Design and test on leaf-stripping device of sugarcane harvester by a vertical clamping-conveying channel

-

摘要:目的

探讨甘蔗立式夹持输送剥叶技术在整秆式收割机中的可行性,解决现有整秆式甘蔗联合收割机甘蔗通道长、作业效率低的问题。

方法以4ZZX-48型甘蔗收割机为作业平台,在输送通道上设计立式剥叶装置。通过收获试验,分析了夹持输送链轮转速(n1)、剥叶辊筒角度(β)、剥叶辊筒转速(n2)和甘蔗喂入率(q)等因素对甘蔗立式夹持输送剥叶性能的影响。

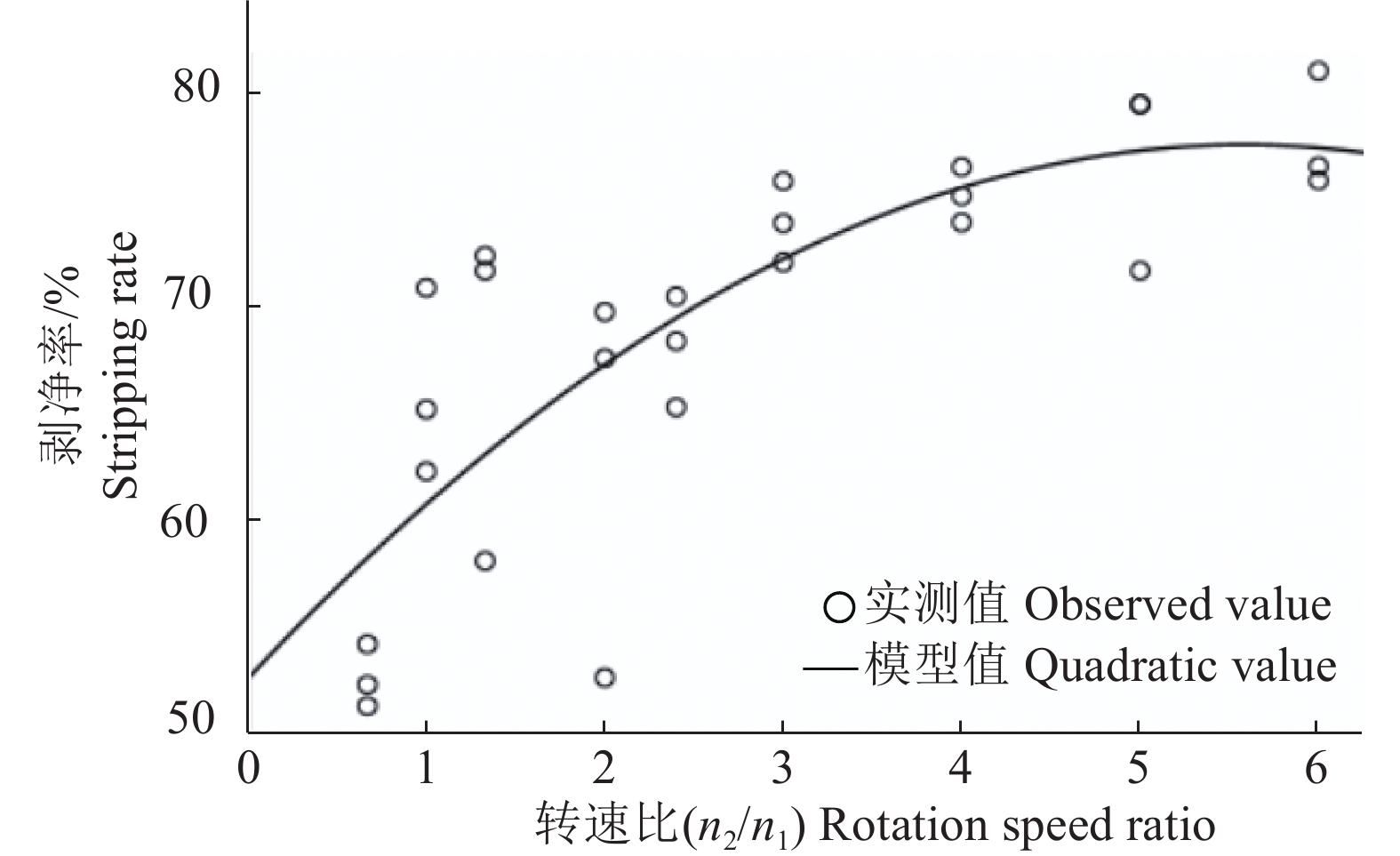

结果n1和n2对剥叶性能有显著影响,各因素对剥叶性能的影响依次为n1>n2>q>β。n1为60 r/min、β为30°、n2为360 r/min、q为7.5 kg/s时,甘蔗叶片剥净率为76.6%,剥叶性能达到最优。曲线回归分析表明,剥叶辊n2/n1与剥净率之间存在着二次多项式关系,n2/n1在5~6之间时,剥净率约77%,达到试验最优值。

结论基于甘蔗立式夹持输送剥叶技术的收割机具有可行性,本研究结果对研发新型整秆式甘蔗收割机有一定参考价值。

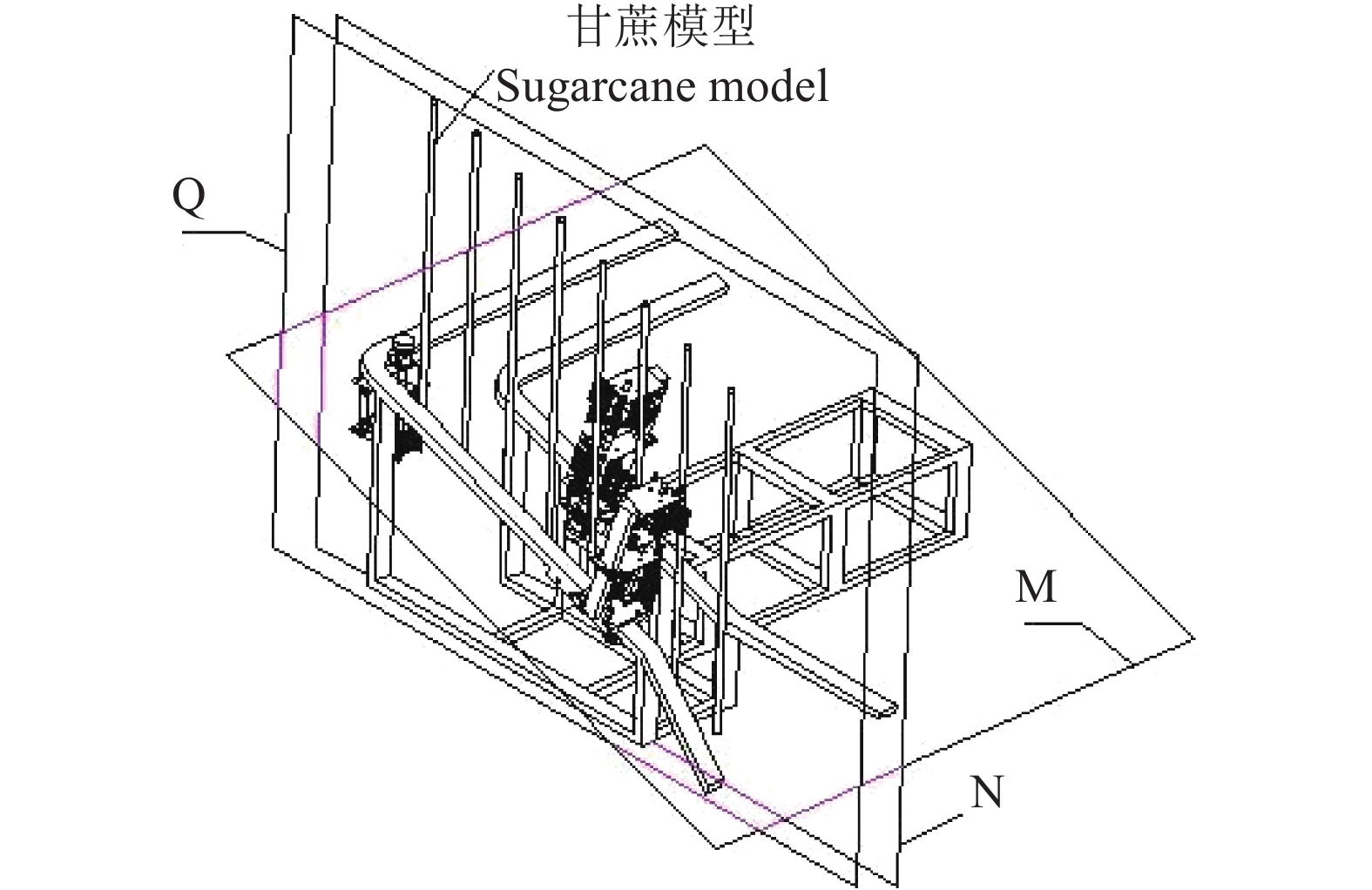

Abstract:ObjectiveTo explore the feasibility of sugarcane vertical clamping-conveying technology for the whole stalk harvester, and provide a technical support for solving the problem of long sugarcane channel and low working efficiency of the existing stalk-type sugarcane combine harvester.

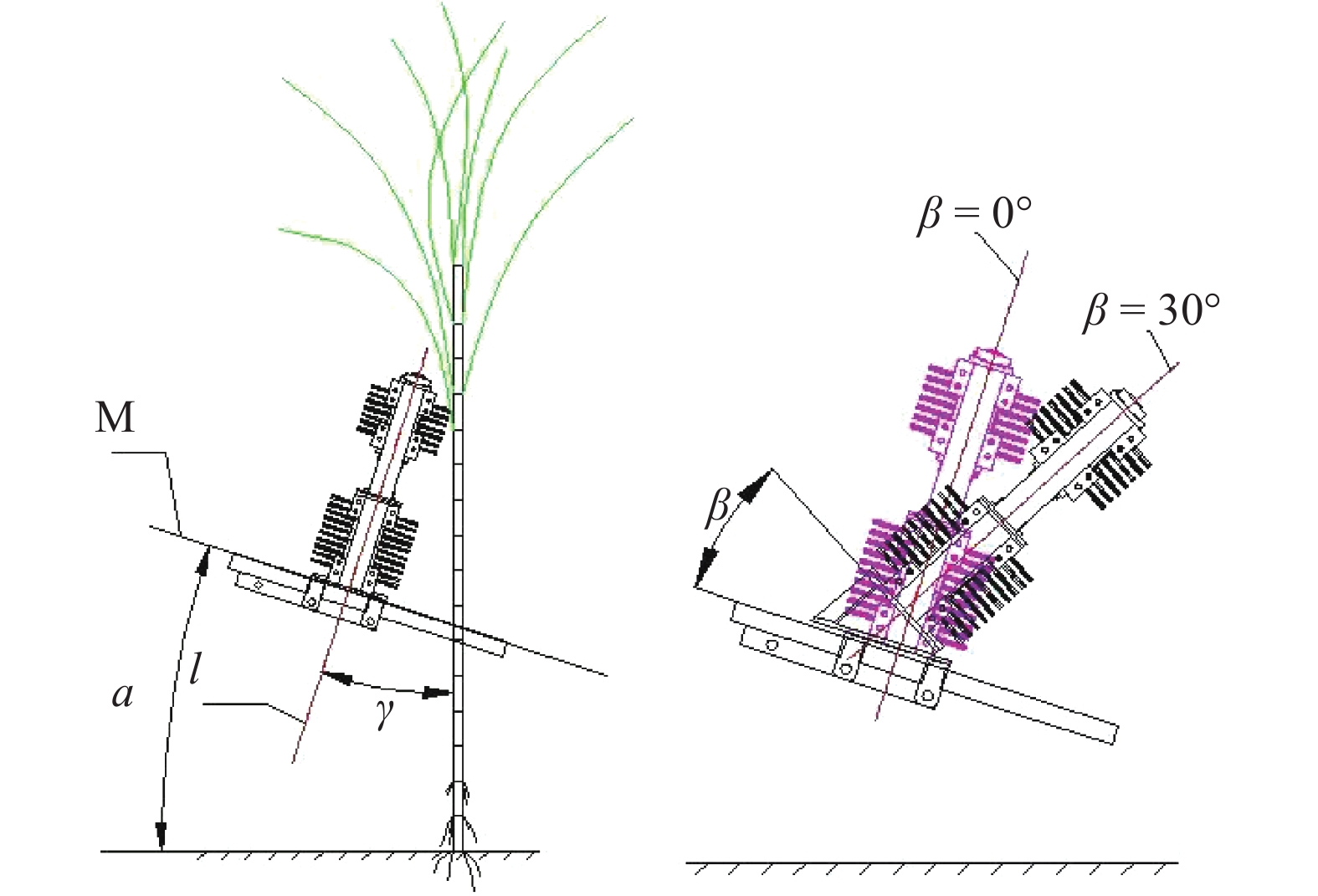

MethodA kind of vertical stripper was designed in a clamping-conveying channel for 4ZZX-48 sugarcane harvester . A harvesting test of this device was conducted in field. The influence factors of leaf stripping effect were analyzed, including the rotation rate of conveyor chain sprocket(n1), the installation angle of leaf stripping roller(β), the rotation rate of leaf stripping roller(n2) and sugarcane feeding speed(q)

ResultThe values of n1 and n2 had significant impact on leaf stripping effect. The ranking of influence was n1>n2>q>β. When n1 was 60 r/min , n2 was 360 r/min , β was 30° and q was 7.5 kg/s, the machine got the best stripping effect and leaf stripping rate was 76.6%. The results of curve regression analysis showed that there was a quadratic polynomial relation between clearing rate and the ratio of n2 to n1. When the value of n2/n1 ranged from 5 to 6, clearing rate reached the maximum of around 77%.

CluclusionThis harvester, based on sugarcane vertical clamping-conveying and stripping technology, is feasible and has certain reference value for research and development of a new whole stalk sugarcane harvester.

-

Keywords:

- sugarcane harvester /

- erect /

- leaf-stripping mechanism /

- design and test

-

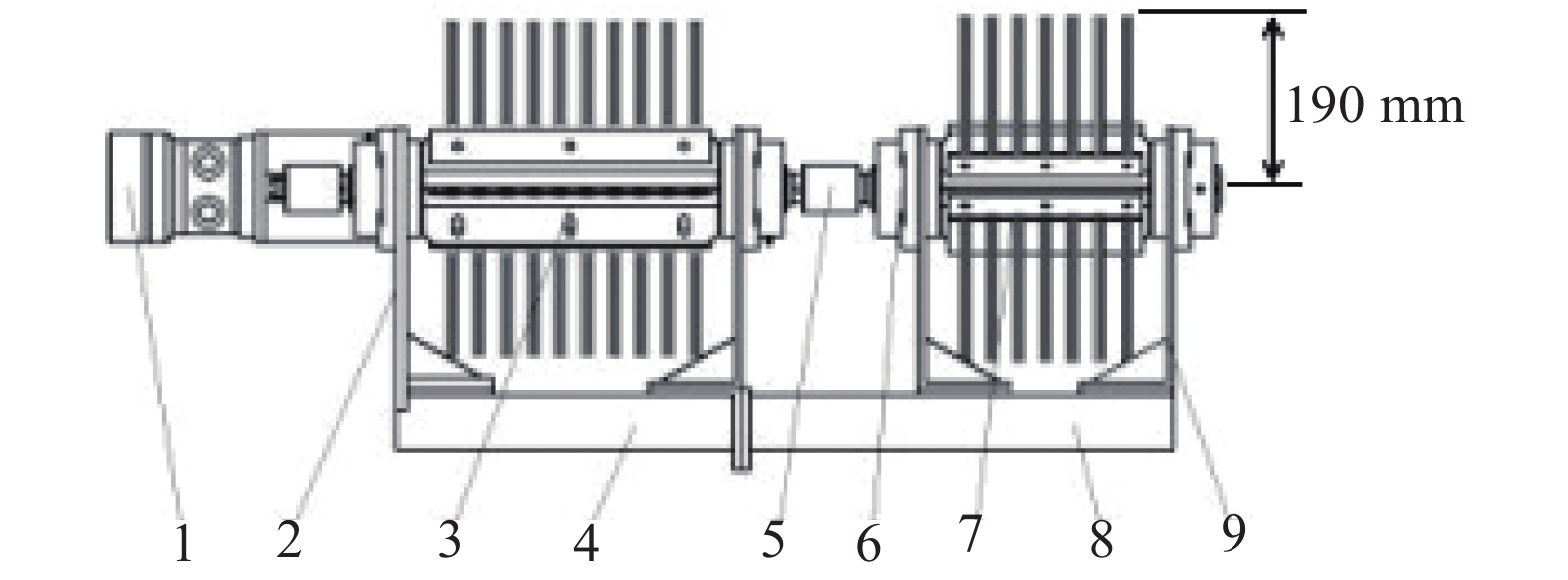

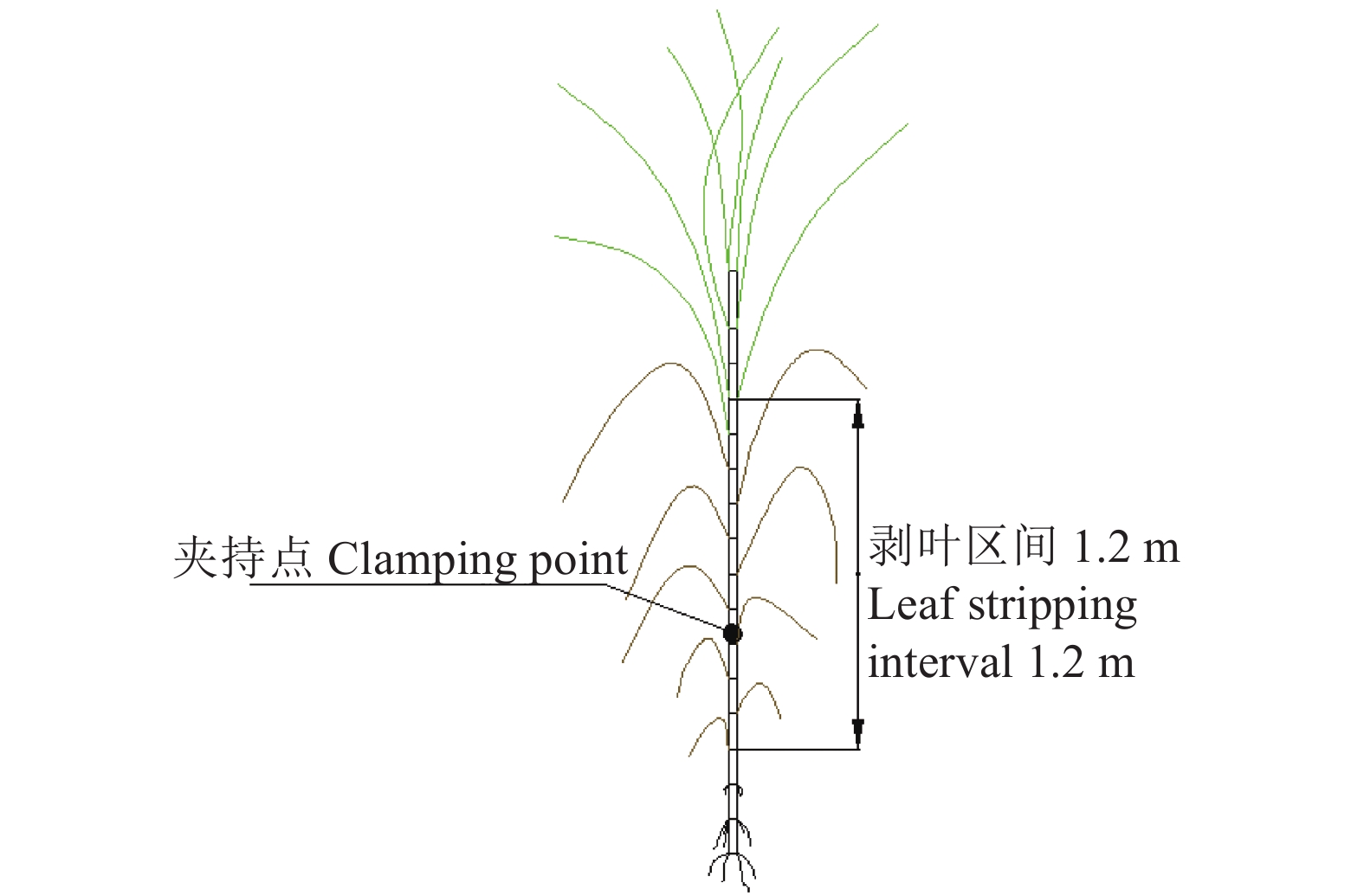

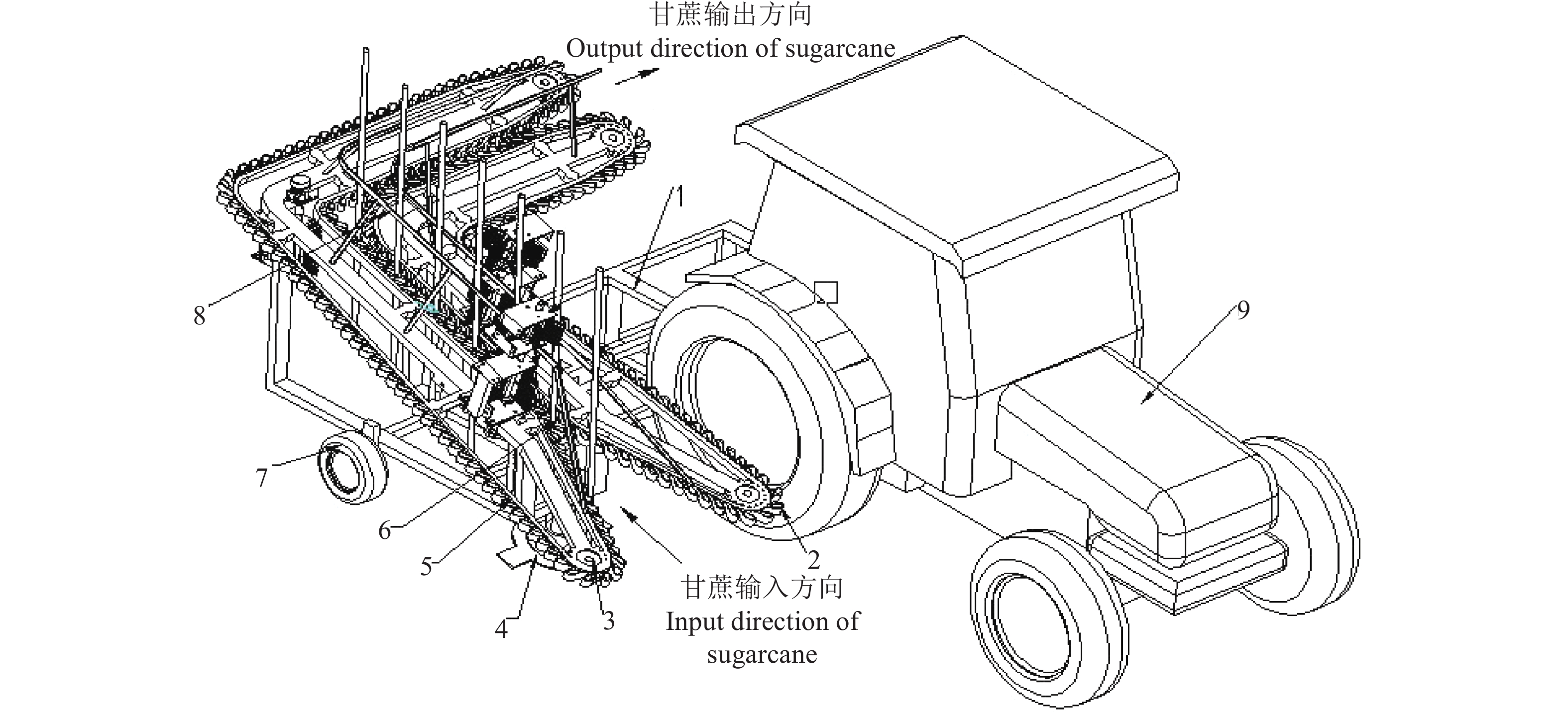

图 1 4ZZX-48型甘蔗收割机

1:架,2:夹持橡胶块,3:夹持输送链轮,4:甘蔗切割刀盘,5:夹持输送链条,6:夹持点位置,7:收割机支撑轮,8:甘蔗导向杆,9:驱动拖拉机

Figure 1. Type 4ZZX-48 sugarcane harvester

1:Frame,2:Clamping rubber block,3:Clamping conveyor sprocket,4:Sugarcane cutter,5:Clamping conveyor chain,6:Clamping point,7:Supporting wheel of sugarcane harvester,8:Guide rod for sugarcane,9:A tractor as power

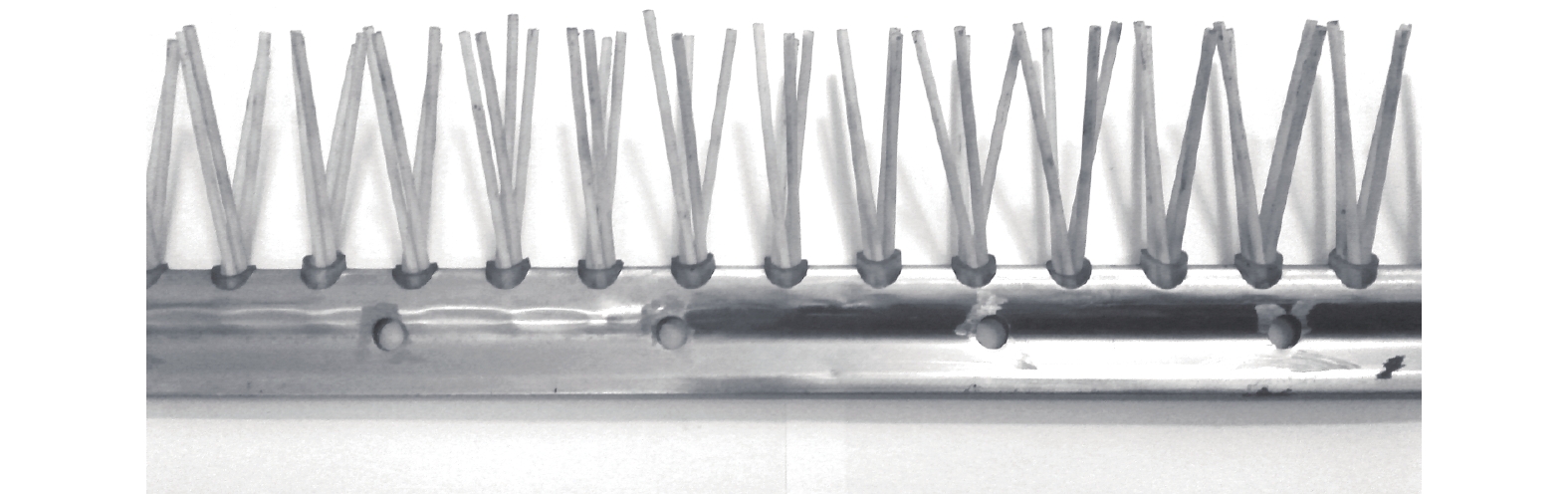

图 2 剥叶装置

1:驱动马达,2:下剥叶辊筒架,3:下剥叶辊筒,4:下立柱,5:联轴器,6:轴承,7:上剥叶辊筒,8:上立柱,9:上剥叶辊筒架

Figure 2. Leaf stripping device

1:Drive motor,2:Lower shelf of leaf stripping roller,3:Lower leaf stripping roller,4:Lower column,5:Coupling,6:Bearing,7:Upper leaf stripping roller,8:Upper column,9:Upper shelf of leaf stripping roller

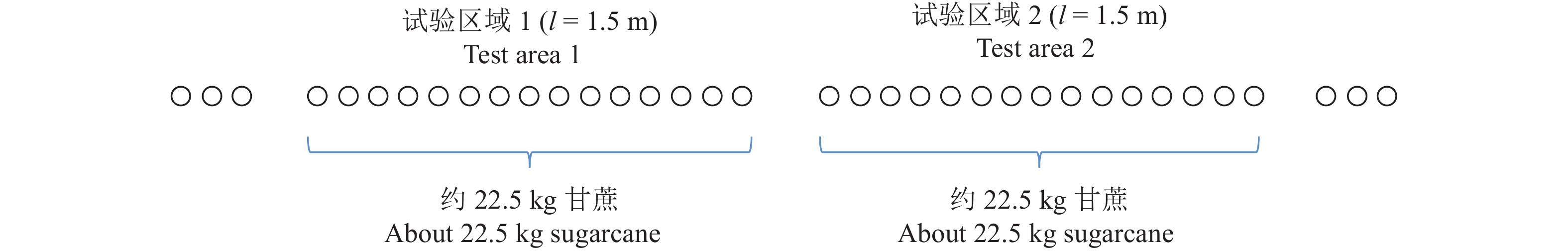

表 1 链轮转速与链条线速度对应关系表

Table 1 The relationship between sprocket speed and chain-line speed

链轮转速/(r·min)

Sprocket speed60 90 120 150 180 输送链速度/(m·s–1)

Chain-line speed0.57 0.86 1.14 1.43 1.71 表 2 收割机前进速度与喂入率对应关系表

Table 2 The relationship between harvester speed and feeding rate

收割机前进速度/(m·s–1)

Harvester speed0.3 0.4 0.5 0.6 0.7 甘蔗喂入率/(kg·s–1)

Feeding rate of sugarcane4.5 6.0 7.5 9.0 10.5 表 3 双因素试验安排表

Table 3 Schedule of double factor test r·min–1

水平Level 输送链轮转速

Speed of conveying sprocket剥叶辊筒转速

Speed of leaf roller1 60 120 2 120 240 3 180 360 表 4 不同夹持输送链轮转速水平的剥净率和方差分析结果

Table 4 The results of stripping rates of different speed levels and variance analysis

项目 Item 60 r·min–1 90 r·min–1 120 r·min–1 150 r·min–1 180 r·min–1 剥净率/% Stripping rate 76.0 74.0 72.1 68.1 50.5 标准误/% Standard error 3.9 1.8 1.1 1.5 5.7 变异来源 Variation source SS DF MS F P 组间 Between groups 0.126 4 0.032 9.649 0.002 组内 Within groups 0.033 10 0.003 总计 Total 0.159 14 表 5 不同剥叶辊筒安装角度水平的剥净率和方差分析结果

Table 5 The results of stripping rates of different installation angles and variance analysis

项目 Item 0° 15° 30° 剥净率/%

Stripping rate70.6 70.8 71.6 标准误/%

Standard error1.57 1.64 3.81 变异来源

Variation sourceSS DF MS F P 组间 Between groups 0.000 2 0.000 0.047 0.954 组内 Within groups 0.012 6 0.002 总计 Total 0.012 8 表 6 不同剥叶辊筒转速水平的剥净率和方差分析结果

Table 6 The results of stripping rates of different roller speeds and variance analysis

项目 Item 120 r·min–1 180 r·min–1 240 r·min–1 300 r·min–1 360 r·min–1 剥净率/% Stripping rate 67.6 75.9 76.6 76.9 81.1 标准误/% Standard error 1.75 1.66 2.60 2.60 2.66 变异来源 Variation source SS DF MS F P 组间 Between groups 0.029 4 0.007 4.574 0.023 组内 Within groups 0.016 10 0.002 总计 Total 0.045 14 表 7 不同喂入率的剥净率和方差分析结果

Table 7 The results of stripping rates of different feeding rates and variance analysis

项目

Item4.5 kg·s–1 7.5 kg·s–1 10.5 kg·s–1 剥净率/%

Stripping rate73.8 68.5 64.5 标准误/%

Standard error2.12 1.21 2.31 变异来源

Variation sourceSS DF MS F P 组间 Between groups 0.013 2 0.007 5.782 0.040 组内 Within groups 0.007 6 0.001 总计 Total 0.020 8 表 8 双因素试验的剥净率和方差分析结果

Table 8 The results of stripping rates of double factor test and variance analysis

输送链轮转速(n1)/(r·min–1)

Speed of conveying sprocket不同剥叶辊筒转速(n2)的剥净率(n2)/%

Stripping rate at different speed of leaf roller120 r·min–1 240 r·min–1 360 r·min–1 60 70.60 75.20 76.60 120 66.10 71.00 74.00 180 52.60 67.40 67.70 变异来源 Variation source SS DF MS F P 修正模型 Corrected model1) 0.135 8 0.017 9.397 0.000 截距 Intercept 12.957 1 12.957 7.236E3 0.000 n1 0.070 2 0.035 19.536 0.000 n2 0.054 2 0.027 15.060 0.000 n1×n2 0.011 4 0.003 1.497 0.245 误差 Error 0.032 18 0.002 合计 Total 2) 13.1242) 27 1) R2=0.807(修正R2=0.721);2) 修正合计SS为0.167,DF 为26

1) R2=0.807(Adjusted R2=0.721);2) Corrected total SS was 0.167,DF was 26表 9 转速比与剥净率关系

Table 9 The relationship between speed ratio and stripping rate

转速比(n2/n1) Rotation speed ratio 0.7 1.0 1.3 2.0 2.4 3.0 4.0 5.0 6.0 剥净率/% Stripping rate 52.5 64.2 67.4 62.5 68.1 73.4 75.2 76.9 77.9 表 10 转速比与剥净率相关分析1)

Table 10 Correlation analysis between rotation speed ratio and stripping rate

模型 Model R2 F DF1 DF2 P 常量 Constant b1 b2 一元线性 Linear 0.573 33.541 1 25 0.000 0.586 0.037 二次多项式 Quadratic 0.632 20.602 2 24 0.000 0.526 0.090 –0.008 1) 自变量为转速比

1) The independent variable was rotation speed ratio -

[1] 刘芳建, 杨学军, 刘赟东, 等. 我国整秆式甘蔗剥叶机械研究现状及思考[J]. 农机化研究, 2013, 35(10): 238-241. doi: 10.3969/j.issn.1003-188X.2013.10.060 [2] 刘正龙. 甘蔗机械剥叶原理分析与新款机型构思[J]. 农机科技推广, 2013(2): 50-51. doi: 10.3969/j.issn.1671-3036.2013.02.024 [3] 张威, 周新民, 邓道路, 等. 适用于云南山区小型整秆式甘蔗剥叶机的设计[J]. 企业技术开发, 2011(10): 11-12. [4] 程绍明, 王俊, 王永维. 我国整秆式甘蔗联合收割机的现状和问题[J]. 现代农业科技, 2013(20): 193-194. doi: 10.3969/j.issn.1007-5739.2013.20.122 [5] 解福祥, 区颖刚, 刘庆庭, 等. 侧悬挂推倒式整秆甘蔗收获机设计与试验[J]. 农业机械学报, 2011, 42(S1): 26-29. [6] 刘庆庭, 莫建霖, 区颖刚, 等. 我国整秆与切段2种甘蔗收获方式发展历程与前景分析[J]. 甘蔗糖业, 2013(6): 45-55. doi: 10.3969/j.issn.1005-9695.2013.06.010 [7] 肖宏儒, 王明友, 宋卫东, 等. 整秆式甘蔗联合收获机降低含杂率的技术改进与试验[J]. 农业工程学报, 2011, 27(11): 42-45. doi: 10.3969/j.issn.1002-6819.2011.11.008 [8] 刘芳建, 狄明利, 米义, 等. 甘蔗逆剥剥叶方式的试验研究[J]. 农机化研究, 2015, 37(1): 174-176. [9] 牟向伟, 区颖刚, 吴昊, 等. 甘蔗叶鞘在弹性剥叶元件作用下破坏高速摄影分析[J]. 农业机械学报, 2012, 43(2): 85-89. doi: 10.6041/j.issn.1000-1298.2012.02.018 [10] DEUGAN J. Dynamic mechanical properties of sugarcane[C]//ZHANG J, TAN H H. Proceedings of 2013 2nd International Conference on Mechanical Properties of Materials and Information Technology(ICMPMIT 2013). Hong Kong: Information Engineering Research Institute, 2013: 321-325.

[11] 牟向伟. 弹性齿对甘蔗茎秆的动态打击力与叶鞘剥离机理研究[J]. 农业机械学报, 2015, 46(3): 103-109. [12] 牟向伟, 黄煜, 万理, 等. 甘蔗整秆剥叶关键技术与剥叶机理研究[J]. 农机化研究, 2013, 35(11): 13-17. doi: 10.3969/j.issn.1003-188X.2013.11.003 [13] YANG N J. Research on integrated design platform of sugarcane harvester[C]//IEEE. Measuring technology and mechatronics automation (ICMTMA 2010). Beijin: IEEE, 2010: 252.

[14] 李炅, 林茂, 王伟, 等. 甘蔗剥叶机含杂率试验研究[J]. 机械设计与制造, 2017(4): 144-147. doi: 10.3969/j.issn.1001-3997.2017.04.037 [15] 张增学. 梳刷式甘蔗剥叶机剥叶机理的试验研究[D]. 广州: 华南农业大学, 2002. [16] 蒙艳玫, 刘正士, 李尚平, 等. 甘蔗收获机械排刷式剥叶元件虚拟试验分析[J]. 农业机械学报, 2003, 34(4): 43-46. doi: 10.3969/j.issn.1000-1298.2003.04.013 [17] 牟向伟, 区颖刚, 刘庆庭, 等. 甘蔗叶鞘剥离过程弹性齿运动分析与试验[J]. 农业机械学报, 2014, 45(2): 122-129. [18] LAI X, LIANG S, LIU D M, et al. Virtual simulation analysis and experiment study on a new peel scratch relieving design of sugarcane leaf cleaning device[C]//IEEE. Measuring Technology and Mechatronics Automation. Beijin: IEEE, 2009: 499-500.

[19] 牟向伟, 区颖刚, 刘庆庭, 等. 弹性齿滚筒式甘蔗剥叶装置[J]. 农业机械学报, 2012, 43(4): 60-65. doi: 10.6041/j.issn.1000-1298.2012.04.013 [20] 黎毓鹏, 郑广平, 宋咏春, 等. 小型甘蔗剥叶机的试验与研究[J]. 装备制造技术, 2010(2): 14-15. doi: 10.3969/j.issn.1672-545X.2010.02.006 [21] 王光炬, 乔艳辉, 吕勇. 甘蔗剥叶机理研究[J]. 山东农业大学学报(自然科学版), 2007, 38(3): 461-464. doi: 10.3969/j.issn.1000-2324.2007.03.030 [22] 孔林, 周德俭, 谌炎辉. 新型小型甘蔗剥叶机剥叶机构设计与优化[J]. 中国农机化学报, 2015, 36(2): 124-127. [23] 黄深闯, 杨望, 杨坚, 等. 甘蔗茎秆–蔗叶系统有限元建模方法研究[J]. 农机化研究, 2018, 40(6): 19-23. doi: 10.3969/j.issn.1003-188X.2018.06.004 [24] 王华准, 方卫山, 牛宪伟, 等. 轮式拖拉机驱动型甘蔗剥叶机研究开发[J]. 现代农业装备, 2017(2): 31-35. doi: 10.3969/j.issn.1673-2154.2017.02.011 [25] 刘志华, 林茂. 甘蔗收割机剥叶元件的优化研究[J]. 机械设计与制造, 2015(2): 253-256. doi: 10.3969/j.issn.1001-3997.2015.02.068 [26] 王伟, 林茂. 甘蔗剥叶元件的运动参数试验分析[J]. 机械设计与制造, 2016(4): 203-206. doi: 10.3969/j.issn.1001-3997.2016.04.053 -

期刊类型引用(6)

1. 徐凤英,夏腾飞,刘庆庭,邹小平,陈震,罗菊川. 甘蔗整秆立式收获集捆装置多刚体动力学仿真与试验. 华南农业大学学报. 2025(01): 124-132 .  本站查看

本站查看

2. 赖晓,陈森,陈佩钟,陈德健. 甘蔗收获机输送系统堵塞的仿真与试验. 农机化研究. 2025(09): 162-170 .  百度学术

百度学术

3. 刘庆庭,黄瑶,蒋姣丽,武涛. 甘蔗机械化收获技术与装备研究综述. 农业机械学报. 2024(12): 1-21 .  百度学术

百度学术

4. 万星宇,武安阳,廖庆喜,马国庆,李运通,廖宜涛. 气力机械组合式藜蒿脱叶机设计与试验. 农业机械学报. 2023(08): 132-142 .  百度学术

百度学术

5. 周阳,黄海东,张国忠,房震,徐中杰,魏明. 艾草脱叶机设计与试验研究. 农机化研究. 2022(02): 197-202 .  百度学术

百度学术

6. 谢卢鑫,王俊,程绍明,曾伯胜,杨子增,陈保善,黄有总. 整秆式甘蔗收割机剥叶过程仿真分析与试验. 农业工程学报. 2020(18): 56-65 .  百度学术

百度学术

其他类型引用(5)

下载:

下载: