Design and experiment of the beating-leveler controlled by laser for paddy field

-

摘要:目的

满足水稻种植对田面平整度的要求,减少拖拉机进田次数,提高打浆平地质量和效果,实现一次进田完成水田打浆和平地作业。

方法采用先打浆后平地原理,设计了激光控制水田打浆平地机、打浆机与平地铲自动调平机构、平地铲高程自动调节机构和通过集成带自动调平的激光平地控制系统,并进行田间试验;利用2台姿态航向参考系统分别测量拖拉机车身和打浆平地机的横滚角,采用水准测量试验田块作业前后的田面平整度。

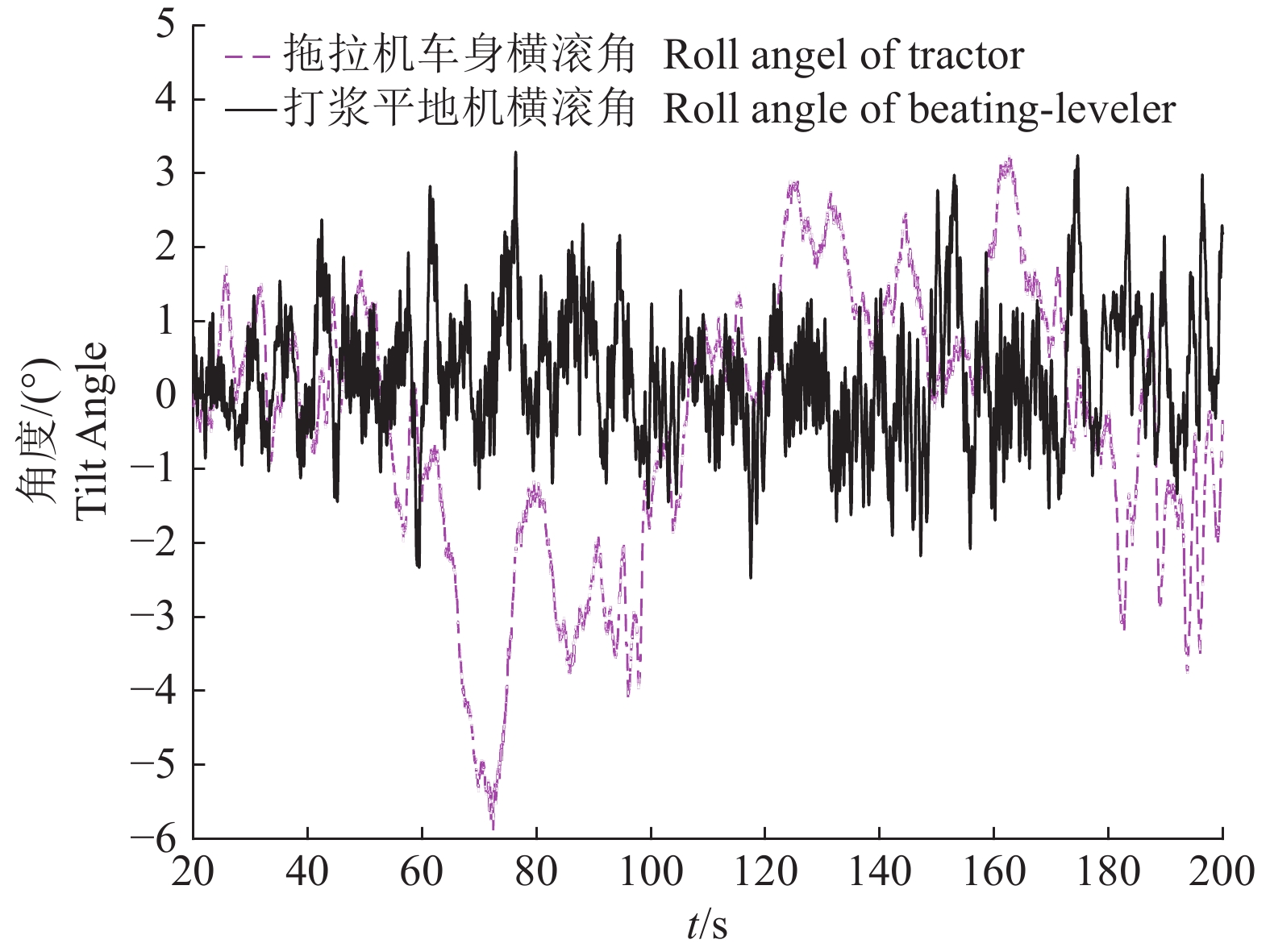

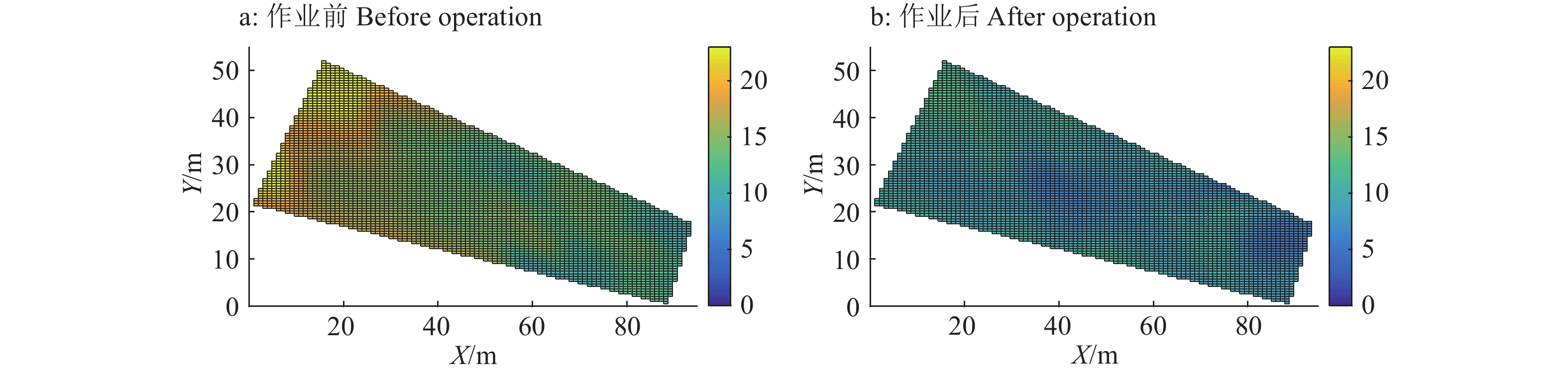

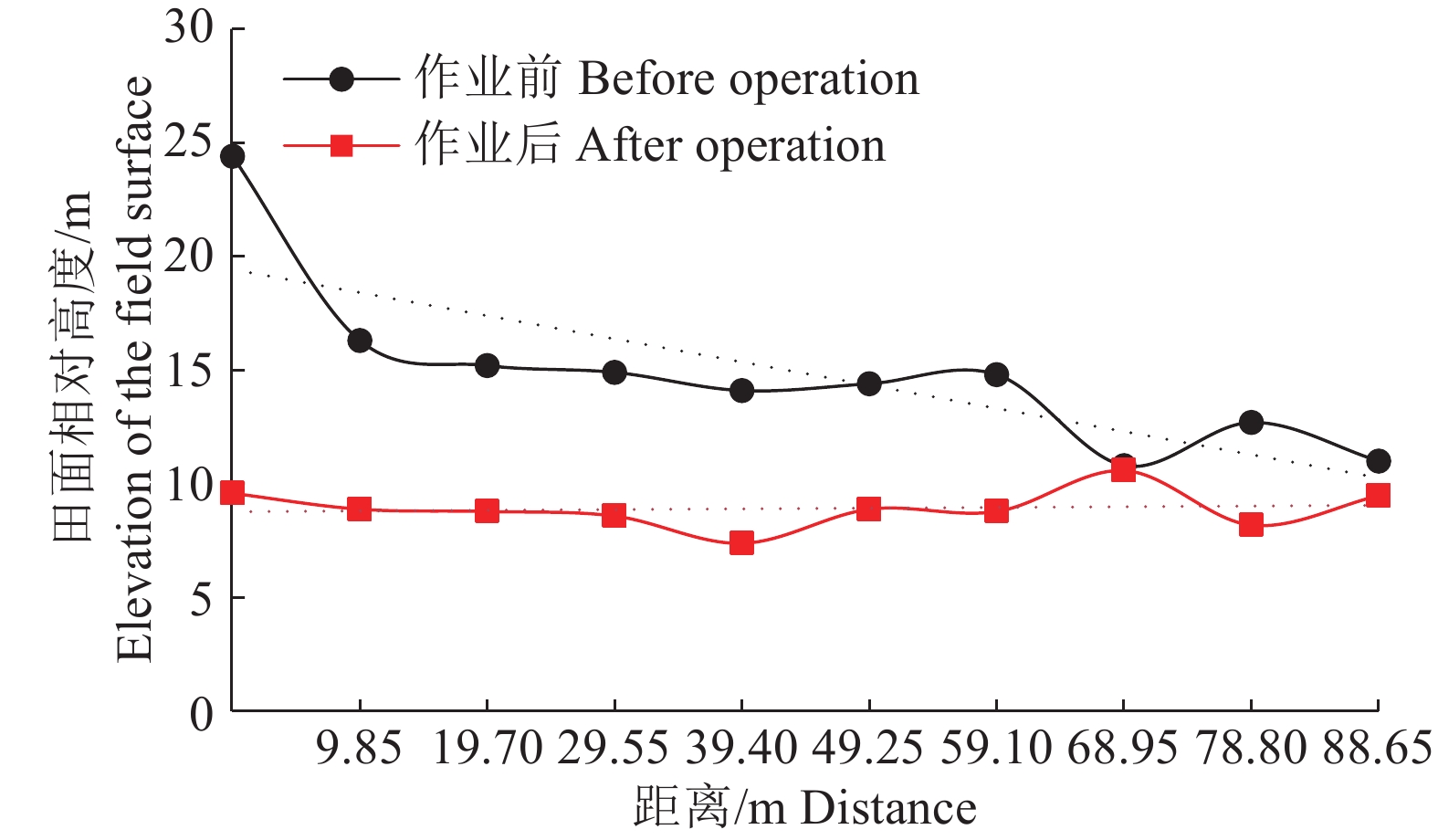

结果拖拉机横滚角在±4.5°内变化,打浆平地机的横滚角始终保持在±1°内,表明调平自动控制系统明显提高了水田打浆平地机构水平稳定性;打浆平地作业后田面最大高差从作业前的17.7 cm降低到6.7 cm,标准偏差值从作业前的4.08 cm下降到1.75 cm,绝对差值不大于3 cm的平整度采样点占比由作业前的62%提高到82%以上。

结论激光控制水田打浆平地机打浆平地作业后可显著改善田面平整情况。

Abstract:ObjectiveTo meet the requirement of field flatness in rice planting, reduce the number of times that tractors enter the field, improve the effect and quality of beating and leveling, and realize beating and leveling through one field entry.

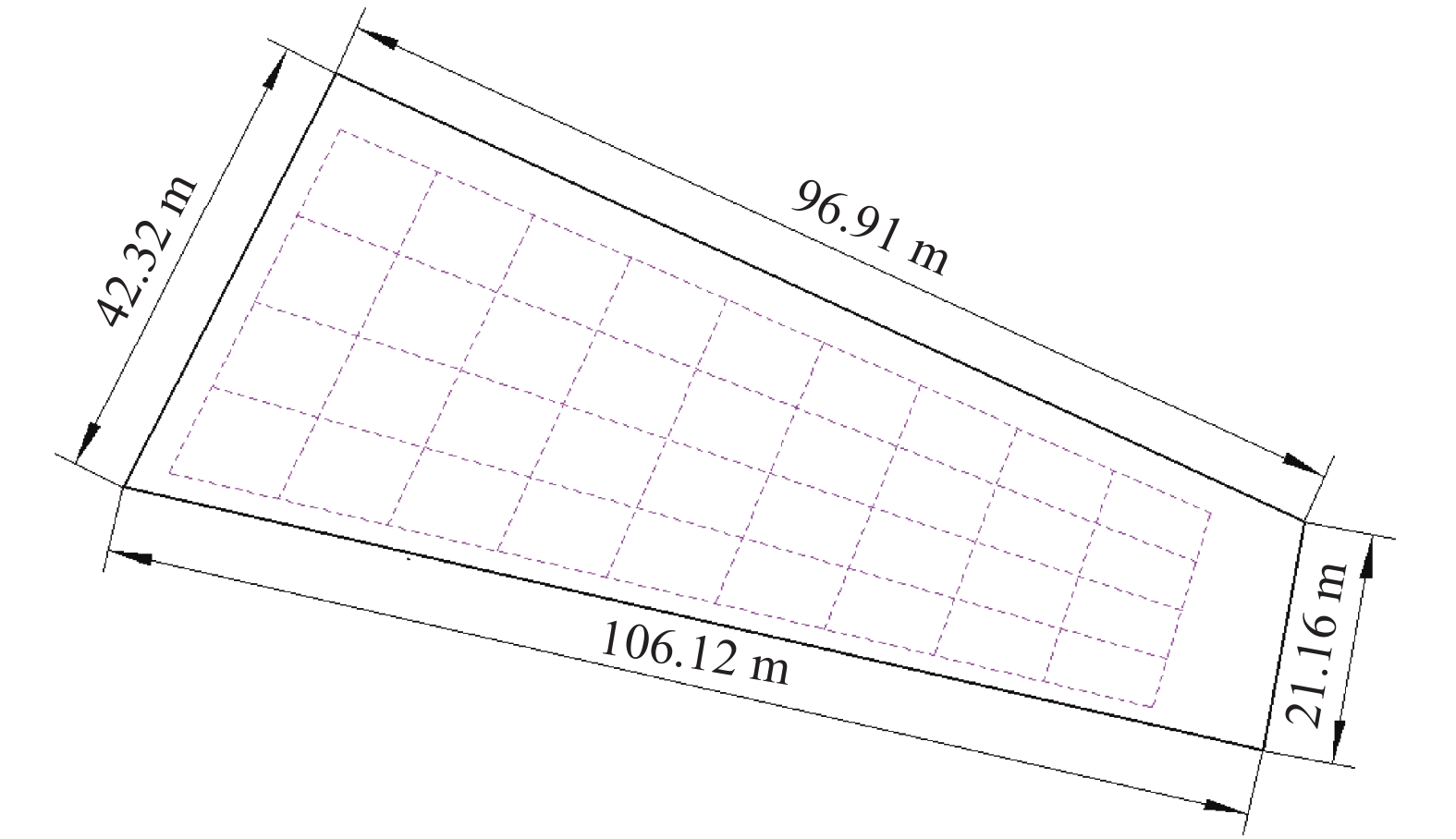

MethodA beating-leveler was developed using the principle of beating followed with leveling. The beating machine, automatic leveling mechanism and automatic elevation adjusting mechanism were developed. Field experiments were performed using the laser-controlled leveling system integrated with automatic leveling function. The roll angles of the tractor and the beating-leveler were respectively measured using two attitude and heading reference systems (AHRS). Field flatness before and after leveling operation was measured using a balance level.

ResultThe roll angle of the beating-leveler maintained within ±1°, while the roll angle of the tractor varied within ±4.5°, indicating that the automatic leveling system obviously improved the leveling stability of the beating-leveler in paddy field. The maximum height difference of the field surface reduced from 17.7 cm (before operation) to 6.7 cm (after operation). Its standard deviation reduced from 4.08 cm (before operation) to 1.75 cm (after operation). The percentage of sampling points with absolute difference of ≤ 3 cm increased from 62% (before operation) to 82% (after operation).

ConclusionThe laser-controlled beating-leveler can significantly enhance the flatness of the field surface.

-

Keywords:

- laser-control /

- beating-leveler /

- paddy field /

- surface flatness

-

砷(As)是土壤污染中常见的有毒元素之一。我国首次土壤污染普查结果显示,As的点位超标率为2.7%[1]。As不仅危害作物,还通过食物链影响人体健康[2-3]。水稻是我国重要粮食作物之一,供应了我国40%的粮食[4],但当前稻田中As污染非常严重[5-7],如何修复As污染土壤及减少水稻糙米中As累积成为近几年的研究热点[8]。如今降低稻米As含量的研究很多,如挑选低As积累水稻品种在污染区种植[9],加入不同的外源添加剂或施硅肥等[7],有研究表明改变水稻种植期间水分条件也可以减少水稻糙米As累积[10]。目前常用的土壤As污染修复方法有物理化学修复[11-12]和植物修复[13-14],植物修复是通过植物转移、吸收土壤中的As以降低土壤中As含量,达到修复土壤的目的。植物修复是目前最热门的修复技术之一。有研究显示,对轻度As污染的土壤,种植1~2次粉叶蕨可使土壤中As含量降到环境安全标准以下[15]。Ampiah-Bonney等[16]用蓉草Leersia oryzoides修复As含量为110 mg·kg−1的污染土壤时,发现种植蓉草16周后可从1 hm2土壤中提取130 g As,效果显著。

水稻与其他作物间作可以提高对土壤养分的利用效率,增加作物产量[17],同时减少水稻对重金属的吸收[18],减缓重金属对水稻的胁迫。宁川川等[19]发现水稻和雍菜间作可以促进水稻对硅和氮的吸收,增强水稻的竞争能力;吴华杰等[20]在镉污染土壤上间作小麦与水稻,发现2种作物地上部镉吸收和累积量都有所降低。苋菜在我国消费量较大,不仅是人类的食用蔬菜,还可以用作牲畜饲料,具有一定的重金属修复潜力。不同苋菜品种的As吸收能力已有过相关研究,如张骞等[21]研究发现不同品种苋菜的地上部As含量差异显著,说明不同苋菜品种对As的吸收能力存在差异。水稻与不同品种苋菜间作,能否边生产边修复,在尽可能多地修复污染土壤的同时生产出能够安全食用的水稻或者苋菜。这是个值得探讨的问题,基于此,本文选取水稻与3种生物量较大的苋菜品种进行间作,探讨在As污染土壤间作水稻与苋菜实现边生产边修复的可能性。

1. 材料与方法

1.1 试验材料与试验区

试验采用的水稻品种为领科8号,3种苋菜品种分别为圆叶白苋菜、籽粒苋与红苋菜,试验地点位于广东省广州市天河区华南农业大学生态系农场(E113°37′,N23°16′)。使用水泥池进行小区试验,水泥池规格为长1 m、宽1 m、高0.65 m。水泥池土壤来自连续种植3年水稻的As污染稻田,基本化学性质:pH 6.45,有机质25.02 g·kg−1,铵态氮23.12 mg·kg−1,速效磷120.66 mg·kg−1,速效钾137.20 mg·kg−1,总As 66.40 mg·kg−1。

1.2 试验设计

以高畦(畦高5 cm,种植苋菜,保持不淹水)深沟(种植水稻,保持淹水)的方式间作,畦沟面积比为1∶1。试验设置4个处理,每个处理重复3次,4个处理分别为:水稻与圆叶白苋菜间作、水稻与籽粒苋间作、水稻与红苋菜间作、水稻单作(对照)。采用小区试验,间作时每个小区种植8株水稻与8株苋菜,均分2行种植,每行4株,株行距均20 cm,对照处理每个小区种植16株水稻。水稻育秧于温室大棚进行,育秧时间为2017年8月1日—8月20日,在“三叶一心”期(2017年8月21日)移栽,苋菜同步播种并在真叶期后间苗。水稻秧苗移栽后土壤表层保持2 cm水层,苋菜畦面保持土壤湿润不淹水。植株样品和土壤样品在水稻收获期取样测定,取样时间为2017年11月27日。每个试验小区均设置保护行,统一用自来水浇灌。

1.3 样品处理与分析

植株样品:每小区取水稻和苋菜各1株。样株先用自来水冲洗干净,再用去离子水反复冲洗叶片与根部后,置于105 ℃烘箱中杀青30 min,然后在60 ℃烘干至恒质量。获得样品的地上部、地下部干质量后,粉碎备用。

土壤样品:水稻取样后,将水稻根系上附着的土壤用镊子轻轻剥离,作为根际土壤,风干后磨碎,过1 mm筛备用。

总As含量测定:称取0.2 g植物干样置于消解管中,通风橱内先加入8 mL硝酸,再加入2 mL体积分数为30%的过氧化氢,随后进行微波消解,消解液中总As含量用双道原子荧光光度计(AFS-230E,北京科创海光仪器有限公司)测定。样品制备和测定过程均用植物标准样品GBW(E)100349进行质量控制。

水稻经济产量按理论产量计算。单位面积产量=每个水泥池总有效穗数×每穗粒数×千粒质量/1 000。

土壤速效养分含量测定:采用联合浸提−比色法测定,具体参考中华人民共和国农业部发布的标准NY/T 1849—2010[22]。

土壤有机质含量测定:风干土壤样品过100目筛后,先用1 mol·L−1 HCl溶液浸泡0.5 h,然后于105 ℃烘干,称取约25 mg包进锡舟中,用TOC测定仪测定有机碳(C)含量。w(有机质) =w(C)×10×1.724,1.724是土壤有机碳换算成土壤有机质的平均换算系数。

1.4 数据统计与分析

试验结果用Microsoft Excel 2003和SPSS 18.0进行数据处理和分析,数据统计分析方法为单因素方差分析,数据结果用3次重复的平均值±标准误表示。

2. 结果与分析

2.1 间作对水稻生物量(干质量)及产量的影响

由表1可知,4个处理中水稻单株地上部生物量最大的为与圆叶白苋菜间作,显著高于对照、与籽粒苋间作和与红苋菜间作,比对照提高63.28%。4个处理间单株地下部生物量差异不显著。与对照相比,间作处理水稻千粒质量与每穗粒数无显著变化,水稻与圆叶白苋菜间作单株产量最高,显著高于与籽粒苋和红苋菜间作;间作处理每个试验小区种植8株水稻,仅为对照的一半,导致间作条件下每试验小区的水稻总有效穗数均显著降低;对照处理水稻产量为185.34 g·m−2,间作处理水稻产量较对照均有不同程度下降,水稻与圆叶白苋菜、籽粒苋和红苋菜间作处理产量分别为对照的59.16%、46.22%和46.28%。

表 1 单作与间作处理水稻生物量、产量及单株产量1)Table 1. Biomass, yield per unit area and yield per plant of rice in monoculture and intercropping treatments处理

Treatment生物量/g Biomass 总有效穗数

Total effective panicles每穗粒数

Grains per panicle千粒质量/g

1 000-grain weight产量/

(g·m−2)

Yield单株产量/g

Yield per plant地上部

Shoot地下部

Root水稻单作(对照)

Rice monocropping (control)11.63±1.24b 0.87±0.14a 72.00±2.08a 117.30±2.49a 21.93±0.70a 185.34±10.23a 11.58±0.64ab 水稻与圆叶白苋菜间作

Rice-white amaranth intercropping18.99±0.62a 0.74±0.06a 43.33±1.86b 117.17±3.62a 21.59±0.34a 109.65±6.50b 13.71±0.81a 水稻与籽粒苋间作

Rice-grain amaranth intercropping8.36±0.88c 0.61±0.10a 35.00±0.58c 116.43±1.51a 21.01±0.59a 85.67±3.72b 10.71±0.47b 水稻与红苋菜间作

Rice-red amaranth intercropping10.76±0.43bc 0.93±0.19a 34.33±2.40c 111.61±1.72a 22.52±0.53a 85.78±6.57b 10.72±0.82b 1) 同列数据后的不同小写字母表示差异显著(P<0.05,Duncan’ s 法)

1) Different lowercase letters in the same column indicate significant differences(P<0.05, Duncan’ s method)2.2 间作对水稻各部位As吸收的影响

水稻地上部、地下部、谷壳和糙米中As含量最高的均为与圆叶白苋菜间作,比对照分别提高了88.50%、65.38%、68.25%和45.45%。总体看来,水稻地上部、地下部、谷壳、糙米中As含量大小均表现为水稻与圆叶白苋菜间作>水稻与籽粒苋间作>水稻与红苋菜间作>对照,说明水稻与苋菜间作能在一定程度上提高水稻各部位对As的吸收(表2)。

表 2 单作与间作处理水稻各部位As含量1)Table 2. As contents in various parts of rice in monoculture and intercropping treatmentsw(As)/(mg·kg−1) 处理

Treatment地上部

Shoot地下部

Root谷壳

Husk糙米

Brown rice水稻单作(对照)

Rice monocropping (control)11.74±1.16b 103.63±11.66b 0.63±0.10b 0.44±0.03c 水稻与圆叶白苋菜间作

Rice-white amaranth intercropping22.13±1.97a 171.38±12.95a 1.06±0.21a 0.64±0.02a 水稻与籽粒苋间作

Rice-grain amaranth intercropping20.55±1.76a 167.43±13.21a 0.86±0.04a 0.52±0.01b 水稻与红苋菜间作

Rice-red amaranth intercropping18.81±1.03a 133.33±12.60ab 0.80±0.04ab 0.52±0.01b 1)同列数据后的不同小写字母表示差异显著(P<0.05,Duncan’ s 法)

1) Different lowercase letters in the same column indicate significant differences(P<0.05, Duncan’ s method)2.3 不同品种苋菜生物量(干质量)及As吸收的差异

圆叶白苋菜、籽粒苋和红苋菜地上部与地下部生物量存在一定差异,圆叶白苋菜地上部生物量最大,单株26.57 g,显著高于籽粒苋,与红苋菜差异不显著。地下部生物量最大的同样是圆叶白苋菜,单株5.20 g,显著高于籽粒苋与红苋菜(表3)。地上部As含量最高的为籽粒苋,达3.18 mg·kg−1,显著高于圆叶白苋菜与红苋菜;圆叶白苋菜与红苋菜地上部As含量无显著差异,分别为1.54、1.22 mg·kg−1。地下部As含量最高的是红苋菜,为25.42 mg·kg−1,显著高于另外2个品种(表3)。若以叶菜类蔬菜的平均含水率90%计算鲜质量As含量,3个品种苋菜食用部分即地上部As含量均未超出GB 2762—2017[23]的食用安全限量标准(0.5 mg·kg−1)。

表 3 不同品种苋菜单株生物量及As含量1)Table 3. Biomass per plant and As contents in various parts of different amaranth varieties品种

Variety生物量/g Biomass w(As)/(mg·kg−1) 地上部

Shoot地下部

Root地上部

Shoot地下部

Root圆叶白苋菜 White amaranth 26.57±2.10a 5.20±1.35a 1.54±0.07b 16.14±0.81b 籽粒苋 Grain amaranth 14.56±0.23b 0.44±0.07b 3.18±0.13a 13.76±0.81b 红苋菜 Red amaranth 24.81±2.46a 1.48±0.02b 1.22±0.18b 25.42±0.37a 1)同列数据后的不同小写字母表示差异显著(P<0.05,Duncan’ s 法)

1) Different lowercase letters in the same column indicate significant differences(P<0.05, Duncan’ s method)2.4 单作与间作处理土壤As提取效率的差异

单作与间作处理土壤As提取量存在一定差异,水稻与圆叶白苋菜间作能从1 m2土壤中提取5.43 mg As,显著高于其他处理;对照从1 m2土壤中提取3.25 mg As,仅为与圆叶白苋菜间作的59.85%;水稻与籽粒苋、红苋菜间作处理土壤As提取量与对照无显著差异(表4)。总体来讲,水稻与圆叶白苋菜间作能从土壤中提取更多的As。间作品种不同,As吸收量有差异,说明通过间作提取土壤中的As,要同时考虑种植模式和作物品种。与对照相比,与圆叶白苋菜间作处理土壤中As含量有一定程度的降低,但差异未达到显著性水平;水稻与籽粒苋、红苋菜间作处理土壤As含量略微高于对照,差异不显著(表4)。

表 4 单作与间作处理植株不同部位As累积量及土壤中As含量1)Table 4. As accumulations in various parts of plants and As contents in soil in monoculture and intercropping treatments处理

TreatmentAs累积量/(mg·m−2) As accumulations w(As)土壤/

(mg·kg−1)

As concent in soil水稻地上部

Rice shoot水稻地下部

Rice root苋菜地上部

Amaranth shoot苋菜地下部

Amaranth root总和

Sum水稻单作(对照)

Rice monocropping (control)2.21±0.29b 1.04±0.09a 3.25±0.38b 63.53±0.96a 水稻与圆叶白苋菜间作

Rice-white amaranth intercropping3.36±0.24a 1.05±0.16a 0.33±0.03a 0.69±0.16a 5.43±0.34a 59.81±1.49a 水稻与籽粒苋间作

Rice-grain amaranth intercropping1.39±0.17b 0.84±0.04a 0.37±0.01a 0.05±0.01b 2.65±0.20b 65.18±1.68a 水稻与红苋菜间作

Rice-red amaranth intercropping1.63±0.12b 0.76±0.07a 0.24±0.01b 0.30±0.00b 2.93±0.16b 63.64±2.03a 1)同列数据后的不同小写字母表示差异显著(P<0.05,Duncan’ s 法)

1) Different lowercase letters in the same column indicate significant differences(P<0.05, Duncan’ s method)2.5 间作对水稻根际土壤速效养分与有机质含量的影响

与对照相比,间作处理水稻根际土壤中铵态氮、速效磷、速效钾、有机质含量均有不同程度的提高,其中水稻与圆叶白苋菜间作铵态氮、速效磷、速效钾和有机质含量最高,比对照分别提高了38.16%、9.89%、16.29%和27.23%,差异显著,说明间作可以提高水稻根际土壤中养分含量(表5)。

表 5 单作与间作水稻根际土壤速效养分与有机质含量1)Table 5. Available nutrient and organic matter contents in rice rhizosphere soil in monoculture and intercropping treatments处理

Treatmentw(铵态氮)/(mg·kg−1)

Ammonia nitrogen contentw(速效磷)/(mg·kg−1)

Available phosphorous contentw(速效钾)/(mg·kg−1)

Available potassium contentw(有机质)/(g·kg−1)

Organic matter content水稻单作(对照)

Rice monocropping (control)25.86±0.89b 126.81±3.64b 91.67±5.37b 36.09±0.12c 水稻与圆叶白苋菜间作

Rice-white amaranth intercropping35.73±0.45a 139.35±2.12a 106.60±1.27a 45.92±1.84a 水稻与籽粒苋间作

Rice-grain amaranth intercropping27.37±0.56b 128.44±3.00ab 99.17±3.87ab 40.69±0.36b 水稻与红苋菜间作

Rice-red amaranth intercropping27.90±0.89b 130.83±3.93ab 98.40±0.75ab 41.26±1.85b 1)同列数据后的不同小写字母表示差异显著(P<0.05,Duncan’ s 法)

1) Different lowercase letters in the same column indicate significant differences(P<0.05, Duncan’ s method)3. 讨论与结论

3.1 水稻苋菜间作对水稻吸收累积As的影响

间套作能充分利用时间与空间,是我国传统农业的精髓。不少学者在重金属污染土壤上进行了不同作物间作下土壤修复与粮食安全的效果和机理研究,如Gove等[24]研究表明Zn超富集植物天蓝遏蓝菜与大麦间作可以降低大麦对Zn的吸收;Whiting等[25]研究表明在添加Zn的土壤上Zn超富集植物天蓝遏蓝菜和非超富集植物菥蓂互作可减少菥蓂对锌的吸收。水稻与不同作物间作,水稻对重金属的吸收有差异。赵冰等[26]研究显示小麦东南景天间作、水稻套作模式降低了水稻稻米对Cd的吸收;本研究单作糙米As含量达0.44 mg·kg−1,超过国家卫生安全标准(GB 2762—2017)[23] 2倍以上(0.2 mg·kg−1),间作未降低糙米As含量,相反间作时糙米As含量显著高于单作。这种差异可能是植株类型引起的,因为间作体系中植株吸收重金属变化趋势主要由植株本身特性决定,选择不同的植物与目标作物间作,可能产生不一样的结果。李凝玉等[27]研究了不同作物与玉米间作对玉米吸收累积Cd的影响,结果表明,与不同的植物间作玉米对Cd的吸收发生明显变化,与豆科作物间作能显著提高玉米对Cd的积累,与籽粒苋间作在一定程度上抑制玉米对Cd的积累。本研究中水稻与3种不同品种苋菜间作,水稻地上部、地下部与谷壳中As含量均较单作升高,与张静静等[28]研究结果类似。本试验初步研究表明水稻与苋菜间作促进水稻对As的吸收累积。

若单纯从水稻产量效益看,水稻单作产量更高,但单作时水稻As含量超出安全标准,仅能作为工业原料处理,土地不能进行安全的农业生产。综合考虑生态效益及农业生产,对中轻度的As污染农田,水稻与圆叶白苋菜间作要优于与籽粒苋、红苋菜间作及水稻单作,因为水稻与圆叶白苋菜间作,水稻单株地上部生物量与单株产量均显著高于其他处理,而且在水稻种植面积减少一半的情况下,单位面积产量仍达到对照的59.16%。同时水稻与圆叶白苋菜间作能从污染土壤中提取更多的As,种植的苋菜也符合国家卫生安全标准,可以在As污染土壤中同时进行安全的农业生产和土壤As修复。种植后As含量超标的水稻可以通过焚烧、堆肥等措施处理,或是作为新兴技术“植物冶金”的原料[29]。

3.2 水稻苋菜间作对根区土壤速效养分及有机质的影响

研究表明玉米与花生间作能提高整个间作系统根区土壤碱解氮、速效磷及有机质含量[30-31],长期间作可以增加土壤肥力[32]。间作系统中根系分泌物和微生物活性增加使得土壤中难溶性养分的分解和转化速度加快,从而提高土壤速效养分含量[33]。本研究中,水稻与圆叶白苋菜间作显著提高了收获期水稻根际土壤速效养分与有机质含量,与单作相比,3个品种苋菜与水稻间作,收获期水稻根际土壤中铵态氮、速效磷以及速效钾含量均有不同程度的提高。

有机质能够影响土壤中As的移动及环境行为,Norton等[34]研究显示添加有机质能增加土壤溶液中As的有效性。本研究间作处理显著提高了收获期水稻根区土壤有机质含量,这在一定程度上解释了为什么间作时水稻各部位As吸收量都显著增加,可能是间作时根系活力提高,微生物繁殖速度加快,消耗了更多氧气,导致土壤溶液中氧化还原电位降低,As更容易从铁氧化物和氢氧化物中释放出来,从而增加As的有效性[35],土壤中As有效性增加促进了水稻对As的吸收。

本研究水稻与苋菜间作增强了水稻各部位对As的吸收,说明间作苋菜可以增加水稻对土壤As的提取,同时生产出来的苋菜食用部分As含量也未超过GB 2762—2017[23]的食用安全限量标准0.5 mg·kg−1,可以达到边生产边修复的目的。但本研究间作未降低稻米在As暴露环境下累积As的风险。单作和间作处理中水稻糙米As含量都超过了GB 2762—2017[23]的食用安全限量标准0.2 mg·kg−1。今后的研究可以考虑在间作体系中结合水分调控或是添加外源调理剂等方式联合降低水稻对As的吸收,使水稻非食用部分吸收更多的As以净化土壤,降低糙米As含量,使其达到食用安全标准以下。

3.3 结论

水稻与3种不同品种苋菜间作均能不同程度地增加水稻对As的吸收累积,同时提高水稻根区土壤速效养分与有机质含量。水稻与圆叶白苋菜间作能从As污染土壤中提取最多的As,生产出的苋菜也符合国家安全标准,可以实现边生产边修复的目的,为最优方案。

-

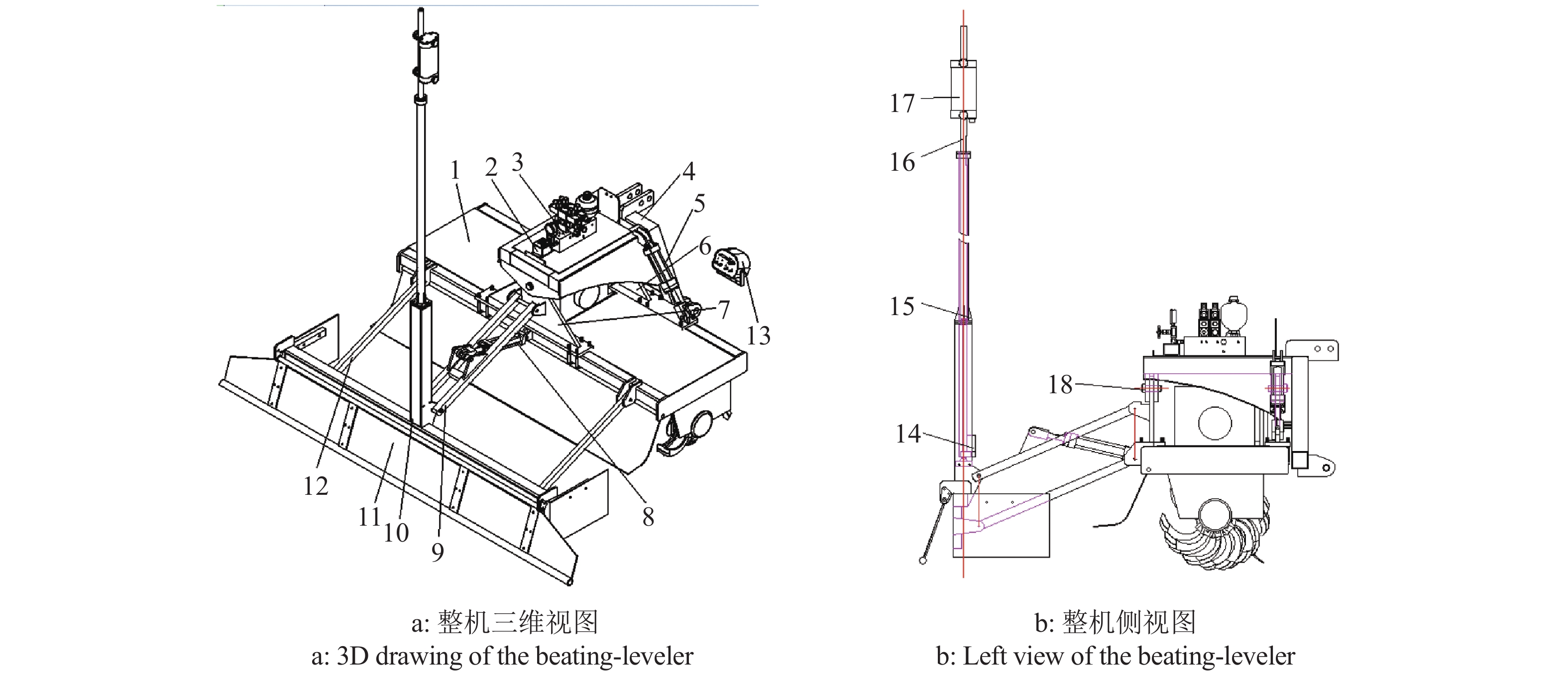

图 1 整机结构简图

1:打浆机构;2:倾角传感器;3:液压阀块及阀组;4:调平支撑架;5:调平油缸;6:前调平连接板;7:后调平连接板;8:高程油缸;9:上平地连接架;10:平地机构;11:平地拖板;12:下连接杆;13:控制器;14:直线电机;15:接收器升降杆安装座;16:接收器升降杆;17:激光接收器;18:调平销轴

Figure 1. Sketch map of the beating-leveler

1: Beating mechanism; 2: Roll angle sensor; 3: Hydraulic valve module; 4: Tilt adjustment bracket; 5: Tilt adjustment cylinder; 6: Front leveling connection plate; 7: Back leveling connection plate; 8: Elevation cylinder; 9: Upper grade connection bracket; 10: Leveling mechanism; 11: Tail plate; 12: Lower connection rod; 13: Controller; 14: Linear motor; 15: Mounting plate of lifting rod for laser receiver; 16: Lifting rod for laser receiver; 17: Laser receiver; 18: Leveling pin

-

[1] AGARWAL M C, GOEL A C. Effect of field leveling quality on irrigation efficiency and crop yield[J]. Agric Water Manage, 1981, 4(1/2/3): 89-97.

[2] ARYAL J P, MEHROTRA M B, JAT M L, et al. Impacts of laser land leveling in rice-wheat systems of the north-western indo-gangetic plains of India[J]. Food Secur, 2015, 7(3): 725-738. doi: 10.1007/s12571-015-0460-y

[3] FINNEY C. The benefits of land leveling on irrigation schemes in Turkey and Sindh Province, Pakistan[J]. ICID J, 1996, 45(1): 1523-1539.

[4] 李福祥, 许迪, 李益农. 农田土地平整设计与激光控制土地平整技术适应性研究[J]. 中国农村水利水电, 2002, 2: 27-29. doi: 10.3969/j.issn.1007-2284.2002.10.010 [5] LUO X W, ZHAO Z X, LI Q. Study on leveling control for a paddy laser leveler[C]. ASAE Annual Meeting Presentation. USA: ASAE, 2007: 071078.

[6] 李庆, 罗锡文, 汪懋华, 等. 采用倾角传感器的水田激光平地机设计[J]. 农业工程学报, 2007, 23(4): 88-93. doi: 10.3321/j.issn:1002-6819.2007.04.017 [7] 赵祚喜, 罗锡文, 李庆, 等. 基于MEMS惯性传感器融合的水田激光平地机水平控制系统[J]. 农业工程学报, 2008, 24(6): 119-124. doi: 10.3321/j.issn:1002-6819.2008.06.023 [8] 陈君梅, 赵祚喜, 陈嘉琪, 等. 水田激光平地机非线性水平控制系统[J]. 农业机械学报, 2014, 45(7): 79-84. doi: 10.6041/j.issn.1000-1298.2014.07.013 [9] 陈嘉琪, 赵祚喜, 施垒, 等. 水田激光平地机调平系统动力学建模[J]. 农业工程学报, 2015, 31(7): 18-23. [10] 胡炼, 林潮兴, 罗锡文, 等. 农机具自动调平控制系统设计与试验[J]. 农业工程学报, 2015, 31(8): 15-20. [11] 严乙桉, 罗锡文, 资双飞, 等. 基于50马力轮式拖拉机的水田激光平地机设计与试验[C]. 中国农业工程学会2011年学术年会, 重庆: 中国农业工程学会, 2011. [12] 胡炼, 罗锡文, 林潮兴, 等. 1PJ-4.0型水田激光平地机设计与试验[J]. 农业机械学报, 2014, 45(4): 146-151. doi: 10.6041/j.issn.1000-1298.2014.04.023 [13] ONODERA T, TSURUTA M, OSARI H. Leveling rice paddies using a laser land leveler when tilling[J]. Trans JSIDRE, 2002, 6: 1-8.

[14] 丁为民, 孙元昊, 赵思琪, 等. 犁旋一体机自动调平系统设计与试验[J]. 农业工程学报, 2018, 34(17): 25-31. doi: 10.11975/j.issn.1002-6819.2018.17.004 [15] 刘林. 基于拖拉机三点悬挂机构耕作机具调平系统研究[D]. 长沙: 湖南农业大学, 2014. [16] 王益新. 旋耕机组液压水平自动控制系统的研发[D]. 杭州: 浙江理工大学, 2015. [17] 于志成, 王熙. 水田复式整地机自动调平装置的设计与研究[J]. 农机化研究, 2017, 8: 175-179. doi: 10.3969/j.issn.1003-188X.2017.08.035 [18] 李明金. 水田搅浆机平地装置的设计与试验研究[D]. 黑龙江: 黑龙江八一农垦大学, 2014. [19] XU C L, ZHANG C L, LI L, et al. Optimization of working parameters for puddling and flatting machine in paddy field[J]. Int J Agr Biol Eng, 2016, 9(3): 88-96.

[20] 万松, 陈子林, 展鹏程, 等. 基于传感技术的水田旋耕机平地系统的设计与试验[J]. 华中农业大学学报, 2016, 35(4): 129-135. [21] 杨青丰. 水田激光搅浆平地系统设计[D]. 昆明: 昆明理工大学, 2018. [22] 周浩, 胡炼, 罗锡文, 等. 旋耕机自动调平系统设计与试验[J]. 农业机械学报, 2016(S1): 117-123. [23] 李益农, 许迪, 李福祥, 等. 农田土地激光平整技术应用及初步评价[J]. 农业工程学报, 1999, 15(2): 85-90. doi: 10.3321/j.issn:1002-6819.1999.02.018 -

期刊类型引用(4)

1. 熊明彪,舒芬,郑钦峰,李学明,孙博文,王博,王巧红,杨远祥. 三种观赏富集植物间作对水稻铅镉积累的影响. 四川农业科技. 2025(02): 52-58 .  百度学术

百度学术

2. 段佳鑫,臧庆吉,薛世明,方云霞,蔡明,刘彦培,侯洁琼,黄梅芬,钟绍丽,张美艳. 亚热带区玉米和籽粒苋间作对饲草产量和品质的影响. 草业科学. 2024(06): 1471-1482 .  百度学术

百度学术

3. 梁富威,肖丽莎,李镇城,黄思映,黎华寿. 中国土壤砷污染与植物修复的研究进展. 生态科学. 2024(06): 250-258 .  百度学术

百度学术

4. 游梦,邹茸,王丽,王楷,范洪黎. 不同富集植物与小麦间作对镉吸收转运的影响. 中国土壤与肥料. 2022(04): 201-208 .  百度学术

百度学术

其他类型引用(4)

下载:

下载: