Experiment on drop collision damages during litchi picking by robot

-

摘要:目的

减小机器人采摘荔枝时因回收放置不当产生的跌落碰撞损伤。

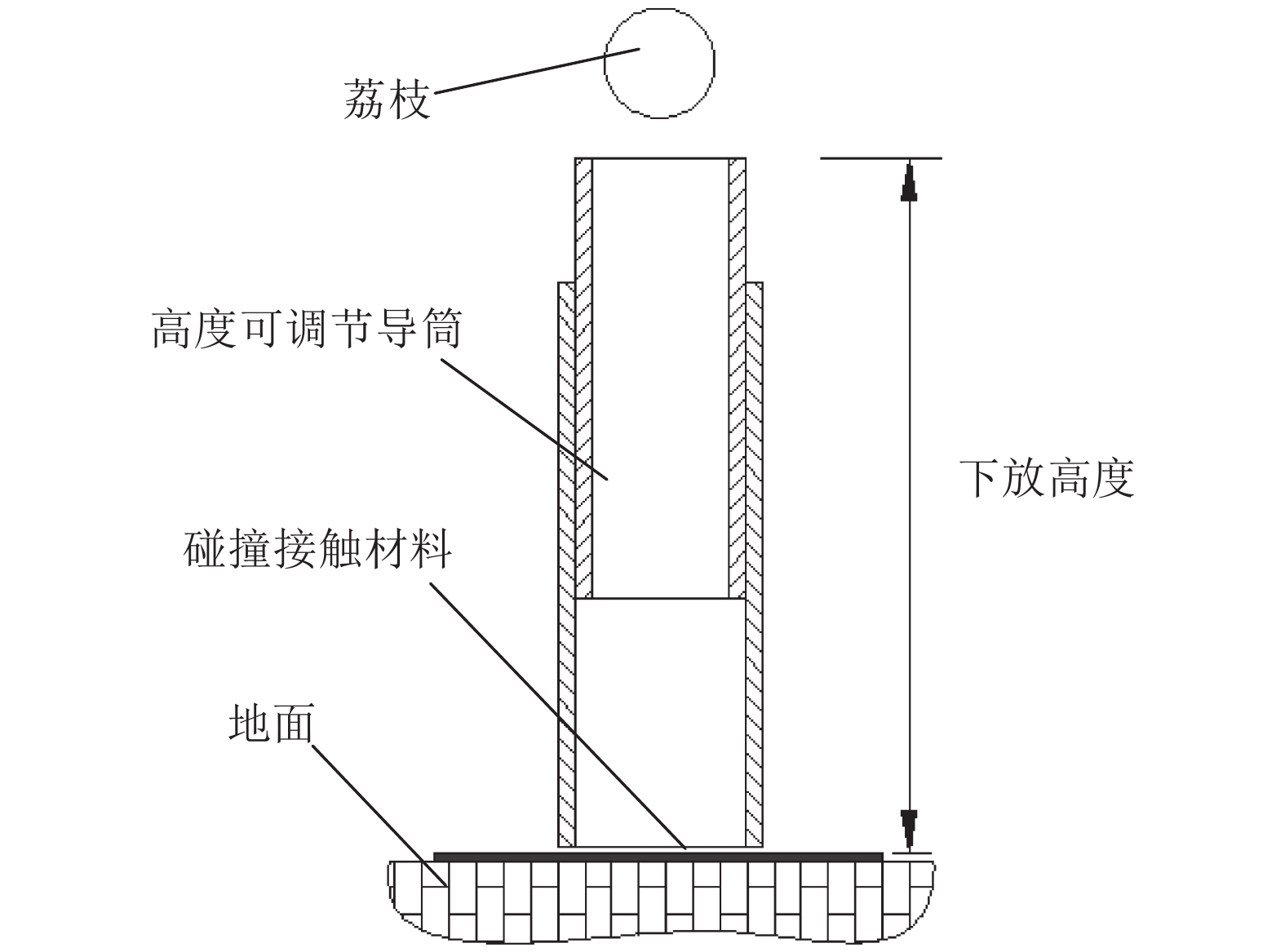

方法对荔枝进行跌落碰撞试验,分析不同的跌落碰撞条件对荔枝失质量率及果壳褐变指数的影响。

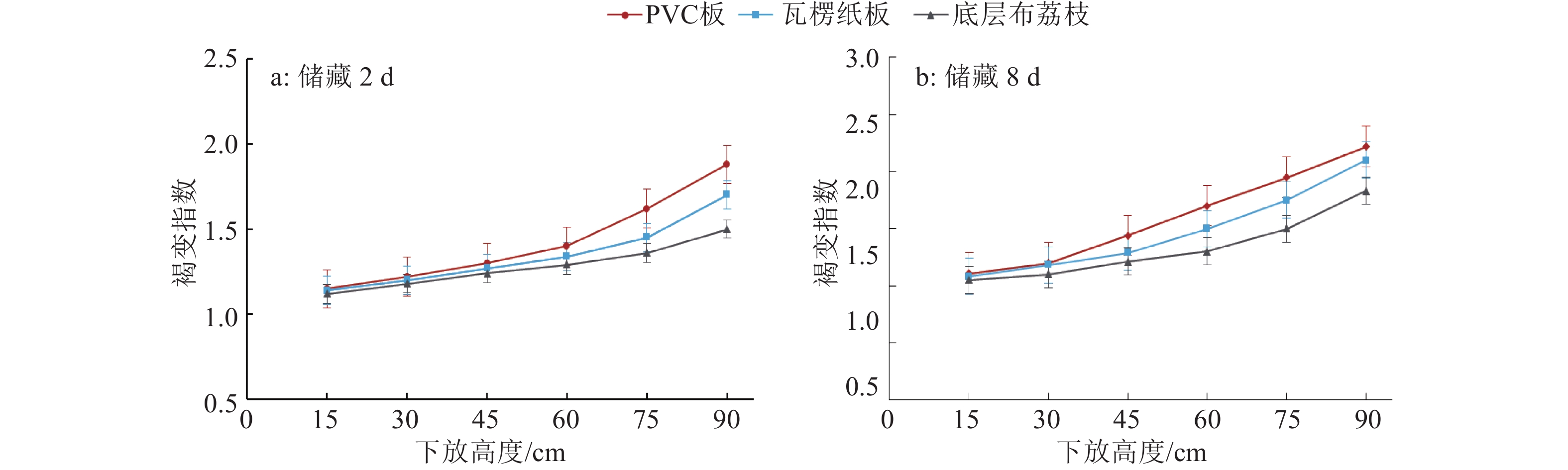

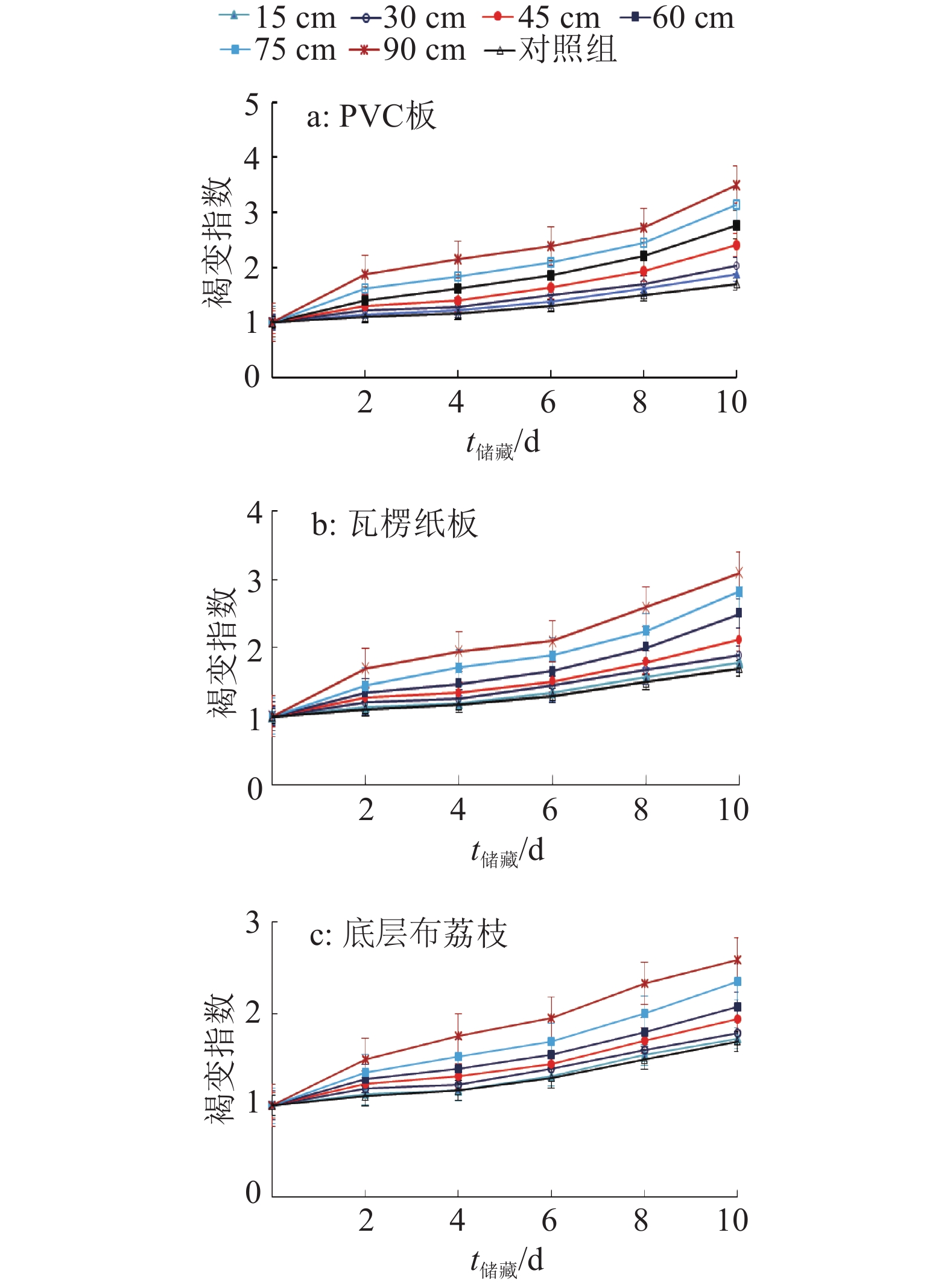

结果荔枝失质量率及果壳褐变指数随着采摘回收下放高度的提高和储藏时间的延长而分别增加;相同下放高度,碰撞接触材料为PVC板时,荔枝失质量率及果壳褐变指数最大;试验范围内,回收装置采用塑料框时,储藏2 d机器人采摘回收的最大起始下放高度为60 cm,储藏1周为30 cm;回收装置为瓦楞纸果箱,储藏2 d机器人采摘回收的最大起始下放高度为75 cm,储藏1周为45 cm;回收装置底层布满荔枝后,储藏2 d机器人采摘回收的最大起始下放高度可提高到90 cm,储藏1周可提高到60 cm。

结论该研究可为荔枝机器人采摘回收放置减损策略的构建提供指导。

Abstract:ObjectiveTo reduce the drop collision damages during litchi picking by robot due to improper placement and recycling.

MethodThe drop collision experiment of litchi was performed. The influences of different drop collision conditions on weight loss and pericarp browning indexes of litchi were analyzed.

ResultThe weight loss and pericarp browning indexes of litchi both increased with the dropping height of picking and placing and increased with the storage time. At the same dropping height, the weight loss and pericarp browning indexes of litchi were the highest when the impact contact material was PVC slab at collision. Within the scope of the experiment, it was conducive to reducing drop collision damages of litchi using the following maximum initiative dropping heights during the picking and placing process by robot: 60 cm after 2 d storage and 30 cm after one week storage when the recycling device was made from PVC plastic; 75 cm after 2 d storage and 45 cm after one week storage when the recycling device was made from corrugated board; 90 cm after 2 d storage and 60 cm after one week storage when the bottom of the recycling device was filled with litchi.

ConclusionThe research can provide guidance for developing strategies to decrease damage during the litchi picking and placing process based on robot.

-

Keywords:

- picking robot /

- litchi /

- drop collision damage /

- dropping height /

- contact material

-

-

表 1 虚拟变量的设置和赋值

Table 1 Settings and assignments for virtual variables

碰撞接触材料 虚拟变量 L1 L2 PVC 0 1 瓦楞纸 1 0 底层布荔枝 1 1 表 2 减少损伤的最大回收下放高度

Table 2 The rmaximum dropping height during recycling for damage reducing

cm t储藏/d PVC 板 瓦楞纸板 底层布荔枝 果壳褐变指数 失质量率 果壳褐变指数 失质量率 果壳褐变指数 失质量率 2 60 60 75 75 90 90 4 45 60 60 75 75 90 6 45 45 60 60 75 75 8 30 45 45 60 60 60 10 30 30 45 45 60 60 -

[1] WALKER R J, SCHOORL D, HOLT J E. The vibration bruising of apples[C]//Anon. Conference of Agriculture Engineering. Toowoomba, Queensland: Institution of Engineers, Australia. 1978: 29-31.

[2] RAGNI L, BERARDINELLI A. Mechanical behaviour of apples, and damage during sorting and packaging[J]. J Agr Eng Res, 2001, 78(3): 273-279.

[3] 王剑平, 王俊, 陈善锋, 等. 黄花梨的撞击力学特性研究[J]. 农业工程学报, 2002, 18(6): 32-35. [4] 吴杰, 郭康权, 葛云, 等. 香梨果实跌落碰撞时的接触应力分布特性[J]. 农业工程学报, 2012, 28(1): 250-254. [5] 卢立新, 王志伟. 苹果跌落冲击力学特性研究[J]. 农业工程学报, 2007, 23(2): 254-258. [6] 李晓娟, 孙诚, 黄利强, 等. 苹果碰撞损伤规律的研究[J]. 包装工程, 2007, 28(11): 44-46. [7] 桑永英, 张东兴, 张梅梅. 马铃薯碰撞损伤试验研究及有限元分析[J]. 中国农业大学学报, 2008, 13(1): 81-84. [8] 王俊, 腾斌. 桃下落冲击动力学特性及其与坚实度的相关性[J]. 农业工程学报, 2004, 20(1): 193-197. [9] 李心平, 马福丽, 高连兴. 玉米种子的跌落式冲击试验[J]. 农业工程学报, 2009, 25(1): 113-116. [10] 陈燕, 谈建豪, 向和平, 等. 机械损伤对荔枝电特性的影响[J]. 食品与发酵工业, 2014, 40(4): 47-50. [11] 张连文, 杨传民, 王勇, 等. 樱桃番茄运输包装件振动冲击性能试验[J]. 农业机械学报, 2011, 42(3): 125-130. [12] 陈燕, 向和平, 谈建豪, 等. 挤压对荔枝机械损伤和力学参数的影响[J]. 湖南农业大学学报(自然科学版), 2013, 39(6): 688-692. [13] MARTÍNEZ-CASTELLANOS G, PELAYO-ZALDÍVAR C, PÉREZ-FLORES L J, et al. Postharvest litchi (Litchi chinensis, Sonn.) quality preservation by Lactobacillus plantarum[J]. Postharvest Bio Technol, 2011, 59(2): 172-178.

[14] 杨松夏, 吕恩利, 陆华忠, 等. 不同保鲜运输方式对荔枝果实品质的影响[J]. 农业工程学报, 2014, 30(10): 225-232. [15] 李建国. 荔枝学[M]. 北京: 中国农业出版社, 2008: 542-556.

下载:

下载: