Design and test of seed cleaning device of pneumatic metering device for rice

-

摘要:目的

为了改善水稻气力式排种器工作时稻种的重吸附现象,设计了一种垂直于排种盘平面的清种装置。

方法对水稻气力式排种器工作时稻种的受力与清种装置的工作原理进行了分析,建立了吸种过程中的受力模型。采用超级杂交稻‘五丰优615’为试验对象,在有、无清种装置的条件下进行了排种器的精度试验。在吸室负压为4.0 kPa的条件下,进行了清种块厚度和排种盘转速的两因素试验分析。

结果采用清种装置后,1~3粒/穴的占比由62.02%提升至90.00%左右,≥4粒/穴的占比由37.98%降至5.00%,改进效果较为明显。当清种块厚度为3.5 mm、排种盘转速为15、20和25 r/min时,1、2和3粒/穴的占比分别为95.18%、95.16%和95.23%,空穴率分别为2.07%、2.76%和4.56%,满足超级杂交稻的田间播种需求。

结论当吸室负压一定时,降低排种盘转速可以提高清种装置的清种效果,提高排种器的播种精度。本文针对水稻气力式排种器的结构,设计了一种清种装置,有效地清除了排种器重吸附的稻种,为提高水稻气力式排种器的精度提供了依据。

Abstract:ObjectiveIn order to reduce the reabsorption of rice seeds in pneumatic metering device, a seed cleaning device vertical to the surface of the seed metering plate was designed.

MethodThe force acting on rice seed and the working principle of the seed cleaning device were analyzed when the pneumatic metering device was working, and the force model during the seed suction process was established. The super hybrid rice ‘Wufengyou 615’ was used as the experimental object. The precision test of seed metering device was carried out with or without seed cleaning device. Under a negative pressure of 4.0 kPa in the suction chamber, the effects of two factors, including the thickness of seed cleaning block and the rotational speed of seed metering plate, on seed cleaning were tested and analyzed.

ResultAfter using the seed cleaning device, the ratio of 1−3 seeds per hill increased from 62.02% to 90.00%, and the ratio of ≥4 seeds per hill decreased from 37.98% to 5.00%. When the thickness of seed cleaning block was 3.5 mm and the rotational speeds of seed metering plate were 15, 20 and 25 r/min respectively, the ratios of 1, 2 and 3 seeds per hill were 95.18%, 95.16% and 95.23% respectively, and the missing hill rates were 2.07%, 2.76% and 4.56% respectively, which met the requirements of field sowing for super hybrid rice.

ConclusionWhen the negative pressure in suction chamber is constant, reducing the rotational speed of seed plate can improve the cleaning effect of the seed cleaning device and the sowing precision of the seed metering device. Based on the structure of rice pneumatic metering device, we designed a seed cleaning device which can effectively clear rice seeds adsorbed by the seed metering device, and this research provides a basis for improving the precision of rice pneumatic metering device.

-

Keywords:

- rice /

- seed cleaning device /

- pneumatic metering device /

- readsorption /

- precision

-

-

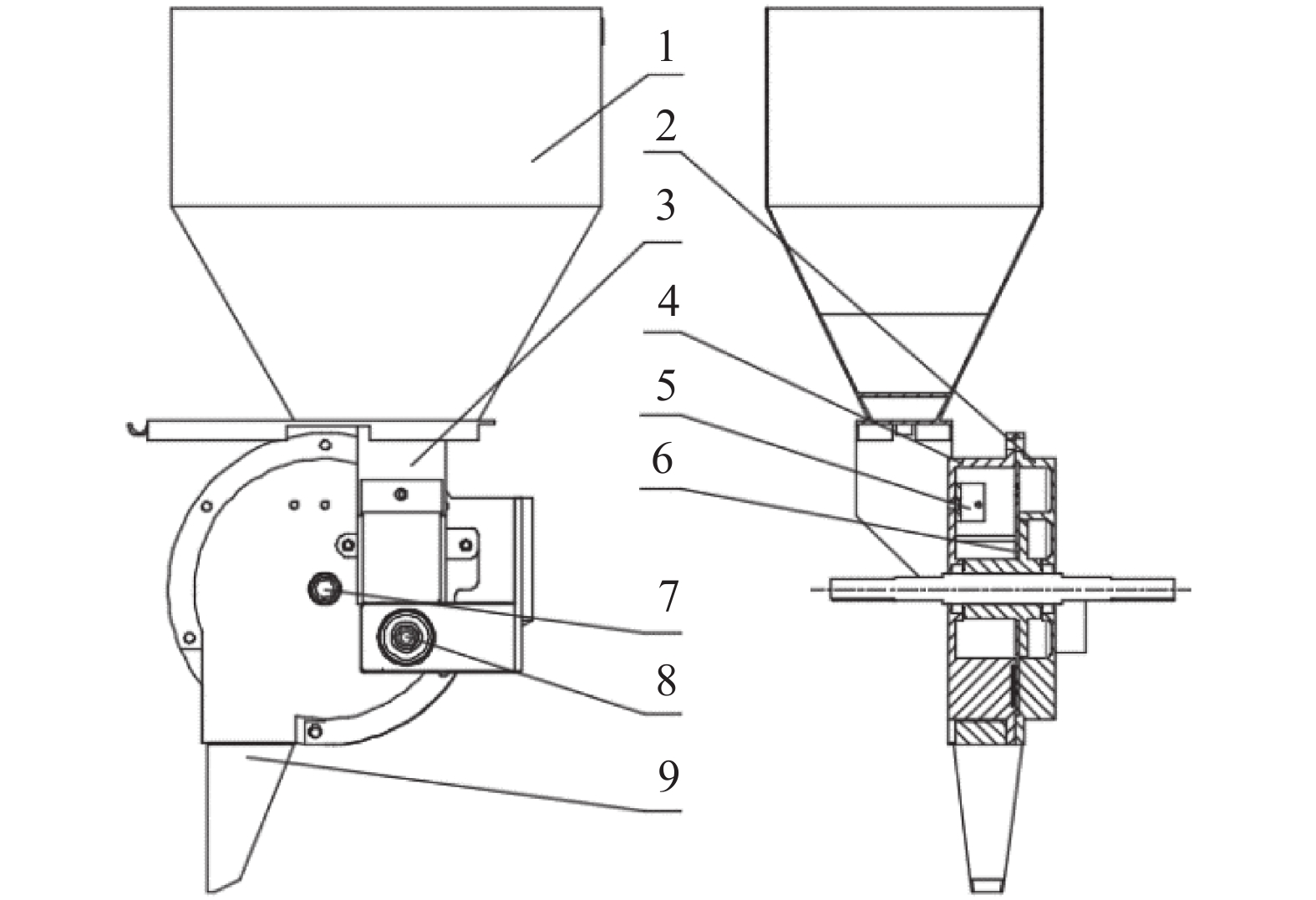

图 1 水稻气力式排种器结构图

1:种箱,2:气吸壳体,3:分层充种室,4:排种壳体,5:清种装置,6:排种盘,7:排种轴,8:搅种装置,9:排种管

Figure 1. Structural diagram of pneumatic seed metering device for rice

1: Seed box, 2: Gas chamber shell, 3: Stratified seed filling room, 4: Seed metering shell, 5: Seed cleaning device, 6: Seed metering plate, 7: Seed metering shaft, 8: Seed stirring device, 9: Seed metering tube

表 1 清种试验因素水平

Table 1 Factors and levels of seed cleaning test

水平 Level 因素 Factor 清种块厚度/mm Thickness of seed cleaning block (A) 排种盘转速/(r·min−1) Rotational speed of seed metering plate (B) 1 3.0 15 2 3.5 20 3 4.0 25 表 2 清种试验结果及方差分析1)

Table 2 Seed cleaning test results and variance analysis

试验序号

Test No.因素和水平

Factor and level不同充种状况的占比/%

Percentage of different seed filling conditionA B 空穴

0 seed per hill1粒/穴

1 seed per hill2粒/穴

2 seeds per hill3粒/穴

3 seeds per hill≥4粒/穴

≥4 seeds per hill1~3粒/穴

1~3 seeds per hill1 1 1 0.66 11.96 51.38 29.96 6.04 93.30 2 1 2 0.79 13.07 52.58 27.86 5.70 93.51 3 1 3 0.87 18.86 50.06 25.41 4.80 94.33 4 2 1 1.33 13.52 55.50 26.16 3.49 95.18 5 2 2 2.07 15.42 57.74 22.00 2.77 95.16 6 2 3 2.76 19.71 56.88 18.64 2.01 95.23 7 3 1 4.56 17.63 52.62 21.66 3.53 91.91 8 3 2 6.86 20.97 54.84 15.72 1.61 91.53 9 3 3 10.51 25.91 50.31 11.89 1.38 88.11 10 0 1.20 24.30 36.52 37.98 62.02 SS A 0.007 0.008 0.005 0.019 0.002 0.003 B 0.001 0.008 0.001 0.008 0 0 MS A 0.004 0.004 0.002 0.010 0.001 0.002 B 0 0.004 0.001 0.004 0 0 F A 15.381 78.396 19.235 52.248 55.754 8.759 B 2.070 80.999 4.502 21.701 11.734 0.393 P A 0.013* 0.001** 0.009** 0.001** 0.001** 0.035* B 0.242 0.001** 0.095 0.007** 0.021* 0.698 1) df=2; “*”和“**”分别表示影响达到0.05和0.01的显著水平

1) df=2; “*” and “**” indicate the effect reaches 0.05 and 0.01 significance levels respectively -

[1] PANDEY S, VELASCO L. Trends in crop establishment methods in Asia andresearch issues[C]//IRRI. Rice is Life: Scientific Perspectives for the 21st Century, Proceedings of the World Rice Research Conference. Tsukuba: IRRI, 2004: 178-181.

[2] FAROOQ M, SHAHZAD M A, BASRA N, et al. Enhancing the performance of transplanted coarse rice by seed priming[J]. Paddy Water Environ, 2009, 7(1): 55-63. doi: 10.1007/s10333-008-0143-9

[3] 张洪程, 龚金龙. 中国水稻种植机械化高产农艺研究现状及发展探[J]. 中国农业科学, 2014, 47(7): 1273-1289. doi: 10.3864/j.issn.0578-1752.2014.07.004 [4] 郑天翔, 唐湘如, 罗锡文, 等. 不同灌溉方式对精量穴直播超级稻产生的影响[J]. 农业工程学报, 2010, 26(8): 52-55. doi: 10.3969/j.issn.1002-6819.2010.08.008 [5] ISMET O, DEGIRMENCIOGLU A, YAZGI A. An evaluation of seed spacing accuracy of a vacuum type precision metering unit based on theoretical considerations and experiments[J]. Turk J of Agric For, 2012, 36: 133-144.

[6] GAIKWAD B B, SIROHI N P S. Design of a low-cost pneumatic seeder for nursery plug trays[J]. Biosyst Eng, 2008, 99(10): 322-329.

[7] YASIR S H. Design and test of a pneumatic precision metering device for wheat[D]. Wuhan: Huazhong Agricultural University, 2011.

[8] YAZGI A, DEGIRMENCIOGLU A. Measurement of seed spacing uniformity performance of a precision metering unit as function of the number of holes on vacuum plate[J]. Measurement, 2014, 56(6): 128-135.

[9] JACK D S, HESTERMAN D C, GUZZOMI A. Precision metering of Santalum spicatum (Australian Sandalwood) seeds[J]. Biosyst Eng, 2013, 115(3): 171-183.

[10] KARAYEL D. Performance of a modified precision vacuum seeder for no-till sowing of maize and soybean[J]. Soil Till Res, 2009, 104(2): 121-125.

[11] 赵月霞, 蹇兴东. 机械式精密排种器清种过程分析[J]. 农业机械学报, 2006, 37(11): 133-134. doi: 10.3969/j.issn.1000-1298.2006.11.035 [12] 祁兵, 张东兴, 刘全威, 等. 集排式精量排种器清种装置设计与性能试验[J]. 农业工程学报, 2015, 31(1): 20-27. doi: 10.3969/j.issn.1002-6819.2015.01.003 [13] 李成华, 夏建满, 何波. 倾斜圆盘勺式精密排种器清种过程分析与试验[J]. 农业机械学报, 2004, 35(3): 68-72. doi: 10.3969/j.issn.1000-1298.2004.03.019 [14] 李兆东, 李姗姗, 曹秀英, 等. 油菜精量气压式集排器排种性能试验[J]. 农业工程学报, 2015, 31(18): 17-25. doi: 10.11975/j.issn.1002-6819.2015.18.004 [15] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 单粒(精密)播种机试验方法: GB/T 6973-2005 [S]. 北京: 中国标准出版社, 2005.

下载:

下载: