Microstructures and properties of porous filter parts ofselective laser melted 316L stainless steel

-

摘要:目的

揭示选区激光熔化316L不锈钢粉末成型多孔过滤零件的成型规律和机理。

方法试验设计孔洞尺寸为1 mm的圆形、正方形多孔316L不锈钢过滤零件,采用选区激光熔化方法进行成型,选用光学显微镜、扫描电子显微镜、X射线衍射等手段对其组织特征和性能进行分析检测,采用显微硬度计测量其显微硬度。

结果获得了无气孔、裂纹、偏析等缺陷, 且致密度达到95%的成型组织。组织内部主要由垂直于界面呈现外延生长的树枝晶组成,所得组织分层均匀,各层间呈冶金结合,定向凝固特征明显。

结论多孔过滤零件成型件由奥氏体组成,显微硬度为:258~294 HV0.3。采用选区激光熔化方法可以成型孔洞尺寸较小的过滤零件。

Abstract:ObjectiveTo reveal the formation patterns and mechanisms of selective laser melted 316L stainless steel porous filter parts.

MethodBoth cubical and cylindrical 316L stainless steel porous filter parts with 1 mm pore size were designed and formed by selective laser melting (SLM). Microstructures and properties of these filter parts were investigated using optical microscope, scanning electron microscope and X-ray diffraction. Micro hardness of the parts was measured using microhardness tester.

ResultThe formed filter parts were obtained with 95% density and without defects such as pore, crack and segregation. The intra-structure was mainly composed of dendrite crystals which were vertical to the interface and grew along the epitaxy. The microstructure obtained had even layers which were metallurgically bonded. There was clear evidence of directional solidification for the formed parts.

ConclusionThe formed parts are composed of austenite, and microhardness ranges from 258 to 294 HV0.3. SLM can be used in prototyping filter parts with relatively small pore size.

-

中国是农业大国,水资源的不平衡分布限制了农业的发展,据不完全统计我国每年作物受旱面积约10.25万m2[1]。生活用水的重复利用能够缓解农业用水短缺[2]。过滤器是过滤废水的核心部件,通过多层滤网拦截水中杂质来满足灌溉用水需要。过滤器由5层丝网组成:保护层、过滤控制层、分散层、支撑骨架层和骨架层。常规的过滤器采用不锈钢的烧结网[3],制作周期长、工艺复杂、成本较高。

选区激光熔化技术(Selective laser melting,SLM)是金属3D打印技术的一种,是20世纪以来新兴的零件制造技术[4]。该技术采用激光将金属粉末熔化,实现金属粉末间冶金结合,理论上可成型任意形状的金属零件,并使其致密度达到95%以上[5]。采用SLM制造出的零件具有致密度高、机械性能好、零件尺寸精度高(零件尺寸误差小于0.1 mm)、无需或仅需简单处理(如喷砂、抛光等)即可直接使用等特点,在零件设计和制造时间等方面优于传统技术[6-7]。

目前采用选区激光熔化技术成型过滤网的主要问题是成型质量不高、过滤网孔洞尺寸较大、过滤效果不理想。Yadroitsev等[8]得到了选区激光熔化316L不锈钢的最佳工艺参数。Zhang等[9]研究了加工参数对选区激光熔化316L不锈钢成型零件性能的影响。Giovanni等[10]研究了选区激光熔化成型316L的表面粗糙度及其表面粗糙度计算模型。以上研究主要集中在成型参数与成型零件组织性能的关系方面,鲜见对采用优化后参数所得零件的组织分析。本研究将316L不锈钢制成粉末,设计全新的小孔径多孔过滤零件,通过SLM成型零件,对成型零件的组织和性能进行分析,可为今后采用选区激光熔化技术成型过滤器提供基础数据和研究思路。

1. 材料与方法

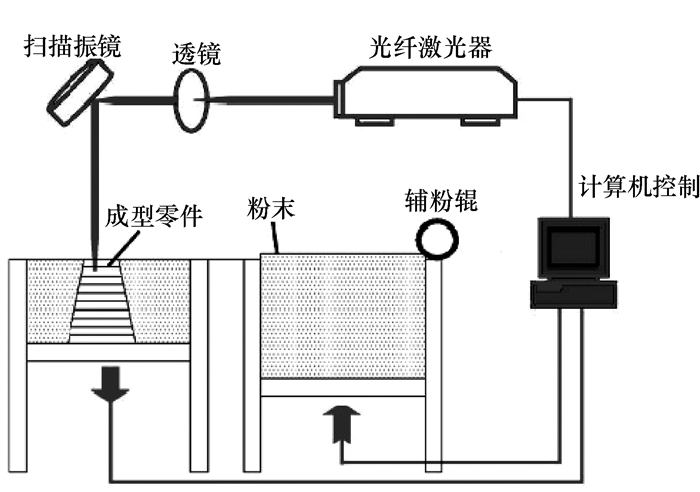

华南理工大学自主研发的DiMetal-100选区激光熔化系统,主要结构见图 1。选区激光熔化系统的主要参数:激光波长1 075 nm,SPI 200W连续光纤激光器,最大成型尺寸:100 mm×100 mm×150 mm, 扫描速度5~5000 mm·s-1,光束质量M2≤1.1,光斑直径70 μm,铺粉厚度20~80 μm。试验选用气雾化316L粉末,粉末组成及质量分数为Ni(11.930%)、Cr(16.700%)、Mo(2.020%)、Mn(0.420%)、Si(0.900%)、C(0.035%)、P(0.029%)、S(0.032%)、Fe(67.934%),粉末平均粒径25 μm。

试验选用100 mm ×100 mm× 10 mm的316L不锈钢基板进行加工,成型参数:激光功率150 W,扫描速度700 mm·s-1,扫描策略正交层错,线间距0.08 mm,氩气保护,成型室内含氧量(φ)低于0.2%。采用200、400和800号砂纸进行金相处理,硝酸乙醇(体积比为5:95)溶液进行腐蚀。采用NOVA NANOSEM 430和EVO18电子显微镜进行组织观察,采用X′Pert Pro进行X射线衍射分析,401MVA显微硬度计检测零件的显微硬度。

2. 结果与分析

参考过滤器中过滤网结构,设计孔洞尺寸为1 mm,几何尺寸为8 mm×8 mm×8 mm的正方体多孔零件和直径8 mm、高度10 mm的圆柱形多孔零件。

2.1 选区激光熔化多孔过滤零件成型和组织特征

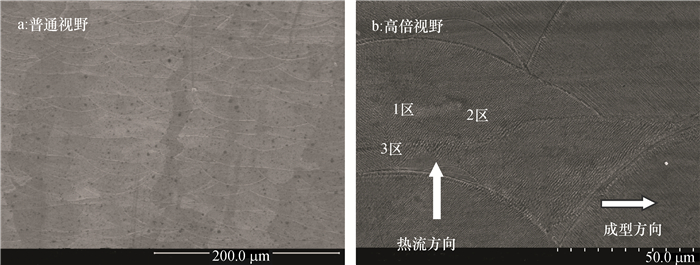

图 2a所示为选区激光熔化316L组织形貌,可以看出,选区激光熔化316L不锈钢由多个熔池组成,每个熔池的宽度和深度大致相同,熔池深宽比为2.5~4.0。所有粉末完全熔化,熔池呈纵向周期性变化,这是扫描策略对熔池的影响。出现熔池层时扫描方向垂直截面,未出现熔池层时扫描方向平行截面。图 2b为成型组织高倍形貌,可以看到层与层之间形成了良好的冶金结合区,晶粒生长方向垂直于熔池底部,熔池呈椭圆形,在该生长情况下,熔池分为3个区域,1区与水平方向呈锐角,2区垂直于水平方向,3区与水平方向呈钝角。1区和3区生长方向相互垂直,树枝晶之间的间隙大致相同。由于受到1区和3区生长条件的影响,2区有些生长方向和1区一样,有些和3区一样,还有些垂直生长,生长方向较紊乱,出现大量方向交错的树枝晶。图 2b表明由于扫描方式的不同使得成型组织发生改变,扫描方向与截面平行层中出现大量树枝晶,在该层生长中也出现了大量和上一层生长方向相同的树枝晶,这也充分表明了成型组织外延生长的特点,扫描方向不同的2层也为良好的冶金结合。图 2b中外延生长有明显的2个方向,激光凝固有较强的方向趋向性,这种方向趋向性是受到熔池温度梯度和熔池曲率的影响。如图 2b所示,新生层带阻止了外延生长的继续,新生层带温度梯度较高,熔池底部凝固速率较小,熔池底部曲率与上一层带曲率不同时可能阻止外延生长。成型组织呈定向凝固和外延生长特征。整个成型组织主要由垂直于界面外延生长的柱状晶、胞状晶组成,无气孔、裂纹、偏析等缺陷,组织分层均匀、稀释率小、各熔池、层间呈冶金结合、定向凝固特征明显。

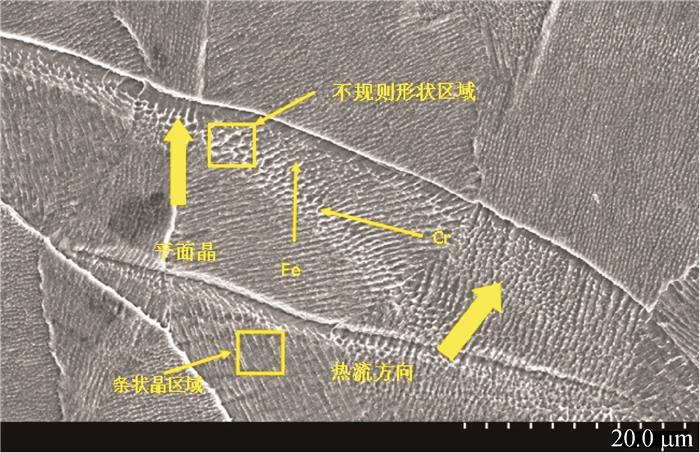

选区激光熔化316L不锈钢的显微组织受众多因素影响,主要因素为合金的成分、界面能、温度梯度、冷却速率等。如图 3所示,在选区激光熔化开始时,新熔池底部与基板相接触,基板为冷却源,熔池底部的冷却速率较大,虽然温度梯度不是最大,但温度梯度与冷却速率的比值却很大,几乎不存在成分过冷,凝固组织形成无偏析的白亮的平面晶层[11]。随着凝固的继续,熔池中部远离冷却源,温度梯度不断降低,温度梯度与凝固速率的比值不断减小,熔池沿纵向散热已不明显,开始向周围散热,外延生长被打破。冷却到熔池顶部时,由于和空气相接触使得温度梯度再次增大,但温度梯度方向与熔池底部温度梯度方向相反。

图 3中存在2种组织形貌:不规则形状和条形。存在2种组织形貌的原因是晶粒的长大速度不同,不规则形状晶粒的长大速度快,条形组织的晶粒长大速度慢。图 3中白亮色部分是Cr元素,暗色部分是Fe元素,成型零件由奥氏体组成。图 3表明有大量树枝晶存在,从上到下完全存在于某个层带中,树枝晶的存在表明结晶过程中晶粒生长速度低,以胞晶向枝晶转变为主,生长过程中沿胞晶尖端部分出现侧向分支、侧向分支生长和形成多次晶枝的过程。侧向分支存在必须满足2个条件[11]:胞壁失稳、有足够的糊状区使失稳后胞壁下的凸起长大,形成侧向分支。而温度梯度对转换有较明显的影响,在负温度梯度下将会大大降低枝晶向胞晶转换[12]。

选区激光熔化是一个快速冷凝过程,在加工过程中如果能够保证较高的温度梯度和足够狭窄的合金结晶温度区域, 那么枝晶向胞晶转变的速度就可以大于胞晶向枝晶转变的速度[13]。在较强的定向生长条件下,溶质将在凝固界面前形成富集的成分过冷区[14]。胞晶的尖端快速生长而侧胞晶侧向扰动被强烈加速,使得在这个层带中可以看到全是树枝晶组成的情况[15]。

2.2 选区激光熔化316L不锈钢XRD分析和显微硬度检测

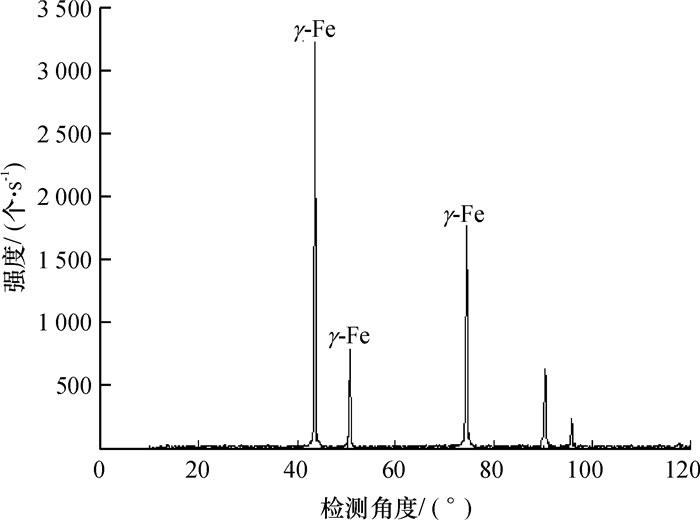

图 4表明选区激光熔化316L不锈钢成型零件主要由面心立方的奥氏体γ相组成。由于选区激光熔化是一种快速熔化、沿单一方向急速冷却的定向凝固冶金过程,冷却速度快、凝固时间短。316L不锈钢组织的最大特点含有铁-镍固溶体[15]。铁-镍固溶体镍的加入改变了晶体结构,使原本在常温下不稳定的奥氏体相能够稳定存在,最大的优势是降低了固溶体析出碳元素的温度,大大降低了碳元素的析出。证明结果在成型组织中无偏析,成型组织以γ相的面心立方奥氏体为主。

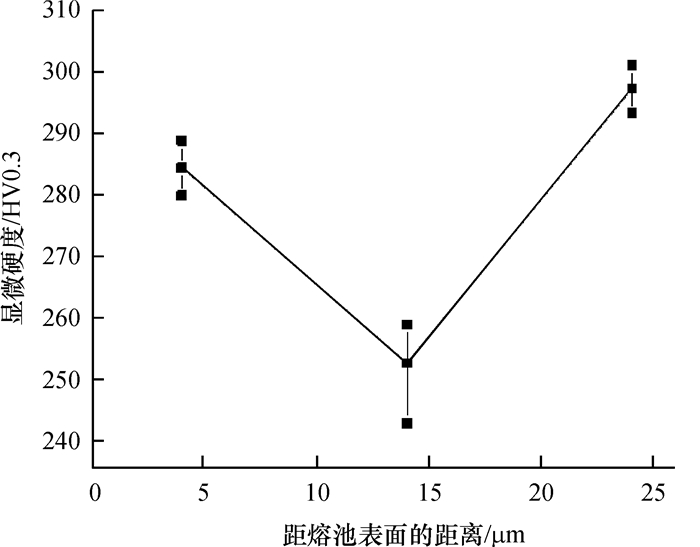

采用显微硬度计测量成型零件的显微硬度,结果见图 5。同一深度至少选择3个硬度值,取平均值作为测量深度的显微硬度值,显微硬度值采用维氏硬度,将3个不同深度硬度打入同一个熔池。图 5表明成型零件的显微硬度值为258~294 HV0.3。在单个熔池表面显微硬度值较大,随着深度的增加中心的显微硬度减少,底部的显微硬度又有所增加。与普通铸造316L不锈钢相比显微硬度有所提升,普通铸造316L不锈钢显微硬度为200 HV0.3。

3. 结论

1) 采用选区激光熔化方法可以制备孔洞尺寸为1 mm的多孔过滤零件。

2) 选区激光熔化316L不锈钢多孔过滤成型零件组织由不规则形状和条形组成,条形组织主要由树枝晶组成,组织细小、致密、无偏析、无缺陷等,定向凝固特征明显,层与层之间实现了冶金结合,XRD检测表明组织主要为奥氏体。

3) 与传统铸造加工方法相比,选区激光熔化316L不锈钢多孔过滤零件的显微硬度有所提高,硬度值为258~294 HV0.3,随着熔池深度的增加显微硬度先降低后增加,在熔池顶部和底部显微硬度大于熔池中部。

-

-

[1] 高晓薇, 邵薇薇, 刘学欣, 等.城镇化与工业化进程对农业用水的影响[J].人民黄河, 2015, 37(7): 59-63. doi: 10.3969/j.issn.1000-1379.2015.07.015 [2] 康超, 黄一, 路婕.农业水资源利用新技术研究进展[J].河南农业, 2015(1): 28-29. doi: 10.3969/j.issn.1006-950X.2015.01.022 [3] 杨骞, 刘华军.污染排放约束下中国农业水资源效率的区域差异与影响因素[J].数量经济技术经济研究, 2015, 32(1): 124-128. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=663042337 [4] SUN J F, YANG Y Q, WANG D. Mechanical properties of regular hexahedral lattice structure formed by selective laser melting[J]. Laser Phys, 2013, 23(6): 1-9. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=JJ0229940746

[5] VAN B S, KERCKHOFS G, MOESEN M. Micro-CT-based improvement of geometrical and mechanical controllability of selective laser melted Ti6Al4V porous structures[J]. Mat Sci Eng A-Struct, 2015, 528(24): 7423-7431. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=JJ0223076374

[6] SONG B, DONG S, ZHANG B, et al. Effects of processing parameters on microstructure and mechanical property of selective laser melted Ti6Al4V[J]. Mater Design, 2012, 35: 120-125. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=JJ0226430756

[7] SUN J F, YANG Y Q, WANG D. Parametric optimization of selective laser melting for forming Ti6Al4V samples by Taguchi method[J]. OPT Laser Technol, 2013, 49: 118-124. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=JJ0229893776

[8] YADROITSEV I, KRAKHMALEVB P, YADROITSAVAA I, et al. Energy input effect on morphology and microstructure of selective laser melting single track from metallic powder[J].J Mater Process Tech, 2013, 213(4): 606-613. doi: 10.1016/j.jmatprotec.2012.11.014

[9] ZHANG B, DEMBINSKI L, CODDET C. The study of the laser parameters and environment variables effect on mechanical properties of high compact parts elaborated by selective laser melting 316L powder[J]. Mat Sci Eng A-Struct, 2013, 584: 21-31. doi: 10.1016/j.msea.2013.06.055

[10] GIOVANNI S, LIANG H, RICHARD M E, et al. Surface roughness analysis, modelling and prediction in selective laser melting[J]. J Mater Process Tech, 2013, 213(4): 589-597. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=JJ0228888955

[11] RIEMER A, LEUDERS S, THOENE M, et al. On the fatigue crack growth behavior in 316L stainless steel manufactured by selective laser melting[J]. Eng Fract Mech, 2014, 120: 15-25. doi: 10.1016/j.engfracmech.2014.03.008

[12] HUANG W D, GENG X G, ZHOU Y H. Primary spacing selection of constrained dendritic growth[J]. J Cryst Growth, 1993, 134(1/2): 105-115. doi: 10.1016-0022-0248(93)90015-O/

[13] FLEMINGS M C. Solidification technology in the foundry and cast house[M]. London: The institute of metals, 1980: 42-45.

[14] SHUZU L, HUNT J D. Numerical analysis of dendritic and cellular array growth: The spacing adjustment mechanisms[J]. J Cryst Growth, 1992, 123(1/2): 17-34. doi: 10.1007%2FBF02648950

[15] HUNT J D. Numerical analysis of dendritic and cellular growth of a pure material investigating the transition from 'array' to 'isolated' growth[J]. Acta Metall Mater, 1991, 39(9):2117-2133. doi: 10.1016/0956-7151(91)90182-Z

下载:

下载: