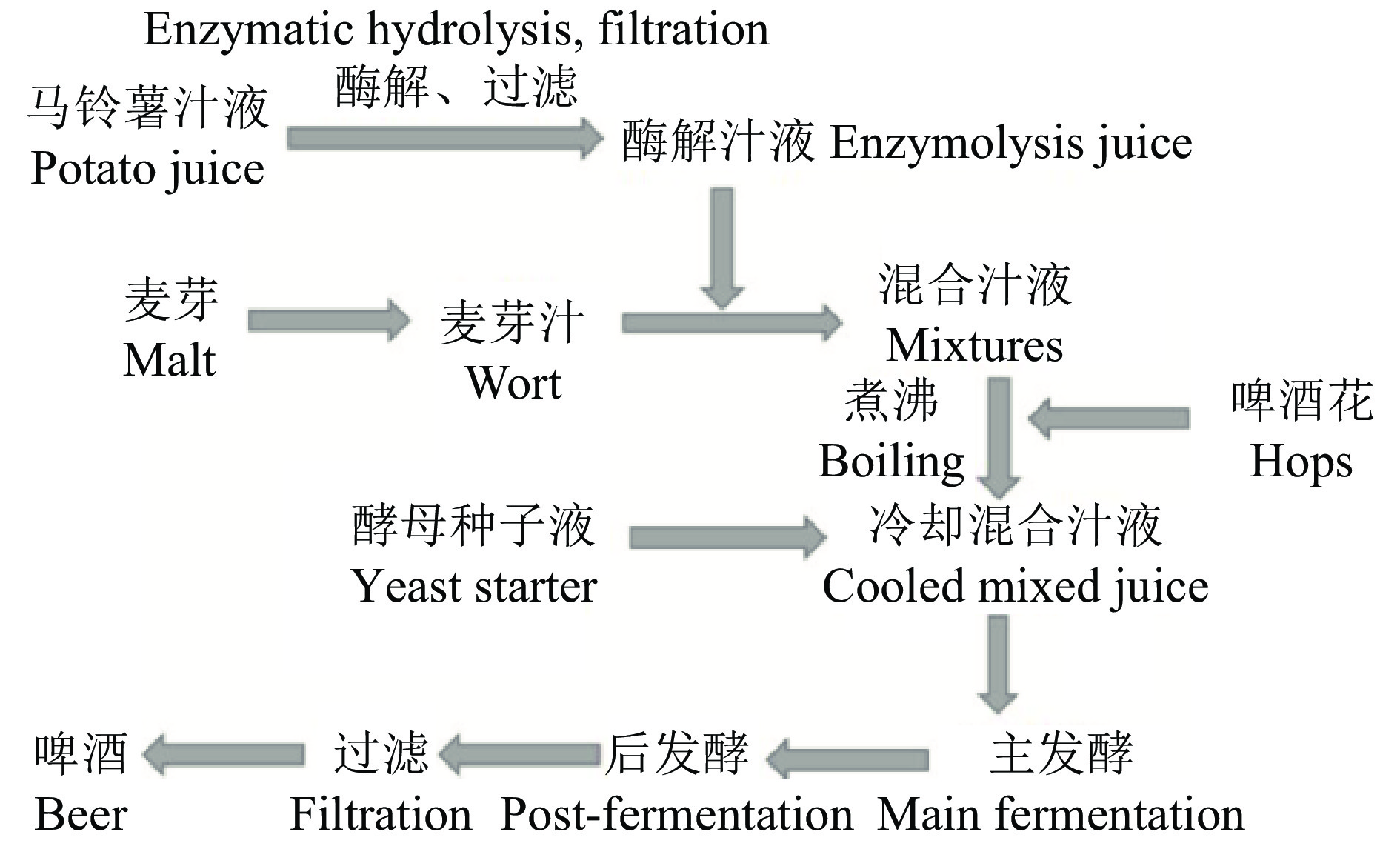

Abstract:ObjectivePotato juice of freeze-thaw process is the liquid by-product derived from the production of purple potato flour by solid-liquid separation method, and it is rich in carbohydrates and anthocyanins. In order to increase the utilization value of the liquid by-product, the enzymolysis juice was added as supplementary ingredient into wort to prepare dark beer by fermentation.

MethodSingle factor test combining orthogonal experiment was performed to optimize the fermentation conditions. The contents and activities of antioxidant components in the dark beer were evaluated.

ResultThe optimum fermentation conditions for dark beer preparation with addition of purple potato enzymolysis liquid were as follows: Content of potato enzymolysis liquid was 25% (φ), initial pH was 6.5, inoculation of 2% (φ) M21 beer starter, and fermentation for 10 d under the temperature of 15 ℃. The prepared beer was amber color and crystal clear, had harmonious flavor and mellow taste. Its sensory score was 86.9, alcohol content was 5.84%, total acid content was 15.6 mL/L beer, total reducing sugar content was 18.69 mg/mL, chroma was 37.71 EBC, total phenol content was 360.2 mg/L, chlorogenic acid content was 685.7 mg/L, and anthocyanin content was 208.4 mg/L. The total reduction capacity of 10-fold diluent beer was equivalent to that of 0.150 mg/mL vitamin C, the scavenging rate of DPPH radical was 49.9%, which was equivalent to that of 0.043 mg/mL vitamin C, and the scavenging rate of ABTS+ was 83.9%.

ConclusionAddition of purple potato juice of freeze-thaw process can partially replace wort for brewing of dark beer with high antioxidant activities.

-

Keywords:

- purple potato /

- freeze-thaw seperation /

- dark beer /

- fermentation condition /

- antioxidant activity

-

表 1 啤酒发酵条件正交试验因素水平

Table 1 Factors and levels of orthogonal experiment for beer fermentation conditions

水平 Level 因素 Factor 紫色马铃薯酶解汁液添加体积分数/%

Addition of purple potato enzymolysis juice (A)pH(B) θ/℃ (C) 1 75 5.0 12 2 50 5.5 15 3 25 6.5 18 表 2 紫色马铃薯酶解汁液添加体积分数对浓色啤酒感官评分及理化指标的影响1)

Table 2 Effects of potato enzymolysis juice addition on sensory score and physicochemical properties of dark beer

φ(紫色马铃薯

酶解汁液)/%

Addition of purple potato enzymolysis juice感官评分

Sensory

score酒精度(φ)/%

Alcohol contentρ(还原糖)/

(mg·mL−1)

Reducing sugar content色度/EBC

Chromaφ(总酸)/

(mL·L−1)

Total acidspH 发酵度/%

Fermentative degree发酵力/

(g·L−1·d−1)

Fermentation capacity0(CK) 85.8 4.48±0.03a 32.53±4.89a 34.83±0.25ab 12.8±0.3a 4.17 60.87 6.85 25 88.0 4.28±0.02b 9.96±0.02f 34.35±0.26b 7.9±0.1c 4.81 56.47 6.09 33 84.8 4.23±0.04b 10.10±0.03e 35.04±0.20a 8.1±0.1c 4.74 53.85 5.41 50 80.5 4.11±0.05c 11.16±0.03c 30.84±0.15d 9.1±0.3b 4.54 52.43 4.26 67 76.6 3.14±0.03d 10.37±0.02d 27.23±0.20e 9.3±0.4b 4.33 50.32 3.21 75 72.2 3.08±0.05d 12.59±0.03b 20.19±0.20c 9.4±0.4b 4.25 48.89 3.21 1)同列数据后的不同小写字母表示差异显著(P<0.05,Duncan’s法)

1)Different lowercase letters in the same column indicate significant differences (P<0.05,Duncan’s test)表 3 不同初始pH对浓色啤酒感官评分及理化指标的影响1)

Table 3 Effects of initial pH on sensory score and physicochemical properties of dark beer

初始 pH

Initial pH感官评分

Sensory score酒精度(φ)/%

Alcohol contentρ(还原糖)/

(mg·mL−1)

Reducing sugar content色度/EBC

Chromaφ(总酸)/

(mL·L−1)

Total acidspH 发酵度/%

Fermentative degree发酵力/

(g·L−1·d−1)

Fermentation capacity5.0 82.6 4.49±0.04b 18.92±0.15a 39.50±0.20a 9.7±0.1a 4.67 66.15 4.67 5.5 83.2 4.26±0.04d 18.64±0.20a 38.88±0.10ac 9.7±0.1a 4.69 63.08 4.76 6.0 85.4 4.53±0.03c 13.96±0.20b 38.29±0.20bc 9.4±0.1b 4.68 64.62 4.85 6.5 82.3 4.66±0.02a 8.61±0.21c 34.88±0.15e 8.2±0.1c 4.73 65.38 5.18 7.0 80.2 4.63±0.05a 5.75±0.31d 36.52±0.20d 8.0±0.1d 4.66 61.52 5.22 1)同列数据后的不同小写字母表示差异显著(P<0.05,Duncan’s法)

1)Different lowercase letters in the same column indicate significant differences (P<0.05,Duncan’s test)表 4 不同酵母菌种对浓色啤酒感官评分及理化指标的影响1)

Table 4 Effects of yeast strains on sensory score and physicochemical properties of dark beer

酵母菌株

Yeast starter感官评分

Sensory score酒精度(φ)/%

Alcohol contentρ(还原糖)/

(mg·mL−1)

Reducing sugar content色度/EBC

Chromaφ(总酸)/

(mL·L−1)

Total acidspH 发酵度/%

Fermentative degree发酵力/

(g·L−1·d−1)

Fermentation capacityM20 84.3 4.49±0.00a 15.18±0.05b 36.06±0.06b 9.5±0.3a 4.56 51.54 5.84 M21 86.3 4.25±0.00b 13.47±0.03c 35.66±0.11c 9.5±0.2a 4.53 53.08 5.54 M36 80.8 4.26±0.00b 8.70±0.02e 37.21±0.35a 9.1±0.3a 4.61 60.38 5.83 M44 84.1 4.24±0.00b 15.72±0.03a 34.94±0.26d 10.5±2.1a 4.34 47.31 4.66 M47 81.6 4.17±0.00c 12.92±0.04d 33.17±0.10e 9.1±1.0a 4.62 53.08 5.74 1)同列数据后的不同小写字母表示差异显著(P<0.05,Duncan’s法)

1)Different lowercase letters in the same column indicate significant differences (P<0.05,Duncan’s test)表 5 不同酵母接种体积分数对浓色啤酒感官评分及理化指标的影响1)

Table 5 Effects of yeast inoculation doses on sensory score and physicochemical properties of dark beer

φ(酵母接种)/%

Yeast inoculation

dosage感官评分

Sensory score酒精度(φ)/%

Alcohol contentρ(还原糖)/

(mg·mL−1)

Reducing

sugar content色度/EBC

Chromaφ(总酸)/

(mL·L−1)

Total acidspH 发酵度/%

Fermentative degree发酵力/

(g·L−1·d−1)

Fermentation capacity2 82.1 5.84±0.00a 9.39±0.04c 33.24±0.15c 10.1±0.2a 4.57 61.54 6.06 4 85.1 5.09±0.00c 9.25±0.03d 32.18±0.10d 9.7±0.1a 4.64 61.15 6.20 6 87.2 5.01±0.00d 9.41±0.04c 33.01±0.20c 9.6±0.2a 4.64 60.38 6.19 8 81.2 4.83±0.00e 11.01±0.12a 34.02±0.15a 9.1±0.9a 4.61 60.38 6.53 10 78.5 5.33±0.00b 10.14±0.03b 33.60±0.15b 9.6±1.4a 4.51 59.62 7.80 1)同列数据后的不同小写字母表示差异显著(P<0.05,Duncan’s法)

1)Different lowercase letters in the same column indicate significant differences (P<0.05,Duncan’s test)表 6 不同发酵温度对浓色啤酒感官评分及理化指标的影响1)

Table 6 Effects of fermentation temperatures on sensory score and physicochemical properties of dark beer

发酵温度/℃

Fermentation temperature感官评分

Sensory score酒精度(φ)/%

Alcohol contentρ(还原糖)/

(mg·mL−1)

Reducing

sugar content色度/EBC

Chromaφ(总酸)/

(mL·L−1)

Total acidspH 发酵度/%

Fermentative degree发酵力/

(g·L−1·d−1)

Fermentation capacity10 85.1 4.62±0.00d 11.65±0.02a 39.80±0.20a 10.4±0.5a 4.71 55.38 5.52 12 84.8 4.59±0.00e 8.83±0.04b 38.42±0.15b 9.7±0.1ab 4.70 60.38 5.67 15 86.3 4.85±0.00a 8.59±0.02c 37.96±0.15b 9.1±0.2b 4.85 60.77 8.87 18 84.1 4.79±0.00b 8.77±0.02b 36.45±0.20c 9.3±1.0ab 4.46 60.77 6.53 22 76.2 4.65±0.00c 8.59±0.03c 34.97±0.20d 8.9±0.9b 4.71 60.38 5.50 1)同列数据后的不同小写字母表示差异显著(P<0.05,Duncan’s法)

1)Different lowercase letters in the same column indicate significant differences (P<0.05,Duncan’s test)表 7 添加紫色马铃薯酶解汁液的浓色啤酒发酵正交试验结果

Table 7 Results of orthogonal experiment for dark beer fermentation with addition of purple potato enzymolysis juice

试验号

Experiment No.A B C 误差

Error感官评分

Sensory score1 1 1 1 1 73.2 2 1 2 2 2 78.8 3 1 3 3 3 79.6 4 2 1 2 3 78.7 5 2 2 3 1 68.8 6 2 3 1 2 83.7 7 3 1 3 2 75.0 8 3 2 1 3 81.5 9 3 3 2 1 86.9 k1 72.150 70.603 74.450 71.250 k2 72.050 71.333 76.433 74.137 k3 76.103 78.367 69.420 74.917 极差 Range 4.053 7.764 7.013 3.667 表 8 添加紫色马铃薯酶解汁液的浓色啤酒与市售浓色啤酒抗氧化成分含量比较1)

Table 8 Contents of antioxidants in commercial dark beer and dark beer with addition of purple potato enzymolysis juice

样品

Sampleρ/(mg·L−1) 总酚 Total phenol 绿原酸 Chlorogenic acid 花青素 Anthocyanin 添加紫色马铃薯酶解汁液的浓色啤酒

Dark beer with addition of purple potato enzymolysis juice360.2±3.9a 685.7±11.6c 208.4±6.0b 未发酵混合汁液 Mixture juice before fermentation 352.7±1.8b 1104.9±7.9a 691.3±23.1a 纯麦芽浓色啤酒 Dark beer prepared with pure wort 186.0±1.5c 1020.0±41.9b 0 某市售浓色啤酒 A commercial dark beer 124.2±2.8d 602.1±24.4d 0 1)同列数据后的不同小写字母表示差异显著(P<0.05,Duncan’s法)

1)Different lowercase letters in the same column indicate significant differences (P<0.05,Duncan’s test)表 9 添加紫色马铃薯酶解汁液的浓色啤酒与市售浓色啤酒体外抗氧化能力比较1)

Table 9 Comparison of antioxidant capacities in vitro between commercial dark beer and dark beer with addition of purple potato enzymolysis juice

样品

Sample总还原力

Total reduction capacityDPPH自由基清除能力

DPPH radical scavenging capacityABTS自由基

清除率/%

ABTS radical scavenging rate还原值

Reduction

valueρ(维生素C)/

(mg·mL−1)

Vitamin C content清除率/%

Scavenging

rateρ(维生素C)/

(mg·mL−1)

Vitamin C

content添加紫色马铃薯酶解汁液的浓色啤酒

Dark beer with addition of purple potato enzymolysis juice0.9509±0.022 4a 0.150±0.016a 49.9±0.6b 0.043±0.003b 83.9±2.3a 未发酵混合汁液

Mixture juice before fermentation0.9138±0.006 5b 0.143±0.019a 55.3±0.8a 0.048±0.004a 37.0±3.3c 纯麦芽浓色啤酒

Dark beer prepared with pure wort0.5259±0.006 8c 0.074±0.019b 46.8±0.5c 0.040±0.003c 74.0±3.4b 某市售浓色啤酒 A commercial dark beer 0.3460±0.001 8d 0.042±0.020c 34.6±0.5d 0.028±0.003d 69.9±1.3b 1)同列数据后的不同小写字母表示差异显著(P<0.05,Duncan’s法)

1)Different lowercase letters in the same column indicate significant differences (P<0.05,Duncan’s test) -

[1] 王兰, 邓放明, 赵玲艳, 等. 紫色马铃薯保健功效及其利用研究进展[J]. 中国酿造, 2015, 34(7): 117-120. doi: 10.11882/j.issn.0254-5071.2015.07.028 [2] SHEN G, ZHANG L, HU T, et al. Preparation of potato flour by freeze-thaw pretreatment: Effect of different thawing methods on hot-air drying process and physicochemical properties[J]. LWT-Food Science and Technology, 2020, 133: 110157. doi: 10.1016/j.lwt.2020.110157

[3] 罗尚兵, 罗兴友. 节能环保型马铃薯全粉加工方法: CN106072183A[P]. 2016-11-09. [4] 木泰华, 李鹏高. 马铃薯中生物活性成分及其功能[J]. 食品科学, 2016, 37(19): 269-276. doi: 10.7506/spkx1002-6630-201619045 [5] SUN Y, JIANG L Z, WEI D X. Partial characterization, in vitro antioxidant and antiproliferative activities of patatin purified from potato fruit juice[J]. Food and Function, 2013, 4(10): 1502-1511. doi: 10.1039/c3fo60248f

[6] MAKINEN S, KELLONIEMI J, PIHLANTO A, et al. Inhibition of angiotensin converting enzyme I caused by autolysis of potato proteins by enzymatic activities confined to different parts of the potato tuber[J]. Journal of Agricultural and Food Chemistry, 2008, 56(21): 9875-9883. doi: 10.1021/jf8016817

[7] KIM T H, PARK J S, AN S S, et al. Inhibition of thrombina ctivated fibrinolysis inhibitor decreases postoperative adhesion[J]. Journal of Surgical Research, 2015, 193(2): 560-566. doi: 10.1016/j.jss.2014.07.056

[8] LANGNER E, NUNES F M, POZAROWSKI P, et al. Antiproliferative activity of melanoidins isolated from heated potato fiber (potex) in glioma cell culture model[J]. Journal of Agricultural and Food Chemistry, 2011, 59(6): 2708-2716. doi: 10.1021/jf1047223

[9] ANDRE C M, OUFIR M, GUIGNARD C, et al. Antioxidant profiling of native Andean potato tubers (Solanum tuberosum L.) reveals cultivars with high levels of beta-carotene, alpha-tocopherol, chlorogenic acid, and petanin[J]. Journal of Agricultural and Food Chemistry, 2007, 55(26): 10839-10849. doi: 10.1021/jf0726583

[10] 杨婧娀, 王佐民, 于宏伟, 等. 精酿啤酒的发展前景[J]. 酿酒, 2018, 45(4): 35-37. [11] 刘金鹏, 秦艳霞, 俞志敏, 等. 响应面法优化蓝莓啤酒酿制工艺[J]. 大连工业大学学报, 2016, 35(6): 36-39. [12] 孙科. 保健型红枣啤酒发酵工艺研究[J]. 山东食品发酵, 2014, 33(1): 105-108. [13] CARVALHO G B M, SILVA D P, BENTO C V, et al. Banana as adjunct in beer production: Applicability and performance of fermentative parameters[J]. Applied Biochemistry and Biotechnology, 2009, 155(1/2/3): 53-62.

[14] BONCIU C, STOICESCU A. Obtaining and characterization of beers with cherries[J]. Innovative Romanian Food Biotechnology, 2008, 3: 23-27.

[15] NUNES C D S O, SILVA G P D, MACHADO B A S, et al. Cocoa pulp in beer production: Applicability and fermentative process performance[J]. PLoS One, 2017, 12(4): e0175677. doi: 10.1371/journal.pone.0175677

[16] RAY R C, PANDA S K, SWAIN M R, et al. Proximate composition and sensory evaluation of anthocyanin-rich purple sweet potato (Ipomoea batatas L.) wine[J]. International Journal of Food Science and Technology, 2012, 47(3): 452-458. doi: 10.1111/j.1365-2621.2011.02861.x

[17] PANDA S K, SWAIN M R, SINGH S, et al. Proximate compositions of a herbal purple sweet potato (Ipomoea batatas L.) wine[J]. Journal of Food Processing and Preservation, 2013, 37(5): 596-604. doi: 10.1111/j.1745-4549.2012.00681.x

[18] PANDA S K, PANDA S H, SWAIN M R, et al. Anthocyanin-rich sweet potato (Ipomoea batatas L.) beer: Technology, biochemical and sensory evaluation[J]. Journal of Food Processing and Preservation, 2015, 39(6): 3040-3049. doi: 10.1111/jfpp.12569

[19] 李志霞, 聂继云, 闫震, 等. 响应面法对3,5−二硝基水杨酸比色法测定水果中还原糖含量条件的优化[J]. 分析测试学报, 2016, 35(10): 1283-1288. doi: 10.3969/j.issn.1004-4957.2016.10.011 [20] 国家质量监督检验检疫总局. 啤酒分析方法: GB/T 4928—2008[S]. 北京: 中国标准出版社, 2008. [21] 牛广财, 闫公昕, 朱丹, 等. Folin-Ciocalteu比色法测定沙棘酒中总多酚含量的工艺优化[J]. 食品与机械, 2016, 32(4): 80-83. [22] NIO-MEDINA G, ROMO-LONGORIA J D, RAMÍREZ-GONZÁLEZ I V, et al. Phenolic content and antioxidant capacity level in commercial Mexican lager beers[J]. Journal of the American Society of Brewing Chemists, 2017, 75(2): 156-158. doi: 10.1094/ASBCJ-2017-2751-01

[23] 桑戈, 赵力, 谭婷婷, 等. pH示差法测定紫薯酒中花青素的含量[J]. 酿酒科技, 2015(6): 88-91. [24] SINGH S, SINGH R P. In vitro methods of assay of antioxidants: An overview[J]. Food Reviews International, 2008, 24(4): 392-415. doi: 10.1080/87559120802304269

[25] BENZIE I F, STRAIN J J. The ferric reducing ability of plasma (FRAP) as a measure of antioxidant power: The FRAP assay[J]. Analytical Biochemistry, 1996, 239(1): 70-76. doi: 10.1006/abio.1996.0292

[26] 蔡柳, 董文, 胡新喜, 等. 马铃薯块茎中单糖组分及含量的测定[J]. 食品科技, 2018, 43(4): 327-331. [27] 尹乐斌, 周娟, 李立才, 等. 石榴五味子保健酒发酵工艺优化及抗氧化活性研究[J]. 食品与机械, 2019, 35(3): 208-214. [28] 国家质量监督检验检疫总局. 啤酒: GB/T 4927—2008[S]. 北京: 中国标准出版社, 2008. [29] CHEN Y, MA Y, DONG L, et al. Extrusion and fungal fermentation change the profile and antioxidant activity of free and bound phenolics in rice bran together with the phenolic bioaccessibility[J]. LWT-Food Science and Technology, 2019, 115: 108461. doi: 10.1016/j.lwt.2019.108461

[30] ECHEVERRIGARAY S, SCARIOT F J, MENEGOTTO M, et al. Anthocyanin adsorption by Saccharomyces cerevisiae during wine fermentation is associated to the loss of yeast cell wall/membrane integrity[J]. International Journal of Food Microbiology, 2020, 314: 108383. doi: 10.1016/j.ijfoodmicro.2019.108383

[31] 张赟彬, 何国庆. 添加马铃薯辅料酿制高氨基酸营养啤酒的研究[J]. 酿酒, 2004, 31(1): 83-84. doi: 10.3969/j.issn.1002-8110.2004.01.037 [32] 姚立华, 何国庆, 陈启和. 以马铃薯为辅料的黄酒发酵条件优化[J]. 农业工程学报, 2006, 22(12): 228-233. doi: 10.3321/j.issn:1002-6819.2006.12.048 -

期刊类型引用(6)

1. 邱心洋,袁惠君,李梅,程建新,田世龙,李志忠. 马铃薯营养特性及其功能性产品开发研究进展. 中国食品添加剂. 2024(01): 272-278 .  百度学术

百度学术

2. 张露,王新惠,冉凌云,杨婷婷,赵乐乐,吴明阳. 富含花青素紫马铃薯汁护色研究及酶解工艺优化. 中国酿造. 2024(02): 238-242 .  百度学术

百度学术

3. 樊玉婷,李智昊,李月垣,张俊霞,张李一如,王璐,周鹏辉,李进,陈可钦,房玉林,张克坤. 不同品种葡萄添加量对果啤香气、理化指标及抗氧化活性的影响. 食品科学. 2024(13): 164-172 .  百度学术

百度学术

4. 王蕾,赵进修,刘明亮,李博鹏,卢庆华,张玲,李雅丽. 响应面法优化百香果艾尔精酿啤酒发酵工艺. 中国酿造. 2024(11): 187-193 .  百度学术

百度学术

5. 王琼,吴晓杰,郭华春,李俊,肖继坪. 滇紫甘薯新品种抗氧化物质含量及活性测定. 江苏农业科学. 2023(17): 179-185 .  百度学术

百度学术

6. 庞莹莹,陈亮,徐绍丝,黄鹭强. 精酿啤酒特色辅料的应用概况. 福建轻纺. 2021(07): 2-6+10 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: