Effect of laser quenching process on surface hardness and wear performance of wheat grinder roller

-

摘要:目的

研究激光淬火后小麦磨粉机磨辊表面材料性能变化,解决磨辊磨损严重、使用寿命较短等问题。

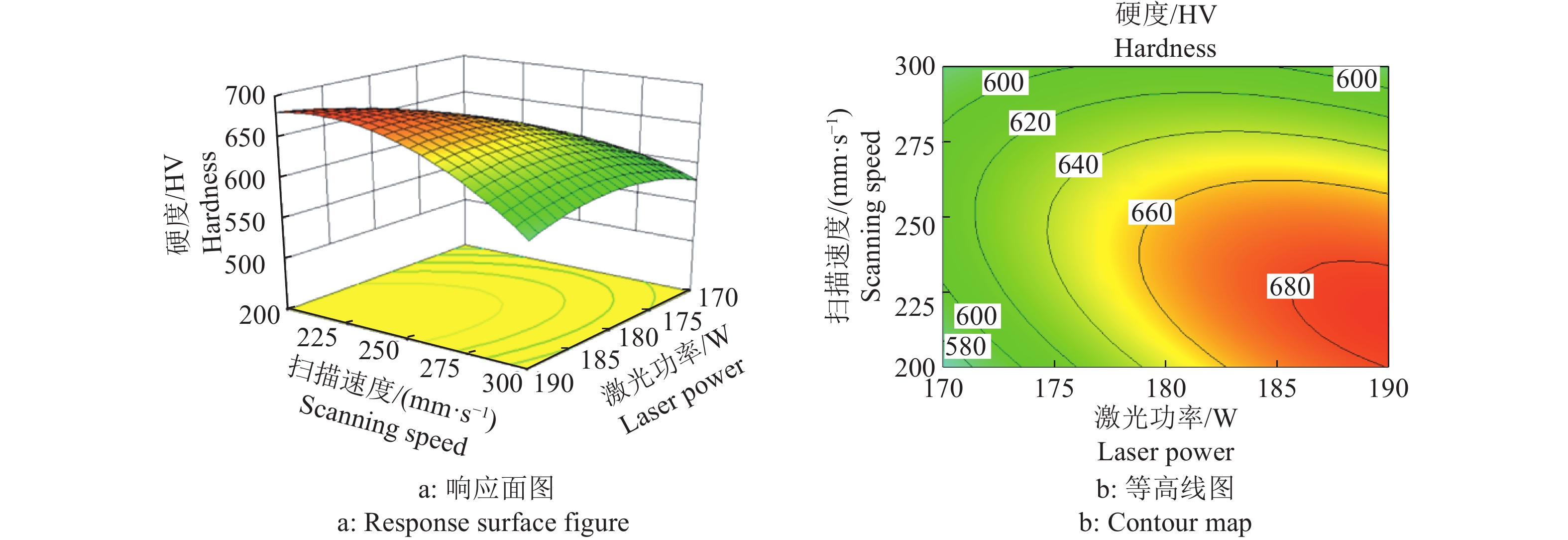

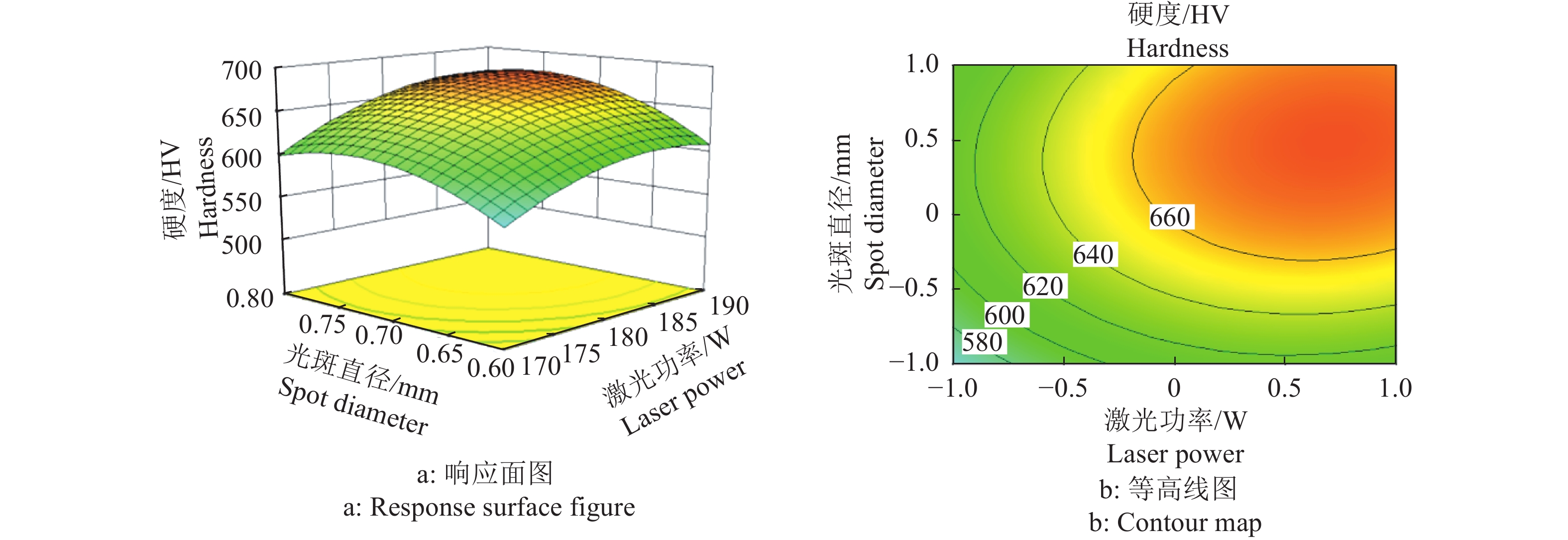

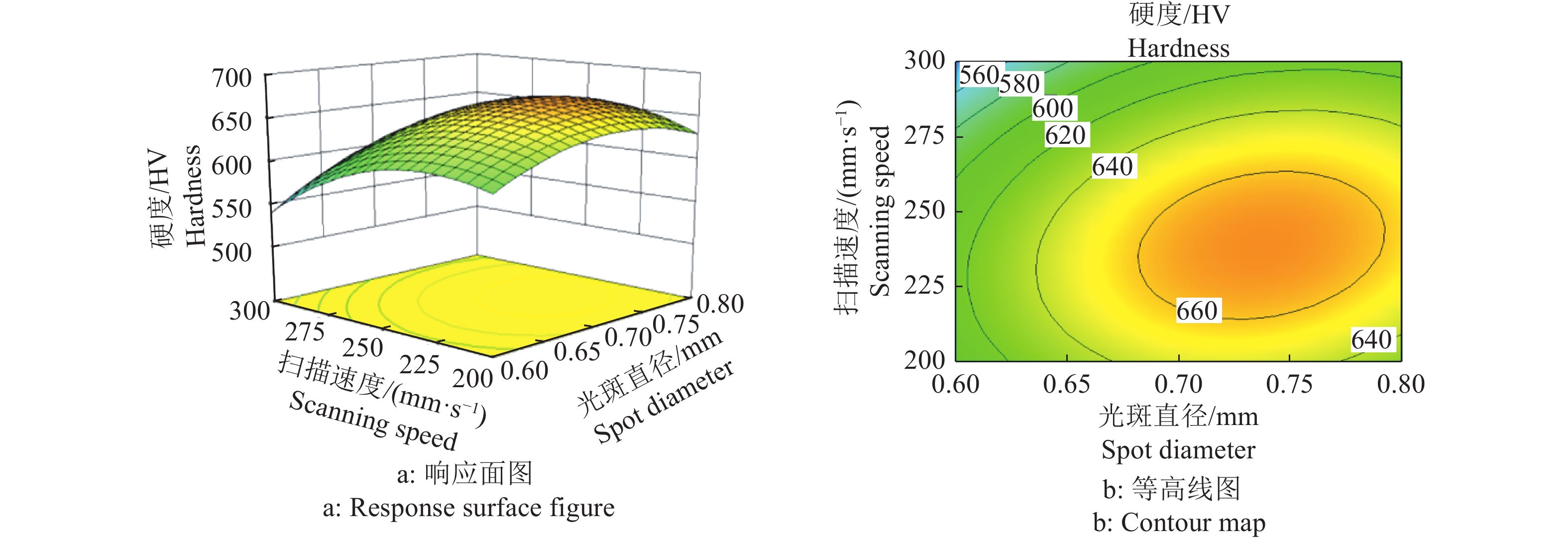

方法采用响应曲面的旋转二次组合设计原理,按照3因素5水平试验方法建立激光功率、光斑直径、扫描速度与磨辊材料表面硬度的数学模型,分析激光功率、光斑直径与扫描速度3因素及各因素间的交互作用对磨辊金属材料表面硬度的影响规律,找出最优的参数组合,探讨淬火后磨辊表面材料的磨损机理。

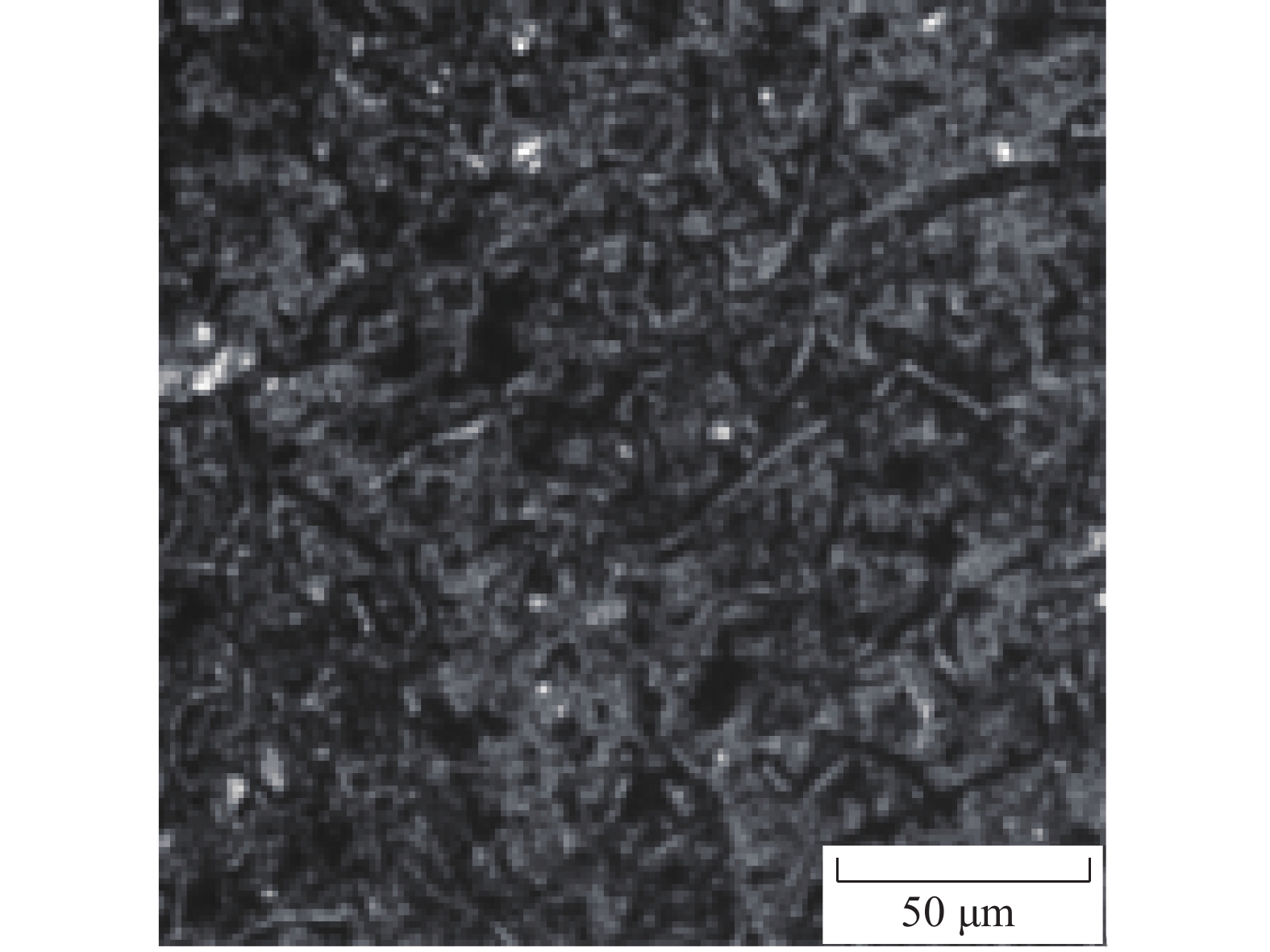

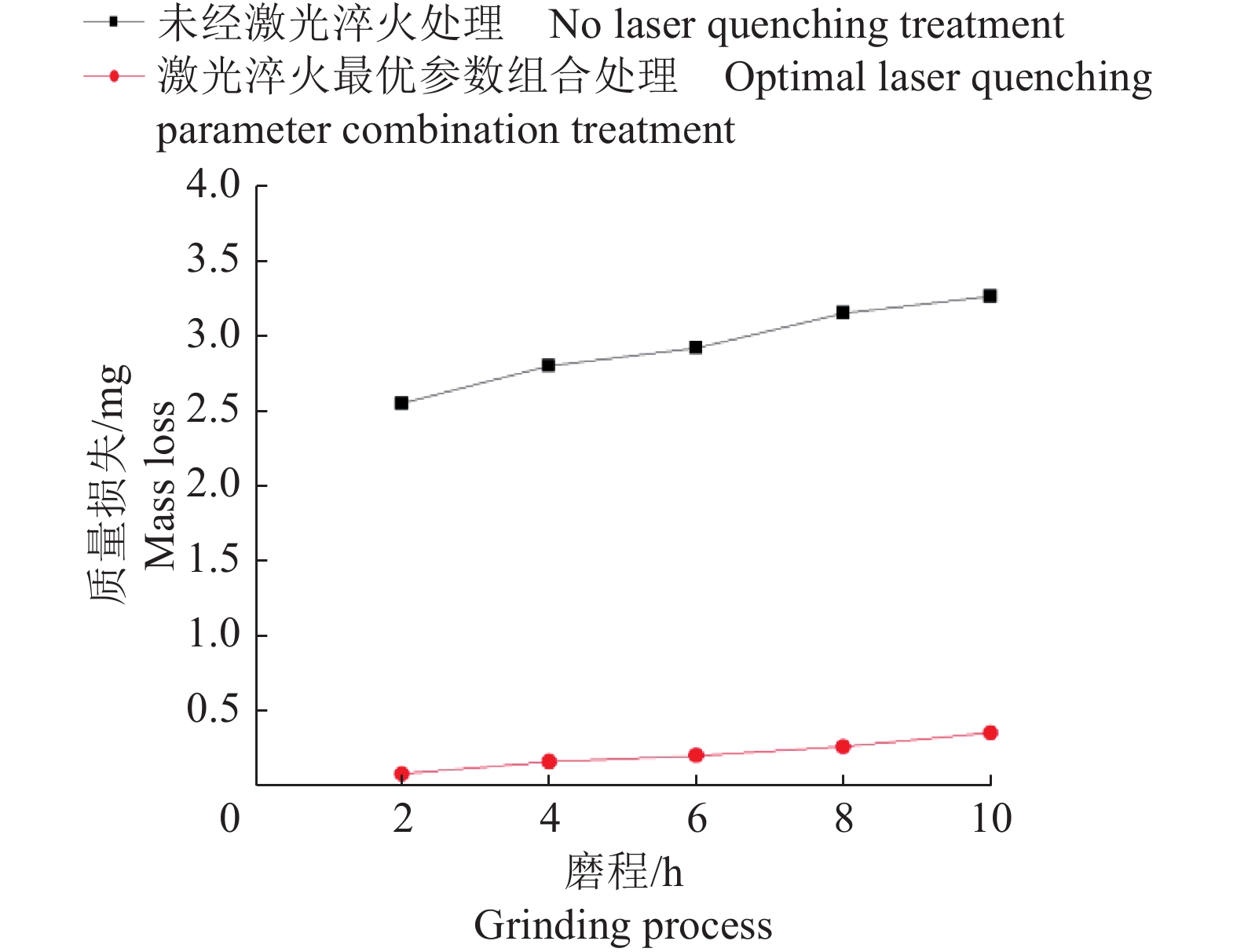

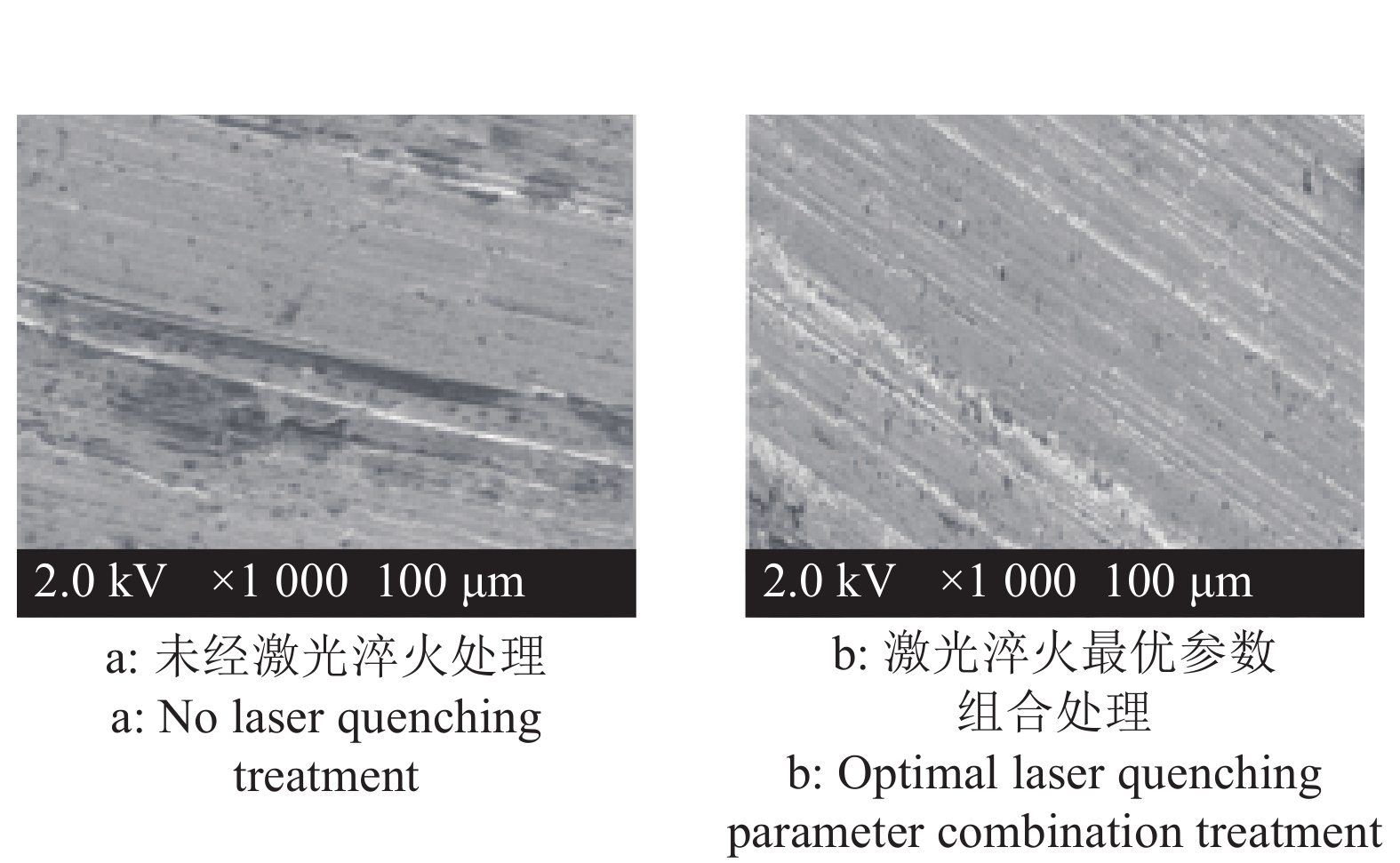

结果激光功率、光斑直径与扫描速度对磨辊材料表面硬度影响显著;激光功率、光斑直径和扫描速度对磨辊材料表面硬度的影响依次由强到弱;最优工艺参数组合为激光功率190 W、光斑直径0.70 mm、扫描速度220 mm/s,该参数组合下得到的试样表面硬度为688.67 HV,比原始硬度提升了35%;经激光淬火最优参数组合处理的试样磨损质量损失约为未处理试样的7%;经激光淬火后的磨辊表面材料与小麦粉料间的摩擦磨损作用减弱,小麦粉料在试样表面产生的划痕较轻较短,沟槽更加浅窄。

结论磨辊表面材料经激光淬火处理后其抗小麦粉料磨损性能明显增强。

Abstract:ObjectiveTo study properties of surface material of wheat grinder roller after laser quenching, and solve the problems of grinding roller such as serious wear and short service life.

MethodUsing the principle of rotating combination design of response surface, a mathematical model of laser power, spot diameter and scanning speed with surface hardness of grinding roller material was established according to three-factor and five-level test method. The effects of laser power, scanning speed, spot diameter and reciprocal action among three factors on grinding roller surface hardness were analyzed. The optimal parameter combination was obtained. The wear mechanism of surface material of the grinding roller after quenching was investigated.

ResultLaser power, spot diameter and scanning speed significantly affected surface hardness of grinding roller material. The effects of laser power, spot diameter and scanning speed on surface hardness of grinding roller material weakened successively. The optimal technological parameter combination was laser power 190 W, spot diameter 0.70 mm and scanning speed 220 mm/s and the sample surface hardness obtained was 688.67 HV, which was 35% higher than original hardness. The mass loss of sample treated by optimal laser quenching parameter combination in wear process was about 7% of the untreated sample. The friction between grinding roller surface material and wheat powder material after laser quenching weakened. The scratches of wheat powder material on sample surface were lighter and shorter. The grooves were shallower and narrower.

ConclusionThe wear resistance against wheat powder material of grinding roller surface material is obviously enhanced after laser quenching treatment.

-

Keywords:

- wheat mill /

- grinding roller /

- response surface test /

- laser quenching /

- hardness /

- wear property

-

近年来随着3C产品对锂电池需求量的稳定增加,以及新能源汽车市场规模逐步扩大和储能电池的需求扩大,锂离子电池作为一种广泛使用的电化学储能器件在我国的生产规模逐渐增加[1]。随着5G时代的到来,对储能电池的需求不断提高,电化学储能的市场需求占比不断上升。截至2020年底,三大运营商5G投入相比2019年成倍提高。尽管锂离子电池有诸多优点,但是全球的锂矿物储量有限且在地球上分布不均,因此学术界和产业界都希望寻求一种新的可持续发展的替代产品或技术来满足全球日益增长的储能需求[2]。钠作为与锂同一主族的元素,具有与锂相似的物理和化学性质,且钠离子电池的储能机理与锂离子电池相似。不仅如此,钠具有更广泛、价格低廉、容易提取、安全性高等优点[2]。因此,近年来,钠离子电池的受关注程度不亚于锂离子电池,被认为是有希望替代锂离子电池用于规模储能的下一代二次电池体系[3]。

电池隔膜是钠离子电池的核心部件之一,它不仅用于电池正负极之间的阻隔及避免正负极直接接触、阻挡电子通过,而且能保证离子穿过[4],隔膜的结构以及孔隙表面和液体电解质之间的相互作用,显著影响离子传输和电池的极化作用[5]。

目前,商业化的电池隔膜主要是基于聚烯烃材料,此类材料在高温下会有严重的热收缩,将直接导致正负极接触等一些危险情况的发生[6],且对钠离子电池常用的电解液溶剂的润湿性不好,不利于电池的性能。玻璃纤维隔膜已被广泛用作可充电钠电池的隔膜[7]。然而,这种玻璃纤维膜的低机械内聚力给大规模生产中的电池组装带来了额外的困难。此外,玻璃纤维膜的过度孔隙率,需要大量的电解液来填充孔隙空间,且与锂电池类似的情况——电解液的泄露和易燃易爆炸的问题依然存在[6]。

纤维素是一种天然且产量大的环境友好型材料,具有易加工、高耐热性、良好的化学稳定性、优异的润湿性等特点,被学者们认为是可以代替聚烯烃类原料制备电池隔膜的材料[8]。近年来,纤维素基材料在电池领域广泛发展,常用的制备方法有溶剂交换法、制孔剂制孔法、超临界干燥法、冷冻干燥法、静电纺丝等[9-11]。许多学者制备出应用在锂离子电池中的高性能的纤维素基气凝胶电池隔膜[12-13],廖海洋[14]利用羟乙基纤维素(HEC)/液体石蜡油(LP)乳液通过冰结晶诱导自组装法制备出多孔HEC气凝胶涂层来改性商业聚丙烯隔膜,制备出具有高亲液率和具有高热尺寸稳定性的锂离子隔膜。近年来,一些学者也开始研究其在钠离子电池中的应用。Casas等[7]通过非溶剂诱导相分离法合成了多孔羧甲基纤维素/羟乙基纤维素膜,在钠离子电池中有较好的应用,但其在简单循环中的循环稳定性不佳。因此,探索制备高性能、低成本的纤维素基材料钠离子电池隔膜具有重要的研究意义。

羧甲基纤维素钠(Carboxy methyl cellulose sodium, CMC)为广泛使用的纤维素衍生物之一,其分子中—COONa阴离子基团和其较低的解离能的存在,有利于钠离子在隔膜中的传输。羧甲基纤维素钠分子中有大量的—OH,高温条件下会与水溶性的聚丙烯酸分子中的—COOH发生化学交联,从而达到提高隔膜强度以及调控孔结构的效果。

因此,本文以羧甲基纤维素钠和聚丙烯酸(Polyacrylic acid, PAA)为原料制备了一种绿色环保的气凝胶型钠离子电池隔膜,并研究了最优制备条件下隔膜的结构与性能。

1. 材料与方法

1.1 主要原料与试剂

羧甲基纤维素钠(黏度600~1 000 mPa·s)、质量分数为50%的聚丙烯酸(平均相对分子质量为3 000)水溶液、金属钠、海藻酸钠[黏度(200±20) mPa·s]均购于上海阿拉丁试剂有限公司;无水乙醇(分析纯)、正丁醇(分析纯),购于广州化学试剂厂;钠离子电解液(1 mol/L 高氯酸钠/碳酸乙烯酯/聚碳酸酯, NaClO4/EC/PC)、硬碳(电池级),购于科路得;铜箔,购于泰州森诺材料科技有限公司;导电炭黑(分析纯),购于广东烛火新能源科技有限公司;GF/D玻璃纤维,购于沃特曼(Whatman)公司。

1.2 主要仪器与设备

MS7-H550-S LED数显磁力搅拌器,为大龙兴创实验仪器(北京)股份公司生产; YTLG-10A冻干机,为上海叶拓科技有限公司生产; CT3001A型电池测试系统,为武汉蓝电电子股份有限公司生产;S-4800冷场发射扫描电子显微镜,为Hitachi株式会社日立制作所生产; OCA20光学接触角测量仪,为德国Dataphysics公司生产;Vertex 70傅立叶变换红外光谱仪,为布鲁克公司生产;超级净化手套箱Super系列,为上海米开罗那机电技术有限公司生产;TG209F1 LibraTM热重分析仪,为德国耐驰仪器制造有限公司生产。

1.3 试样制备

1.3.1 隔膜的制备

隔膜的制备流程如图1所示。将2.00 g的CMC溶解于96 mL的去离子水中,搅拌20 min,滴加质量分数为 50%的PAA水溶液2.00 mL后,再搅拌20 min。将配制好的CMC-PAA水溶液超声脱气处理30 min,室温静置凝胶5 d。将CMC-PAA水凝胶薄片放入−20 ℃预冷冻,然后在−20 ℃条件下冷冻干燥24 h,得到厚度为1.2 mm的CMC-PAA气凝胶薄片。最后,用空心冲将其切成直径18 mm的隔膜,分别在105、130、140和150 ℃下交联4 h,依次记为105 ℃-CMC-PAA、130 ℃-CMC-PAA、140 ℃-CMC-PAA和150 ℃-CMC-PAA。

1.3.2 电池的组装

将硬碳、导电炭黑、海藻酸钠,按照90︰5︰5的质量比溶解在200 mL的去离子水中,充分研磨后均匀地涂布在铜箔上,置于65 ℃的恒温干燥箱中干燥12 h,裁成直径为12 mm的圆片作为负极[15]。

在氩气氛围的干燥的手套箱中,以1 mol/L高氯酸钠(NaClO4)︰碳酸乙烯酯(EC)︰聚碳酸酯(PC)体积比为1︰1︰1的混合溶剂为电解液,以金属钠单质作为正极,分别以105 ℃-CMC-PAA、130 ℃-CMC-PAA、140 ℃-CMC-PAA和150 ℃-CMC-PAA作为电池隔膜组装成CR2032型的钠离子负极半电池。

1.4 测试与表征

采用接触角测量仪对电解液在隔膜表面的接触角进行测试。

采用热重分析仪对隔膜的热稳定性进行分析测试。

采用蓝电电池测试系统测试隔膜的循环性能与倍率性能。

采用电化学工作站对测试体系为双离子阻塞电极和待测的滴加电解液的隔膜进行交流阻抗谱测试(EIS),其中离子阻塞电极使用的是不锈钢。通过式(1)对电导率进行计算:

$$ \gamma =\frac{d}{RS}\text{,} $$ (1) 式中:γ为离子电导率,mS·cm−1;R为隔膜电阻,Ω;S为隔膜面积,cm2;d为隔膜厚度,cm。每个试验设3组平行样。

采用万能力学试验机,以1 mm/min的速度拉伸规格为12 mm×45 mm的试样,测试隔膜的断裂伸长率。

采用傅里叶红外光谱(FTIR)对隔膜进行红外吸收光谱表征,扫描的波数范围为4000~300 cm−1。

采用扫描电子显微镜(SEM)对隔膜表面和横截面的微观形貌进行观察。

采用吸液法对隔膜的吸液率进行测试[15]。将隔膜放入手套箱中,以NaClO4/EC/PC电解液为浸润液,对浸液前后隔膜的质量进行测定,吸液率计算公式如式(2)所示:

$$A = \frac{{{m_1} - {m_0}}}{{{m_0}}} \times 100{\rm{{\text{%}} }}, $$ (2) 式中:A为隔膜的吸液率,%;m0、m1为隔膜浸泡电解液前、后的质量,g。每个试验设3组平行样。

采用正丁醇吸收法测量并计算隔膜的孔隙率,计算公式如式(3)所示:

$$ P = \frac{{{m_1} - {m_0}}}{{\rho V}} \times 100{\rm{{\text{%}} }}, $$ (3) 式中:P为隔膜的孔隙率,%;m0、m1分别为隔膜浸泡正丁醇前、后的质量,g; ρ为正丁醇的密度,g/cm3;V为隔膜的体积,cm3。每个试验设3组平行样[16]。

采用质量差法测试并计算在25 ℃室温下隔膜的电解液流失率,计算公式如式(4)所示:

$$ S'=\frac{M_0-M_1}{M_0}\times 100{\text{%}}\text{,} $$ (4) 式中:S′为隔膜的电解液流失率,%;M0、M1分别为隔膜在施加200 g重量前、后对电解液的吸收质量,g。每个试验设3组平行样[17]。

2. 结果与分析

2.1 隔膜的润湿性与吸液率

采用接触角测量仪对电解液在隔膜表面的接触角进行测试(图2),不同交联温度条件下制备的隔膜均能在0.033 s内快速吸收电解液溶剂EC/PC。在手套箱中采用吸液法对隔膜的电解液吸液率进行测定,不同交联温度条件下制备的隔膜吸液率均大于900%。这些结果表明,CMC/PAA气凝胶对电解液溶液的润湿性出色,有利于减少电池组装过程及电池组装后静置的时间,还能避免因电解液与电池隔膜之间浸润性不好而使得隔膜与极片之间存有过多气泡或者电池漏液的现象[12]。

2.2 隔膜的热稳定性

CMC-PAA气凝胶型隔膜的热重(Thermogravimetric,TG)分析曲线如图3a所示,所有气凝胶的失重曲线呈现相似趋势。在100 ℃之前质量快速下降是由于吸附水的脱除,在100~155 ℃之间,质量基本保持稳定,155~275 ℃时,质量再次下降,这主要是由于PAA中羧基会加速CMC的降解。随着温度的继续升高,失重速率在330 ℃达到峰值,此时PAA和CMC都发生了强烈的降解作用。由图3b可以看出,在322 ℃时130 ℃-CMC-PAA、140 ℃-CMC-PAA和150 ℃-CMC-PAA差热重量(Derivative thermogravimetric,DTG)分析曲线的峰值均略高于105 ℃-CMC-PAA的DTG峰值。其可能原因是高温热处理使得PAA的羧基和CMC的羟基发生脱水生成酯键,从而降低了CMC-PAA气凝胶体系中的羧基含量,因而热稳定性有所提高。

将130 ℃-CMC-PAA气凝胶型隔膜裁剪成直径为18 mm的圆片,分别在25℃(室温)及105、155和205 ℃静置2 h,结果如图4所示。205 ℃的热处理使气凝胶薄片的颜色发黄,结合图3a TG的结果可知,气凝胶薄片在该温度下发生轻微降解,但隔膜的尺寸基本保持不变,表明CMC-PAA气凝胶型隔膜拥有良好的耐热收缩特性和较高的分解温度,因此,当电池处于较高温度时,该隔膜依然可以起到有效隔绝电池的正、负极的作用,并防止电池短路发生爆炸等危险情况的发生。

2.3 电化学性能

图5a展示了在105、130、140和150 ℃交联温度下制备的Na/硬碳半电池的倍率性能,结果表明,130 ℃-CMC-PAA隔膜表现出最高的充电比容量。图5b展示了与商品玻璃纤维隔膜相比,Na/硬碳半电池在一系列电流密度下进行的充放电循环。一般来说,电流密度越大,充放电速率越快,这对电极和电解液的导电性和离子扩散速度的要求就会更高,若达不到要求,电极将产生极化,故随着电流密度的增加,比容量会有所降低。在25、50、100、250、500、1000和25 mA/g的电流密度下,130 ℃-CMC-PAA隔膜的充电比容量分别表现为345.8、317.3、274.2、136.8、84.8、61.8和341.4 mA·h/g,而在同样的电流密度条件下,玻璃纤维的充电比容量分别为279.0、233.1、190.5、105.9、69.6、49.4和275.1 mA·h/g。当从大电流1000 mA/g电流密度条件下的充放电速率回到25 mA/g电流密度条件下的充放电速率时,130 ℃-CMC-PAA隔膜的容量保持率(98.7%)略高于玻璃纤维隔膜的容量保持率(98.6%),不同电流密度的第一圈充放电循环如图5c所示。综上可知,使用130 ℃-CMC-PAA隔膜的Na/硬碳半电池具有良好的循环可逆性。

![]() 图 5 不同隔膜制备的钠离子半电池在室温条件下的电化学性能测试a:不同交联温度条件的隔膜制备的半电池在25、50、100、250、500和1 000 mA/g条件下测定的充电倍率曲线;b:130 ℃-CMC-PAA隔膜与玻璃纤维制备的半电池在25、50、100、250、500和1 000 mA/g条件下测定的充电倍率曲线; c:130 ℃-CMC-PAA隔膜制备的半电池在25、50、100、250、500和1 000 mA/g条件下测定的充电倍率曲线中第1、6、11、16、21、26周时的充放电曲线;d:130 ℃-CMC-PAA隔膜制备的半电池在25、50 mA/g条件下测定的充电倍率曲线Figure 5. Electrochemical performances of room-temperature sodium ion half cell with different separatorsa: The charge rate curves of the half cell prepared by separators under different cross-linking temperatures measured at 25, 50, 100, 250, 500 and 1 000 mA/g; b: The charge rate curves of the half cell prepared by 130 ℃-CMC-PAA separator and glass fiber measured at 25, 50, 100, 250, 500 and 1 000 mA/g; c: The charge-discharge curves in the week 1, 6, 11, 16, 21, 26 in the charge rate curves of the half cell prepared by 130 ℃-CMC-PAA separator measured at 25, 50, 100, 250, 500 and 1 000 mA/g; d: The charge rate curves of the half cell prepared by 130 ℃-CMC-PAA separator measured at 25, 50 mA/g

图 5 不同隔膜制备的钠离子半电池在室温条件下的电化学性能测试a:不同交联温度条件的隔膜制备的半电池在25、50、100、250、500和1 000 mA/g条件下测定的充电倍率曲线;b:130 ℃-CMC-PAA隔膜与玻璃纤维制备的半电池在25、50、100、250、500和1 000 mA/g条件下测定的充电倍率曲线; c:130 ℃-CMC-PAA隔膜制备的半电池在25、50、100、250、500和1 000 mA/g条件下测定的充电倍率曲线中第1、6、11、16、21、26周时的充放电曲线;d:130 ℃-CMC-PAA隔膜制备的半电池在25、50 mA/g条件下测定的充电倍率曲线Figure 5. Electrochemical performances of room-temperature sodium ion half cell with different separatorsa: The charge rate curves of the half cell prepared by separators under different cross-linking temperatures measured at 25, 50, 100, 250, 500 and 1 000 mA/g; b: The charge rate curves of the half cell prepared by 130 ℃-CMC-PAA separator and glass fiber measured at 25, 50, 100, 250, 500 and 1 000 mA/g; c: The charge-discharge curves in the week 1, 6, 11, 16, 21, 26 in the charge rate curves of the half cell prepared by 130 ℃-CMC-PAA separator measured at 25, 50, 100, 250, 500 and 1 000 mA/g; d: The charge rate curves of the half cell prepared by 130 ℃-CMC-PAA separator measured at 25, 50 mA/g图5d展示了130 ℃-CMC-PAA隔膜和玻璃纤维制备的Na/硬碳半电池的循环稳定性对比。以25 mA/g电流密度下的充放电速率充放电5个循环,进行充放电活化,再让其在50 mA/g的充放电速率下进行50次充放电循环[18]。经过55次充放电循环后,130 ℃-CMC-PAA隔膜的钠离子电池的充电比容量仍可达到270.2 mA·h/g,占初始充电比容量的92.5%,始终优于玻璃纤维隔膜制备的钠离子电池的充电比容量,且库伦效率一直保持在100%左右。

2.4 隔膜的离子电导率和电解液流失率

电化学阻抗谱是研究电化学界面过程的重要方法。用交流法测量带有电解液的隔膜的电化学阻抗谱图如图6所示。由高频区与实轴的交点计算出隔膜的电阻,通过式(1)进一步计算出离子电导率。105 ℃-CMC-PAA、130 ℃-CMC-PAA 、140 ℃-CMC-PAA 、150 ℃-CMC-PAA 隔膜和玻璃纤维的电阻和离子电导率如表1所示。由表1可以看出,本研究制备的CMC-PAA隔膜的离子电导率均低于玻璃纤维的离子电导率,且不同的交联温度对CMC-PAA隔膜的电阻和离子电导率有明显影响。与电化学性能相对应,离子电导率较高的130 ℃-CMC-PAA 和150 ℃-CMC-PAA隔膜在低电流条件下的充放电比容量更高。

表 1 隔膜的电阻与离子电导率Table 1. Ionic conductivity and resistance of separators隔膜种类

Types of

separatorsR隔膜/Ω

Resistance of

separatorsγ/(mS·cm−1)

Ionic conductivity105 ℃-CMC-PAA 12.48 1.079 130 ℃-CMC-PAA 5.52 1.877 140 ℃-CMC-PAA 10.40 1.143 150 ℃-CMC-PAA 5.32 1.928 玻璃纤维 Glass fiber 2.70 6.596 对比近年来各类改性得到的聚烯烃类材料、纤维素复合材料,其钠离子电池隔膜的离子电导率(表2)均低于CMC-PAA隔膜离子电导率(表1),因此CMC-PAA具有独特的优势。

表 2 各类隔膜的离子电导率Table 2. Ionic conductivity of different separators隔膜种类

Types of separatorsγ/(mS·cm−1)

Ionic conductivity纤维素-PAN-Al2O3复合隔膜 Cellulose–PAN-Al2O3 composite separator 0.751[19] PMTFSINa–接枝隔膜(接枝聚(1−[3(甲基丙烯酰氧基)丙基磺酰基]−1–(三氟甲磺酰基)亚胺钠)) 0.462[16] PMTFSINa-grafted separator (The grafted poly(1-[3(methacryloyloxy)propylsulfonyl]-1-(trifluoromethanesulfonyl)imide sodium)) 涂布有聚偏二氟乙烯–六氟丙烯(PVdF-HFP 共聚物)与ZrO2 纳米颗粒的聚乙烯(PE)隔膜 0.70[20] A polymeric coating layer of polyvinylidene fluoride–hexafluoropropylene (PVdF-HFP co-polymer) with ZrO2 nanoparticles to a polyethylene (PE) separator 聚乙烯 Polyethene 0.10[20] 无纺布/聚(偏二氟乙烯−共−六氟丙烯)/凝胶聚合物电解质 0.82[21] Commercial nonwovens/ Poly (Vinylidene fluoride-co-hexafluoropropylene) /Gel polymer electrolytes 西戈德 Celgard 0.16[21] 通过式(4)计算得到,玻璃纤维的电解液流失率为1.032%,这与Kim[22]的试验结果是相似的;130 ℃-CMC-PAA和150 ℃-CMC-PAA的电解液流失率分别为0.42%和0.64%,这解释了两者在离子电导率相似的情况下,130 ℃-CMC-PAA表现出更好的电化学性能的原因。

2.5 隔膜的FTIR分析

CMC-PAA隔膜的FTIR结果如图7所示。波数3 650~3200、2817、1605和1422 cm−1等位置出现的吸收峰,分别对应CMC中的O—H伸缩振动、CMC和PAA中的C—H伸缩振动、CMC和PAA中—COOH和—COONa的O=C—O—不对称拉伸和 O=C—O—的对称拉伸;波数1 743和1270 cm−1对应酯键中的C=O和C—O—C的伸缩振动[1,8,23]。

通过对比105 ℃-CMC-PAA 和 130 ℃-CMC-PAA的FTIR可以看出,随着交联温度的增加,波数3 650~3200 cm−1处对应的O—H峰和1605、1422 cm−1处对应的—COOH的O=C—O—峰有所降低,这是由于温度的增高,交联度增加,—OH和—COOH减少所致。这证明了随着交联温度的增高,CMC和PAA的交联度也会增加。

2.6 隔膜的断裂伸长率

断裂伸长率是指材料拉伸到断裂时的伸长率(应变率),称为断裂伸长率,用于表述材料能承受最大负荷时的伸长变形能力。对不同温度处理的CMC-PAA隔膜进行拉伸力学测试,结果如表3所示。

表 3 隔膜的电阻断裂伸长率Table 3. Elongation at break of resistance of separators隔膜种类

Types of separators断裂伸长率/%

Elongation at break105 ℃-CMC-PAA 13.06 130 ℃-CMC-PAA 16.35 140 ℃-CMC-PAA 16.36 150 ℃-CMC-PAA 12.70 2.7 隔膜微观形貌分析

如图8所示,CMC-PAA气凝胶的微观结构为三维多孔网络结构,这与冷冻干燥时的冰晶体积相关[24]。从表面和横截面微观结构对比可知,130 ℃-CMC-PAA的平均孔径略小于105 ℃-CMC-PAA的,可能原因是高温热处理气凝胶会使其宏观体积发生轻微收缩。进一步测定两者的孔隙率可知,105 ℃-CMC-PAA的孔隙率为78.93%,130 ℃-CMC-PAA的孔隙率为76.99%。

3. 讨论与结论

本文提出一种由羧甲基纤维素钠和聚丙烯酸2种环境友好型原料制备的气凝胶型隔膜,该隔膜直接以水为溶剂,通过改变制备过程中的交联温度控制隔膜的孔隙率以及孔隙结构,并探究其对隔膜孔结构的影响以及对钠离子电池电化学性能的影响。

对105 、130 、140 和150 ℃温度下交联的CMC-PAA气凝胶型隔膜的测定结果显示, 130 ℃下交联的隔膜具有最佳的性能。在25、50、100、250、500和1 000 mA/g的电流密度下,该隔膜充电放电的比容量均优于玻璃纤维,在简单循环55圈后的充电比容量仍能达到初始状态的92.5%。

基于电化学性能的差异,对隔膜的离子电导率进行了测试,虽然130 ℃-CMC-PAA和150 ℃-CMC-PAA隔膜的离子电导率分别为1.877和1.928 mS/cm,均小于玻璃纤维的离子电导率,但与传统Celgard和其他改性聚烯烃类隔膜相比,其离子电导率是具有优势的。130 ℃-CMC-PAA更低的电解液流失率是其电化学性能优于 150 ℃-CMC-PAA的原因之一;与玻璃纤维相比,更低的电解液流失率降低了液体电解质的泄漏和可能引发爆炸的易燃性风险[24]。

通过SEM图可看出,105 ℃-CMC-PAA和130 ℃-CMC-PAA隔膜的孔径为20~200 µm。这是由于在制备过程中选用冰箱–20 ℃预冷冻,其降温的速度较液氮冷冻慢,而冷冻温度直接决定冷却速率,冷冻速度越慢, 冰晶生长速度越慢, 体积越大[23]。与玻璃纤维的微观结构不同,气凝胶蜂窝状的微观结构更加均匀,一层层的3D立体结构可作为屏障防止杂质从电极渗透,从而使电池有更好的稳定性[22]。对其微观形貌和孔隙率进行对比可知,交联温度升高,孔径会减小,孔隙率也会降低, Yu等[24]的试验也证明了这一点。同时这解释了离子电导率较高的130 ℃-CMC-PAA 和150 ℃-CMC-PAA隔膜在低电流条件下的充放电比容量更高,但在高电流条件下,更高孔隙率的130 ℃-CMC-PAA隔膜电化学性能优于150 ℃-CMC-PAA隔膜的原因。虽然较高孔隙率的结构有利于电解液的吸附与流动,使隔膜对电解液有较好的润湿性和吸液率。但是隔膜上的孔径也不能太大[3]。孙仁诣[25]利用PAA和聚氧乙烯2种高分子交联制备隔膜,该膜具有分布均匀的蜂窝状的孔状结构,并证明了这种分布集中、大小均匀的3D孔状、密集蜂窝状孔结构,更加利于电解液的存储以及离子的传导[26]。

通过对比105 ℃-CMC-PAA和130 ℃-CMC-PAA隔膜的FTIR可知,交联度会因为交联温度的升高而有所上升,高温热处理还会使PAA的羧基和CMC的羟基发生反应,脱水生成酯键,从而降低CMC-PAA气凝胶体系中的羧基含量,大极性羧酸酯基团的存在也能提高热稳定性[27]。因而130 ℃-CMC-PAA隔膜的热稳定性有所提高,使其在高温下拥有更加优于传统聚烯烃类材料的热稳定性。

尹爱淑[26]通过纳米纤维素化学交联聚丙烯酰胺制备出机械性能良好、恢复能力强的二元复合水凝胶,证明了通过化学交联的弹性聚丙烯酰胺网络,可以防止凝胶的永久性塑性变形聚。Surapolchai 等[28]的研究证明,与非相互作用微晶纤维素相比,羧甲基纤维素的自缔合显著提高了气凝胶的机械性能。对隔膜进行拉伸力学测试,随着温度的增高,化学交联度增加,130 ℃-CMC-PAA和140 ℃-CMC-PAA隔膜表现出比105 ℃-CMC-PAA隔膜更良好的力学性能;但随着处理温度的进一步升高,交联点增加,分子链的柔性减小,隔膜脆性增加,导致150 ℃-CMC-PAA的断裂伸长率低于105 ℃-CMC-PAA隔膜。由此可见,随着交联温度在一定范围内的提高,隔膜的力学性能增强,孔结构更加坚固,减少在电池制备过程中隔膜孔结构坍塌的可能性,降低了电阻[29]。未来可进一步探究CMC-PAA隔膜中2种组分的比例对隔膜孔径大小的影响,以及隔膜中—COOH含量对钠离子通过的影响,从而探究提高其在钠离子电池中应用的可能性。

-

表 1 因素水平表

Table 1 Factor-level table

水平

Level激光功率/W

Laser power光斑直径/mm

Spot diameter扫描速度/(mm·s−1)

Scanning speed−1.682 163 0.53 166 −1 170 0.60 200 0 180 0.70 250 +1 190 0.80 300 +1.682 197 0.87 334 表 2 试验设计与结果

Table 2 Experiment design and result

试样编号

Sample number因素 Factor 硬度/HV

Hardness激光功率 Laser power 光斑直径 Spot diameter 扫描速度 Scanning speed 1 −1 −1 −1 545.36 2 1 −1 −1 600.13 3 −1 1 −1 520.86 4 1 1 −1 637.81 5 −1 −1 1 530.77 6 1 −1 1 515.00 7 −1 1 1 592.02 8 1 1 1 560.35 9 −1.682 0 0 532.10 10 +1.682 0 0 695.13 11 0 −1.682 0 534.76 12 0 +1.682 0 658.30 13 0 0 −1.682 627.76 14 0 0 +1.682 521.55 15 0 0 0 644.24 16 0 0 0 680.32 17 0 0 0 659.18 18 0 0 0 663.26 19 0 0 0 687.08 20 0 0 0 631.29 表 3 方差分析表1)

Table 3 Variance analysis table

变异来源 Variance source SS DF MS F P 模型 Model 65 184.71 9 7 242.75 6.14 0.004 5 A 11 625.85 1 11 625.85 9.86 0.010 5 B 7 855.99 1 7 855.99 6.66 0.027 4 C 5 932.68 1 5 932.68 5.03 0.048 8 AB 267.73 1 267.73 0.23 0.644 0 AC 6 003.89 1 6 003.89 5.09 0.047 7 BC 1 090.91 1 1 090.91 0.93 0.358 8 A2 7 396.70 1 7 396.70 6.27 0.031 2 B2 11 866.84 1 11 866.84 10.06 0.010 0 C2 19 125.48 1 19 125.48 16.22 0.002 4 残差 Residual 11 792.58 10 1 179.26 失拟项 Lack of fit 9 567.22 5 1 913.44 4.30 0.067 7 纯误差 Pure error 2 225.36 5 445.07 总计 Total 76 977.29 19 1)A、B、C分别为激光功率、光斑直径、扫描速度

1) A, B and C indicated laser power, spot diameter and scanning speed, respectively -

[1] 张继英, 蒋梅峰, 朱志昂. 实验室小麦磨粉机换辊前后小麦粉品质特性分析[J]. 粮食科技与经济, 2017, 42(3): 49-51. [2] 张克平, 姜良朋, 姚亚萍. 白口铁抗小麦籽粒粉料的磨料磨损试验研究[J]. 中国粮油学报, 2017, 32(1): 109-112. doi: 10.3969/j.issn.1003-0174.2017.01.019 [3] 张克平, 姜良朋, 王久鑫. 不同铬含量白口铸铁的抗小麦粉料磨粒磨损性能[J]. 机械工程材料, 2016, 40(12): 57-60. doi: 10.11973/jxgccl201612013 [4] 张克平, 姜良朋, 黄晓鹏. 小麦磨粉机磨辊材料抗磨损热处理工艺优化[J]. 农业工程学报, 2016, 32(21): 271-276. doi: 10.11975/j.issn.1002-6819.2016.21.037 [5] 吴家祥, 张克平. 小麦制粉过程中辊间压力对磨辊磨损性能的影响[J]. 中国农机化学报, 2015, 36(1): 157-159. [6] 张克平, 吴家祥, 姚亚萍. 影响磨辊磨损失重的技术参数优化[J]. 中国粮油学报, 2016, 31(5): 117-121. doi: 10.3969/j.issn.1003-0174.2016.05.023 [7] 艾云龙, 陈卫华, 丁家圆, 等. 低碳高铬白口铸铁热处理工艺研究[J]. 金属热处理, 2011, 36(6): 107-111. [8] 艾莹珺, 艾云龙, 丁家圆, 等. 热处理对高铬白口铸铁组织与性能的影响[J]. 热加工工艺, 2010, 39(16): 133-135. doi: 10.3969/j.issn.1001-3814.2010.16.040 [9] 苏超然, 吕长乐, 师陆冰, 等. 激光离散淬火对球墨铸铁磨损与损伤性能的影响[J]. 表面技术, 2018, 47(11): 85-90. [10] 刘庆刚, 郭彦书, 于新奇, 等. 激光表面淬火工艺对表面硬度影响实验研究[J]. 制造业自动化, 2018, 40(8): 10-11. doi: 10.3969/j.issn.1009-0134.2018.08.003 [11] 张开熙, 刘永超, 周铁军, 等. 激光淬火在汽车模具制造业中的应用研究[J]. 模具制造, 2018, 18(11): 78-81. [12] 符轲, 张修庆, 续晓霄, 等. 45钢激光淬火工艺优化及性能[J]. 金属热处理, 2017, 42(1): 154-158. [13] 钱振华. 激光微织构技术在关节轴承表面处理中的应用[J]. 机械制造, 2018, 56(7): 85-88. doi: 10.3969/j.issn.1000-4998.2018.07.024 [14] 覃敏. 激光表面处理技术在重工业领域的研究和应用进展[J]. 装备制造技术, 2017(12): 51-53. doi: 10.3969/j.issn.1672-545X.2017.12.016 [15] 封亚明, 何柏林, 江明明, 等. 表面技术在模具制造和修复中的应用[J]. 热加工工艺, 2018, 47(4): 30-34. [16] 何柏林, 江明明. 激光淬火技术在模具表面处理中的应用与展望[J]. 表面技术, 2016, 45(11): 180-186. [17] 刘红宇, 张雷, 黄雄荣. 激光表面改性技术及其在轴承上的应用[J]. 热处理, 2018, 33(3): 40-43. doi: 10.3969/j.issn.1008-1690.2018.03.009 [18] 苏辉, 马冰, 依颖辉, 等. 42CrMo钢激光淬火组织和硬度的研究[J]. 兵器材料科学与工程, 2011, 34(2): 84-86. doi: 10.3969/j.issn.1004-244X.2011.02.025 [19] 万芳新, 黄晓鹏, 吴劲锋, 等. 激光淬火功率对45#钢抗植物磨料磨损性能的影响[J]. 材料科学与工程学报, 2017, 35(5): 719-723. [20] 郜飞飞, 王敬忠, 包汉生. 激光淬火工艺参数对HT210淬硬层深及硬度的影响[J]. 物理测试, 2017, 35(5): 20-25. [21] 贺长林, 陈少克, 周中河, 等. 模具钢718激光淬火的工艺参数研究[J]. 热加工工艺, 2012, 41(20): 169-172. [22] 华希俊, 郝静文, 王蓉, 等. 泥浆泵高铬铸铁材料激光淬火技术及其摩擦磨损性能研究[J]. 表面技术, 2017, 46(6): 215-220. -

期刊类型引用(2)

1. 赵岩,祝文慧,赵晓军,殷辉,任璐,周建波. 不同诱孢方法对辣椒疫霉菌孢子囊消长动态的影响. 山西农业科学. 2023(04): 400-405 .  百度学术

百度学术

2. 孔广辉,冯迪南,李雯,连帅利,习平根,姜子德. 荔枝霜疫病的研究进展. 果树学报. 2021(04): 603-612 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: