Design and test of a trenching depth control system based on laser sensor

-

摘要:目的

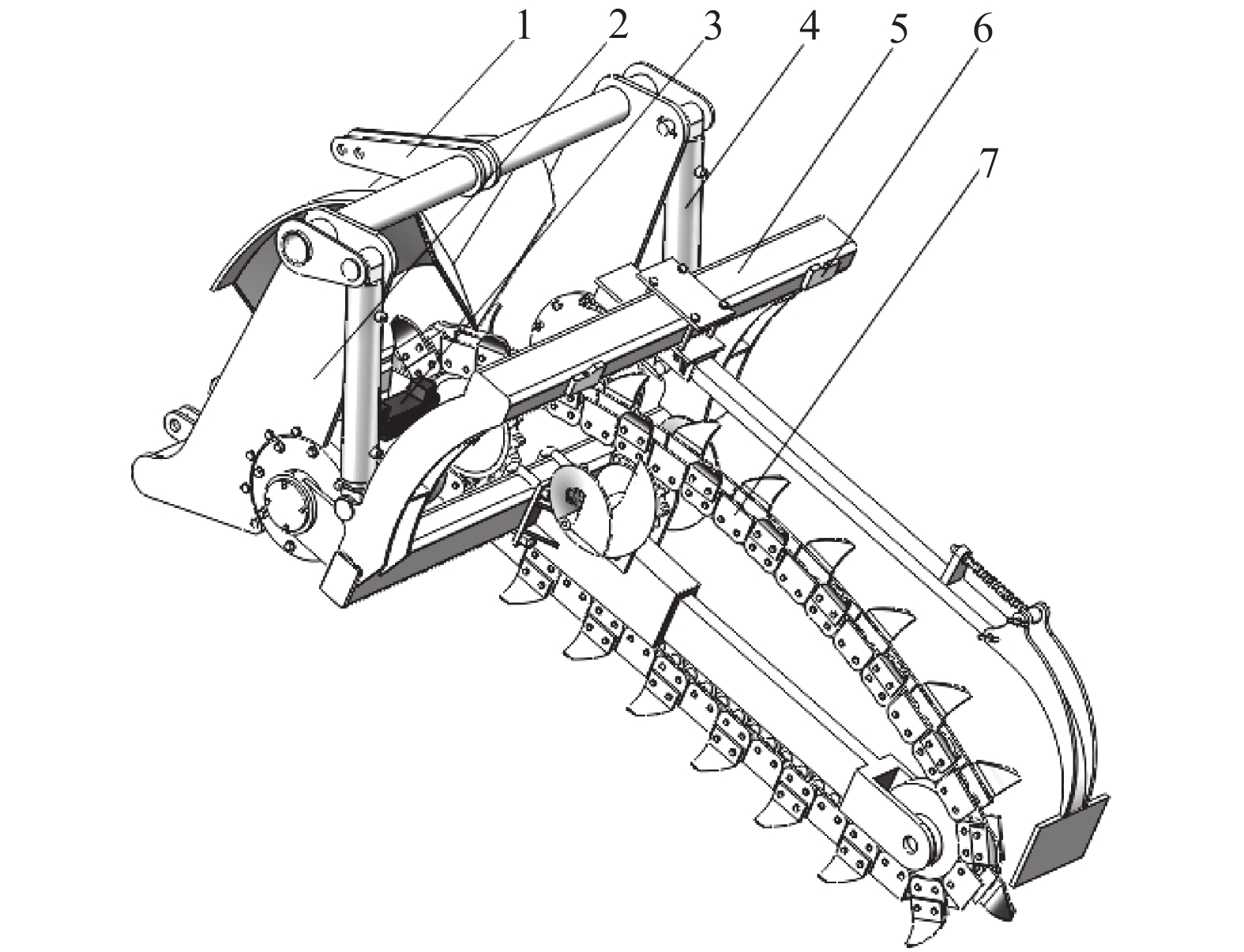

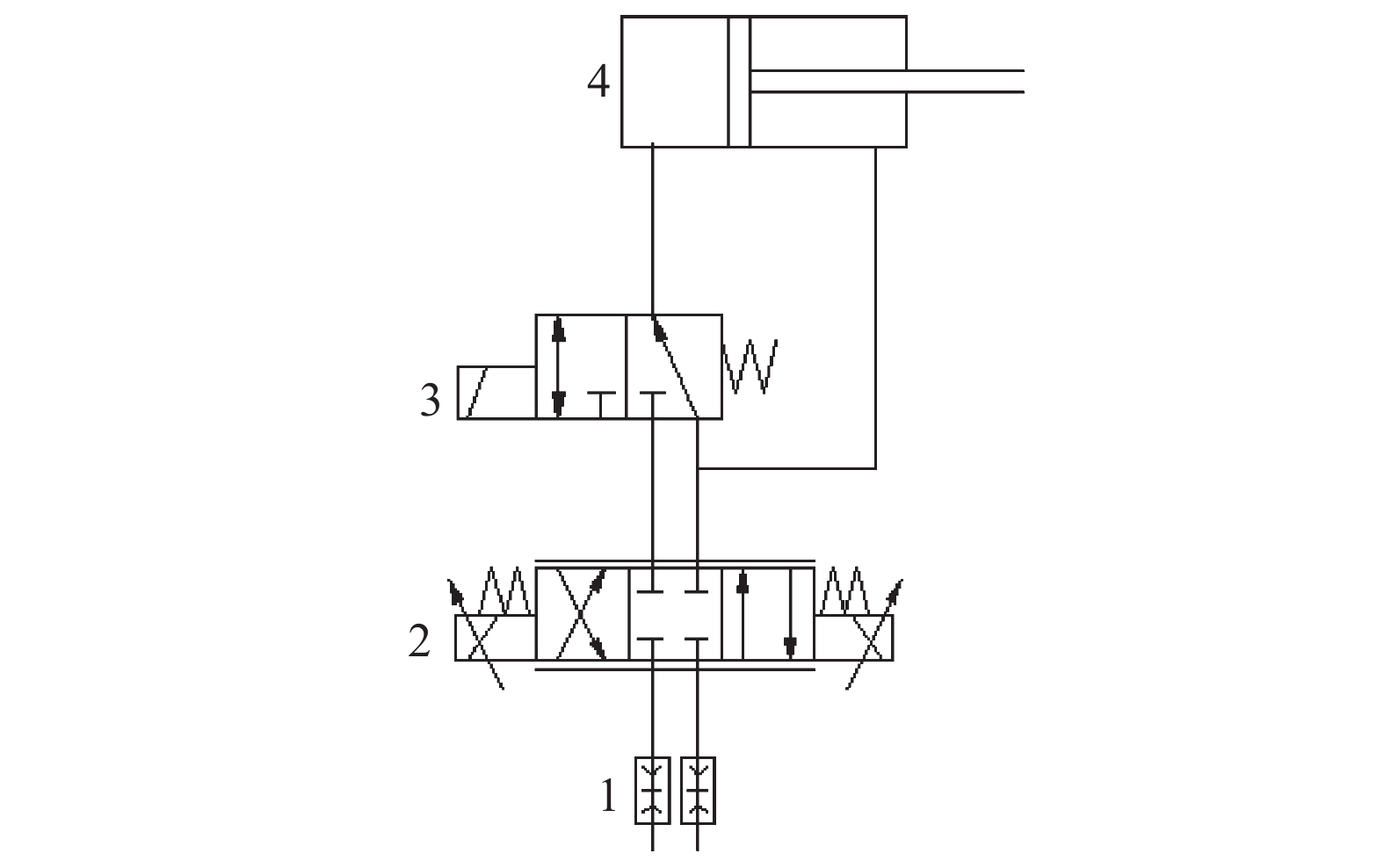

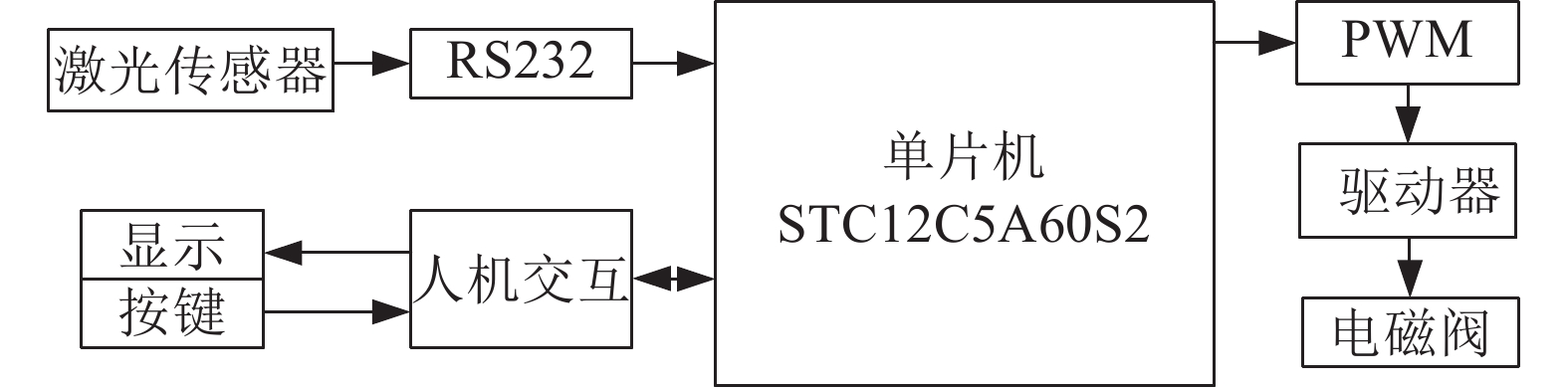

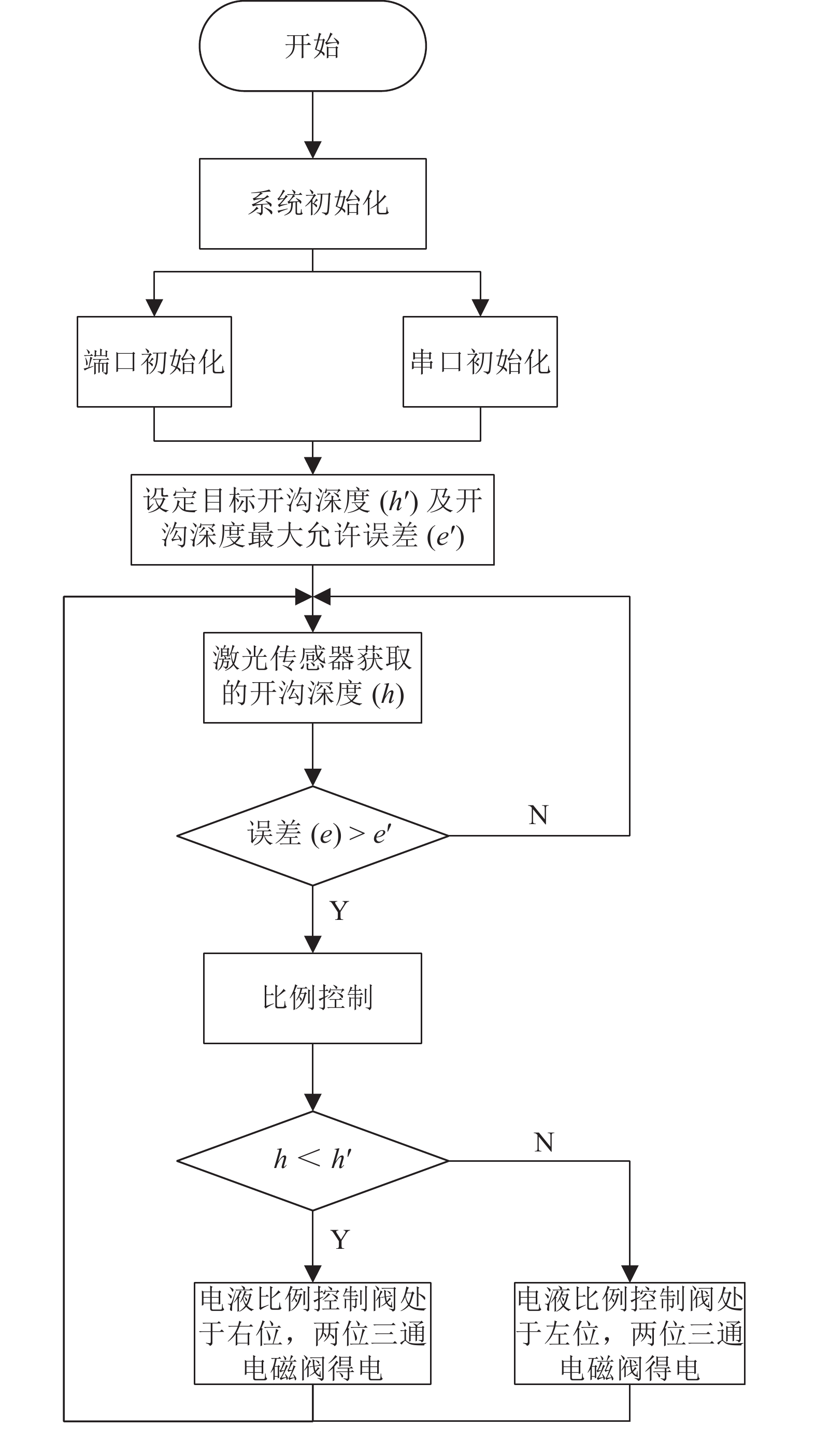

针对链式开沟机开沟深度难以精确调节的问题,设计一种基于激光传感器的开沟深度控制系统。

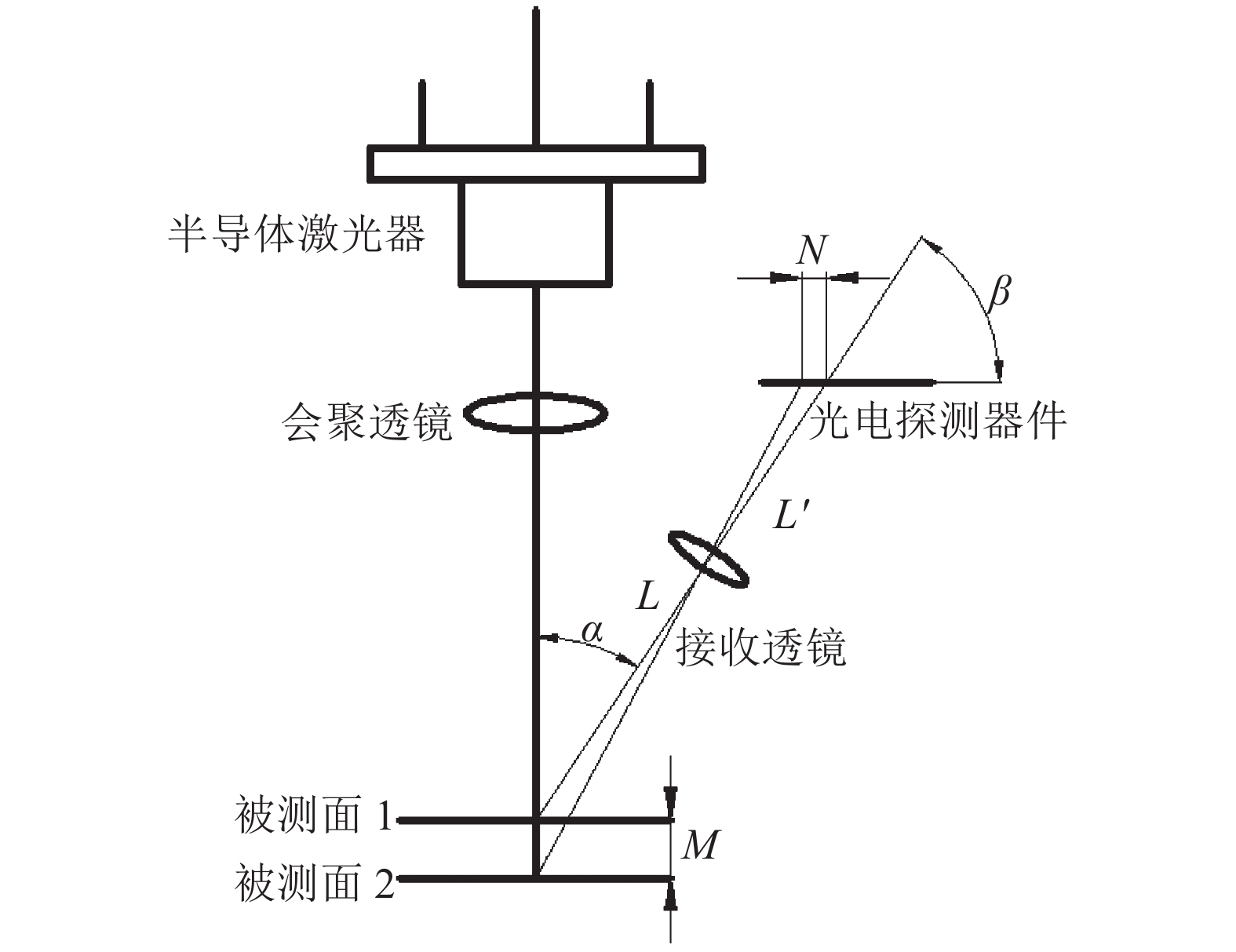

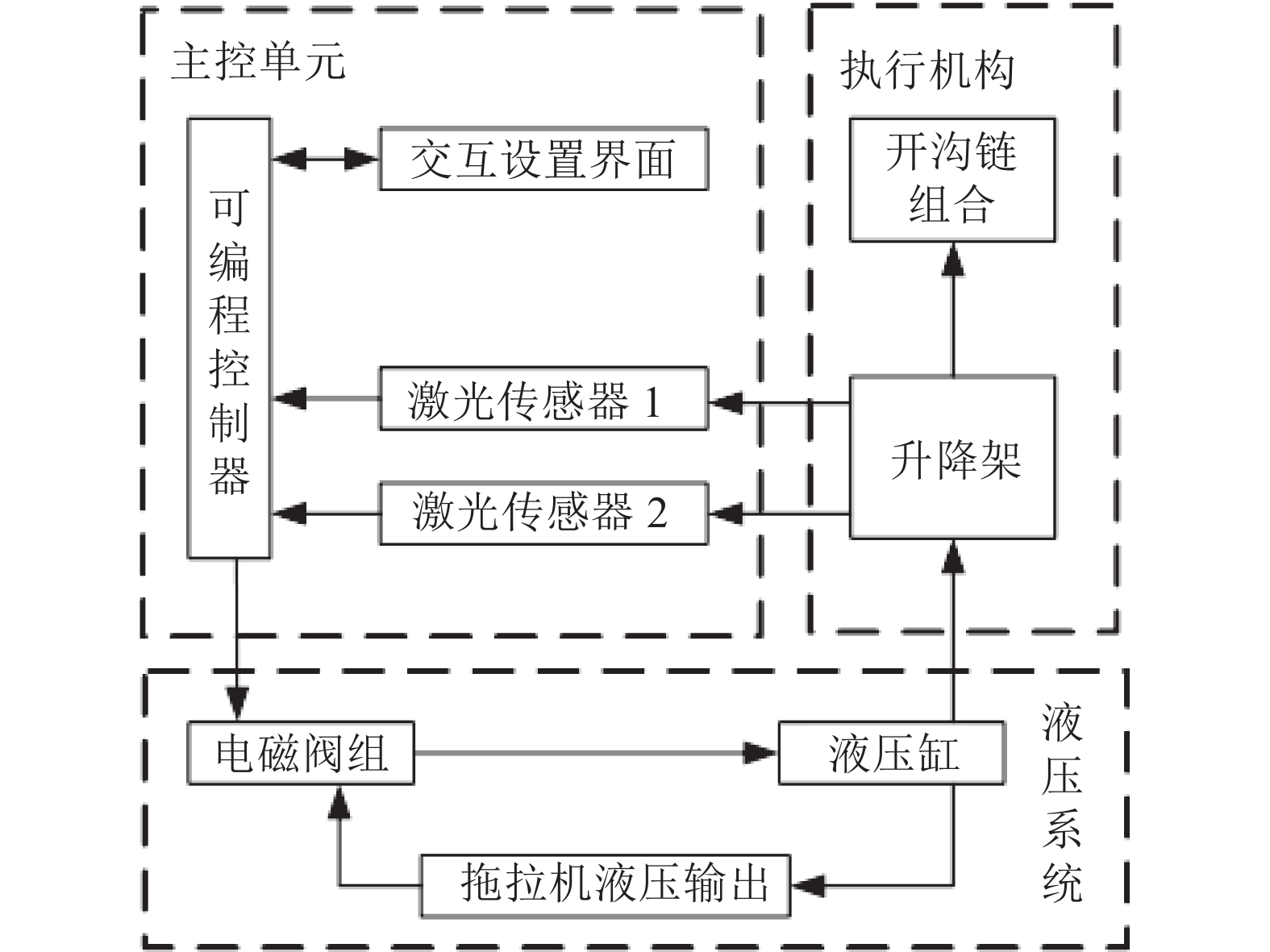

方法采用激光三角反射式位移传感器实时检测开沟深度,并与设定目标值比较;通过控制系统决策驱动液压系统与执行机构,实现开沟深度的闭环控制;通过田间试验,比较了开沟深度控制系统开启前后控制精度和稳定性。

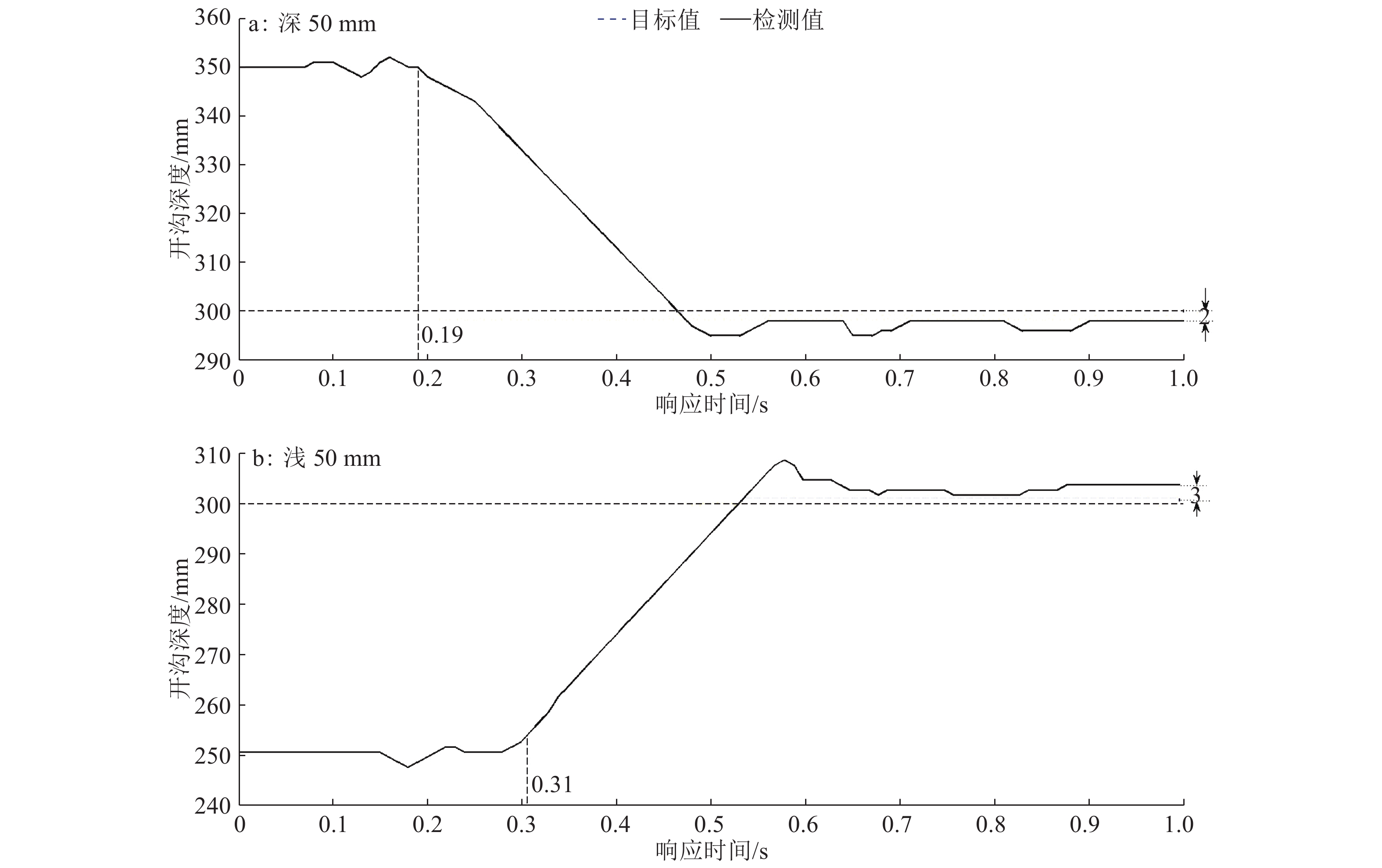

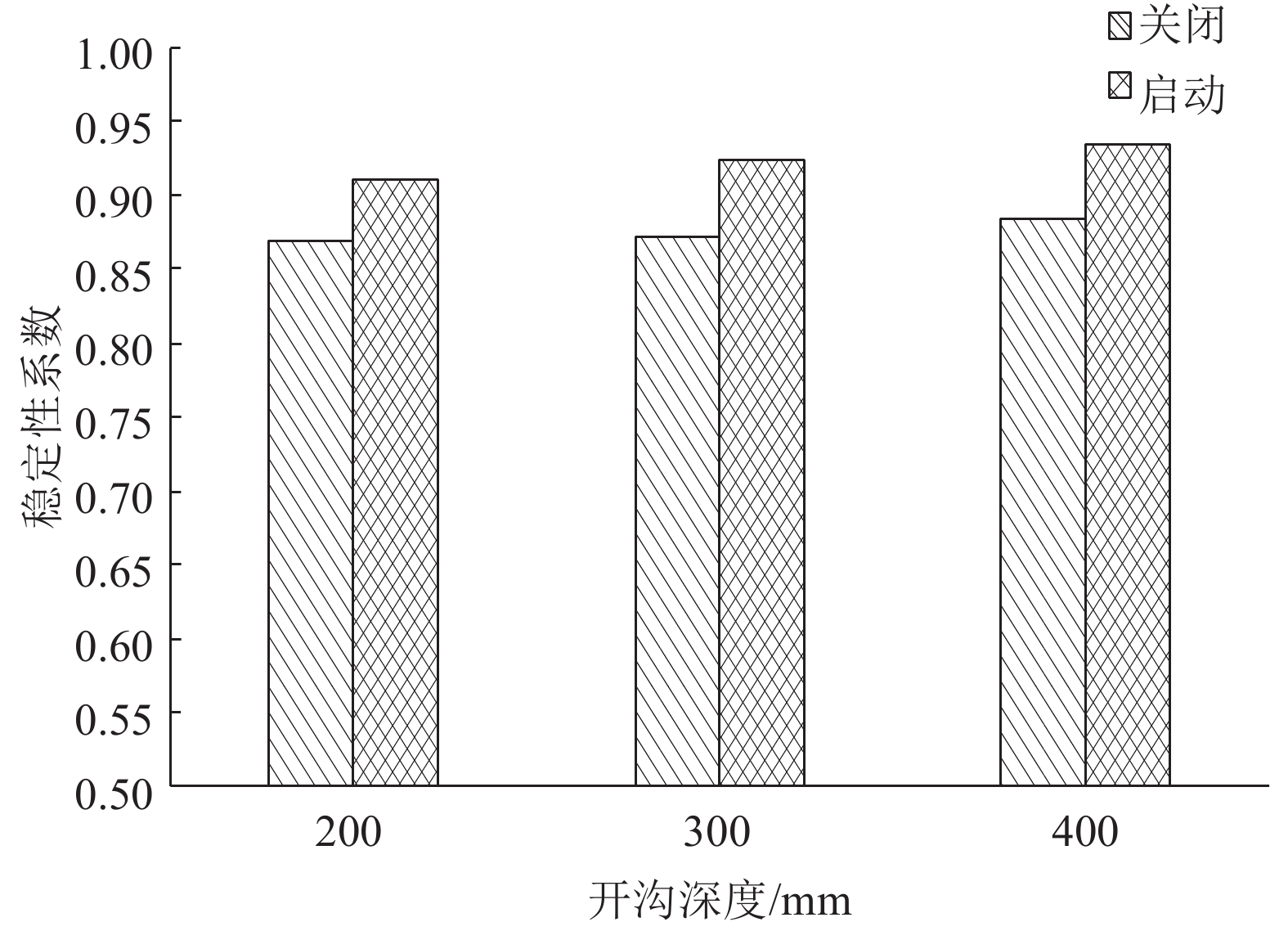

结果静态试验结果表明,当开沟深度检测值与目标值相差±50 mm时,系统响应时间分别为0.19和0.31 s,最大控制误差3 mm。田间试验表明,开沟深度分别为200、300和400 mm,前进速度为3 km·h–1时,启动开沟深度控制系统后,链式开沟机开沟深度的控制精度和稳定性均得到提高;与关闭系统相比,启动系统后控制精度提高了2.3%,稳定性系数提高了4.3%。

结论该控制系统响应迅速、控制精度较高,控制误差满足了设置要求。研究结果为链式开沟机开沟深度控制提供了一种解决方法。

Abstract:ObjectiveTo design a kind of trenching depth control system based on laser sensor, so as to solve the problem that it is difficult to adjust accurately the trenching depth of chain trencher.

MethodThe laser triangular-reflecting displacement sensor was used to detect the trenching depth in real time, which was compared with the target value. The closed-loop control of trenching depth was realized by the control system making decision and driving hydraulic system and actuator. The field experiment was conducted to compare the control precision and stability before and after enabling the system.

ResultThe result of static test showed that when the different values between the detection depth and the target depth were ±50 mm, the response time of the system were 0.19 and 0.31 s respectively, and the maximum control error was 3 mm. The field test showed that when the trenching depths were 200, 300 and 400 mm respectively at the speed of 3 km·h–1, the control precision and stability for trenching depth of the chain trencher were improved after starting the control system. Compared with closing the system, the control precision and stability coefficients increased by 2.3% and 4.3% respectively after opening the system.

ConclusionThis control system responds quickly with a high control accuracy, and the control error satisfies the set requirements. The result provides a solution for controlling the trenching depth of the chain trencher.

-

Keywords:

- laser sensor /

- control system /

- chain trencher /

- trenching depth /

- design and test /

- control accuracy /

- constancy

-

-

表 1 田间试验的土壤参数

Table 1 Parameters of soil in the field experiment

深度/mm 容重/(g·cm–3) 含水量(w)/% 坚实度/MPa 0~100 1.31 21.63 0.91 100~200 1.48 18.45 1.89 200~300 1.55 16.83 2.34 300~400 1.58 15.97 2.87 表 2 不同的选定开沟深度下系统启用前后的实际测量结果

Table 2 The measurement results of different selected trenching depths before and after enabling the system mm

试验点 200 mm 300 mm 400 mm 关闭 启动 关闭 启动 关闭 启动 1 156 213 351 296 422 366 2 181 172 269 319 353 421 3 233 166 344 271 371 396 4 165 187 278 288 353 373 5 178 191 353 323 465 425 6 189 209 286 262 356 376 7 233 196 336 271 449 428 8 239 179 245 322 386 386 9 196 189 329 289 331 389 10 206 216 347 311 418 438 平均值 184.6 191.8 313.8 295.2 390.4 399.8 -

[1] 覃国良, 廖庆喜, 周善鑫, 等. 基于MATLAB的链式开沟机功耗的优化设计与分析[J]. 湖北农业科学, 2009, 48(1): 210-214. [2] 王京风. 微型果园开沟机的设计分析与优化[D]. 杨凌: 西北农林科技大学, 2010. [3] 张琦, 王伟, 廖结安. 国内外果园施肥开沟机的研究现状[J]. 农机化研究, 2016, 38(5): 264-268. [4] 赵金辉, 刘立晶, 杨学军, 等. 播种机开沟深度控制系统的设计与室内试验[J]. 农业工程学报, 2015, 31(6): 35-41. [5] 蔡国华, 李慧, 李洪文, 等. 基于ATmega128单片机的开沟深度自控系统试验台的设计[J]. 农业工程学报, 2011, 27(10): 11-16. [6] WEATHERLY E T, BOWERS J C G. Automatic depth control of a seed planter based on soil drying front sensing[J]. T ASABE, 1997, 40(2): 295-305.

[7] 黄东岩, 朱龙图, 贾洪雷, 等. 基于压电薄膜的免耕播种机播种深度控制系统[J]. 农业机械学报, 2015, 46(4): 1-8. [8] 万国伟, 舒彩霞, 刘晓鹏, 等. 液压驱动式圆盘耙设计与仿真试验[J]. 华南农业大学学报, 2017, 38(5): 117-124. [9] 林家泉, 程绪宇, 周贤民, 等. 一种小型直流电机控制系统硬件设计方案[J]. 自动化与仪表, 2014, 29(11): 73-76. [10] 张锋, 刘丹. 温室大棚数据采集与控制系统设计[J]. 现代化农业, 2018(4): 2-4. [11] 臧胜超. 基于EPA的工业控制器的设计[D]. 大连: 大连交通大学, 2013. [12] 王晓嘉, 高隽, 王磊. 激光三角法综述[J]. 仪器仪表学报, 2004(S2): 601-604. [13] 郝向泽, 何旭鹏, 邹翌, 等. 基于光电传感器的精密播种机排种性能监测系统的研究[J]. 华南农业大学学报, 2017, 38(1): 120-124. [14] 梅剑春, 叶青, 田建国. 钢管管端内外径测量系统的设计与实现[J]. 光学精密工程, 2014, 22(4): 815-821. [15] 冯俊艳, 冯其波, 匡萃方. 高精度激光三角位移传感器的技术现状[J]. 应用光学, 2004(3): 33-36. [16] 魏彬彬. 高淳县生态农业发展规划研究[D]. 扬州: 扬州大学, 2006. [17] 张维理, 徐爱国, 张认连, 等. 土壤分类研究回顾与中国土壤分类系统的修编[J]. 中国农业科学, 2014, 47(16): 3214-3230. [18] YANG H S, YANG B, DAI Y J, et al. Soil nitrogen retention is increased by ditch-buried straw return in a rice-wheat rotation system[J]. Eur J Agron, 2015, 69: 52-58.

[19] WANG X H, YANG H S, LIU J, et al. Effects of ditch-buried straw return on soil organic carbon and rice yields in a rice-wheat rotation system[J]. Catena, 2015, 127: 56-63.

[20] 农机通. 清旋1KJ-35开沟机[EB/OL]. [2018–04–19] . https://www.nongjitong.com/product/11167.html. [21] 几款链式开沟机的性能及特点比较[J]. 农业机械, 2006(20): 6. [22] 中华人民共和国农业部. 田间开沟机械作业质量: NY/T 740—2003[S]. 北京: 中国标准出版社, 2004.

下载:

下载: