Numerical simulation and experiment of air distribution seed-metering device based on coupled EDEM-Fluent

-

摘要:目的

解决水稻机械直播速度慢、效率低的问题。

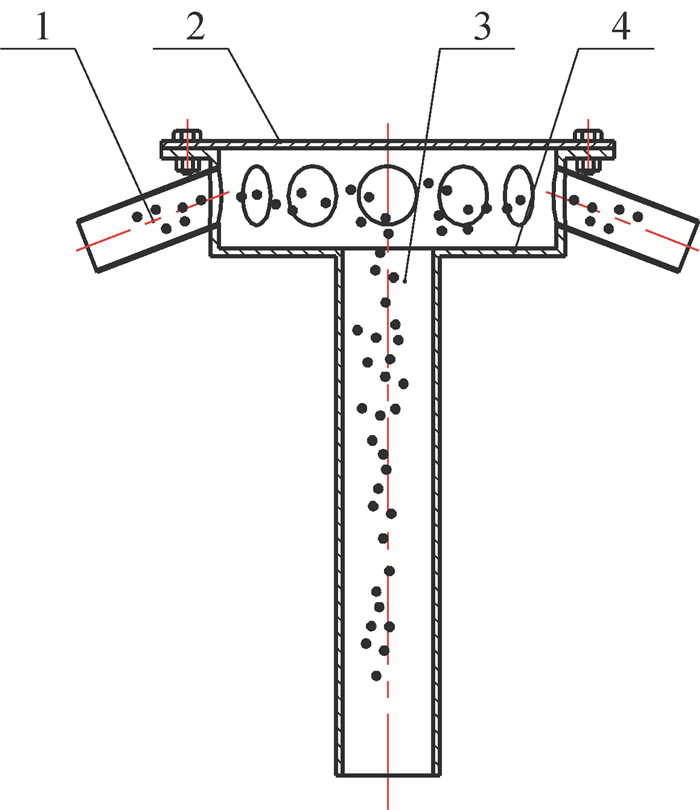

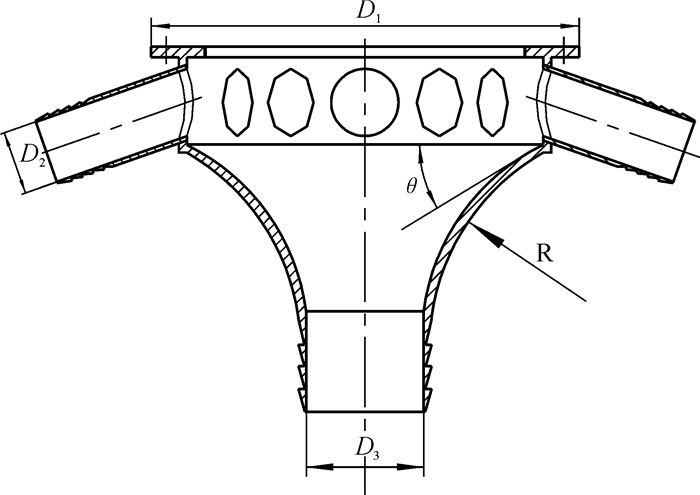

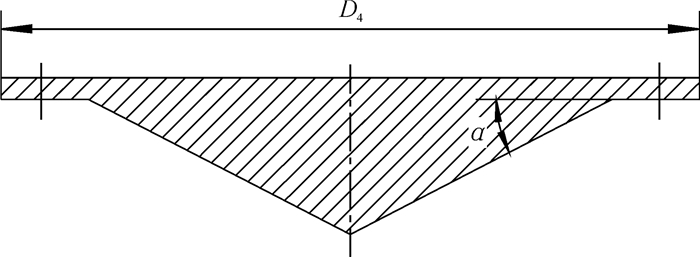

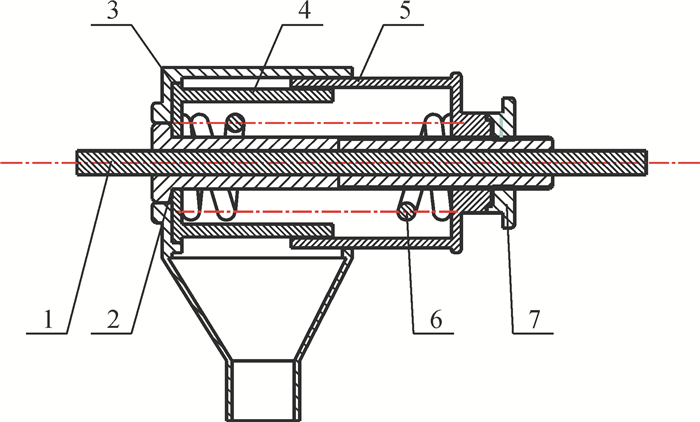

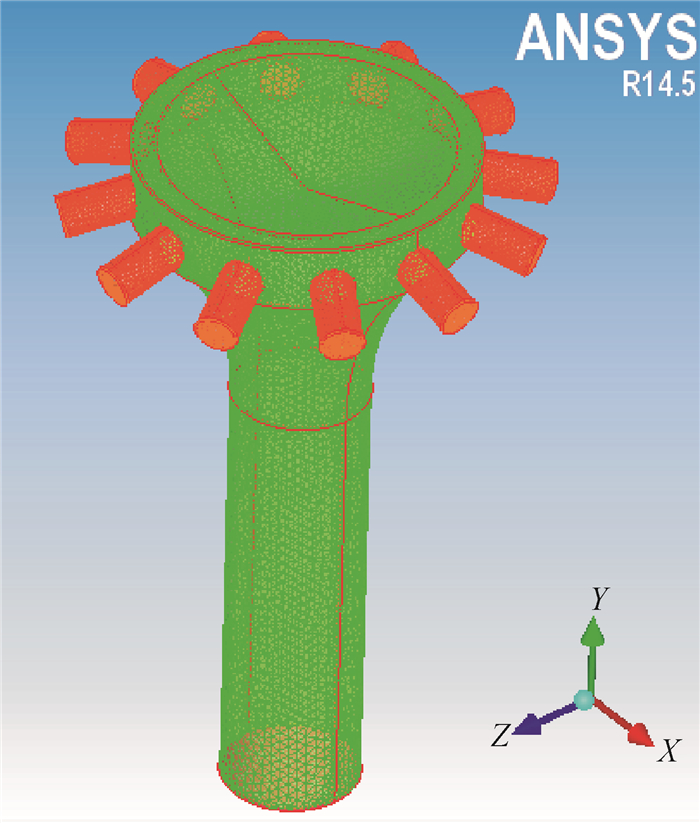

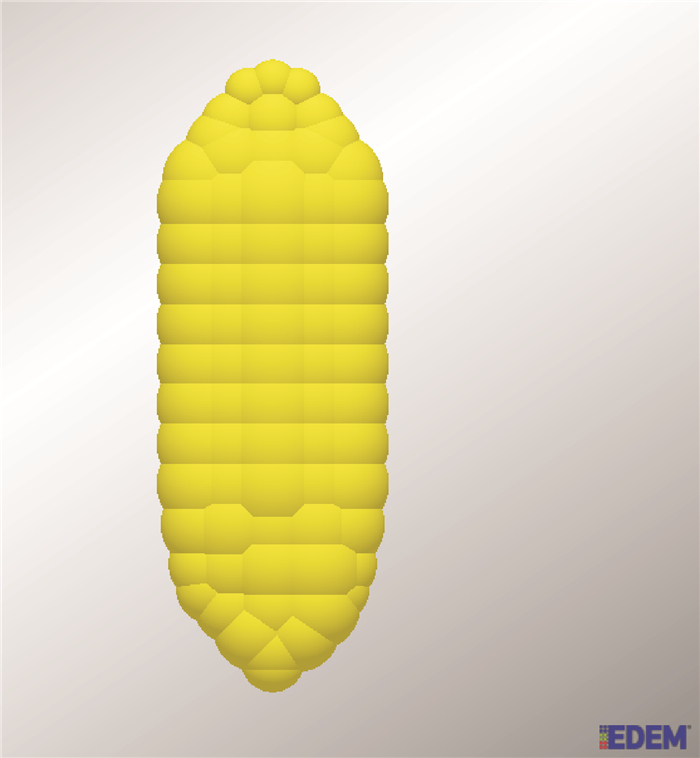

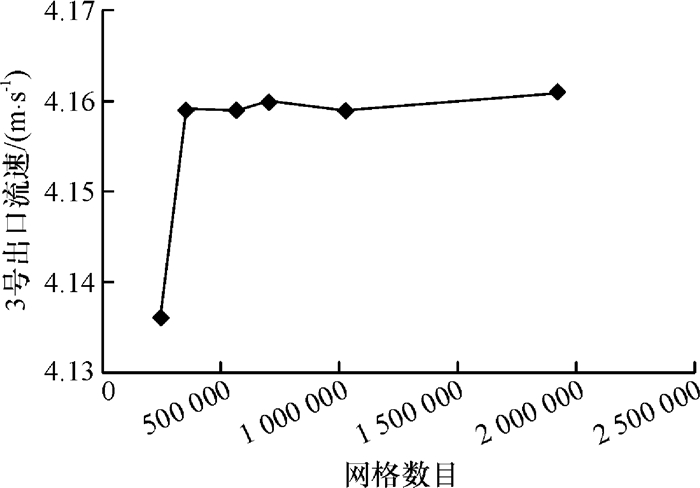

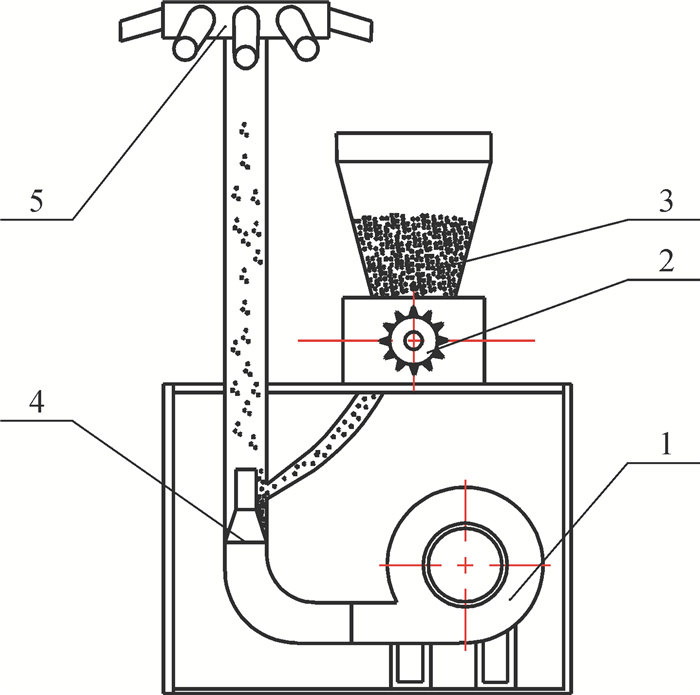

方法采用气流分配式排种器进行水稻直播,优化设计一种由R可调节的喇叭口式内腔与α可变的分流密封盖组成的α-R式气流分配式排种器,利用EDEM-Fluent耦合模块,对气流分配排种过程进行数值模拟;并进行排种性能台架验证试验。

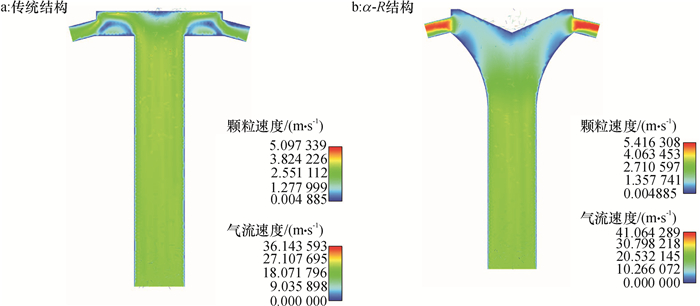

结果仿真结果显示,α-R组合式分配器中水稻颗粒最高运动速度为5.416 m·s-1,且旋涡滞种区域面积也低于传统结构,水稻颗粒在分配器中排出顺畅;R=180 mm、α=20°时,排种均匀性变异系数为24.56%,各行一致性变异系数为3.79%,总排量稳定性变异系数为1.23%,3项指标均为最优。采用3D打印的分配器进行台架试验,结果显示该排种器排种均匀性变异系数为29.17%~30.86%,各行一致性变异系数为4.13%~4.33%,总排量稳定性变异系数为1.4%~1.7%,满足水稻机械直播要求。

结论多次试验结果稳定,与仿真结果较为接近,说明本次设计的气流分配式排种器满足要求,也表明利用EDEM-Fluent耦合模拟的正确性与可行性。

-

关键词:

- 气流分配 /

- 排种器 /

- 水稻 /

- EDEM-Fluent /

- 模拟

Abstract:ObjectiveTo solve the problems of slow speed and inefficiency in mechanical seeding of rice.

MethodRice was directly seeded using the air distribution seed-metering device. An α-R air distribution seed-metering device was designed and optimized. It consisted a bell type lumen with adjustable R and a shunt seal cap with adjustable α. Numerical simulations of air distribution and metering process were performed by using EDEM-Fluent coupling module, and the bench test on seeding performance was carried out.

ResultThe simulation results showed that the highest velocity of rice particles in the combined α-R distributor was 5.416 m·s-1. The area of vortex stagnation was smaller than that of the traditional structure. Rice particles were discharged smoothly from the dispenser. When R=180 mm and α=20°, the variation coefficient of uniformity was 24.56%, the variation coefficient of consistency among rows was 3.79%, the variation coefficient of total displacement stability was 1.23%, and the three indicators were all the optimum values. Bench test was carried out using distributors printed by 3D printer and the results showed that the variation coefficient of uniformity for the seed-metering device was 29.17%-30.86%, the variation coefficient of consistency among rows was 4.13%-4.33% and the variation coefficient of total displacement stability was 1.4%-1.7%, which met the requirements of mechanical seeding of rice.

ConclusionThe results from multiple tests are stable and close to the simulation results. The designed air distribution seed-metering device can meet practical requirements, suggesting that using the EDEM-Fluent coupling simulation is correct and feasible.

-

Keywords:

- air distribution /

- seed-metering device /

- rice /

- EDEM-Fluent /

- simulation

-

-

表 1 试验因素水平

Table 1 Factors and levels of experiment

水平 试验因素 密封锥角

(A)/(°)边壁直径

(B)/mm1 20 80 2 25 130 3 30 180 表 2 仿真试验结果

Table 2 Results of simulation experiment

试验编号 因素水平 试验指标 密封锥角

(A)/(°)边壁直径

(B)/mm均匀性

变异系数/%各行一致性

变异系数/%总排量稳定性

变异系数/%1 1 1 25.77 4.25 1.84 2 1 2 26.62 4.11 1.75 3 1 3 24.56 3.79 1.23 4 2 1 29.14 4.53 1.79 5 2 2 30.06 4.20 1.66 6 2 3 29.89 4.08 1.48 7 3 1 32.14 4.98 1.91 8 3 2 31.86 4.75 1.78 9 3 3 30.59 4.34 1.37 表 3 仿真结果分析

Table 3 Analysis of simulation results

分析项 均匀性变异系数/% 各行一致性变异系数/% 总排量稳定性变异系数/% A B A B A B k1 25.650 29.017 4.050 4.587 1.607 1.847 k2 29.697 29.513 4.270 4.353 1.643 1.730 k3 31.530 28.347 4.690 4.070 1.687 1.360 极差 5.880 1.166 0.640 0.517 0.080 0.487 较优水平 A1 B3 A1 B3 A1 B3 主次因素 A1B3 A1B3 A1B3 表 4 台架试验结果

Table 4 Bench test results

传送带前进速度/

(km·h-1)排种均匀性

变异系数/%各行一致性

变异系数/%总排量稳定性

变异系数/%5 30.55 4.16 1.70 6 29.17 4.13 1.40 7 30.86 4.33 1.70 -

[1] 张国忠, 罗锡文, 臧英, 等.水稻气力式排种器群布吸孔吸种盘吸种精度试验[J].农业工程学报, 2013, 29(6): 13-20. http://www.cnki.com.cn/Article/CJFDTOTAL-NYGU201306003.htm [2] 王洋, 张祖立, 张亚双, 等.国内外水稻直播种植发展概况[J].农机化研究, 2007(1): 48-50. http://www.cnki.com.cn/Article/CJFDTOTAL-NJYJ200701015.htm [3] 罗锡文, 谢方平, 区颖刚, 等.水稻生产不同栽植方式的比较试验[J].农业工程学报, 2004, 20(1): 136-139. http://www.cnki.com.cn/Article/CJFDTOTAL-NYGU200401033.htm [4] 杨慧. 气流输送式排种系统性能试验研究[D]. 北京: 中国农业机械化科学研究院, 2014. [5] 杨慧, 刘立晶.气流输送式条播机现状及我国应用情况分析[J].农机化研究, 2013(12): 216-220. doi: 10.3969/j.issn.1003-188X.2013.12.054 [6] 梅婷, 李仲恺, 王小龙, 等.国内气力式精密播种器的研究综述[J].农业装备与车辆工程, 2013, 51(4): 17-21. http://www.cnki.com.cn/Article/CJFDTOTAL-SDLG201304007.htm [7] 李中华, 王德成, 刘贵林, 等.气流分配式排种器CFD模拟与改进[J].农业机械学报, 2009, 40(3): 64-68. http://www.cnki.com.cn/Article/CJFDTOTAL-NYJX200903013.htm [8] 常金丽, 张晓辉. 2BQ-10型气流一阶集排式排种系统设计与试验[J].农业工程学报, 2011, 27(1): 136-141. http://www.cnki.com.cn/Article/CJFDTOTAL-NYGU201101023.htm [9] 沈景新. 2BQ-12型气流一阶集排式播种机的研究[D]. 泰安: 山东农业大学, 2013. [10] KUMAR V J F, DIVAKER DURAIRAJ C. Influence of head geometry on the distributive performance of air-assisted seed drills[J]. J Agric Engng Res, 2000, 75(1): 81-95. doi: 10.1006/jaer.1999.0490

[11] LI A J, WEBB C, PANDIELLA S S, et al. Solids deposition in low-velocity slug flow pneumatic conveying[J]. Chem Eng Process, 2005, 44(2): 167-173. doi: 10.1016/j.cep.2004.02.011

[12] 北京海基科技发展有限公司. 流体-颗粒系统数值模拟的FLUENT-EDEM解决方案[Z], 2009. [13] 心男. 基于EDEM-FLUENT耦合的气吹式排种器工作过程仿真分析[D]. 长春: 吉林大学, 2013. [14] 张强强. 基于DEM-CFD耦合的颗粒在水中沉降过程仿真分析[D]. 长春: 吉林大学, 2014. [15] KARAYEL D, BARUT Z B, OZMERZI A. Mathematical modeling of vacuum pressure on a precision seeder[J]. Biosyst Eng, 2004, 87(4): 437-444. doi: 10.1016/j.biosystemseng.2004.01.011

[16] 周欣.工程流体力学[M].北京:中国电力出版社, 2014: 205-214. [17] 秦军伟, 张晓辉, 陈彬, 等.集中式排种系统中分配器的设计及试验研究[J].农机化研究, 2007(6): 131-133. http://www.cnki.com.cn/Article/CJFDTOTAL-NJYJ200706042.htm [18] 常金丽. 机械定量气流式集中排种系统的研究及其排种特性试验分析[D]. 泰安: 山东农业大学, 2007. [19] 胡国明.颗粒系统的离散元素法分析仿真[M].武汉:武汉理工大学出版社, 2010: 213-255. [20] 石林榕, 吴建民, 赵武云, 等.基于CFD-EDEM耦合的小区玉米帘式滚筒干燥箱数值模拟[J].干旱地区农业研究, 2014, 32(6): 273-278. doi: 10.7606/j.issn.1000-7601.2014.06.045 [21] 黄波, 陈晶晶.基于CFD-EDEM重介质旋流器内煤颗粒运动特性分析[J].煤矿机械, 2015, 36(7): 268-270. http://www.cnki.com.cn/Article/CJFDTOTAL-MKJX201507109.htm [22] 刘立意, 郝世杨, 张萌, 等.基于CFD-DEM的稻谷通风阻力数值模拟与试验[J].农业机械学报, 2015, 46(8): 27-32. doi: 10.6041/j.issn.1000-1298.2015.08.005 [23] 蒋恩臣, 孙占峰, 潘志洋, 等.基于CFD-DEM的收获机分离室内谷物运动模拟与试验[J].农业机械学报, 2014, 45(4): 117-122. doi: 10.6041/j.issn.1000-1298.2014.04.018 [24] 廖庆喜, 张朋玲, 廖宜涛, 等.基于EDEM的离心式排种器排种性能数值模拟[J].农业机械学报, 2014, 45(2): 109-114. doi: 10.6041/j.issn.1000-1298.2014.02.019 [25] 王汉青.通风工程[M].北京:机械工业出版社, 2007: 276-279. [26] 邵文奇, 钟平, 孙春梅, 等.沿淮地区直播稻品种筛选与播种处理试验[J].现代农业科技, 2009(23): 71-72. doi: 10.3969/j.issn.1007-5739.2009.23.045 [27] 王国强, 郝万军, 王继新, 等.离散单元法及其在EDEM上的实践[M].西安:西北工业大学出版社, 2010: 159-178. [28] 中国机械工业联合会. GB/T 25418—2010水稻覆土直播机[S]. 北京: 中国标准出版社, 2011: 2-3.

下载:

下载: