Design and testing of a seeding monitoring system for four-row garlic planter

-

摘要:目的

基于江苏省大蒜种植农艺要求,设计研发一种四行大蒜播种机的实时播种监测系统,融合多种传感器技术,以实现对大蒜播种过程的实时监测,为后续机械或人工补种提供决策依据。

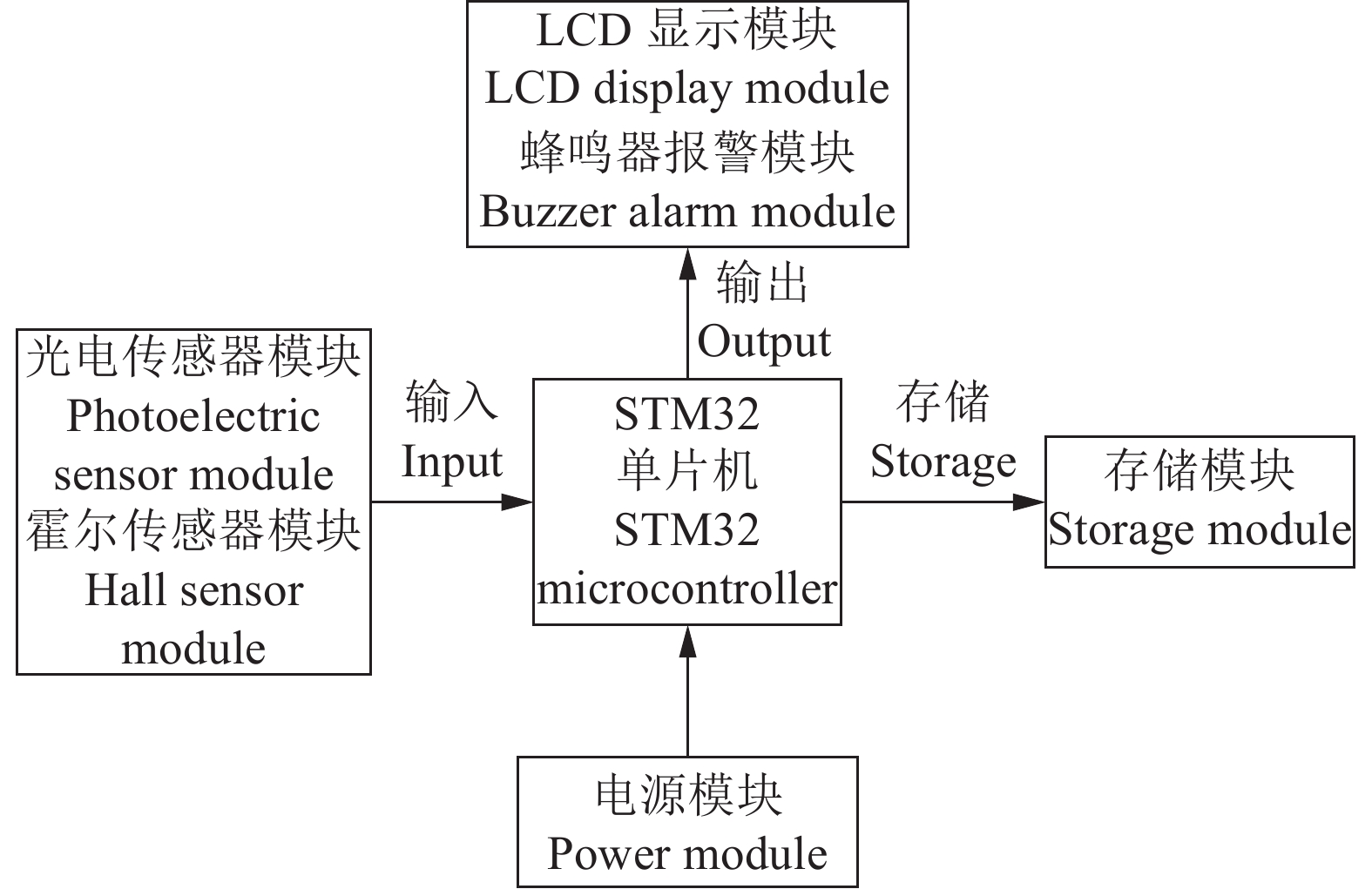

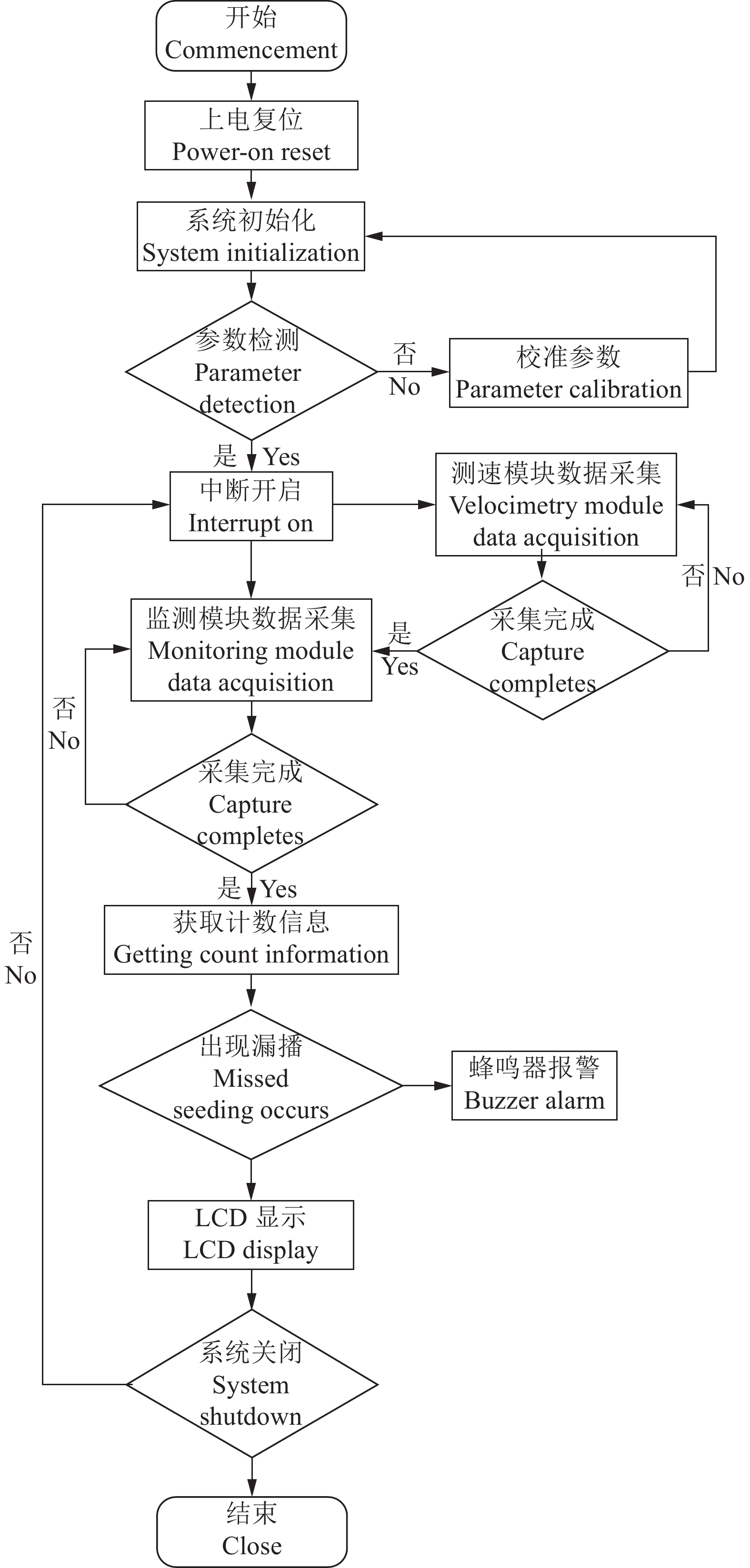

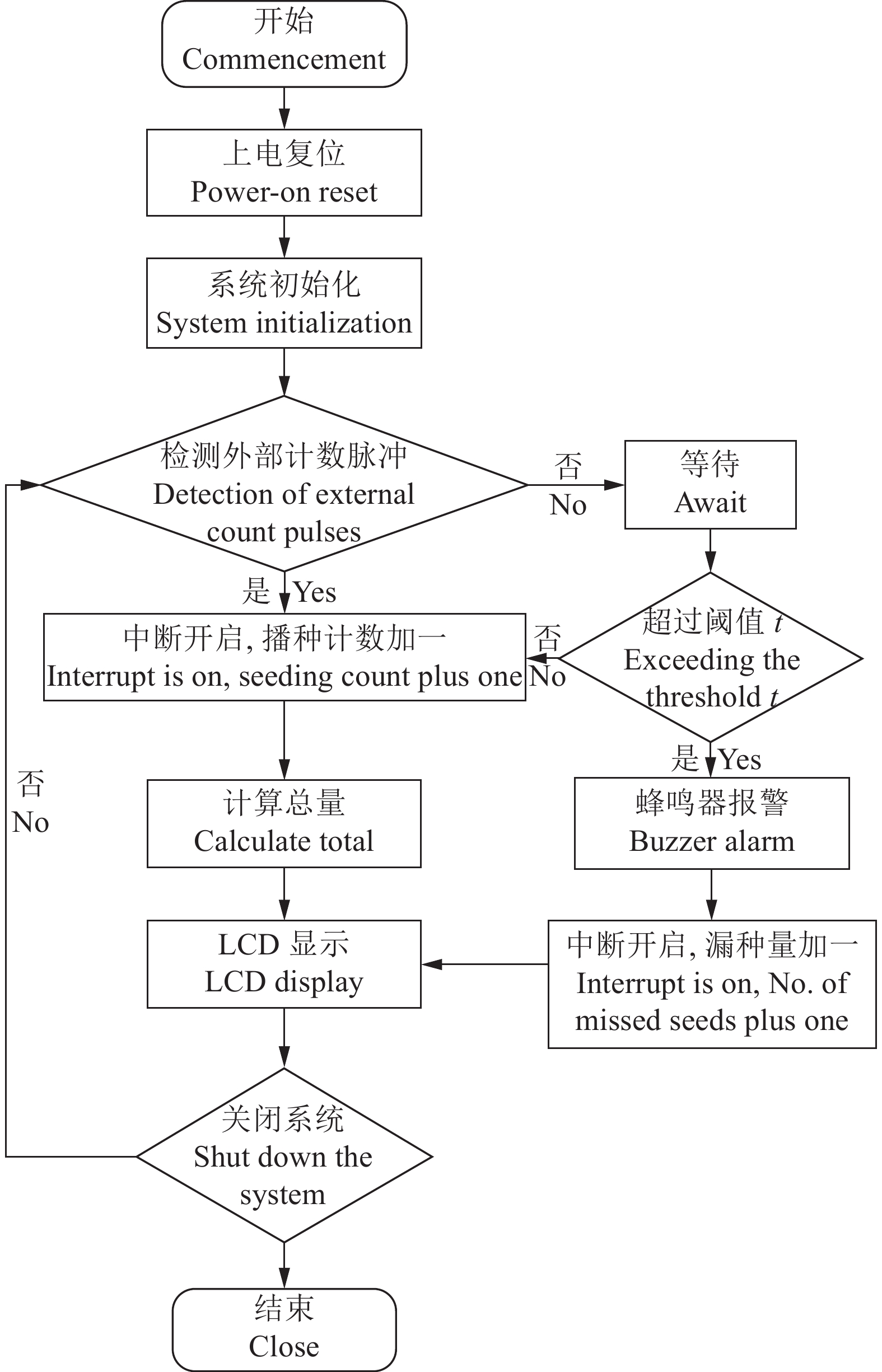

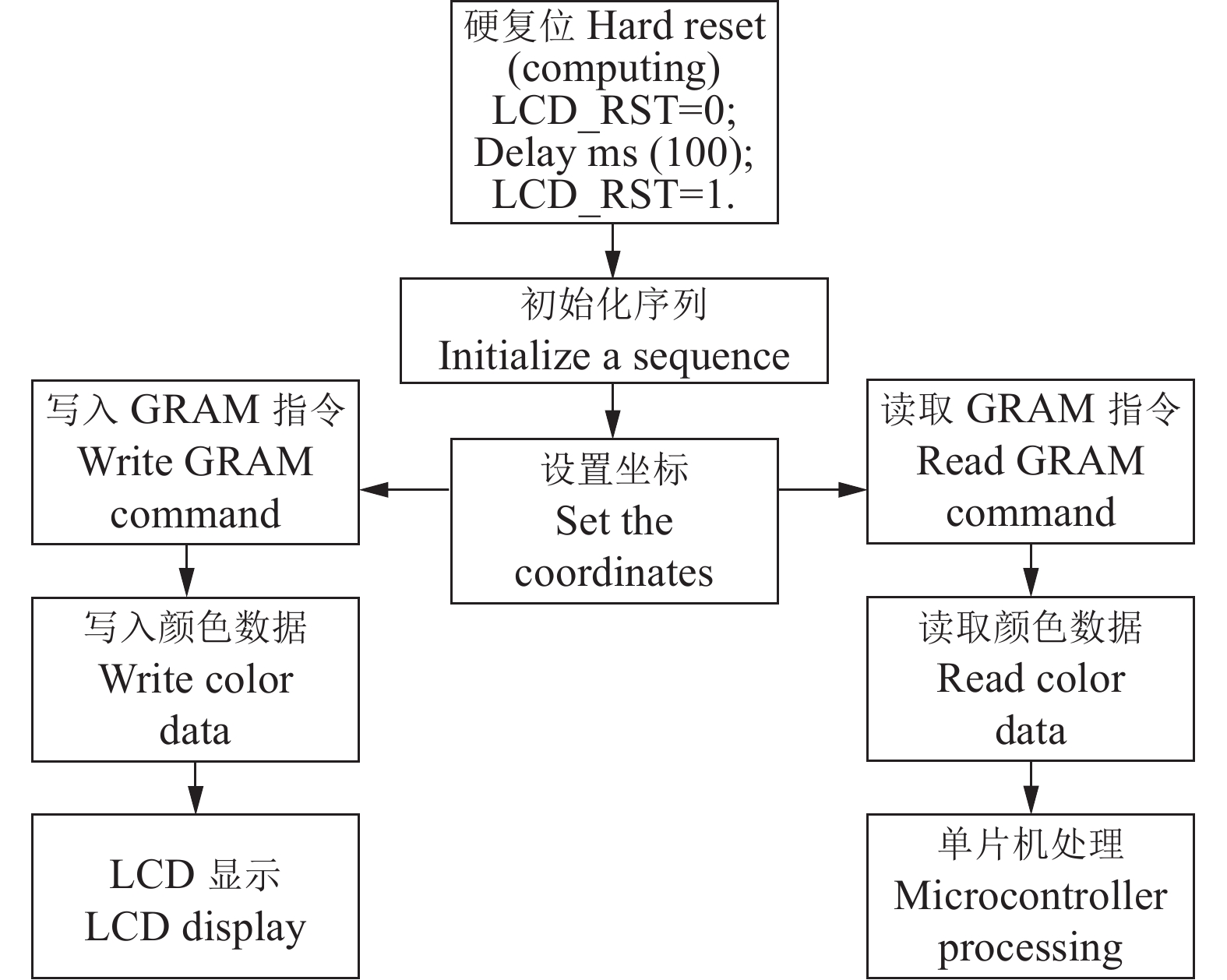

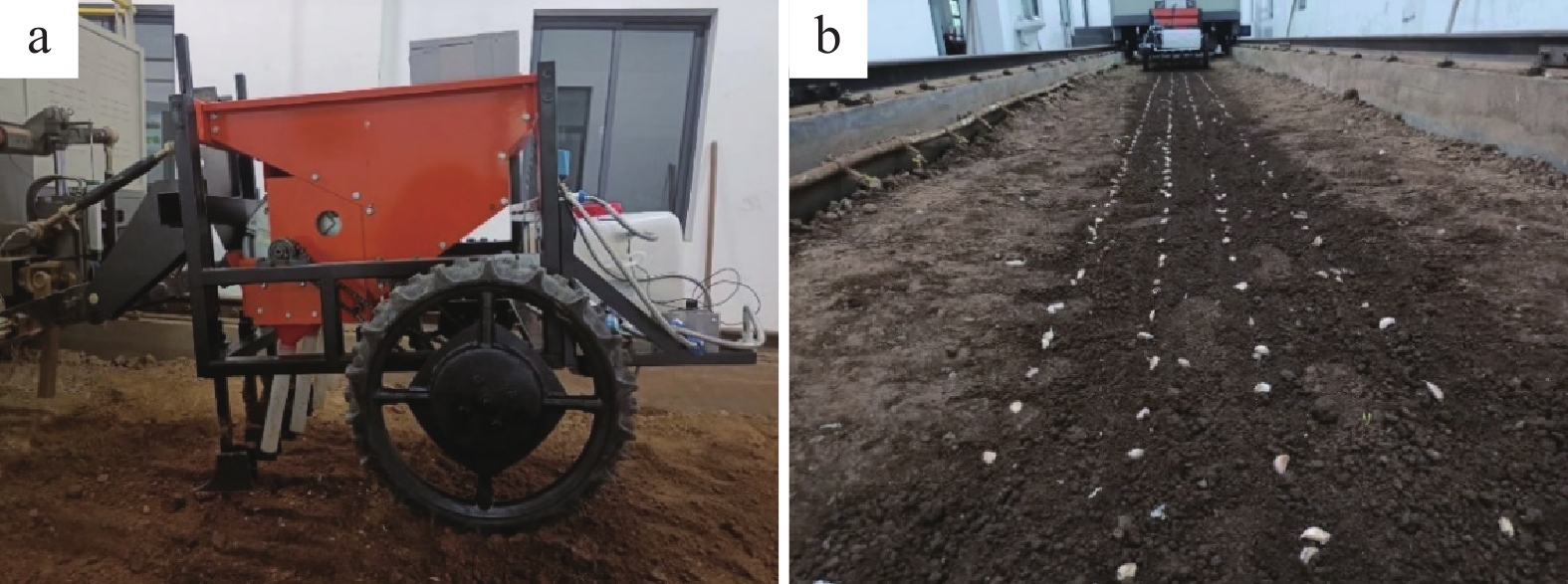

方法以4DS-4四行大蒜播种机为基础,根据实际需求,确定监测系统的设计和选型,包括播种机作业速度监测模块、播种监测模块、显示模块、报警模块以及数据存储模块等;监测系统以STM32F103单片机为主控制器,应用多种传感器技术,根据播种机作业速度和漏种监测的原理,编写播种系统监测程序,实现大蒜播种机作业信息的采集;最后对监测系统进行台架试验完成对监测系统的调试,并利用土槽试验进行测试和验证,检测播种监测系统在实际工作状态下的稳定性和准确性。

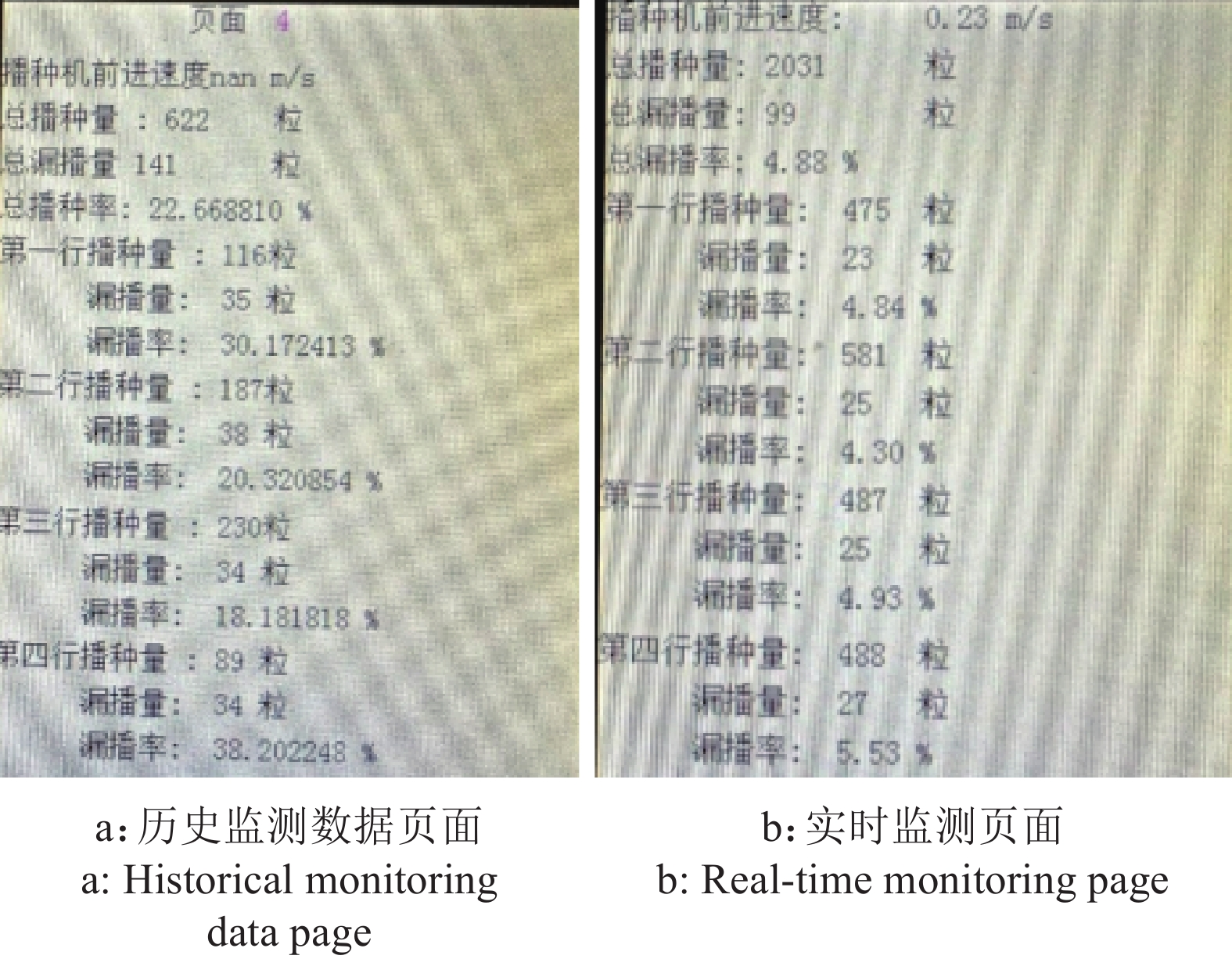

结果台架试验表明,当播种机的播种速度为1 km/h时,已播监测准确度可达96.7%,漏播监测准确度可达97.4%,满足了播种监测系统性能指标需求;土槽试验结果表明,在不同的作业速度下,监测系统测量的播种量相对误差为2.4%~5.2%、平均相对误差为3.86%,漏播量相对误差为2.1%~5.9%、平均相对误差为4.06%。

结论该播种监测系统能在长时间的持续工作过程中保证监测结果的准确性,满足了大蒜播种机监测系统的要求,能够实现播种过程的实时监测。

Abstract:ObjectiveBased on the agronomic requirements of garlic planting in Jiangsu Province, this study designs and develops a real-time seeding monitoring system for a four-row garlic planter, which integrates a variety of sensor technologies. The study aims to realize real-time monitoring of the garlic sowing process, and provide a decision-making basis for the subsequent mechanical or manual replanting.

MethodBased on a 4DS-4 four-row planter, the design and selection of the monitoring system were determined according to the actual requirements. The system included the planter operating speed monitoring module, seeding monitoring module, display module, alarm module and data storage module, etc. The monitoring system was designed with the STM32F103 microcontroller as the main controller, and a variety of sensor technologies were used to design the monitoring principle of speed and seeding. The system monitoring program was written to collect the operation information of the garlic seeder based on the working speed of the seeder and the principle of missed seed monitoring. Finally, the bench test was performed for the monitoring system to complete the commissioning of the monitoring system, and the soil trench test was conducted for further test and validation of the stability and accuracy of the seeding monitoring system in the actual working condition.

ResultThe bench test showed that when the seeding speed of the planter was 1 km/h, the accuracy of the seeding monitoring reached 96.7%, and the accuracy of the missed seeding monitoring reached 97.4%, which met the performance indicators of the seeding monitoring system. The soil trench test results showed that, at different operating speeds, the relative error of the seeded quantity for the measurement by the seeding monitoring system was 2.4%−5.2%, with an average relative error of 3.86%, and the relative error of missed seeding was 2.1%−7.3%, with an average relative error of 4.66%.

ConclusionThis seeding monitoring system can ensure the accuracy of the measurement results during a long period of continuous work, which meets the requirements of the monitoring system for garlic planter and can realize the real-time monitoring of the sowing process.

-

Keywords:

- Garlic planter /

- Intelligent /

- Missed seeding monitoring /

- Real-time monitoring /

- Sensor

-

-

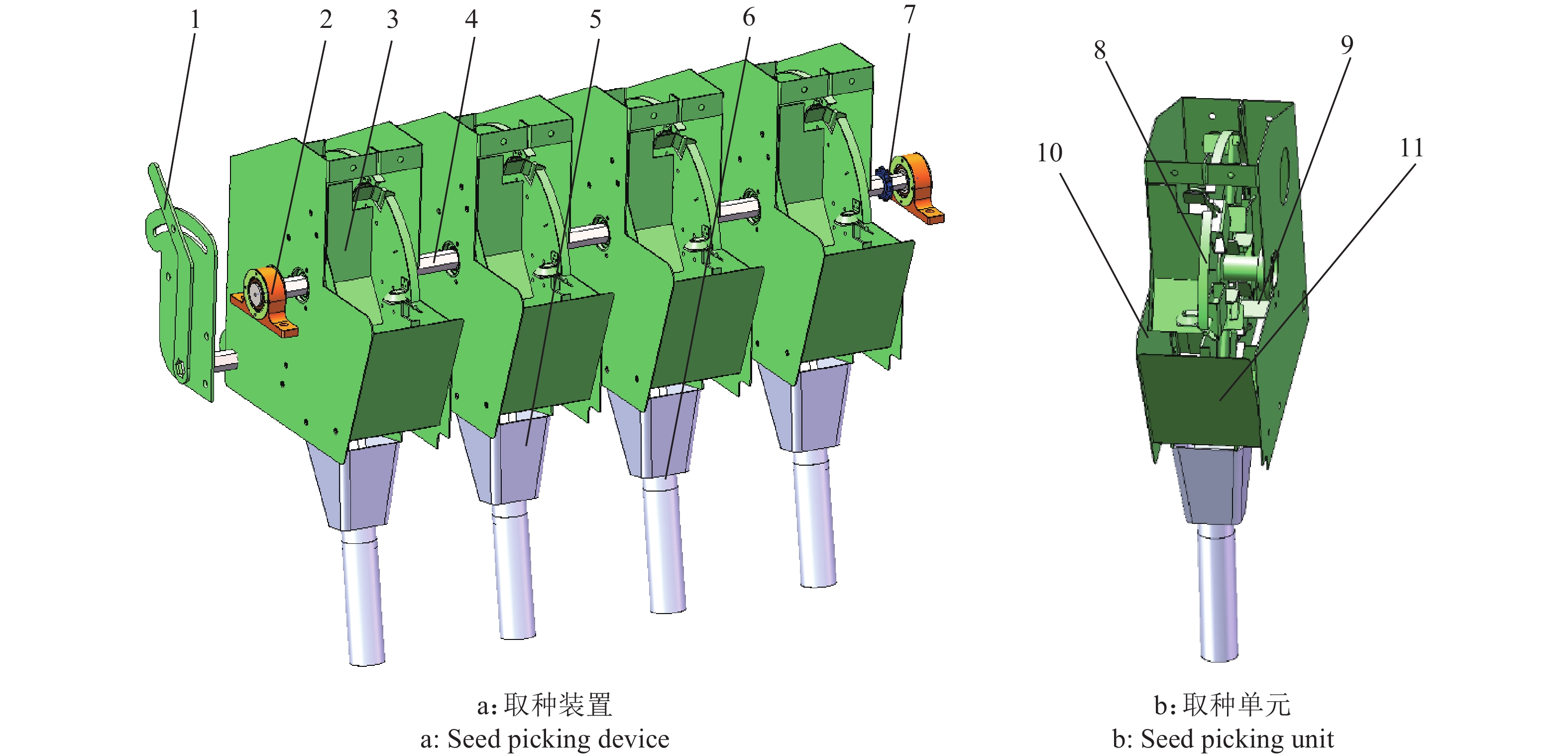

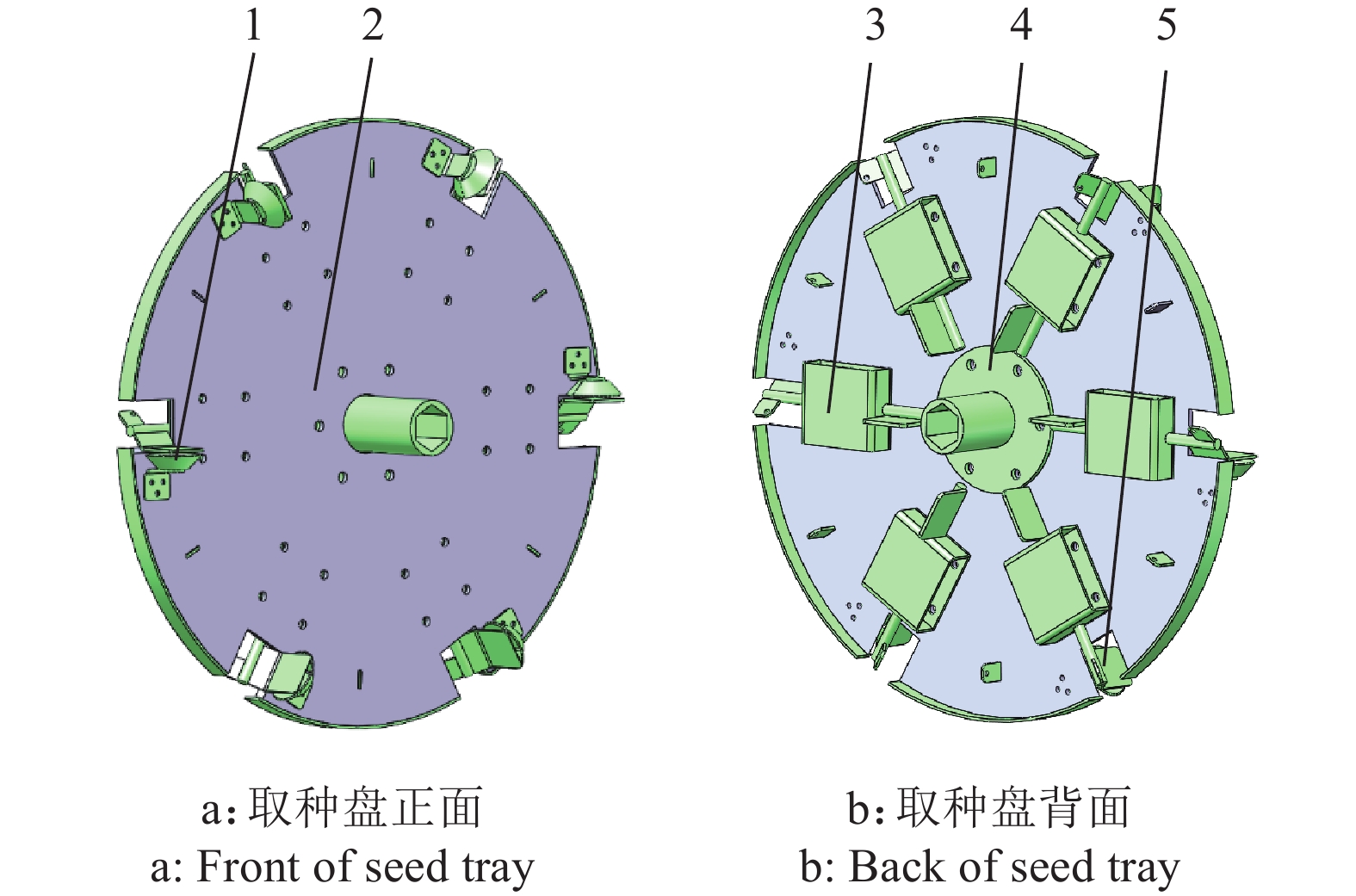

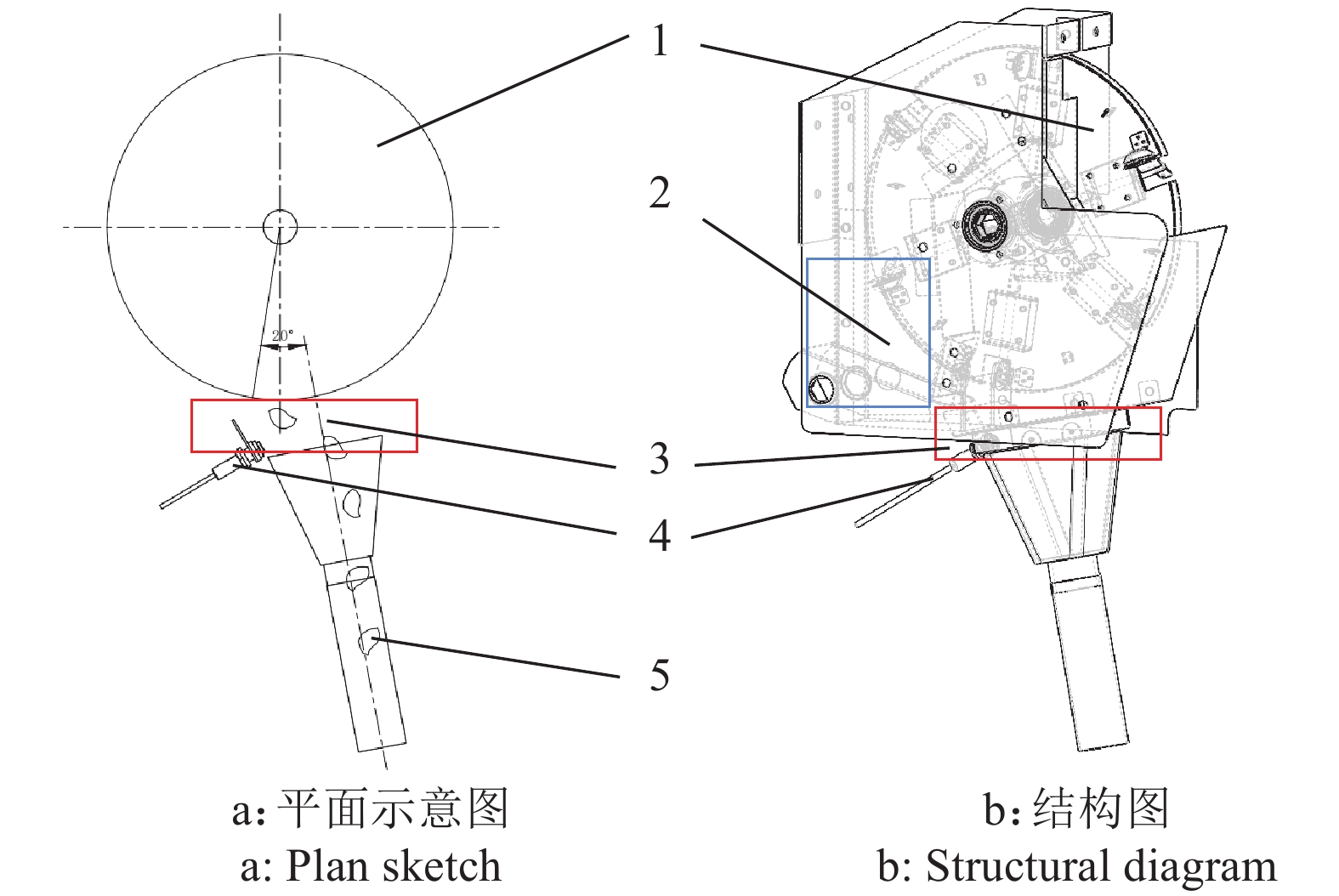

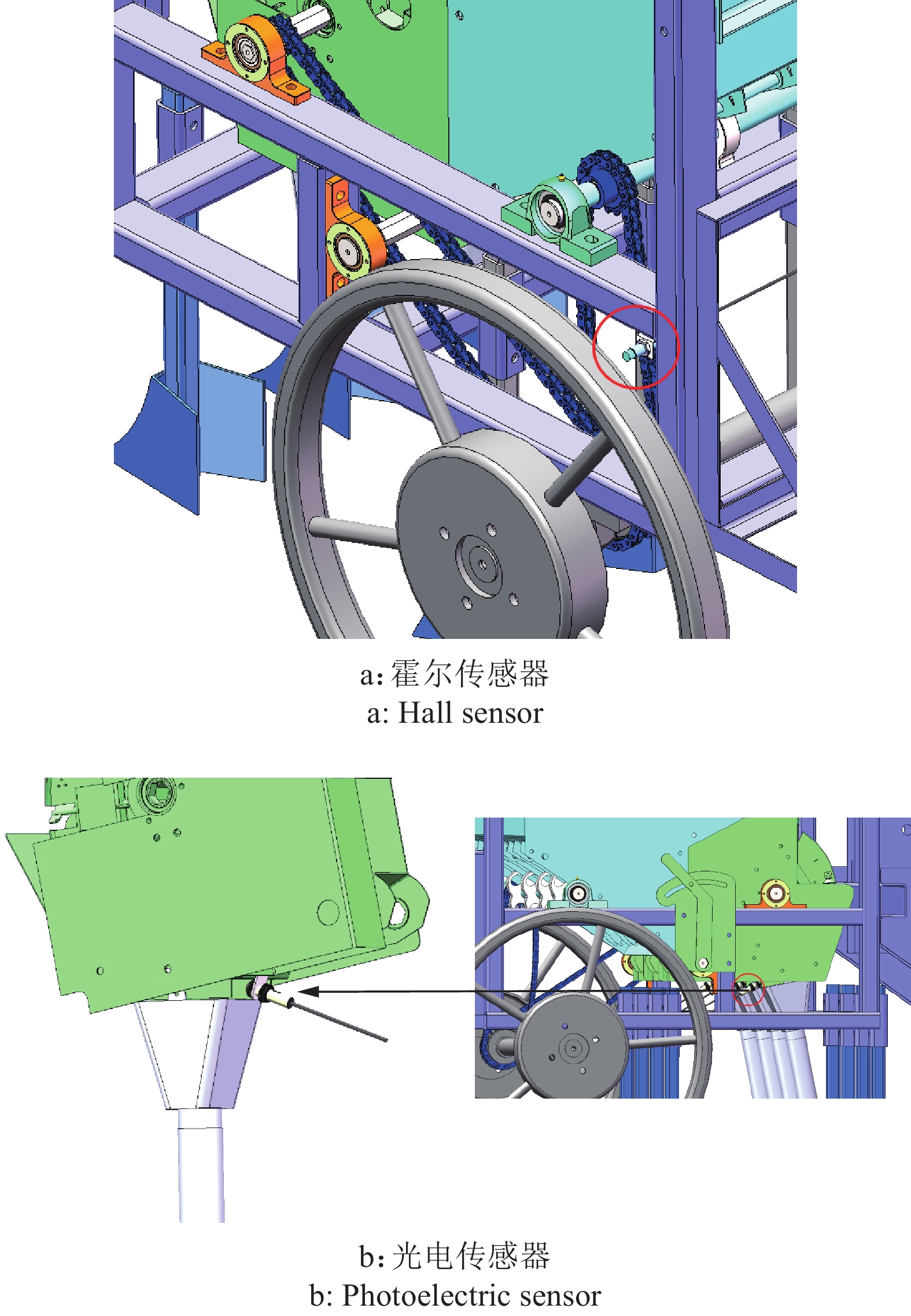

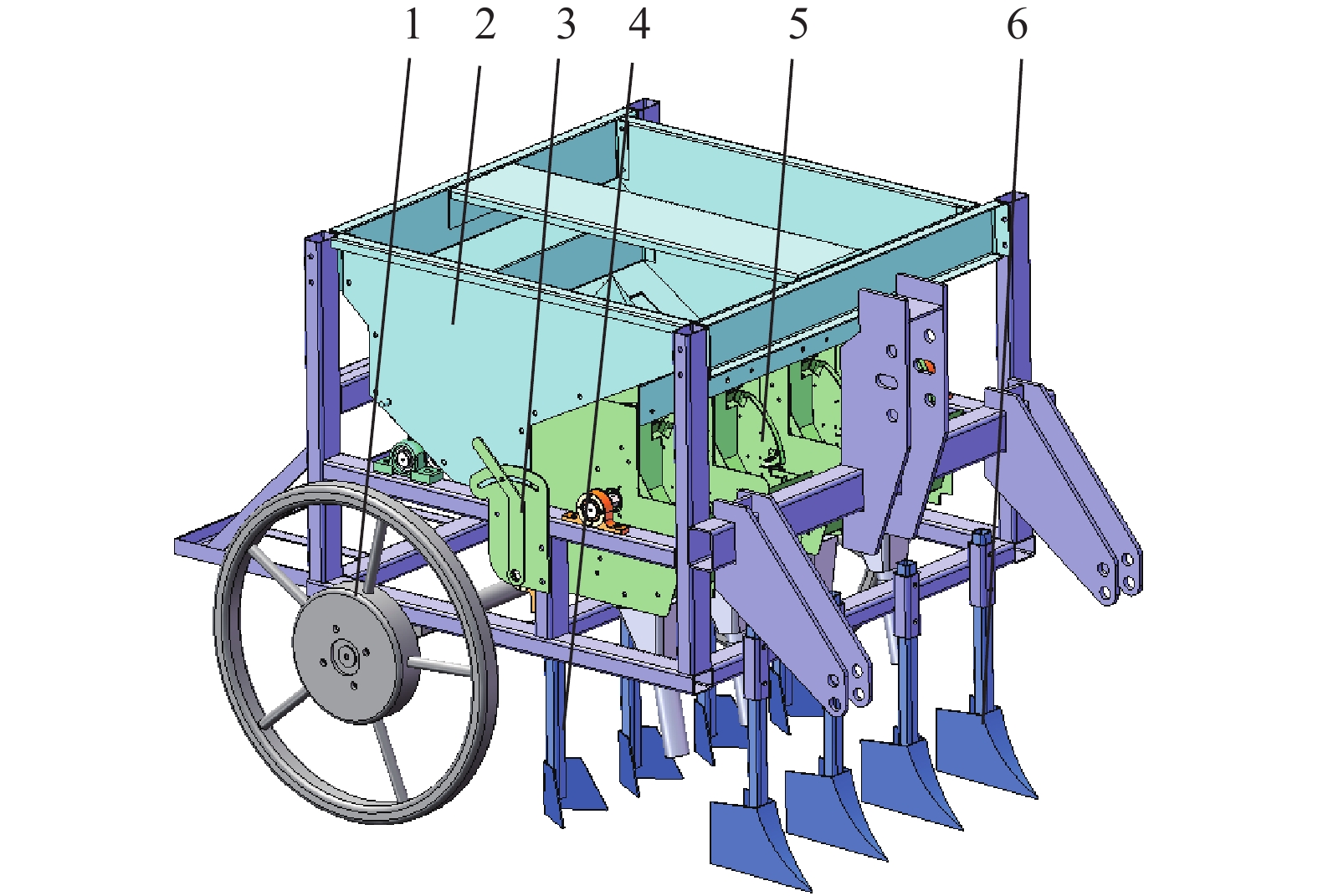

图 2 取种装置结构图

1:清种调节把手;2:带座轴承;3:蒜种防弹挡板;4:六角轴;5:导种漏斗;6:导种管;7:从动链轮;8:取种盘;9:开闭控制器;10:取种外壳;11:隔种挡板

Figure 2. Structure diagram of the seed picking device

1: Seed cleaning adjustment handle; 2: Seat bearing; 3: Garlic seed bullet-proof plate; 4: Hexagonal shaft; 5: Seed guide funnel; 6: Seed guide tube; 7: Slave sprocket; 8: Seed tray; 9: Open/close controller; 10: Seed picking shell; 11: Isolate baffle

表 1 播种数量监测结果

Table 1 Results of seeding quantity monitoring

序号

Serial

number播种量

No. of seeds sown漏播量

No. of missed seeds实际值

Actual value测量值

Measured value相对误差${(\delta _{\text{a}})}$/%

Relative

error实际值

Actual value测量值

Measured value相对误差${(\delta _{\text{b}})}$/%

Relative

error1 281 272 3.2 24 23 4.2 2 288 283 1.7 19 19 0 3 283 269 4.9 27 26 3.7 表 2 土槽试验监测结果

Table 2 Monitoring results of soil trench test

作业速度/(km·h−1)

Working speed播种量

No. of seeds sown漏播量

No. of missed seeds实际值

Actual value测量值

Measured value相对误差/%

Relative

error实际值

Actual value测量值

Measured value相对误差/%

Relative

error1.0 920 882 4.1 37 36 2.9 1.5 911 880 3.4 51 48 5.9 2.0 917 895 2.4 48 47 2.1 2.5 903 865 4.2 77 73 5.1 3.0 749 716 5.2 70 67 4.3 -

[1] 张春岭, 吴晓庆, 谢东波, 等. 电液混合调控式大蒜播种机设计与试验[J]. 农业机械学报, 2021, 52(10): 166-174. doi: 10.6041/j.issn.1000-1298.2021.10.017 [2] 栗晓宇, 耿爱军, 侯加林, 等. 大蒜播种机研究现状及展望[J]. 农业机械, 2017(2): 105-107. [3] 钟志堂, 吴小伟, 唐莉莉, 等. 江苏大蒜生产机械化现状与发展思路[J]. 农机科技推广, 2019(7): 7-8. doi: 10.3969/j.issn.1671-3036.2019.07.003 [4] 陈礼源. 适用于精量播种的播种监测系统设计与试验[D]. 武汉: 华中农业大学, 2022. [5] 丁幼春, 陈礼源, 王登辉, 等. 油菜播种质量监测系统设计与试验[J]. 华南农业大学学报, 2021, 42(6): 43-51. doi: 10.7671/j.issn.1001-411X.202107029 [6] KUMAR R, RAHEMAN H. Detection of flow of seeds in the seed delivery tube and choking of boot of a seed drill[J]. Computers and Electronics in Agriculture, 2018, 153: 266-277.

[7] KARIMI H, NAVID H, BESHARATI B, et al. A practical approach to comparative design of non-contact sensing techniques for seed flow rate detection[J]. Computers and Electronics in Agriculture, 2017, 142: 165-172.

[8] KARIMI H, NAVID H, BESHARATI B, et al. Assessing an infrared-based seed drill monitoring system under field operating conditions[J]. Computers and Electronics in Agriculture, 2019, 162: 543-551.

[9] BESHARATI B, NAVID H, KARIMI H, et al. Development of an infrared seed-sensing system to estimate flow rates based on physical properties of seeds[J]. Computers and Electronics in Agriculture, 2019, 162: 874-881.

[10] 贾洪雷, 路云, 齐江涛, 等. 光电传感器结合旋转编码器检测气吸式排种器吸种性能[J]. 农业工程学报, 2018, 34(19): 28-39. doi: 10.11975/j.issn.1002-6819.2018.19.004 [11] 苑严伟, 白慧娟, 方宪法, 等. 玉米播种与测控技术研究进展[J]. 农业机械学报, 2018, 49(9): 1-18. doi: 10.6041/j.issn.1000-1298.2018.09.001 [12] 卢彩云, 李洪文, 何进, 等. 间歇式自动取样条播排种器排种性能检测试验台研制[J]. 农业工程学报, 2019, 35(24): 10-19. doi: 10.11975/j.issn.1002-6819.2019.24.002 [13] 赵立新, 张增辉, 王成义, 等. 基于变距光电传感器的小麦精播施肥一体机监测系统设计[J]. 农业工程学报, 2018, 34(13): 27-34. doi: 10.11975/j.issn.1002-6819.2018.13.004 [14] 纪超, 陈学庚, 陈金成, 等. 玉米免耕精量播种机排种质量监测系统[J]. 农业机械学报, 2016, 47(8): 1-6. doi: 10.6041/j.issn.1000-1298.2016.08.001 [15] 邱兆美, 张巍朋, 赵博, 等. 小粒种子电动播种机作业质量监测系统设计与试验[J]. 农业机械学报, 2019, 50(4): 77-83. doi: 10.6041/j.issn.1000-1298.2019.04.009 [16] 耿爱军, 栗晓宇, 侯加林, 等. 自动定向大蒜播种机的设计与试验[J]. 农业工程学报, 2018, 34(11): 17-25. doi: 10.11975/j.issn.1002-6819.2018.11.003 [17] 崔荣江, 张华, 徐文艺, 等. 我国大蒜机械化生产现状及发展思路探讨[J]. 农机化研究, 2015, 37(3): 264-268. doi: 10.3969/j.issn.1003-188X.2015.03.064 [18] IM D, KIM J H, MOON D J, et al. Optimization of bucket size of garlic metering device using multibody dynamics simulation[J]. Journal of Biosystems Engineering, 2022, 47(4): 480-488.

[19] 李天华, 张海阔, 韩相龙, 等. 勺链式大蒜播种机漏取种检测与补种装置设计及试验[J]. 农业工程学报, 2022, 38(4): 24-32. doi: 10.11975/j.issn.1002-6819.2022.04.003 [20] 国家质量监督检验检疫总局, 中国国家标准化管理委员会. 农业机械试验条件测定方法的一般规定: GB/T 5262—2008[S]. 北京: 中国标准出版社, 2008. [21] 国家质量监督检验检疫总局, 中国国家标准化管理委员会. 播种监测系统: GB/T 35383—2017[S]. 北京: 中国标准出版社, 2017. 国家质量监督检验检疫总局, 中国国家标准化管理委员会. 播种监测系统: GB/T 35383—2017[S]. 北京: 中国标准出版社, 2017.

[22] LI H F, BAI E C, MI M L, et al. Identification of Euler angles of permanent magnet spherical motor rotor based on Hall sensors array[J]. Measurement, 2022, 199: 111500.

[23] 王奇, 高鹏翔, 王金武, 等. 胡萝卜联合收获机智能监控系统设计与试验[J]. 农业机械学报, 2022, 53(6): 118-128. doi: 10.6041/j.issn.1000-1298.2022.06.012 [24] 刘春旭, 赵德春, 单爱军. 红外反射式播种机电子监测装置的设计[J]. 农机化研究, 2010, 32(6): 117-121. doi: 10.3969/j.issn.1003-188X.2010.06.031 [25] 刘新怡, 陈进, 张西良. 基于STM32的联合收获机清选损失监测装置的研制[J]. 农机化研究, 2020, 42(10): 200-204. doi: 10.3969/j.issn.1003-188X.2020.10.035

下载:

下载: