Design and test of pre-cutting type sugarcane planter

-

摘要:目的

研制一种预切种式甘蔗种植一体机,以便连续完成开沟、施肥、排放种苗、覆土、盖膜等一次性作业。

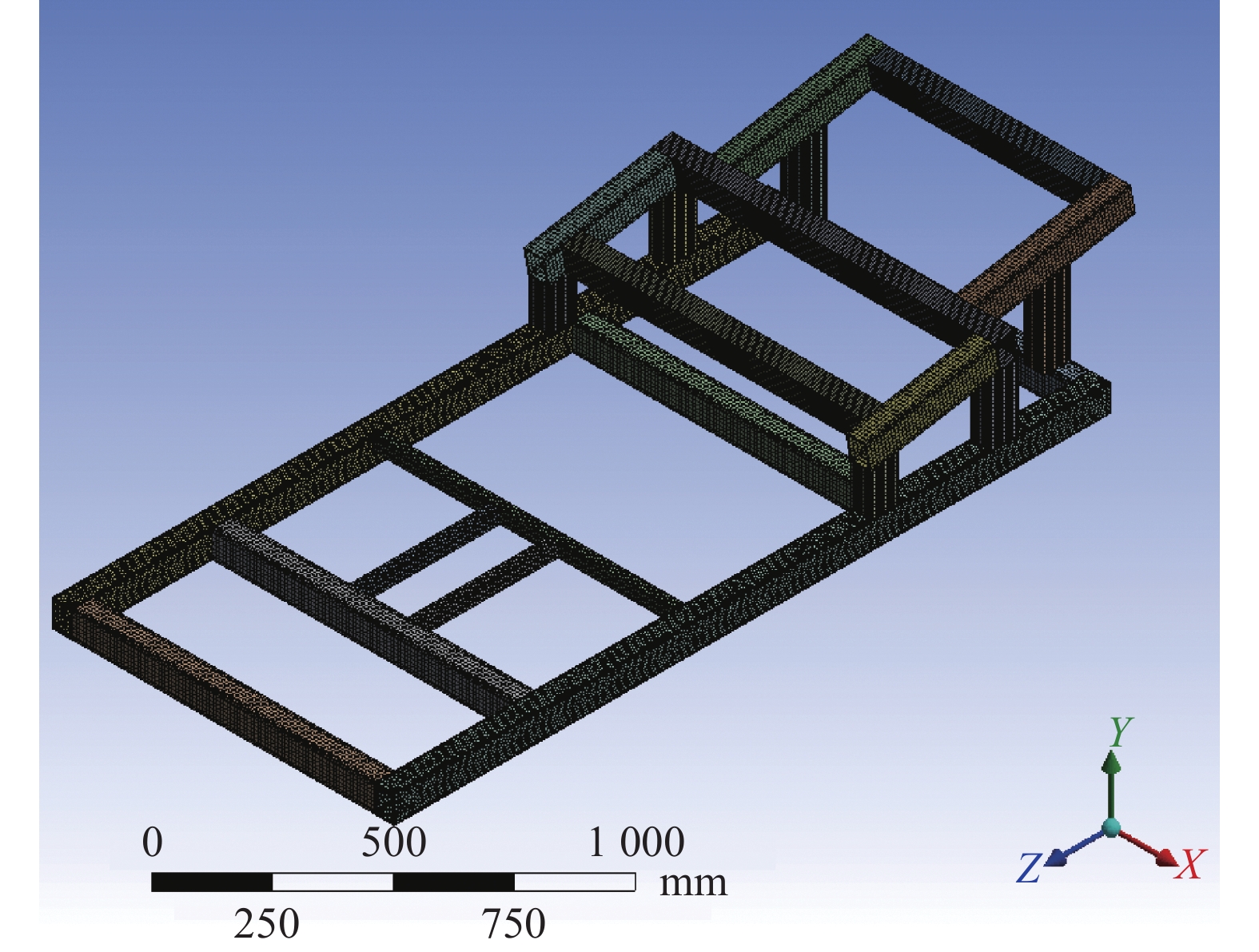

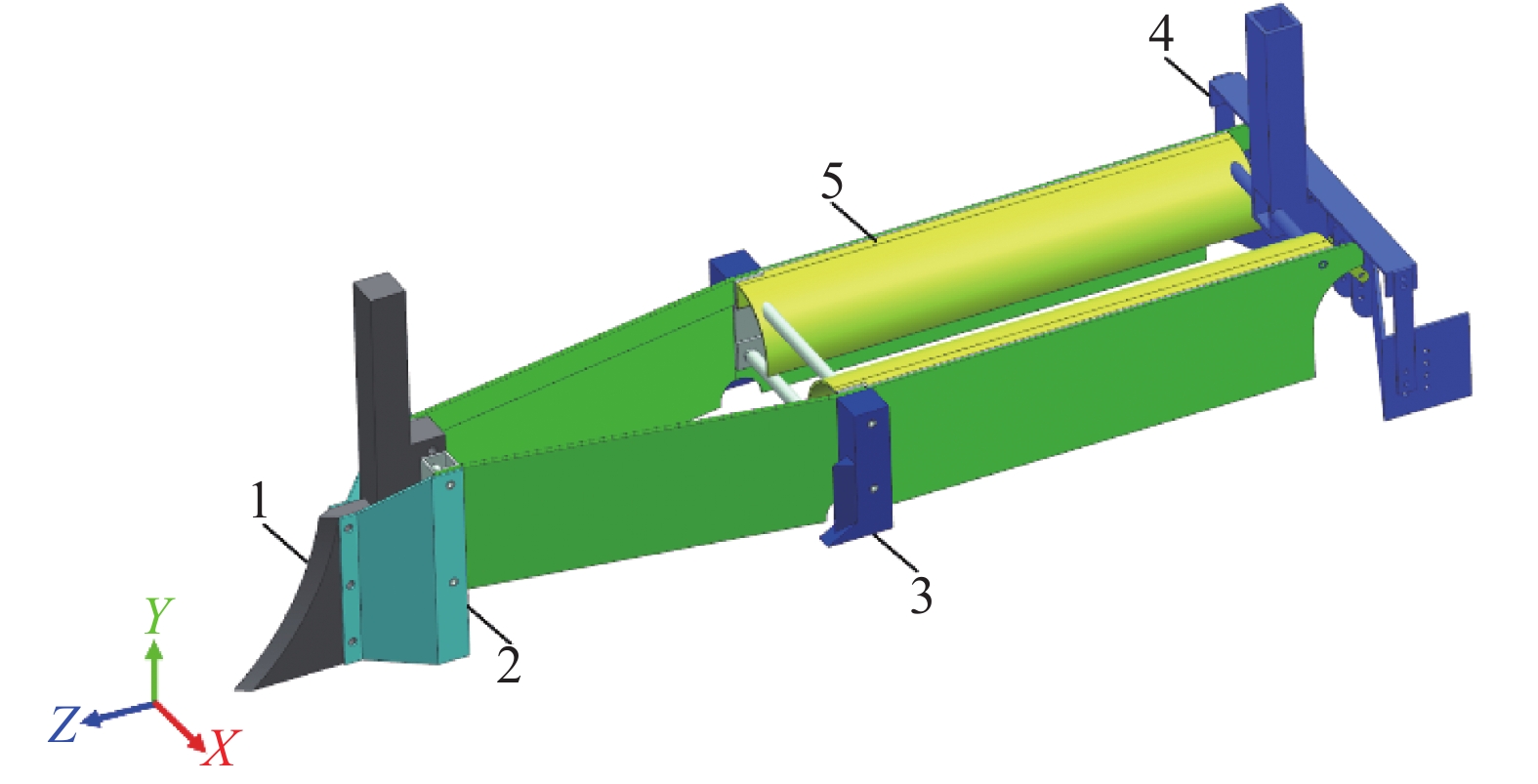

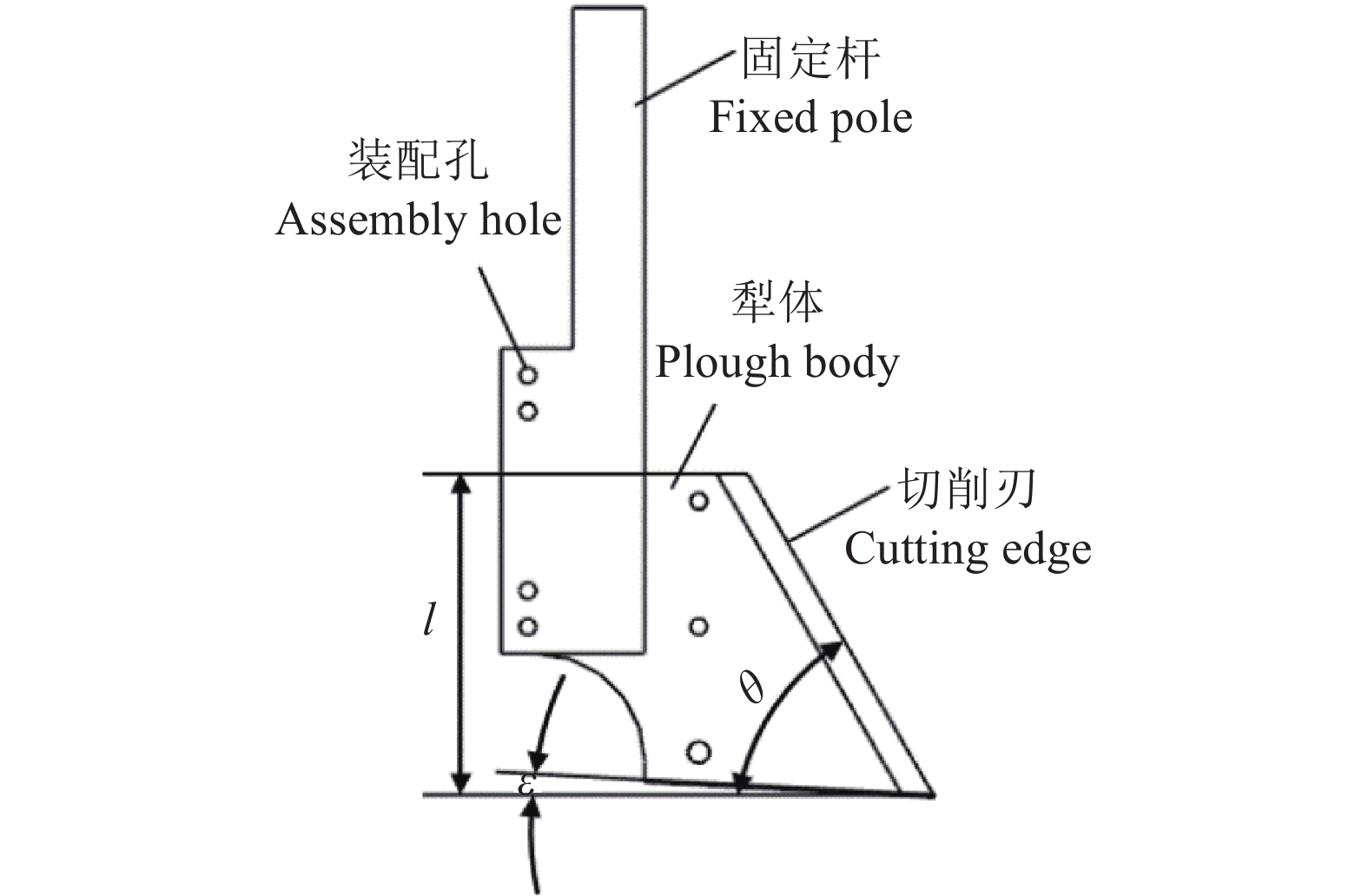

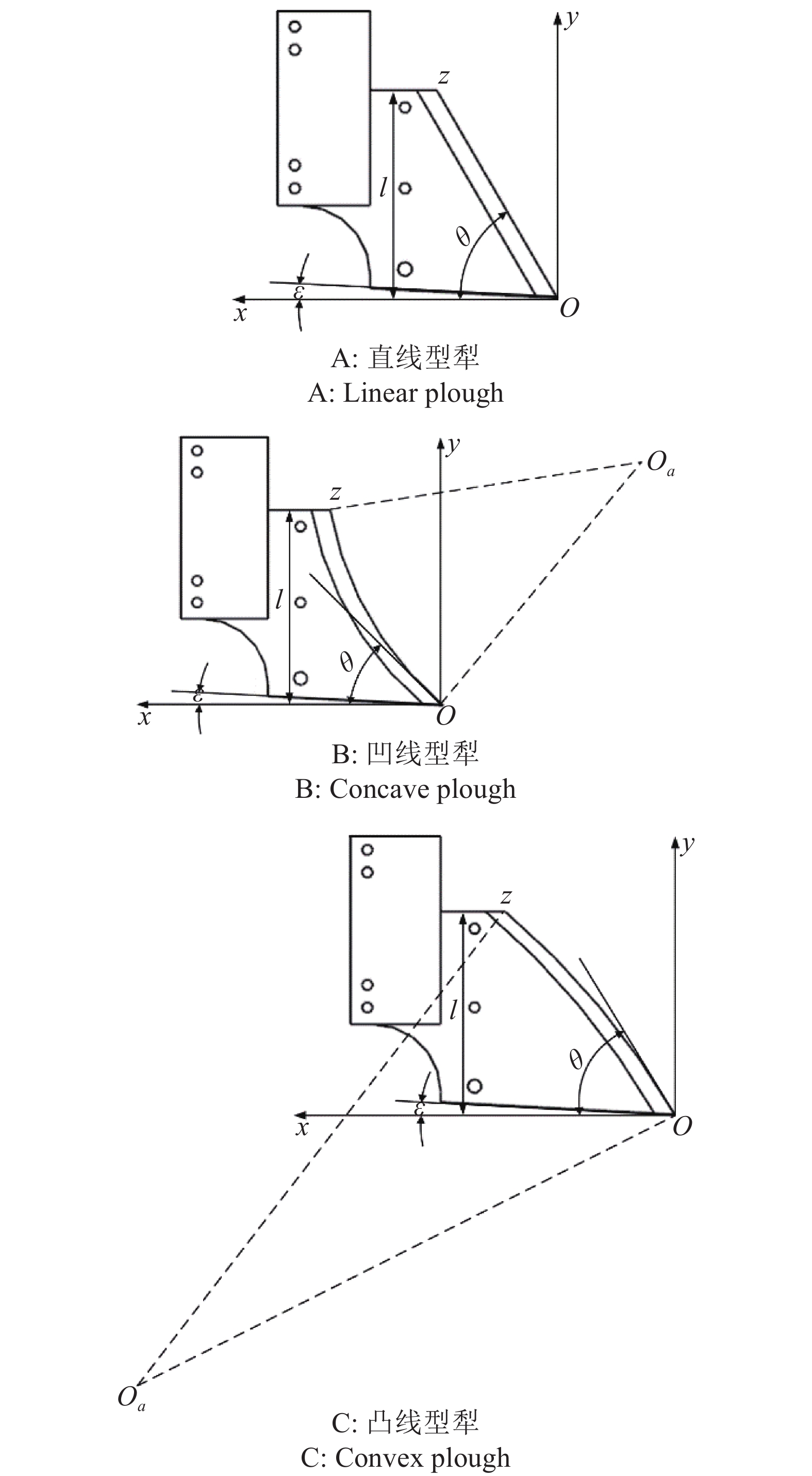

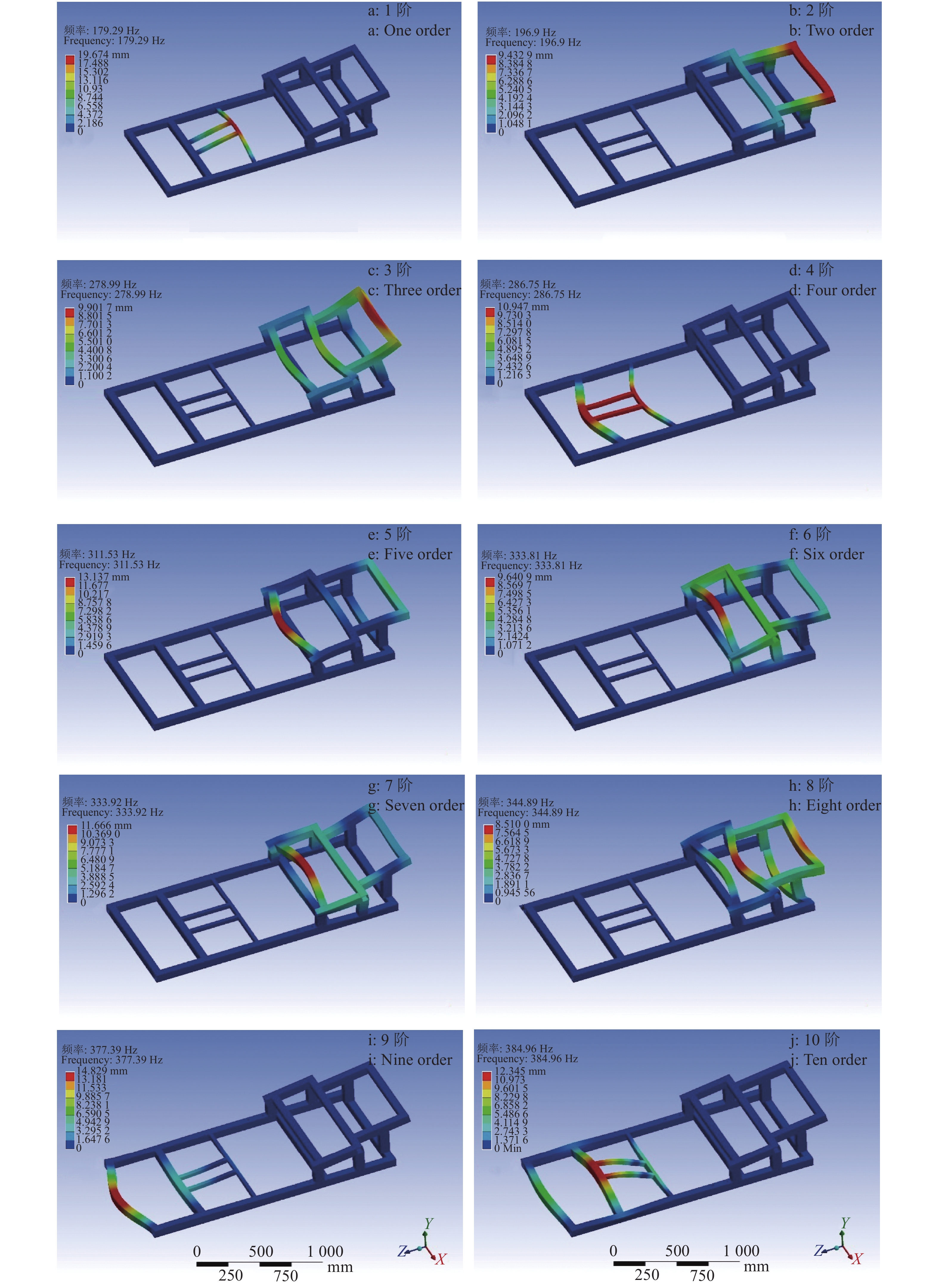

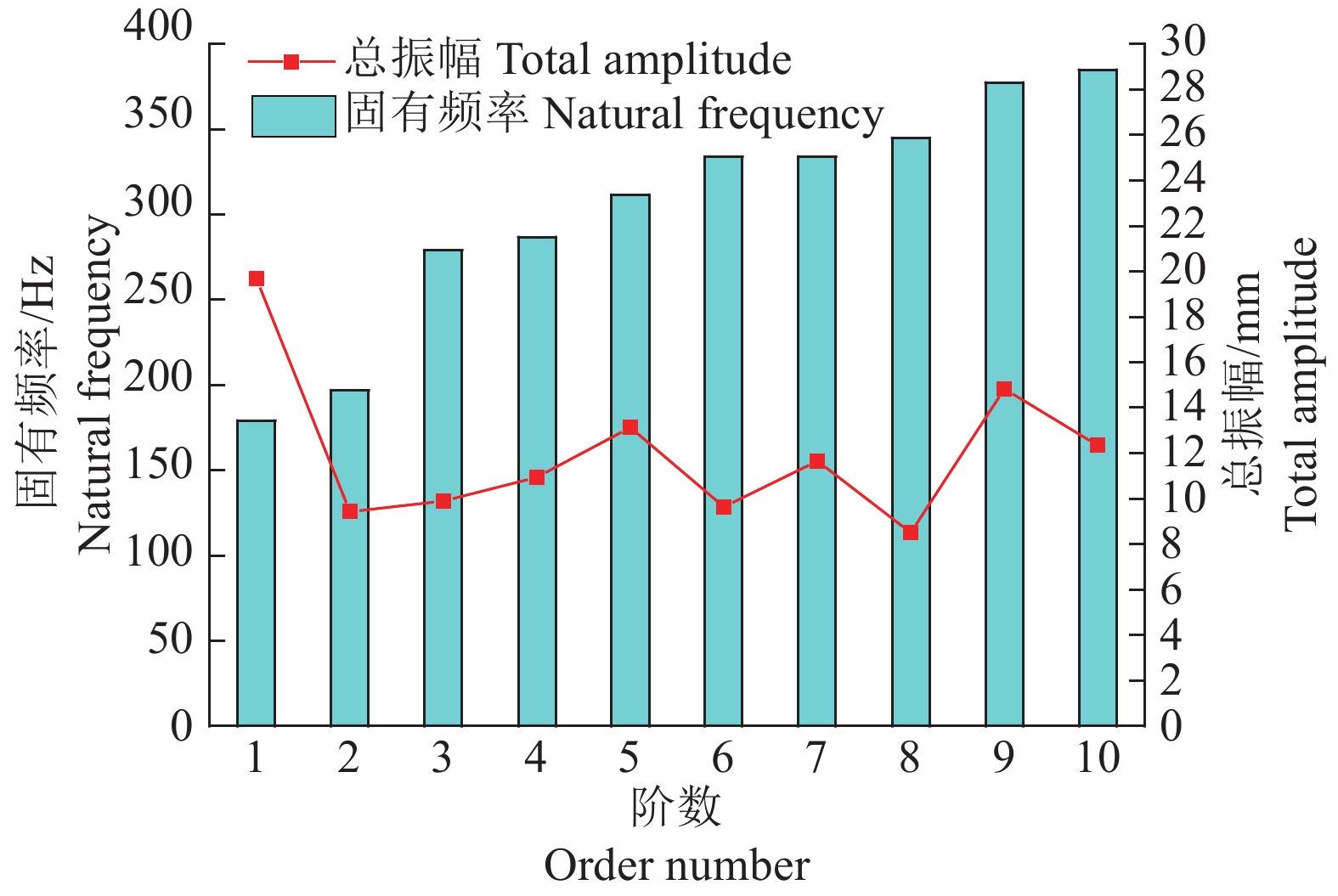

方法利用有限元分析软件ANSYS对甘蔗种植机的机架进行模态分析,通过田间试验获取3种开沟犁的犁沟土壤扰动指数;设计液压传动系统、播种机构、开沟覆土装置、施肥机构和覆膜机构,并通过田间试验获得甘蔗种植机的种植深度合格率、覆土厚度合格率、种植密度、伤芽率、漏株率、施肥量稳定性变异系数、地膜破损率等。

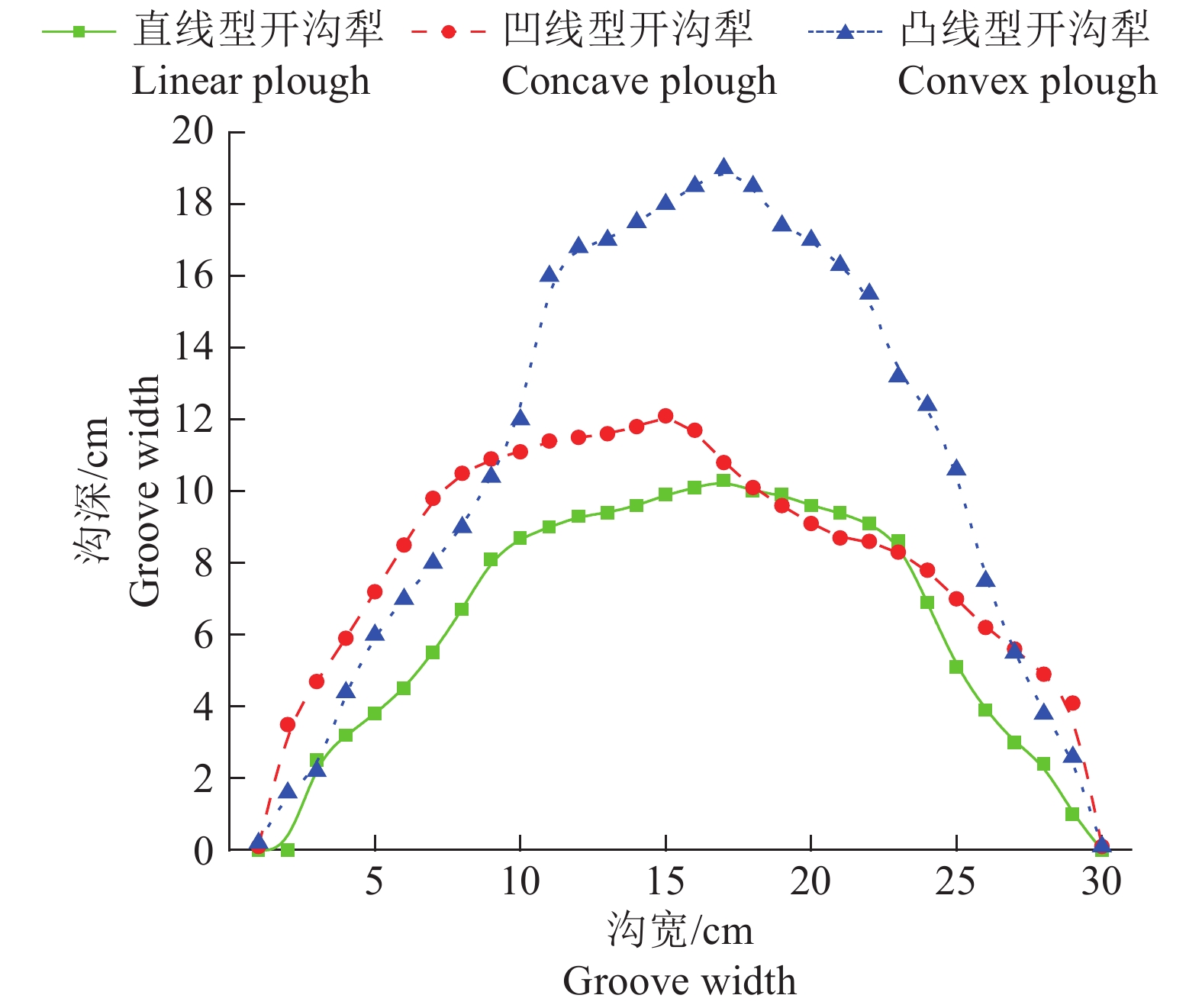

结果模拟结果表明当激励频率为134.47~514.35 Hz时,机架容易发生共振,且最大位移可达19.67 mm。田间试验表明凸线型开沟犁的土壤扰动指数为17.05,最大沟深可达19.13 cm,符合甘蔗种植沟深的标准。甘蔗种植深度合格率为83%,覆土厚度合格率为91%,种植密度为135 331 hm−2,伤芽率为4.7%,漏株率为4.5%,施肥量稳定性变异系数为6.1%,地膜破损率为51%,均符合甘蔗种植机的设计标准。

结论该小型预切种式甘蔗种植一体机符合设计要求,能够显著提高甘蔗种植的效率。

Abstract:ObjectiveTo design a pre-cutting type and all-in-one sugarcane planter, so as to open furrows, fertilize, discharge seedlings, cover soil and cover film during a single operation.

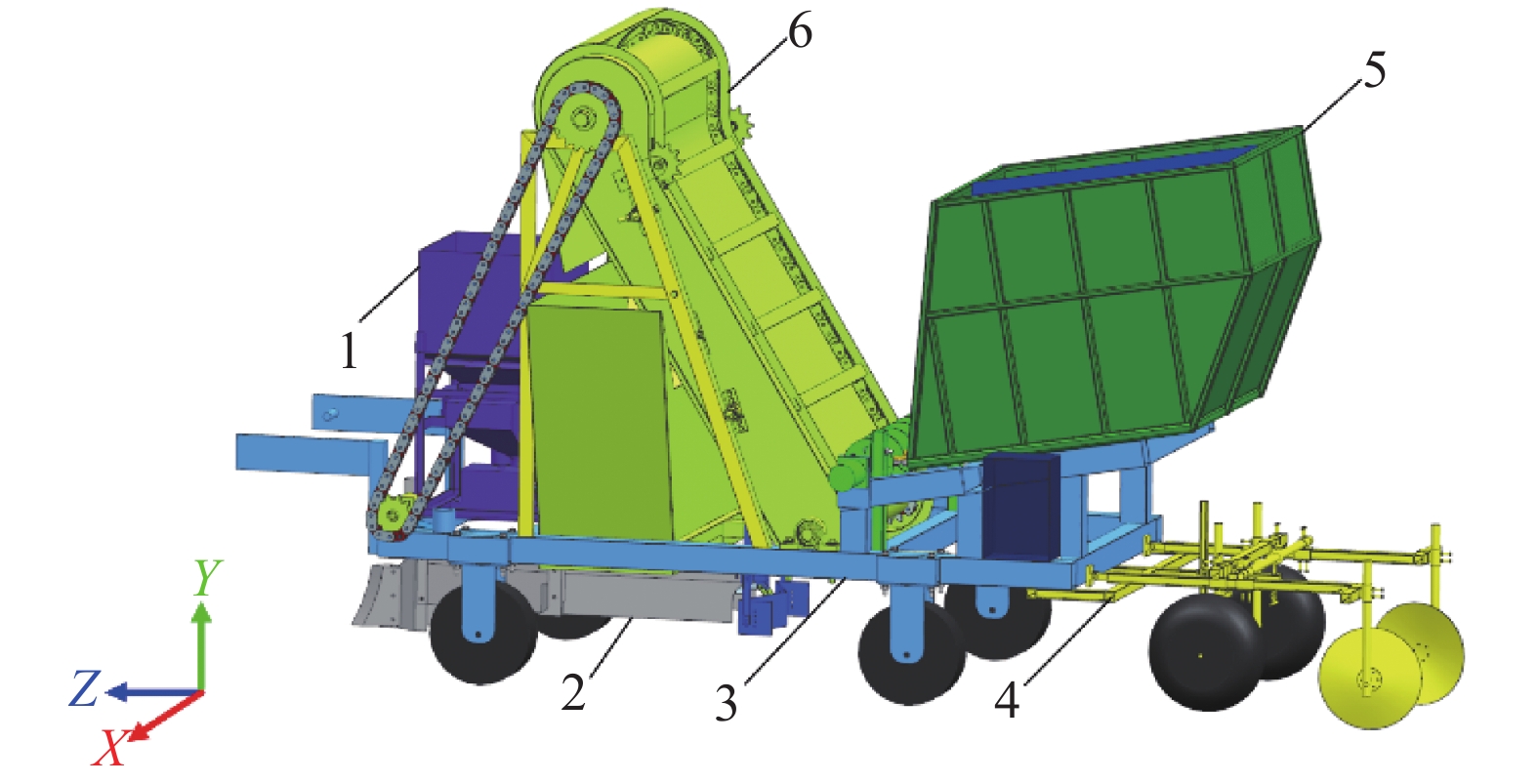

MethodThe finite element analysis software ANSYS was used for modal analysis of the sugarcane planter. The soil disturbance indexes of three furrow ploughs were obtained through field experiments. The hydraulic transmission system, seeding mechanism, furrow covering device, fertilization mechanism and film covering mechanism were designed. We used field experiments to measure the qualified rates of planting depth and covering soil thickness, planting density, bud injury rate, missing rate, coefficient of variation in stability of fertilization amount and rate of plastic film damage of the sugarcane planter.

ResultThe simulation results showed that the frame was prone to resonance when the excitation frequency was from 134.47 to 514.35 Hz, and the maximum displacement could reach 19.67 mm. The results of field experiment showed that the soil disturbance index of convex furrow plough was 17.05, and the maximum furrow depth was 19.13 cm, which met the standard of sugarcane planting furrow depth. The qualified rate of planting depth was 83%, the qualified rate of covering soil thickness was 91%, the planting density was 135 331 hm−2, the bud injury rate was 4.7%, the missing rate was 4.5%, the coefficient of variation in stability of fertilization amount was 6.1%, and the rate of plastic film damage was 51%, which all met the design criteria of sugarcane planter.

ConclusionThis small pre-cutting type and all-in-one sugarcane planting machine meets the design requirements and can significantly improve sugarcane planting efficiency.

-

-

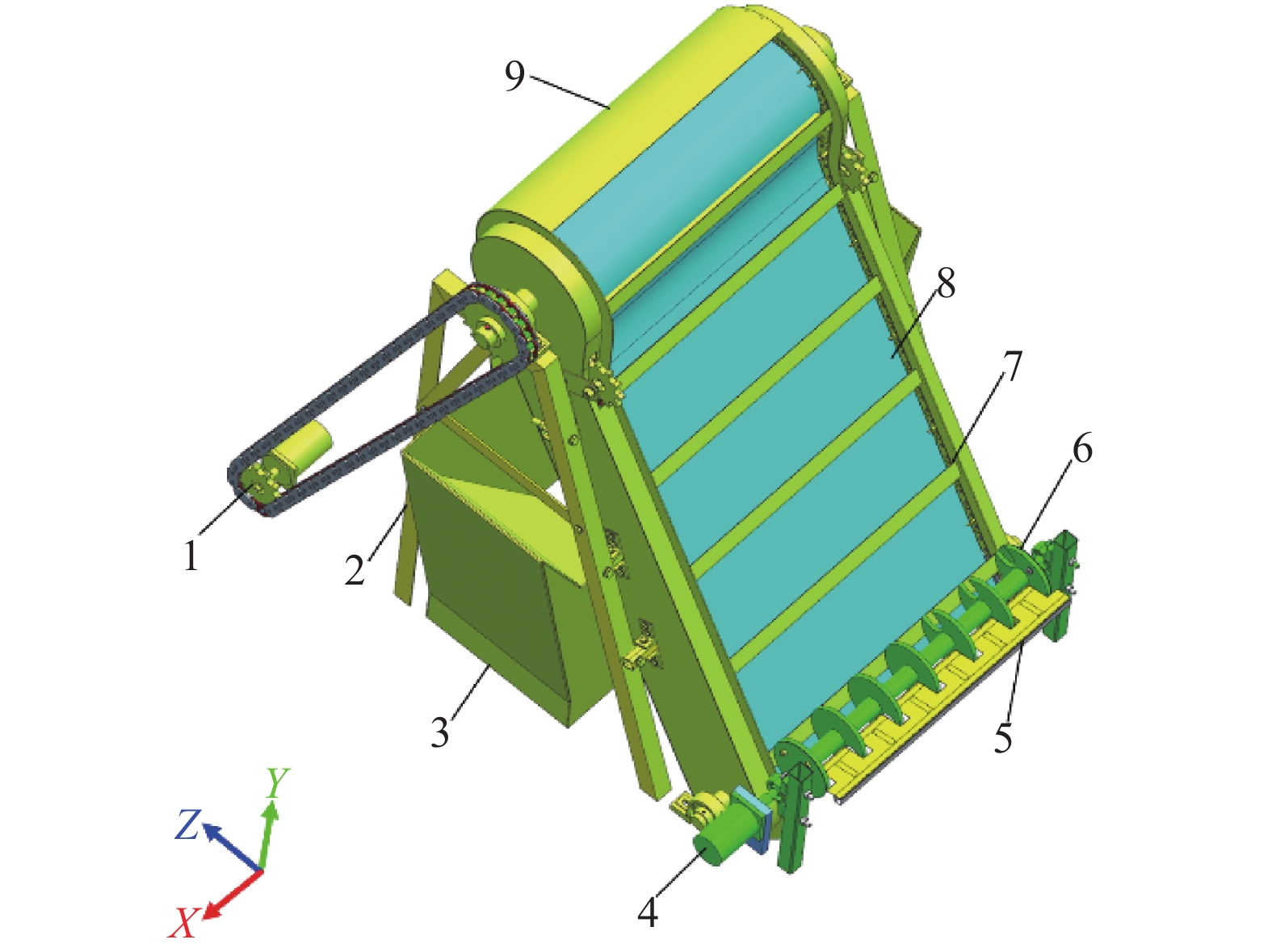

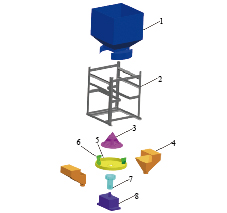

图 8 播种机构

1:液压马达;2:支架;3:排种箱;4:电动机;5:种箱处蔗种引导板;6:U型槽滚轮;7:刮板;8:内挡板;9:传送机构顶部蔗种引导板

Figure 8. Sowing mechanism

1: Hydraulic motor; 2: Bracket; 3: Seed metering box; 4: Motor; 5: Sugarcane seed guiding plate at seed box; 6: U-shape trough roller; 7: Scraper; 8: Inner baffle; 9: Sugarcane seed guiding plate at top of conveyor mechanism

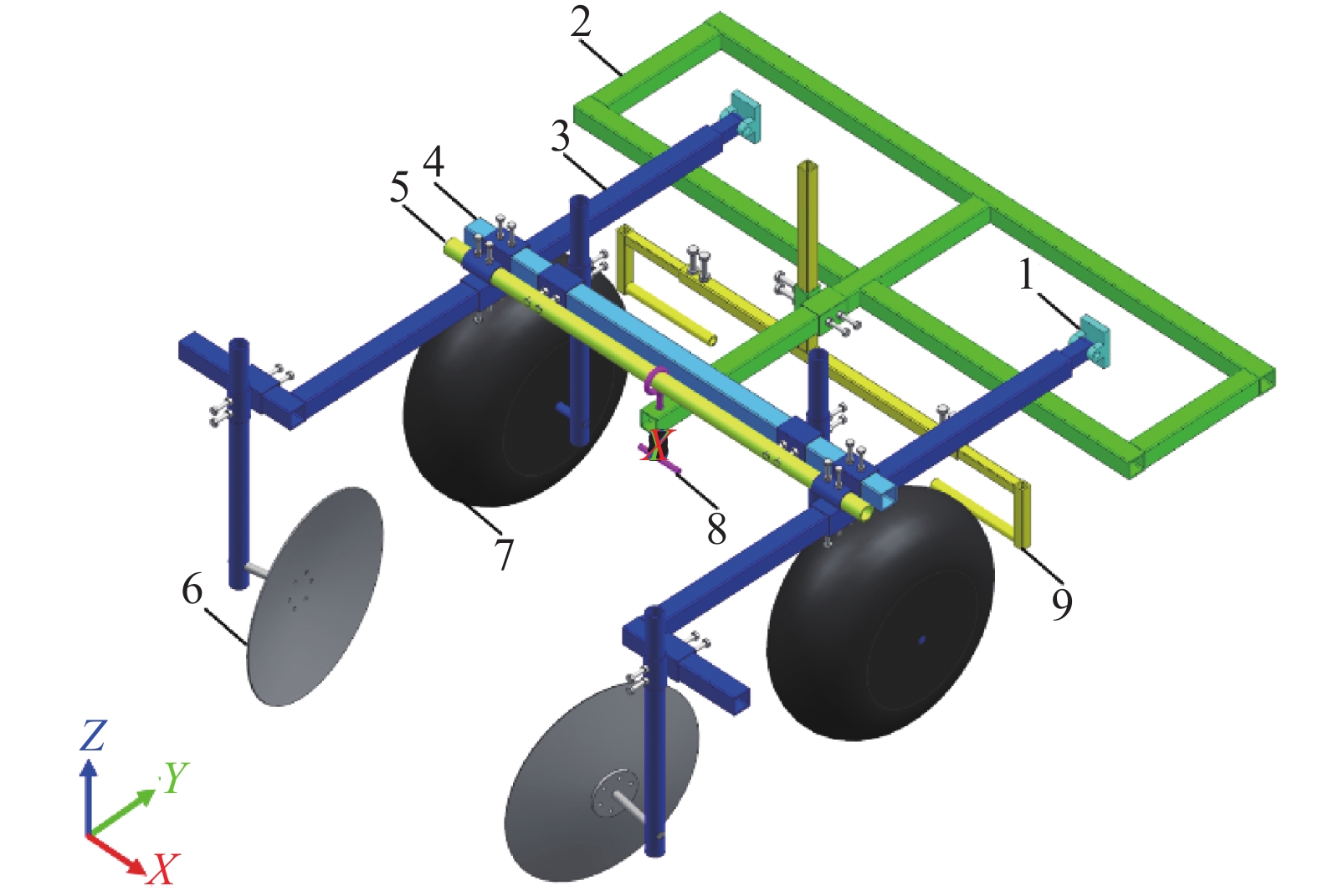

图 11 覆膜机构示意图

1:固定绞链;2:连接架;3:支承架;4:覆膜轮连接杆;5:复位弹簧支架;6:回泥盘7:地膜压实轮;8:复位弹簧安装架;9:装膜支架

Figure 11. Schematic diagram of mulching mechanism

1: Fixed strand; 2: Connecting frame; 3: Supporting frame; 4: Connecting rod of mulching whee; 5: Bracket of reset spring; 6: Mud returning tray; 7: Film compacting wheel; 8: Mounting frame of reset spring; 9: Film mounting bracket

-

[1] GOPI K, SRINIVAS J, MANIKYAM N, et al. Performance evaluation of mechanical and manual harvesting of sugarcane[J]. Int J Curr Microbiol App Sci, 2018, 7(2): 3779-3788. doi: 10.20546/ijcmas

[2] ALENCASTRE-MIRANDA M, DAVIDSON J R, JOHNSONR M, et al. Robotics for sugarcane cultivation: Analysis of billet quality using computer vision[J]. IEEE RA-L, 2018, 3(4): 3828-3835.

[3] 赵莹. 我国甘蔗收获机械化推广应用现状与发展建议[J]. 中国农机化学报, 2016, 37(9): 236-244. [4] USABORISUT P. Progress in mechanization of sugarcane farms in Thailand[J]. Sugar Tech, 2018, 20(2): 116-121. doi: 10.1007/s12355-018-0600-8

[5] 李明, 田洪春, 黄智刚. 我国甘蔗产业发展现状研究[J]. 中国糖料, 2017, 39(1): 67-70. [6] 吴多广, 吴建涛, 谢静, 等. 中国甘蔗生产发展趋势分析[J]. 广东农业科学, 2017, 44(7): 154-160. [7] 周敬辉, 李尚平, 杨代云, 等. 甘蔗收获机刀盘轴向振动对甘蔗宿根切割质量的影响[J]. 农业工程学报, 2017, 33(2): 16-24. [8] 罗菊川, 文晟, 李涵光, 等. 甘蔗尾茎泊松比的试验分析[J]. 华南农业大学学报, 2017, 38(6): 118-124. [9] 莫建霖, 刘庆庭. 我国甘蔗收获机械化技术探讨[J]. 农机化研究, 2013, 35(3): 12-18. doi: 10.3969/j.issn.1003-188X.2013.03.003 [10] 刘庆庭, 莫建霖, 李廷化, 等. 我国甘蔗种植机技术现状及存在的关键技术问题[J]. 甘蔗糖业, 2011(5): 52-58. doi: 10.3969/j.issn.1005-9695.2011.05.011 [11] 沈中华, 李尚平, 麻芳兰, 等. 小型甘蔗收获机喂入能力仿真与试验[J]. 农业机械学报, 2014, 45(11): 117-123. doi: 10.6041/j.issn.1000-1298.2014.11.018 [12] 王美美, 陈联诚, 刘庆庭, 等. 甘蔗种植机漏播监测与标记系统[J]. 农业机械学报, 2013, 44(6): 50-55. [13] 刘存瑞, 程浩然, 周乔, 等. 一种新型地轮驱动式甘蔗种植机关键部件设计[J]. 农机化研究, 2018, 40(1): 120-123. [14] SAENGPRACHATANARUG K, WONGPICHET S, UENO M, et al. Comparative discharge and precision index of a sugarcane billet planter[J]. Appl Eng Agric, 2016, 32(5): 561-567. doi: 10.13031/issn.0883-8542

[15] 孙伟, 闫宪飞, 王茁. 频率依赖性对黏弹性复合结构振动特性的影响分析[J]. 机械工程学报, 2018, 54(5): 121-128. [16] SHEN X, HU W, FAN J. Automatic blade blend modeling and hexahedral mesh regeneration for aircraft engine optimization[J]. Struct Multidiscip O, 2018, 57(3): 1345-1355. doi: 10.1007/s00158-017-1816-z

[17] 金鑫, 陈凯康, 姬江涛, 等. 基于模态置信度准则的插秧机支撑臂模态分析与结构优化[J]. 农业工程学报, 2018, 34(18): 93-101. doi: 10.11975/j.issn.1002-6819.2018.18.012 [18] BERTONHA R S, FURLANI C E A, VICENTE FILHO A S, et al. Fuel demand as a function of furrow opener and soil conditions in no-tillage system[J]. Afr J Agric Res, 2015, 10(11): 1266-1272.

[19] ZHANG X C, LI H W, DU R C, et al. Effects of key design parameters of tine furrow opener on soil seedbed properties[J]. Int J Agr Biol Eng, 2016, 9(3): 67-80.

[20] 裴铁雄, 陈永, 黄培强, 等. 甘蔗新品种的不同种植密度试验研究[J]. 中国糖料, 2014(4): 6-10. [21] 成大先. 机械设计手册[M]. 北京: 化学工业出版社, 2016. [22] 王关平, 孙伟. 一种马铃薯漏播检测及补偿装置的研制[J]. 农业现代化研究, 2016, 37(5): 1008-1014. [23] MO F, WANG J Y, REN H X, et al. Environmental and economic benefits of micro-field rain-harvesting farming system at maize (Zea mays L.) field scale in semiarid east African Plateau[J]. Agric Water Manage, 2018, 206: 102-112. doi: 10.1016/j.agwat.2018.05.002

[24] MO F, LI X Y, NIU F J, et al. Alternating small and large ridges with full film mulching increase linseed (Linum usitatissimum L.) productivity and economic benefit in a rainfed semiarid environment[J]. Field Crop Res, 2018, 219: 120-130. doi: 10.1016/j.fcr.2018.01.036

[25] RAMAKRISHNA A, TAM H M, WANI S P, et al. Effect of mulch on soil temperature, moisture, weed infestation and yield of groundnut in northern Vietnam[J]. Field Crop Res, 2006, 95(2/3): 115-125.

[26] ZHOU L M, LI F M, JIN S L, et al. How two ridges and the furrow mulched with plastic film affect soil water, soil temperature and yield of maize on the semiarid Loess Plateau of China[J]. Field Crop Res, 2009, 113(1): 41-47. doi: 10.1016/j.fcr.2009.04.005

[27] KHAZIMOV Z M, BORA G C, KHAZIMOV K M, et al. Development of a dual action planting and mulching machine for vegetable seedlings[J]. EAEF, 2018, 11(2): 74-78.

[28] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 农业机械试验条件测定方法的一般规定: GB/T 5262—2008[S]. 北京: 中国标准出版社, 2008. [29] 农业部旱田作农机具质量监督检验测试中心. 中华人民共和国农业行业标准: 铺膜穴播机作业质量: NY/T 987—2006[S]. 北京: 中华人民共和国农业部, 2006: 1-10.

下载:

下载: