Design and experiment of adjustable seedling-feeding device for vegetable transplanting machine

-

摘要:目的

为扩大移栽机适用性,实现对多种规格蔬菜穴盘苗的自动取喂苗作业,本文设计了一款蔬菜移栽机可调式喂苗装置。

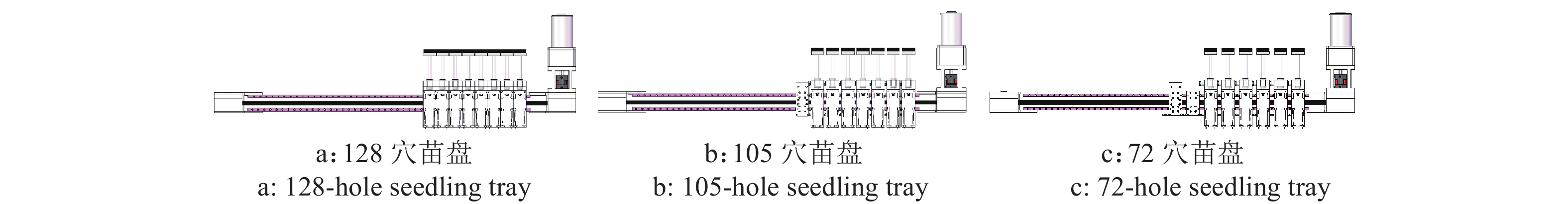

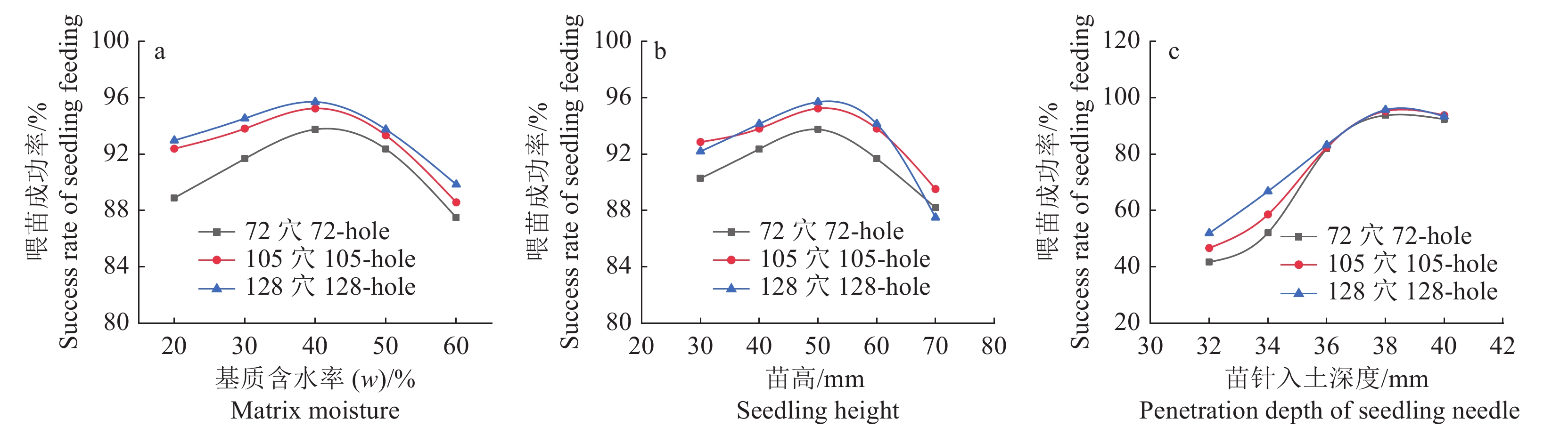

方法设计了带有可调节取喂苗爪的取喂苗臂,优化了喂苗爪的相关参数,并进行了运动学分析。通过调节取喂苗臂上的取喂苗爪数量及间距,选择不同的PLC控制程序,可以配套使用不同穴孔数的穴盘。通过对取喂苗工作过程分析,综合考虑影响喂苗成功率的关键性因素,以苗坨含水率、穴盘苗苗高、苗针入土深度为试验参数,选取72、105、128穴规格的生菜穴盘苗为试验对象,进行单因素试验和多因素正交试验,探究各因素对喂苗成功率的影响。

结果当穴盘苗基质含水率(w)为40%、苗高为50 mm、入土深度为38 mm时,可调式喂苗装置的喂苗成功率最高,72、105、128穴生菜穴盘的喂苗成功率分别为95.83%、96.19%和96.48%。

结论可调式喂苗装置设计符合蔬菜移栽机取喂苗的技术要求,移栽效果较好,可为通用全自动蔬菜移栽机的研制与开发提供参考。

Abstract:ObjectiveIn order to expand the applicability of transplanter and realize the automatic feeding of plug seedlings of various specifications of vegetables, this paper designs a universal automatic seedling-feeding device for vegetable transplanting machine.

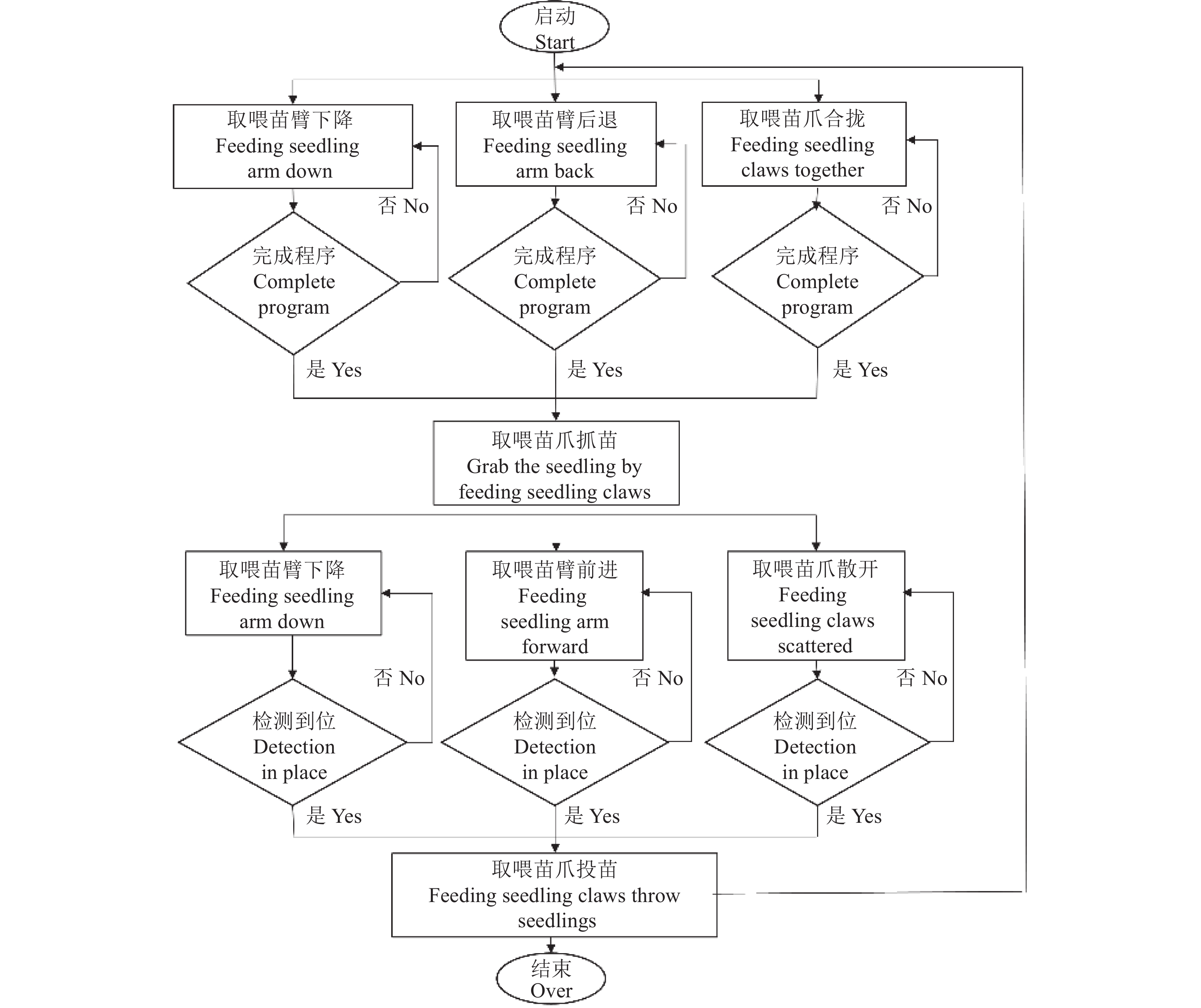

MethodThe seedling-feeding arm with an adjustable feeding claw was designed, the key parameters were optimized and kinematic analysis was performed. Plug trays with different number of holes could be used by adjusting the number and distance of feeding claws on the seedling-feeding arm and choosing different PLC control programs. The key factors affecting the success rate of seedling feeding were comprehensively considered by analyzing the working process of seedling feeding. Taking the water content of the plug, the height of plug seedling, and the depth of seedling needle into soil as the test parameters, the plug seedlings of lettuce in 72-, 105- and 128-hole plug as the test objects, single factor experiment and multi-factor orthogonal experiment were carried out to explore the effect of different factor on the success rate of seedling feeding.

ResultThe test results showed that when the water content of plug seedling substrate was 40%, seedling height was 50 mm, and the depth of seedling needle into soil was 38 mm, the success rates of seedling feeding for adjustable seedling feeding device were the highest, and the seedling-feeding success rates of lettuce in 72-, 105- and 128-hole plug trays were 95.83%, 96.19% and 96.48%, respectively.

ConclusionThe design of adjustable seedling-feeding device meets the technical requirements of vegetable transplanting machine for feeding seedlings, and the transplanting effect is good, which can provide a reference for research and development of the universal automatic vegetable transplanting machine.

-

Keywords:

- Vegetable /

- Plug seedling /

- Transplanting machine /

- Adjustable feeding claw /

- Orthogonal test

-

-

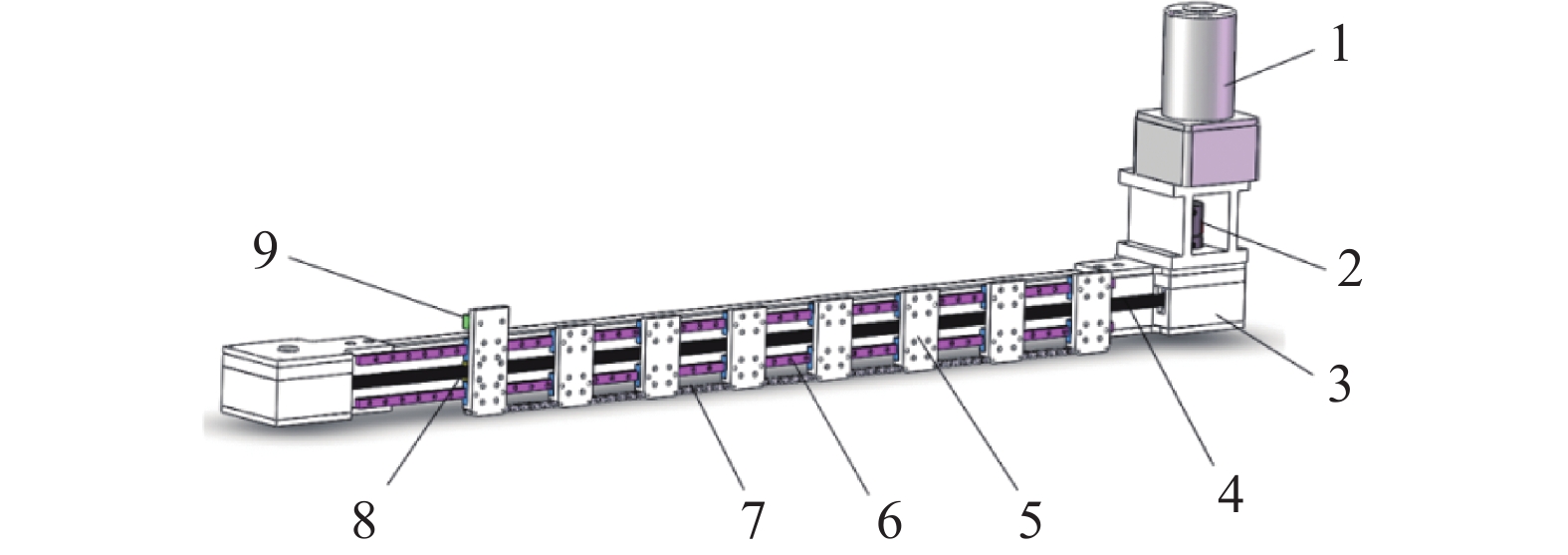

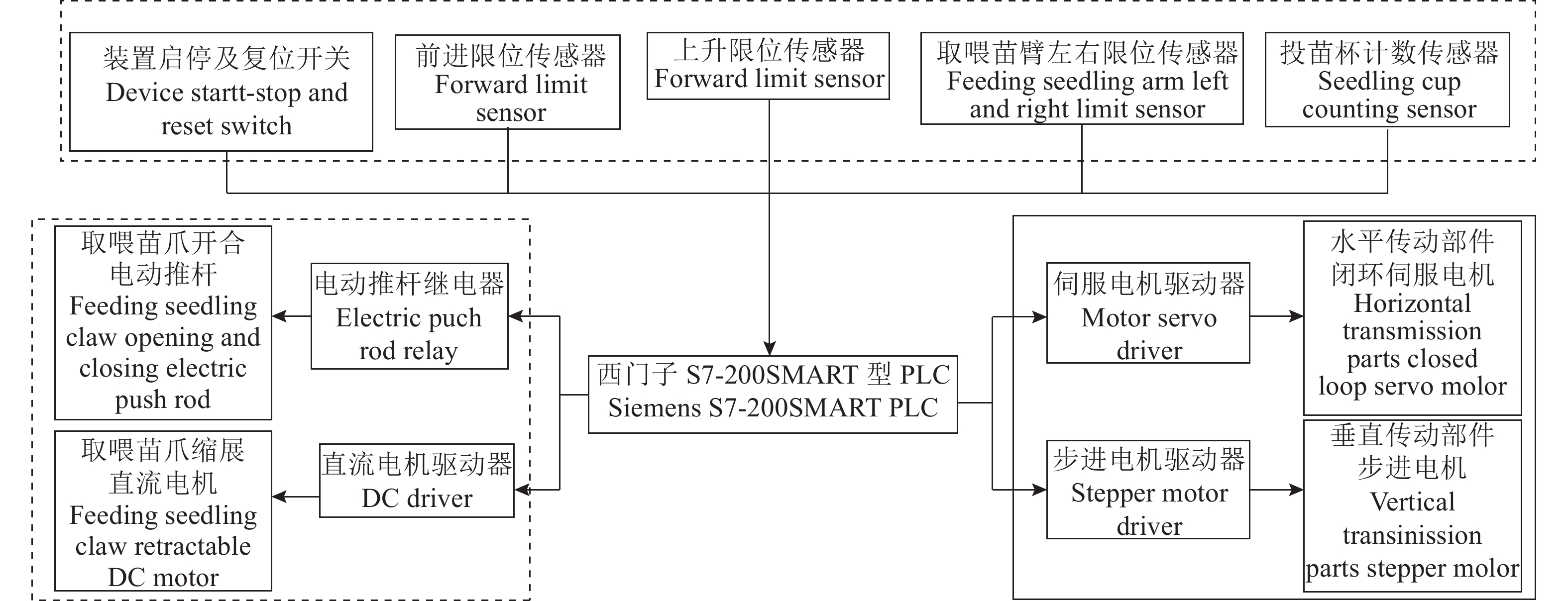

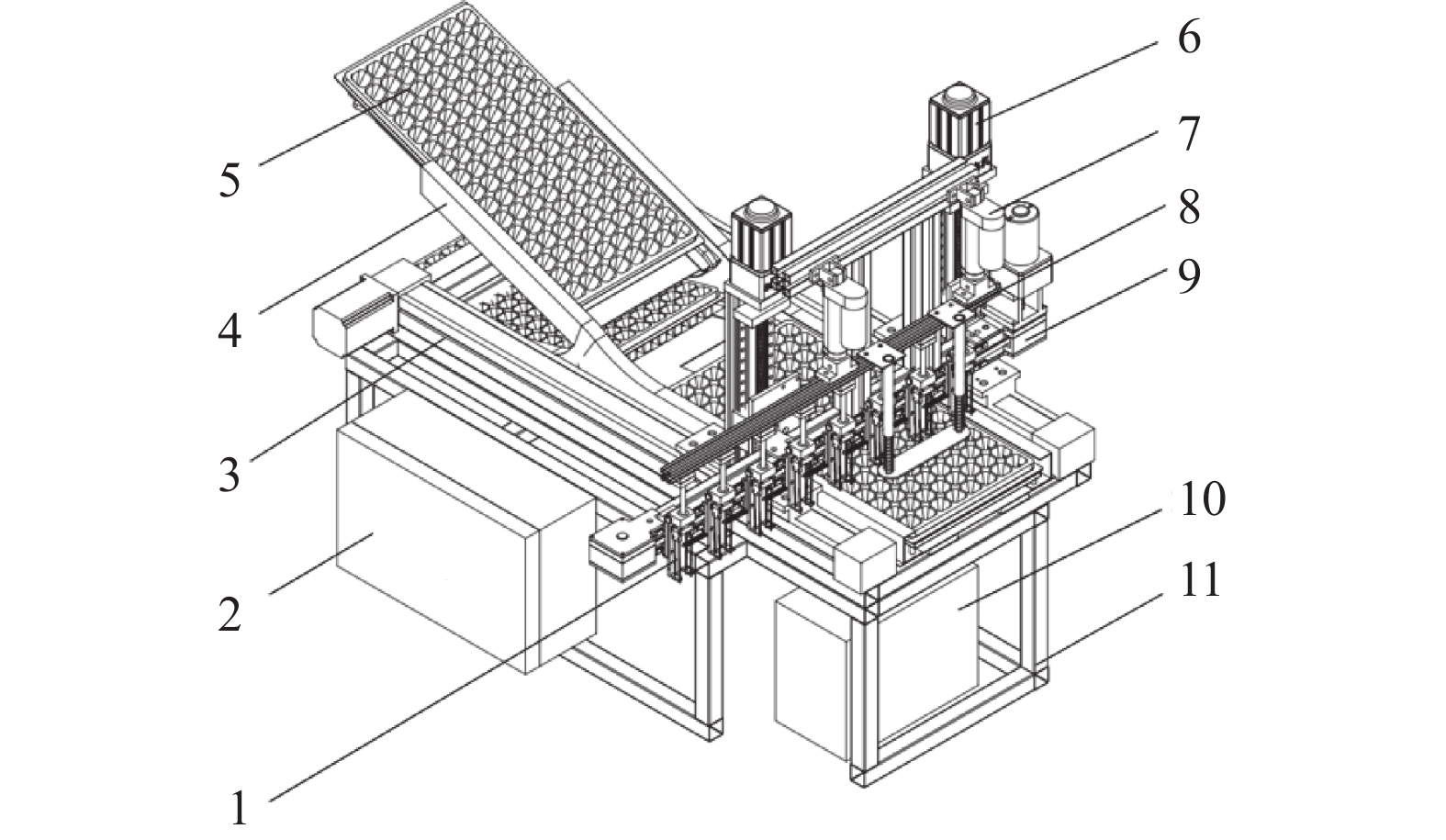

图 1 可调式喂苗装置整机结构示意图

1:取喂苗爪;2:控制箱;3:水平传动部件;4:换盘机构;5:穴苗盘;6:垂直传动部件;7:电动推杆;8:压板;9:取喂苗臂;10:电池;11:机架

Figure 1. Structure diagram of adjustable seedling-feeding device

1: Seedling picking claw; 2: Control cabinet; 3: Horizontal driving unit; 4:Tray changing device; 5: Tray; 6: Vertical driving unit; 7: Linear actuator; 8: Pressure plate; 9: Arm for seedlings picking; 10: Battery; 11: Frame

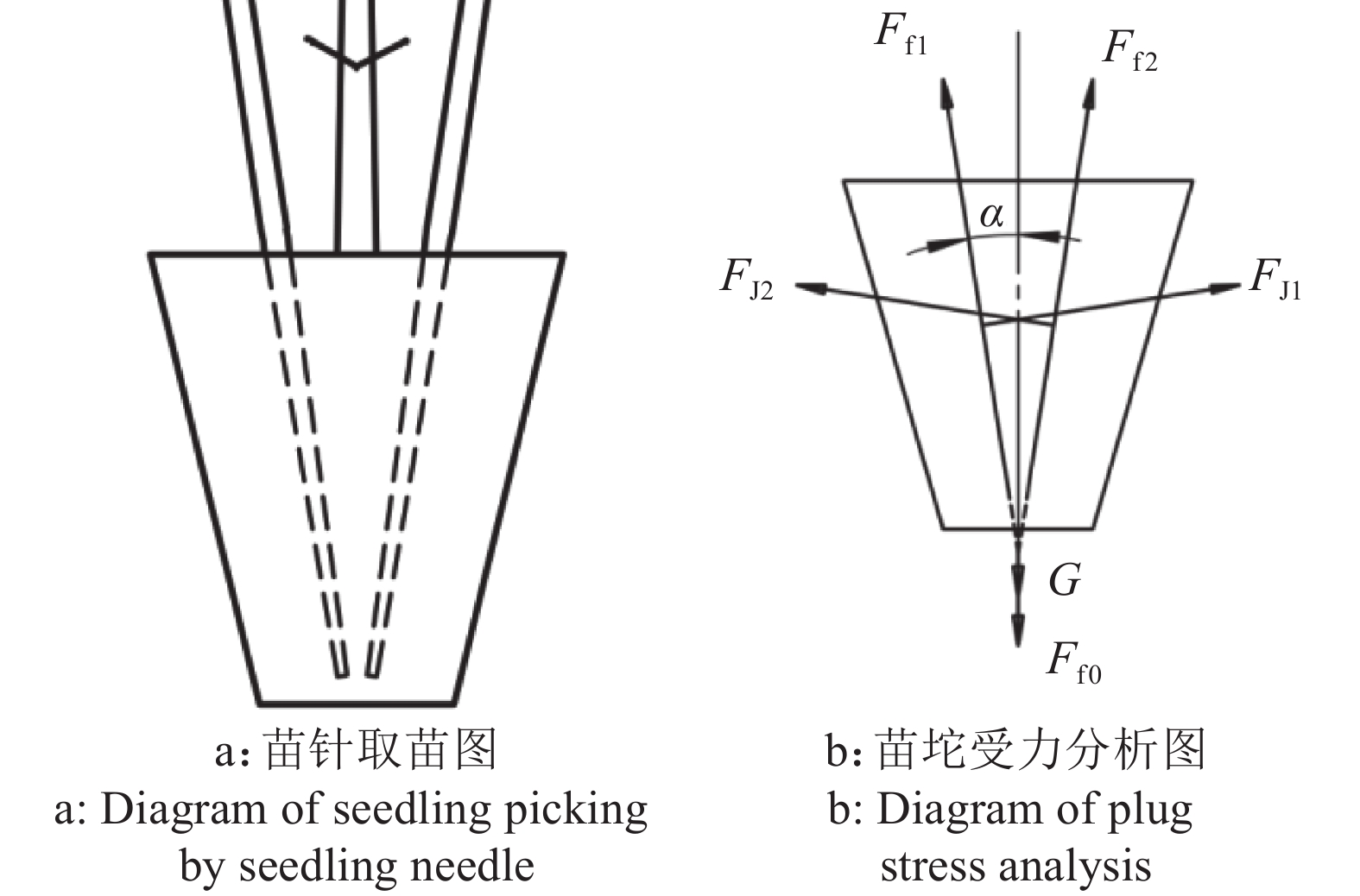

图 4 取苗受力分析图

${F_{{\rm{f}}0}}$:穴盘对苗坨的摩擦力;G:苗坨重力;${F_{{\rm{f}}1}} $、$ {F_{{\rm{f}}2}} $苗针对苗坨产生的静摩擦力;$ {F_{{\rm{J}}1}}$、${F_{{\rm{J}}2}} $:苗针对苗坨产生两侧的夹持力

Figure 4. Stress analysis diagram of seedling picking

$ {F_{{\rm{f}}0}}$: Friction of seedling; G: Seedling gravity; $ {F_{{\rm{f}}1}}$、$ {F_{{\rm{J}}2}}$ Static friction force produced between seedling and seedling needle; $ {F_{{\rm{J}}1}}$、$ {F_{{\rm{J}}2}}$: Seedling clamping force produced by both sides of seedling

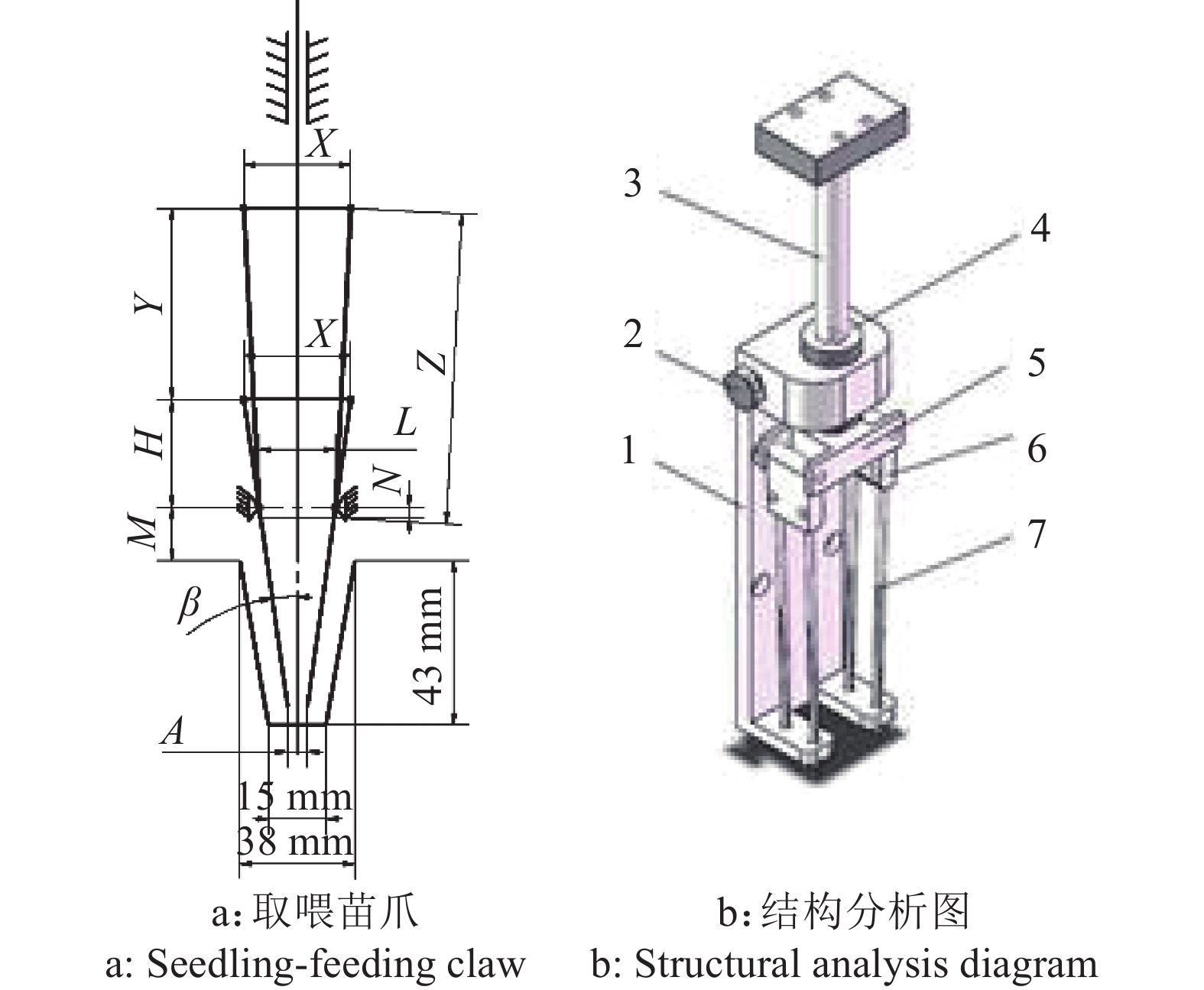

图 5 喂苗爪结构图

a图中,X:苗安装板转动中心之间的距离;Y:苗针下降到最低点的距离;Z:苗针和苗针连接板的长度;H:苗针下降到最低点后安装板和固定板之间的距离;L:固定板下方孔中心距;M:安装板和穴盘之间的距离;N:苗针在最上方时苗针离安装板的距离;A:苗针下降到最低点后针尖之间的距离;β:苗针在最低处时与竖直方向的夹角;b图中,1:固定板;2:限位螺栓;3:推杆;4:直线轴承;5:连接板;6:苗针安装板;7:苗针

Figure 5. Structure of seedling-feeding claw

In figure a, X: Distance between rotation centers of seedling mounting plate; Y: Distance of needle dropping to the lowest point; Z: Length of plate connecting seedling needles; H: Distance between mounting plate and fixed plate after seedling needle dropping to the lowest point; L: Center distance of the square hole under the fixed plate; M: Distance between mounting plate and tray; N: Distance from seedling needle to the mounting plate at the top of the seedling needle; A: Distance between tip of the needle after needle dropping to the lowest point; β: Angle between seedling needle at the lowest point and vertical direction; In figure b, 1: Fixed block; 2: Limit bolt; 3: Push rod; 4: Linear bearing; 5: Junction plate; 6: Seedling needle mounting plate; 7: Seedling needle

表 1 取喂苗爪不同参数的设计尺寸1)

Table 1 Dimensions of different parameters of seedling feeding claw

β/(°) Z/mm H/mm L/mm 10 74.86 74.86 74.86 9 83.10 83.10 83.10 8 93.41 93.41 93.41 7 106.67 106.67 106.67 6 124.37 124.37 124.37 1) β为苗针在最低处时与竖直方向的夹角;Z为苗针和苗针连接板的长度;H为苗针下降到最低点后安装板和固定板之间的距离;L为固定板下方孔中心距 1) β is angle ketneen seedling needle at the lowest point and vertical direction; Z is the length of the connecting plate between the needles; H is the distance between the mounting plate and the fixed plate after the needle drops to the lowest point; L is the center distance of the square hole under the fixed plate 表 2 正交试验因素水平表

Table 2 Factors and levels of orthogonal test

水平 Level 育苗盘规格/穴 Seedling tray specification (A) 基质含水率(w)/% Matrix moisture (B) 苗高/mm Seedling height (C) 入土深度/mm Depth of penetration (D) 1 72 30 40 36 2 105 40 50 38 3 128 50 60 40 表 3 正交试验方案及结果

Table 3 Experiment scheme and results of orthogonal test

序号 No. 因素及水平 Factors and levels 喂苗成功数/株 No. of successful seedling picking 喂苗成功率(η)/% Success rate of seedling feeding A B C D 1 1 1 1 1 115 79.86 2 1 2 3 2 129 89.58 3 1 3 2 3 126 87.50 4 2 1 3 3 189 90.00 5 2 2 2 1 176 83.81 6 2 3 1 2 193 91.90 7 3 1 2 2 239 93.36 8 3 2 1 3 233 91.02 9 3 3 3 1 216 84.38 表 4 极差分析

Table 4 Range analysis

因素 Factor K1 K2 K3 极差 Range 最优方案 Optimal scheme A 256.94 265.71 268.75 11.81 A3 B 263.22 264.41 263.78 1.19 B2 C 262.78 264.67 263.78 1.89 C2 D 248.05 274.85 268.52 26.80 D2 主次 Primary and secondary $ D > A > C > B $ 表 5 方差分析

Table 5 Variance analysis

来源 Source 平方和 Sum of squares 自由度 Degree of freedom 均方 Mean square F 显著性1)Significance A 25.06 2 12.52 106.40 * * B 0.24 2 0.12 C 0.61 2 0.30 2.57 D 130.83 2 65.41 555.56 * * 总和 Sum 156.74 8 1)“**”表示0.01水平差异显著 1)“**” means significant difference at the level of 0.01 -

[1] 玄冠涛, 韩军伟, 邵园园, 等. 我国机械化移栽自动分苗取苗技术研究现状[J]. 农机化研究, 2022, 44(3): 10-15. doi: 10.3969/j.issn.1003-188X.2022.03.002 [2] 张丽娜, 谭彧, 吕昊暾, 等. 温室穴盘苗自动移钵路径优化[J]. 农业工程学报, 2020, 36(15): 65-72. doi: 10.11975/j.issn.1002-6819.2020.15.008 [3] 杜新武, 李灿, 李明勇, 等. 旱作移栽钵苗自动取投苗技术研究进展[J]. 农机化研究, 2018, 40(8): 263-268. doi: 10.3969/j.issn.1003-188X.2018.08.050 [4] JI J T, CHEN K K, JIN X, et al. High-efficiency modal analysis and deformation prediction of rice transplanter based on effective independent method[J]. Computers and Electronics in Agriculture, 2020, 168: 105126. doi: 10.1016/J.COMPAG.2019.105126.

[5] 张丽华, 邱立春, 田素博. 穴盘苗自动移栽机的研究进展[J]. 农业科技与装备, 2009(5): 28-31. doi: 10.3969/j.issn.1674-1161.2009.05.012 [6] 孙晓晓, 刘洋, 李斌, 等. 穴盘苗自动移栽机取苗装置研究现状及展望[J]. 中国农机化学报, 2021, 42(3): 22-28. doi: 10.13733/j.jcam.issn.2095-5553.2021.03.004 [7] YANG Q Z, XU L, SHI X Y, et al. Design of seedlings separation device with reciprocating movement seedling cups and its controlling system of the full-automatic plug seedling transplanter[J]. Computers and Electronics in Agriculture, 2018, 147: 131-145. doi: 10.1016/j.compag.2018.02.004.

[8] 童俊华, 石虎峰, 武传宇, 等. 穴盘移栽指铲式末端执行器苗钵基质抓取仿真与试验[J]. 农业机械学报, 2019, 50(8): 107-116. doi: 10.6041/j.issn.1000-1298.2019.08.012 [9] 田志伟, 马伟, 杨其长, 等. 温室穴盘苗移栽机械研究现状及问题分析[J]. 中国农业大学学报, 2022, 27(5): 22-38. doi: 10.11841/j.issn.1007-4333.2022.05.03 [10] 严宵月, 胡建平, 吴福华, 等. 整排取苗间隔放苗移栽设计与试验[J]. 农业机械学报, 2013, 44(S1): 7-13. [11] 胡建平, 常航, 杨丽红, 等. 自动移栽机整排取苗间隔投苗控制系统设计与试验[J]. 农业机械学报, 2018, 49(6): 78-84. doi: 10.6041/j.issn.1000-1298.2018.06.009 [12] 魏新华, 包盛, 刘晓凯, 等. 穴盘苗全自动移栽机运动协调控制系统设计与移栽试验[J]. 农业机械学报, 2016, 47(12): 1-7. doi: 10.6041/j.issn.1000-1298.2016.12.001 [13] 任玲, 赵斌栋, 曹卫彬, 等. 穴苗移栽机双旋转式分苗装置设计[J]. 农业工程学报, 2021, 37(8): 10-18. doi: 10.11975/j.issn.1002-6819.2021.08.002 [14] 王侨, 曹卫彬, 张振国, 等. 穴盘苗自动取苗机构的自适应模糊PID定位控制[J]. 农业工程学报, 2013, 29(12): 32-39. doi: 10.3969/j.issn.1002-6819.2013.12.005 [15] 王超, 刘彩玲, 李永磊, 等. 蔬菜移栽机气动下压式高速取苗装置设计与试验[J]. 农业机械学报, 2021, 52(5): 35-43. doi: 10.6041/j.issn.1000-1298.2021.05.004 [16] 刘念聪, 杨程文, 刘保林, 等. 全自动单摆式蔬菜钵苗取喂苗系统研制[J]. 农业工程学报, 2020, 36(22): 87-95. doi: 10.11975/j.issn.1002-6819.2020.22.010 [17] 文永双, 张俊雄, 张宇, 等. 蔬菜穴盘苗插入顶出式取苗装置研制[J]. 农业工程学报, 2020, 36(22): 96-104. doi: 10.11975/j.issn.1002-6819.2020.22.011 [18] 田素博, 赵晨希, 胡熙, 等. 蔬菜移栽机自动喂苗装置关键部件设计与试验[J]. 沈阳农业大学学报, 2020, 51(5): 586-592. [19] 赵晨希. 生菜移栽机自动喂苗装置设计与试验研究[D]. 沈阳: 沈阳农业大学, 2020. [20] 王宁, 任玲, 李江全, 等. 穴盘苗移栽机自动取苗技术研究现状与展望[J]. 中国农机化学报, 2021, 42(1): 59-66. doi: 10.13733/j.jcam.issn.2095-5553.2021.01.009 [21] 金鑫. 蔬菜穴盘苗自动移栽技术与装置的研究[D]. 北京: 中国农业大学, 2014. [22] 俞高红, 俞腾飞, 叶秉良, 等. 一种旋转式穴盘苗取苗机构的设计[J]. 机械工程学报, 2015, 51(7): 67-76. [23] 秦大同, 谢里阳. 现代机械设计手册−机械传动设计: 单行本[M]. 北京: 化学工业出版社, 2013. [24] 韩绿化, 毛罕平, 胡建平, 等. 穴盘苗自动移栽钵体力学特性试验[J]. 农业工程学报, 2013, 29(2): 24-29. [25] 文永双, 张宇, 田金元, 等. 蔬菜移栽钵苗检测与缺苗补偿系统设计与试验[J]. 农业机械学报, 2020, 51(S1): 123-129. doi: 10.6041/j.issn.1000-1298.2020.S1.014 [26] 田素博, 邱立春, 张诗. 基于PLC的穴盘苗移栽机械手控制系统设计[J]. 沈阳农业大学学报, 2007, 38(1): 122-124. doi: 10.3969/j.issn.1000-1700.2007.01.026 [27] 陈瑜, 郑欢, 马瑞峻, 等. 基于PLC的拔抛秧机械手监控系统设计与试验[J]. 华南农业大学学报, 2021, 42(5): 97-104. doi: 10.7671/j.issn.1001-411X.202011038

下载:

下载: