Manufacturing technology of composite particleboard using waste newspaper and wood particles

-

摘要:目的

为废纸资源化利用奠定基础,创造重要的经济、生态和环境效益。

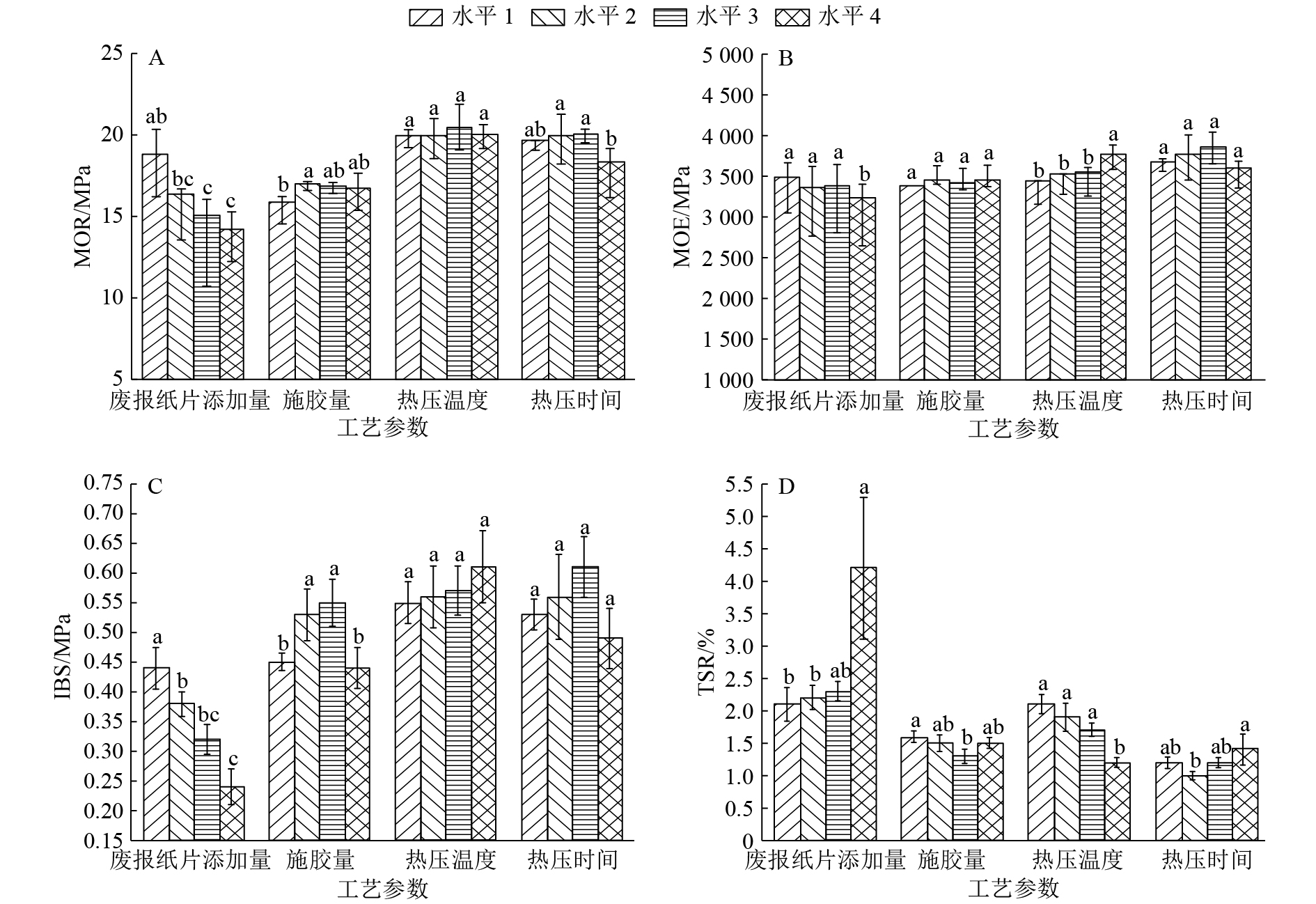

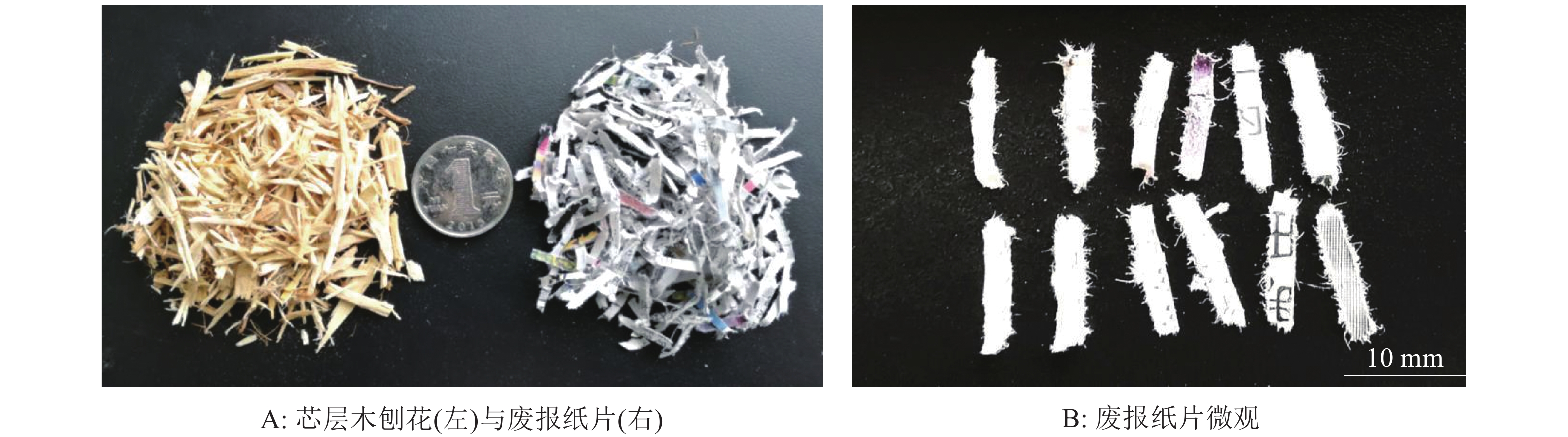

方法以杂木刨花和回收废旧报纸为原料,通过胶合和高温热压相结合的方法制备废纸–木复合刨花板,研究废报纸添加量、环保脲醛树脂胶施胶量和热压工艺等因素对复合刨花板的静曲强度(MOR)、弹性模量(MOE)、内结合强度(IBS)和吸水厚度膨胀率(TSR)等物理力学性能的影响。

结果脲醛树脂胶黏剂(UF)施胶量11%、废报纸用量10%、自制石蜡乳液添加量1.0%、热压温度190 ℃、热压时间(以热压1 mm计)为34 s工艺条件下制备的复合刨花板,游离甲醛释放量为0.022 4 mg·g–1(穿孔萃取法),远低于国标GB 18580—2001 E1级的限量阈值(0.090 0 mg·g–1);MOR、MOE和IBS分别为20.43、3 431.00和0.57 MPa,TSR为1.7%,性能指标均远超过GB 4897—2015中干燥状态下使用的家具型(P2型)刨花板的技术指标。

结论废报纸与木刨花制备复合刨花板是一种有效的废纸利用途径。

Abstract:ObjectiveTo provide a basis for wastepaper recycling and create important economic, ecological and environmental benefits.

MethodComposite particleboard was manufactured using waste newspaper and wood particles of mixed wood species with adhesives under hot pressing. Effects of the addition amount of wastepaper, amount of urea formaldehyde resin (UF), and hot pressing parameters on physical and mechanical properties including the modulus of rupture (MOR), modulus of elasticity (MOE), internal bonding strength (IBS) and thickness swelling rate (TSR) of composite particleboard were studied.

ResultThe optimal manufacture parameters were 11% UF, 10% wastepaper and 1.0% self-made wax emulsion under 190 ℃ of hot pressing temperature and pressing 34 s·mm–1. The formaldehyde emission from the manufactured composite particleboard was 0.002 4 mg·g–1 using the perforator method, which was much lower than the threshold value of 0.009 0 mg·g–1 for E1 level based on the GB 18580—2001 standard. The MOR, MOE and IBS were 20.43, 3 431 and 0.57 MPa respectively, and the TSR was 1.7%. These properties exceeded the requirements of P2-type particle board at dry condition according to GB 4897—2015 standard.

ConclusionIt is an effective way to utilize wastepaper and wood particles for producing composite particleboard.

-

-

图 2 工艺参数对复合刨花板静曲强度(MOR)、弹性模量(MOE)、内结合强度(IBS)和吸水厚度膨胀率(TSR)的影响

各图中,同一工艺参数的不同柱子上方,凡是具有一个相同小写字母者,表示水平间差异不显著(P>0.05,Duncan︐s法)

Figure 2. Effects of manufacturing parameters on modulus of rupture (MOR), modulus of elasticity (MOE), internal bonding strength (IBS) and thickness swelling rate (TSR) of composite particleboards

表 1 废报纸与木质刨花复合刨花板的制备工艺参数

Table 1 Manufacturing parameters of composite particleboard using waste newspaper and wood particles

变量

水平废报纸片

添加量/%芯层施

胶量/%热压温度/

℃热压时间1)/

s1 10 9 170 19 2 20 11 180 26 3 30 13 190 34 4 50 15 200 40 1)以热压1 mm计 -

[1] 郭彩云. 2016年国内外废纸市场概况[J]. 造纸信息, 2017(10): 71-80. doi: 10.3969/j.issn.1006-8791.2017.10.024 [2] 卞琼, 刘明华. 废纸的资源化利用研究[J]. 华东纸业, 2014, 45(1): 45-50. doi: 10.3969/j.issn.1674-6937.2014.01.010 [3] 张效林, 王汝敏. 印刷包装废纸在复合材料领域的回用技术新进展[J]. 材料导报, 2010, 24(17): 96-100. [4] 张海青. 二次纤维在造纸中现存问题及解决措施研究[J]. 民营科技, 2017(1): 61. doi: 10.3969/j.issn.1673-4033.2017.01.055 [5] ODUSOTE J K, ONOWUMA S A, FODEKE E A. Production of paperboard briquette using waste paper and sawdust[J]. J Eng Res, 2016, 13(1): 80-88. doi: 10.24200/tjer.vol13iss1pp80-88

[6] KUPRES K. Composite materials produced from waste paper[D]. Croatia : University of Zagreb, 2015.

[7] LYKIDIS C, PAMAVELA C, GOULOUNIS N, et al. Potential for utilizing waste corrugated paper containers into wood composites using UF and PMDI resin systems[J]. Eur J Wood Wood Prod, 2012, 70(6): 811-818.

[8] NOURBAKHSH A, ASHORI A. Particleboard made from waste paper treated with maleic anhydride[J]. Waste Manage Res, 2010, 28(1): 51-55. doi: 10.1177/0734242X09336463

[9] 岳孔, 叶建, 郑虹, 等. 办公废纸–废木刨花制作家具碎料板的研究[J]. 西北林学院学报, 2008, 23(5): 166-168. [10] NICEWICZ D, PAWLICKI J, BORYSIUK P, et al. Application of waste paper in manufacturing of particleboards[J]. Acta Sci Pol, 2006, 5(1): 163-171.

[11] GRIGORIOU A H. Waste paper-wood composites bonded with isocyanate[J]. Wood Sci Technol, 2003, 37(1): 79-89. doi: 10.1007/s00226-003-0164-x

[12] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 人造板及饰面人造板理化性能试验方法: GB 17657—2013[S]. 北京: 中国标准出版社, 2013: 1-17. [13] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 室内装饰装修材料人造板及其制品中甲醛释放限量: GB 18580—2001[S]. 北京: 中国标准出版社, 2001: 1-13. [14] 杜官本, 雷洪, PIZZI A. 脲醛树脂固化过程的热机械性能分析[J]. 北京林业大学学报, 2009, 31(3): 106-110. doi: 10.3321/j.issn:1000-1522.2009.03.019 [15] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 刨花板: GB 4897—2015[S]. 北京: 中国标准出版社, 2015: 1-7. [16] 罗丽, 赵峰, 刘悦, 等. 用废纸与木片制备复合包装材料的热压工艺研究[J]. 包装学报, 2014, 6(1): 44-47. doi: 10.3969/j.issn.1674-7100.2014.01.010 [17] 雷亚芳. 刨花板热压过程中传热特性的研究[D]. 北京: 北京林业大学, 2005.

下载:

下载: