Data set construction method of virtual assembly classification detection network for agricultural machinery

-

摘要:目的

虚拟装配在工业中可节约生产成本,提升机械部件生产效率。现有的虚拟现实引擎缺乏自动建立碰撞体功能,无法完整还原实际装配过程中的物理属性;通用化构建零件网格实体是提升虚拟装配实用性、精确性及通用性的重要途径。

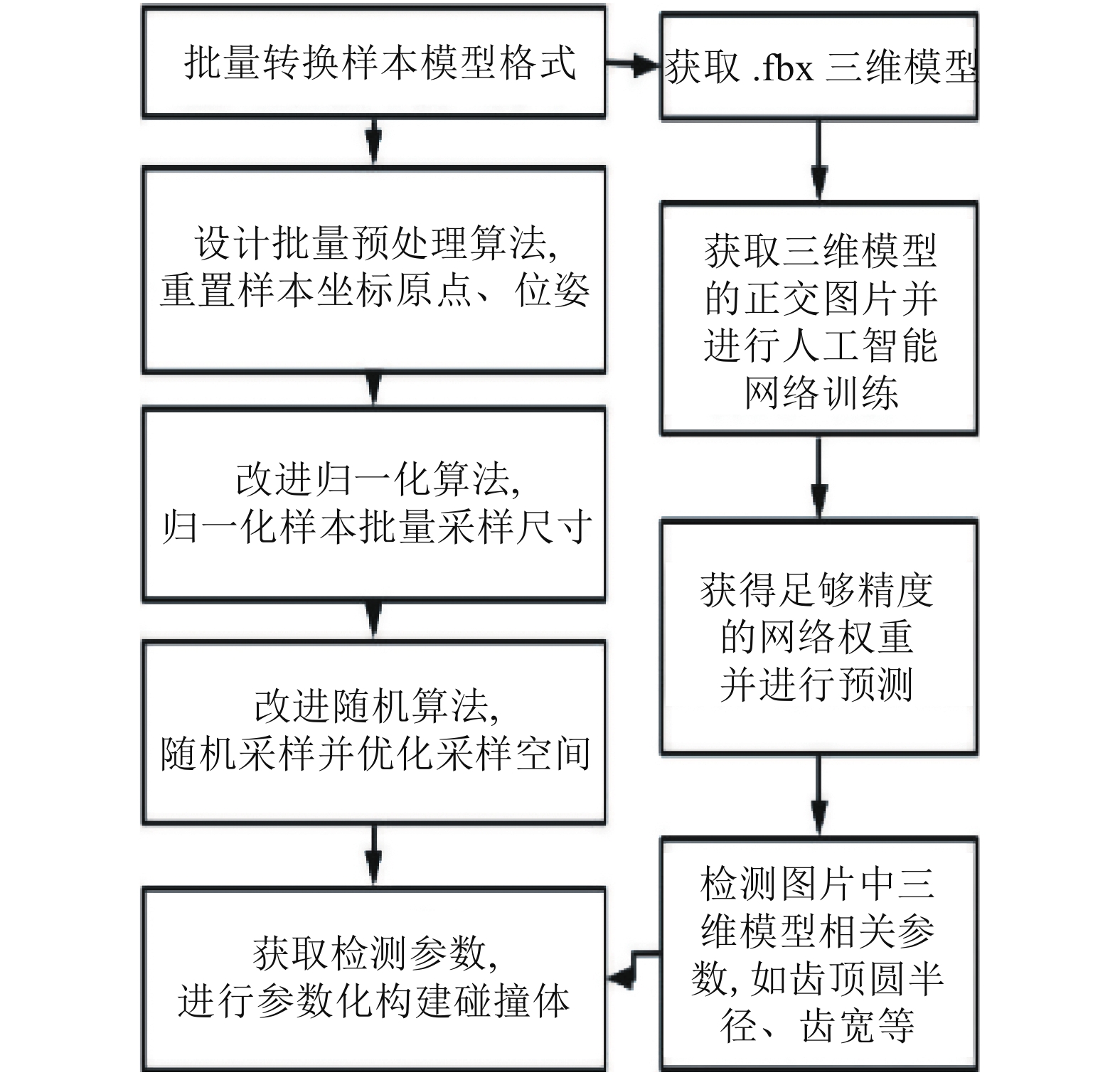

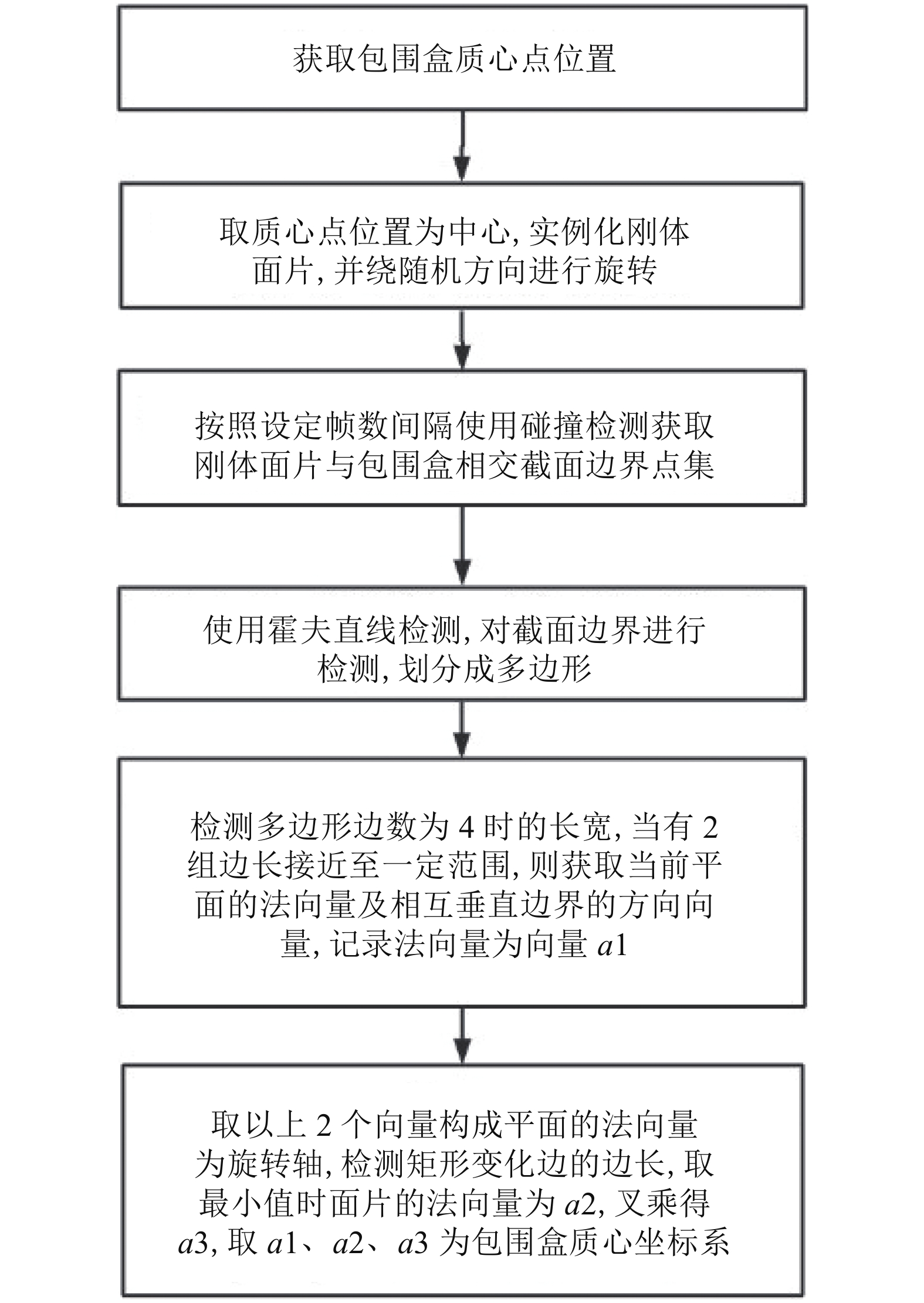

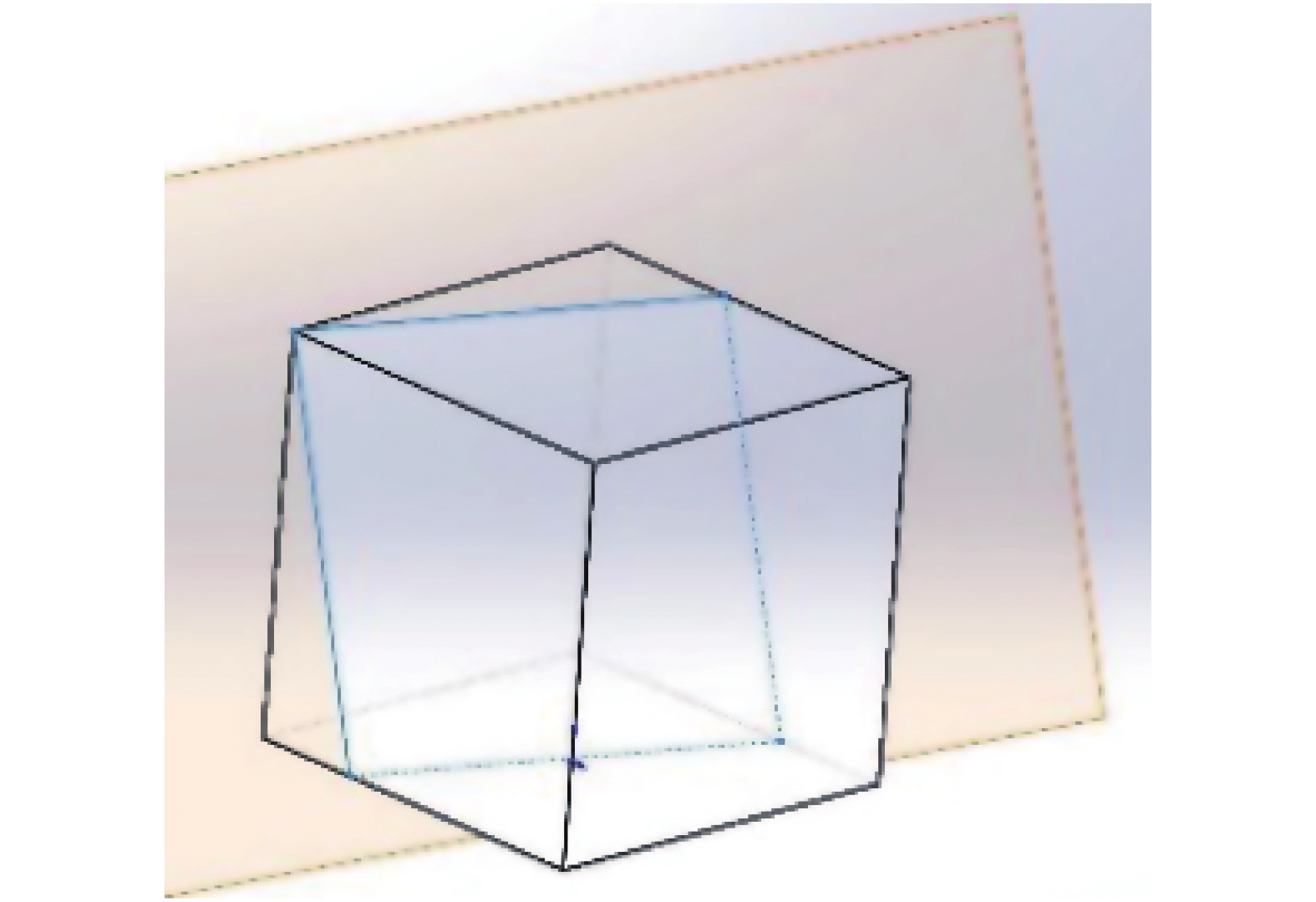

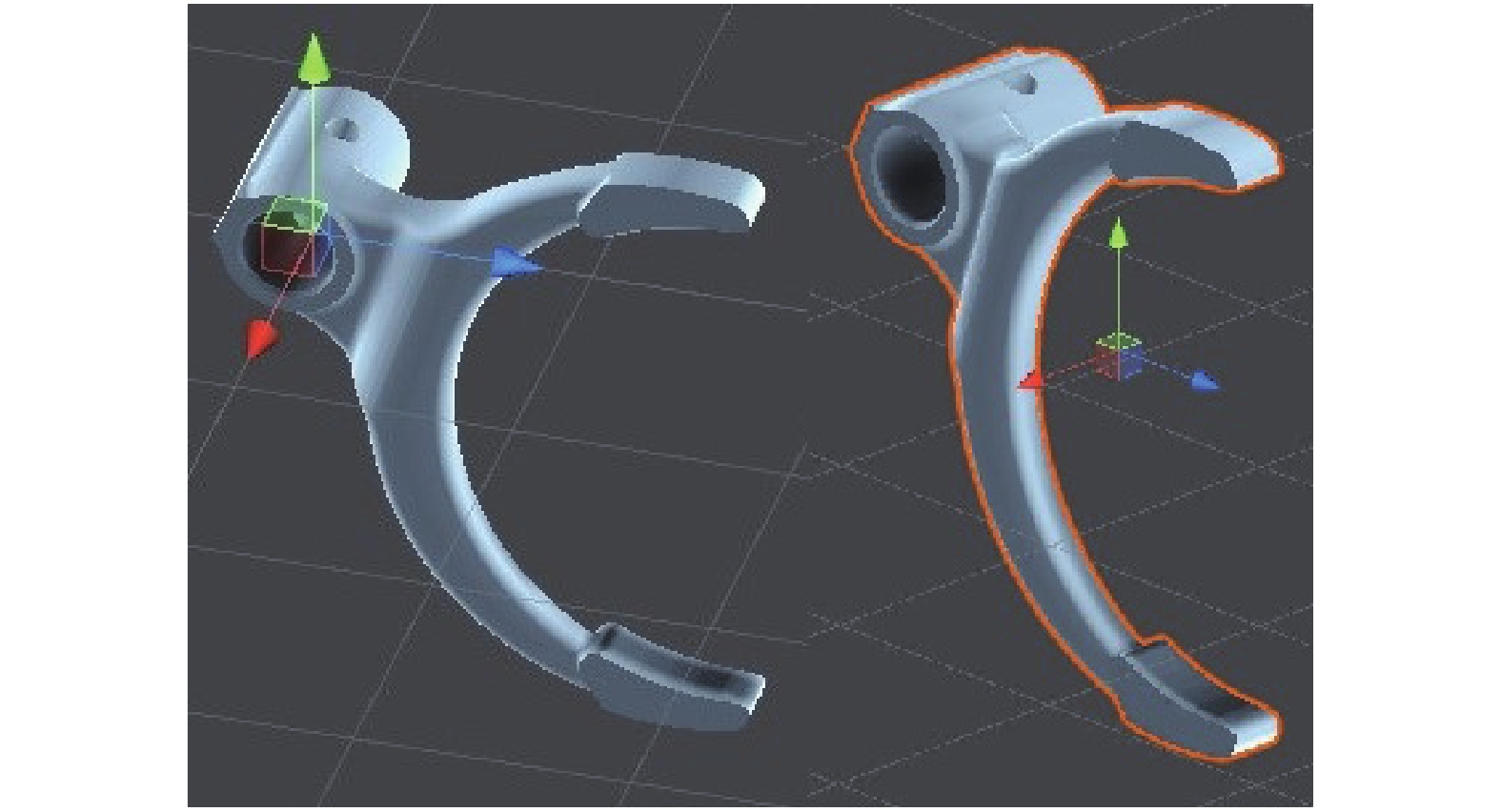

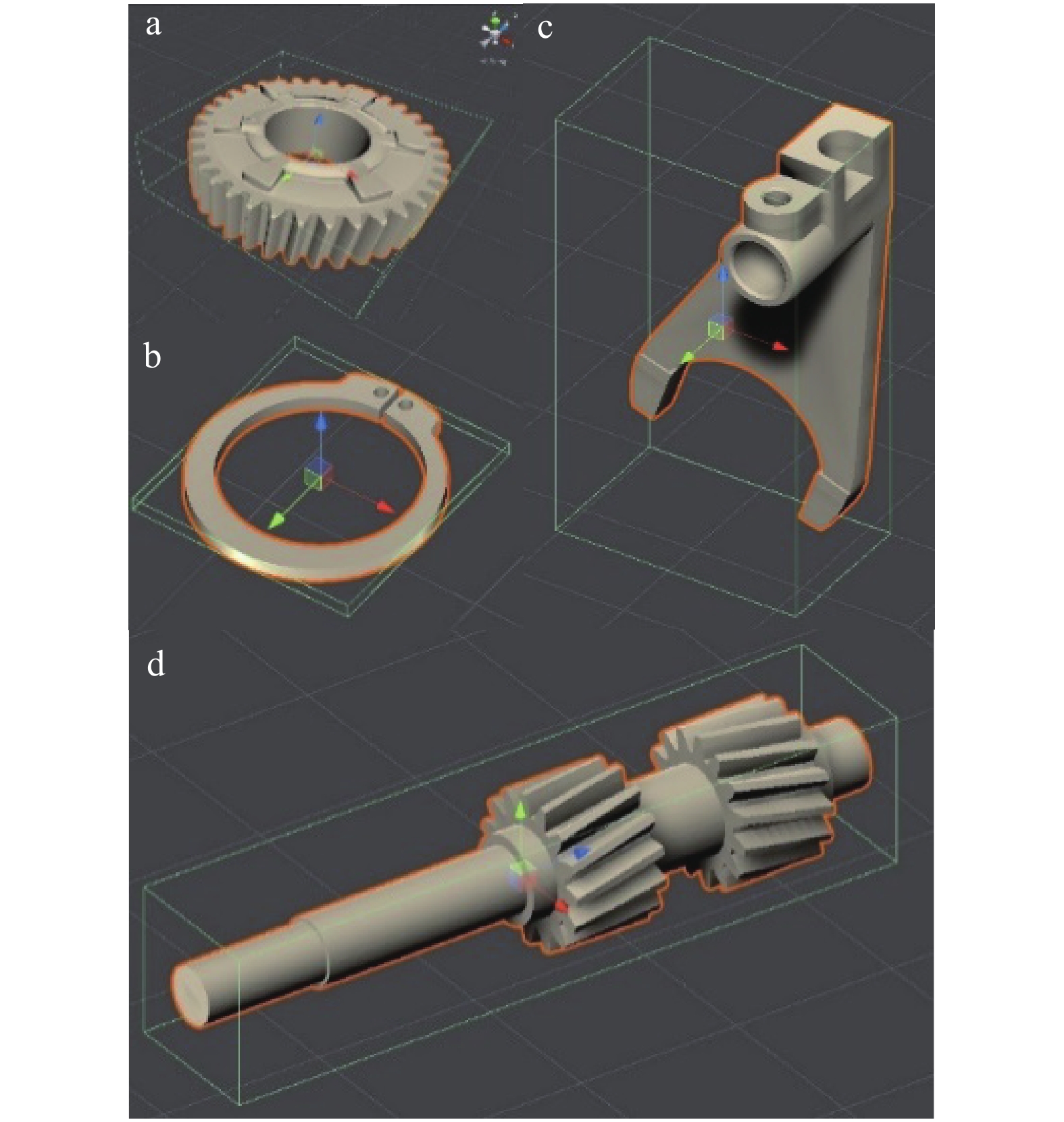

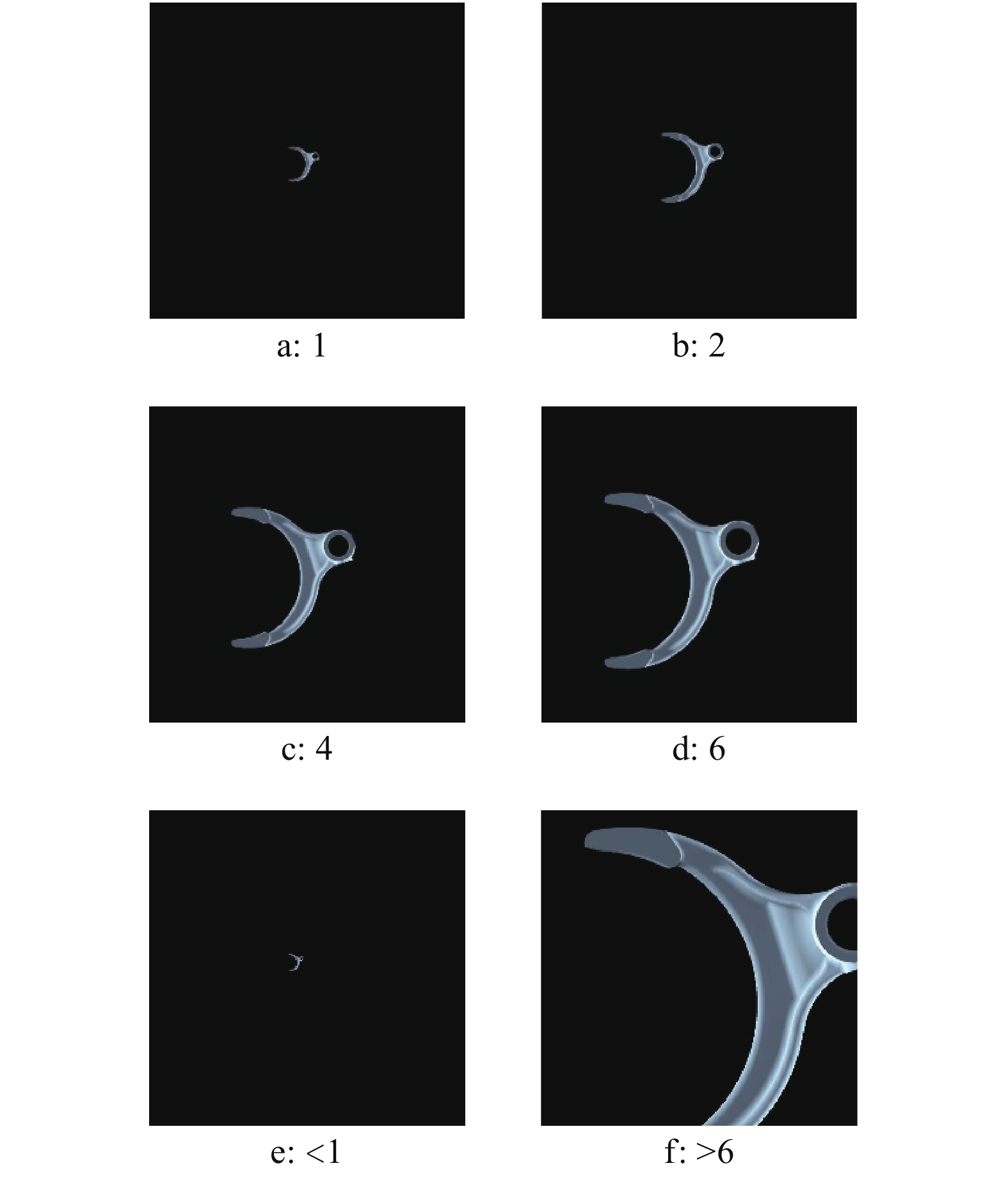

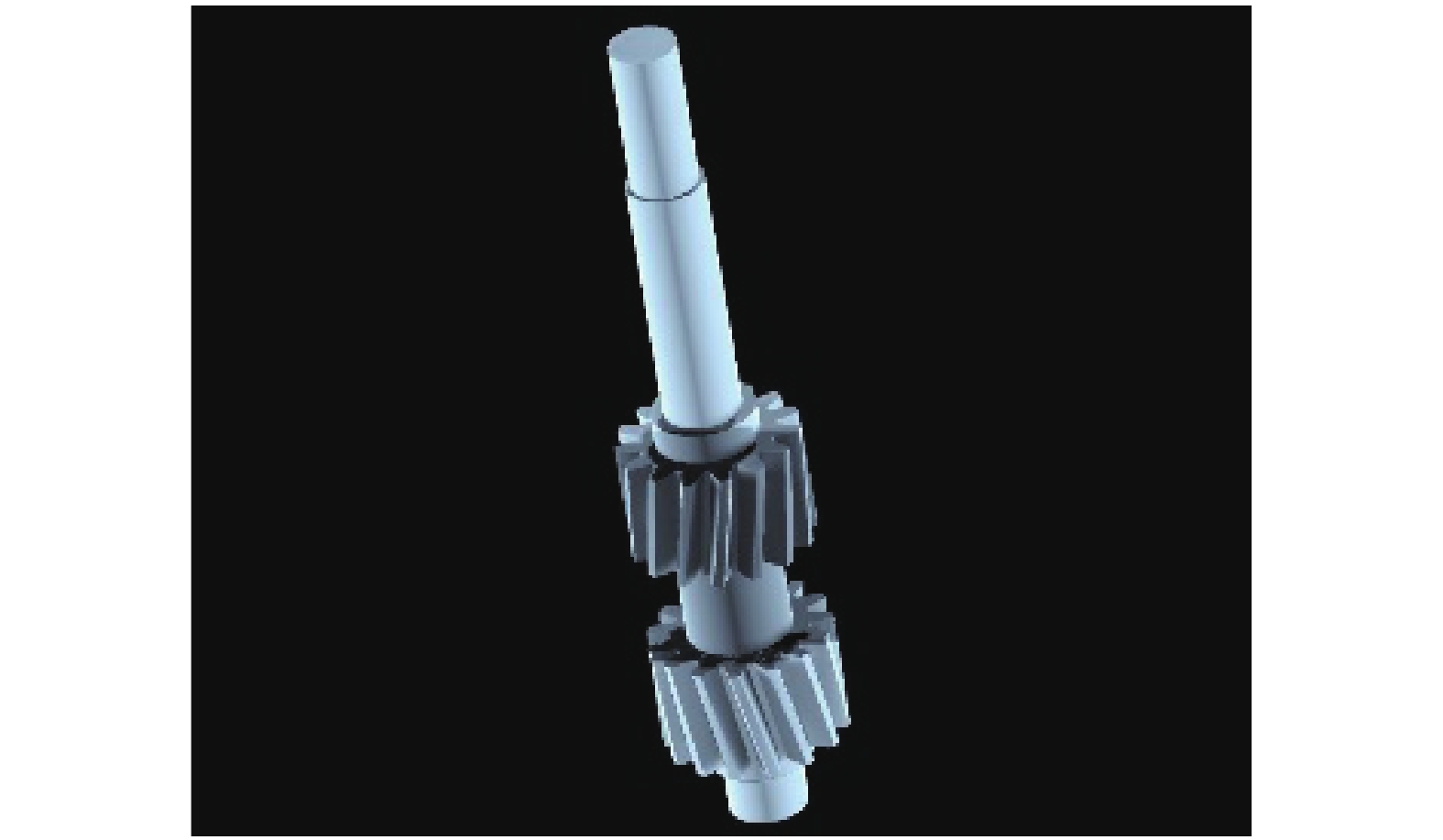

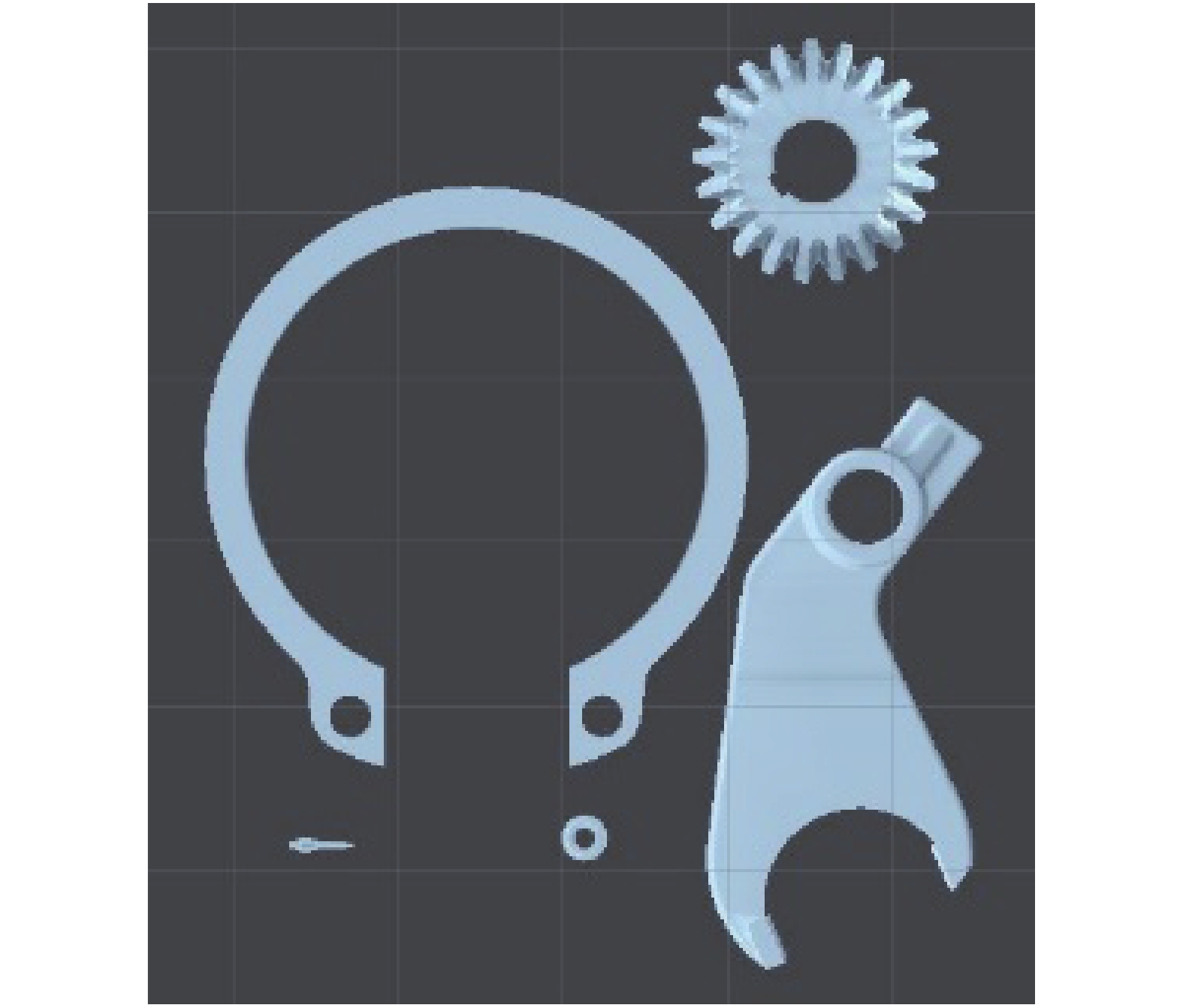

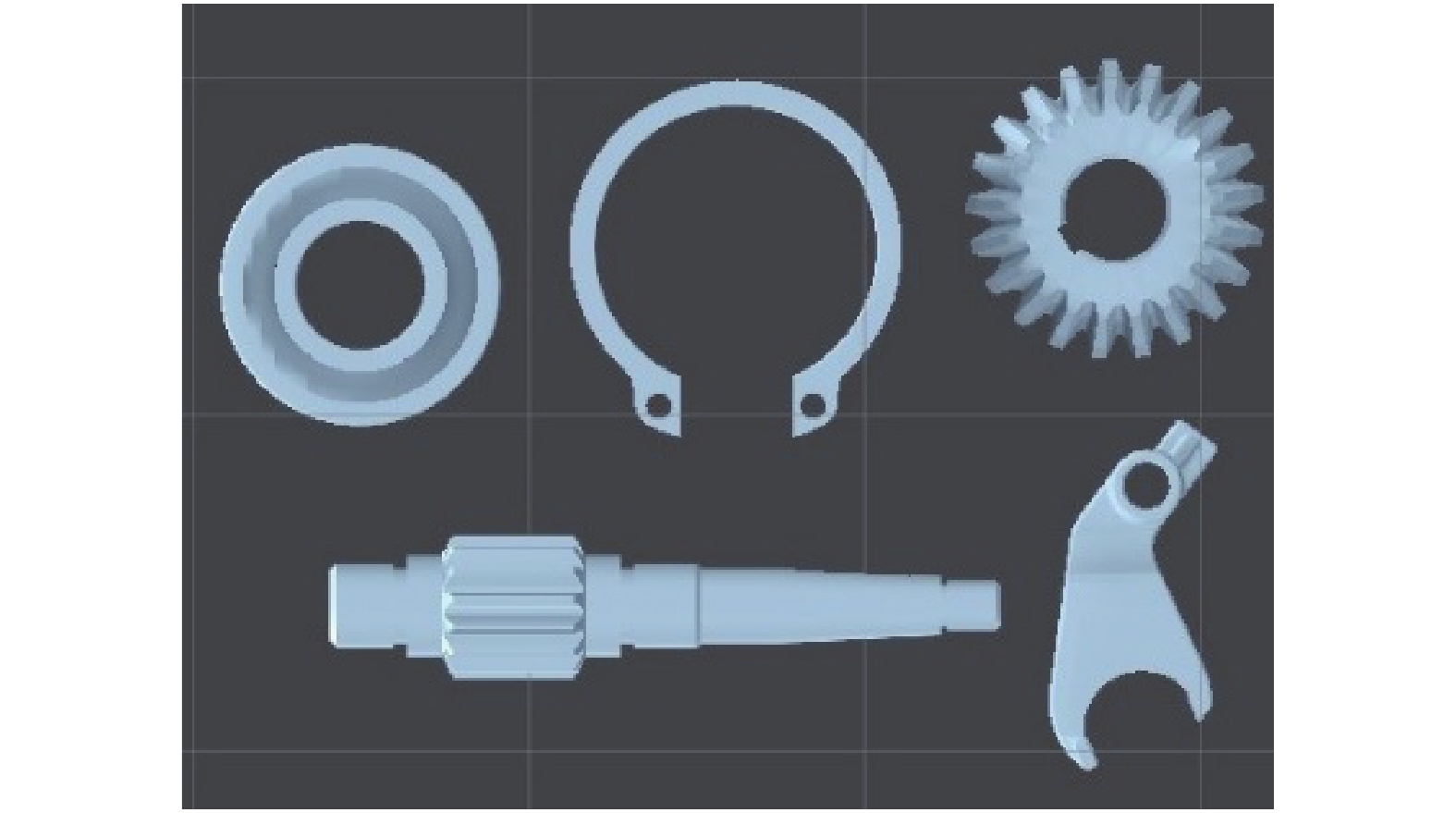

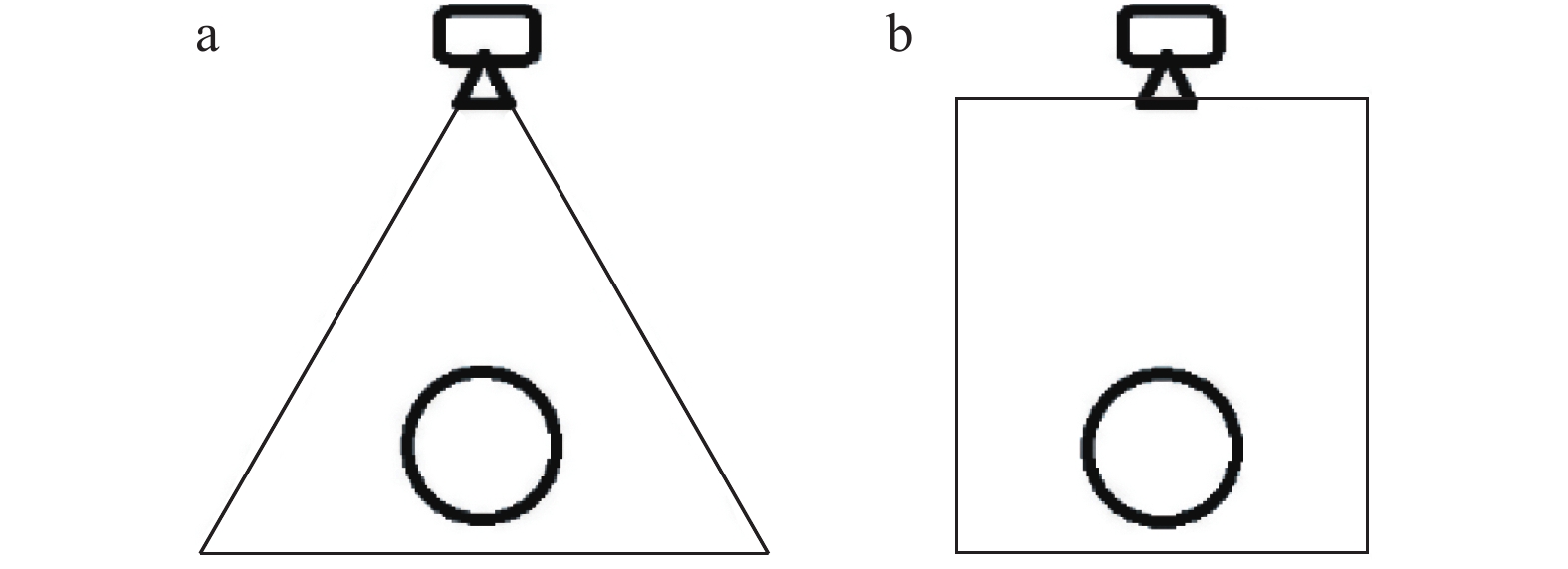

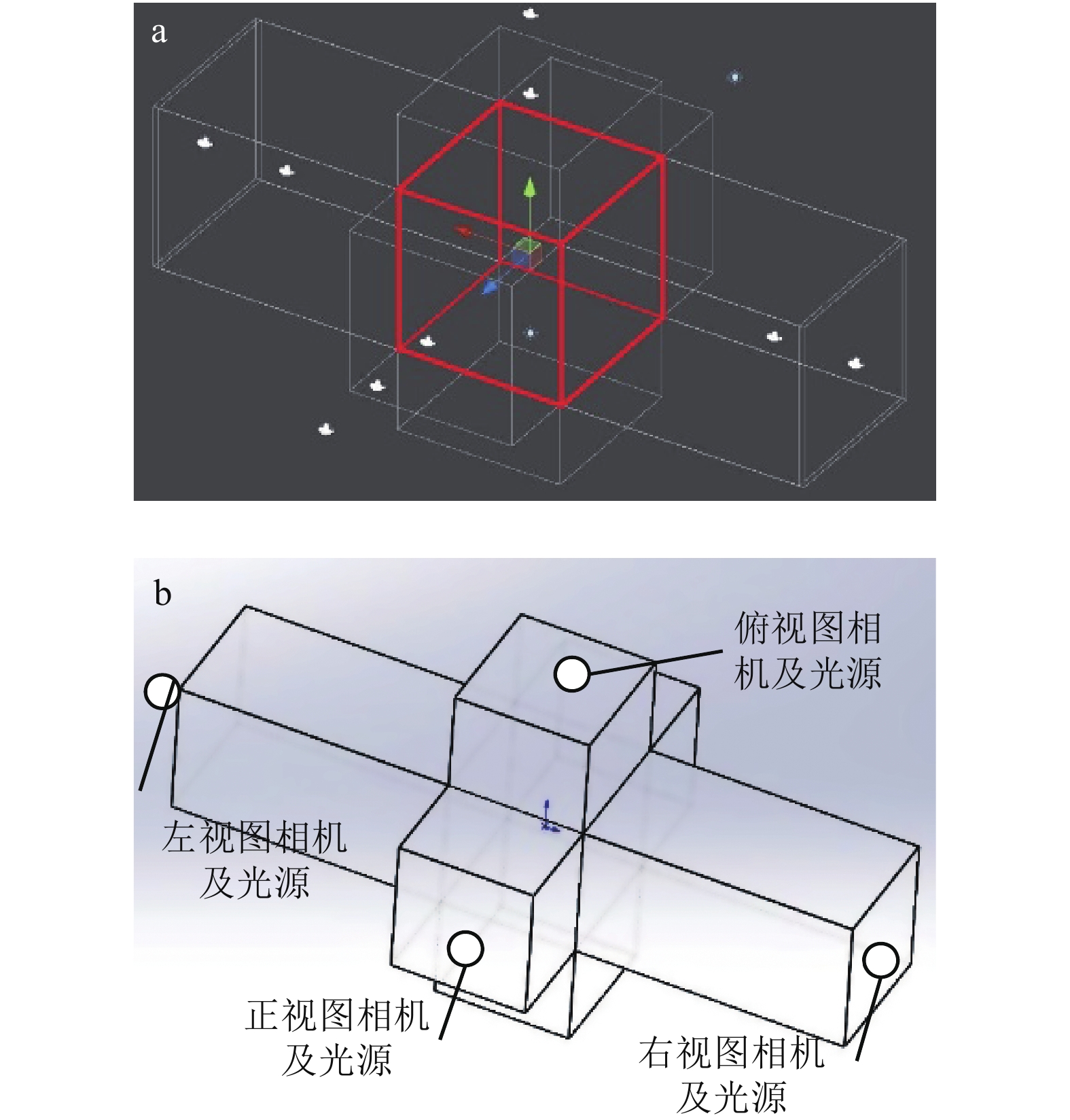

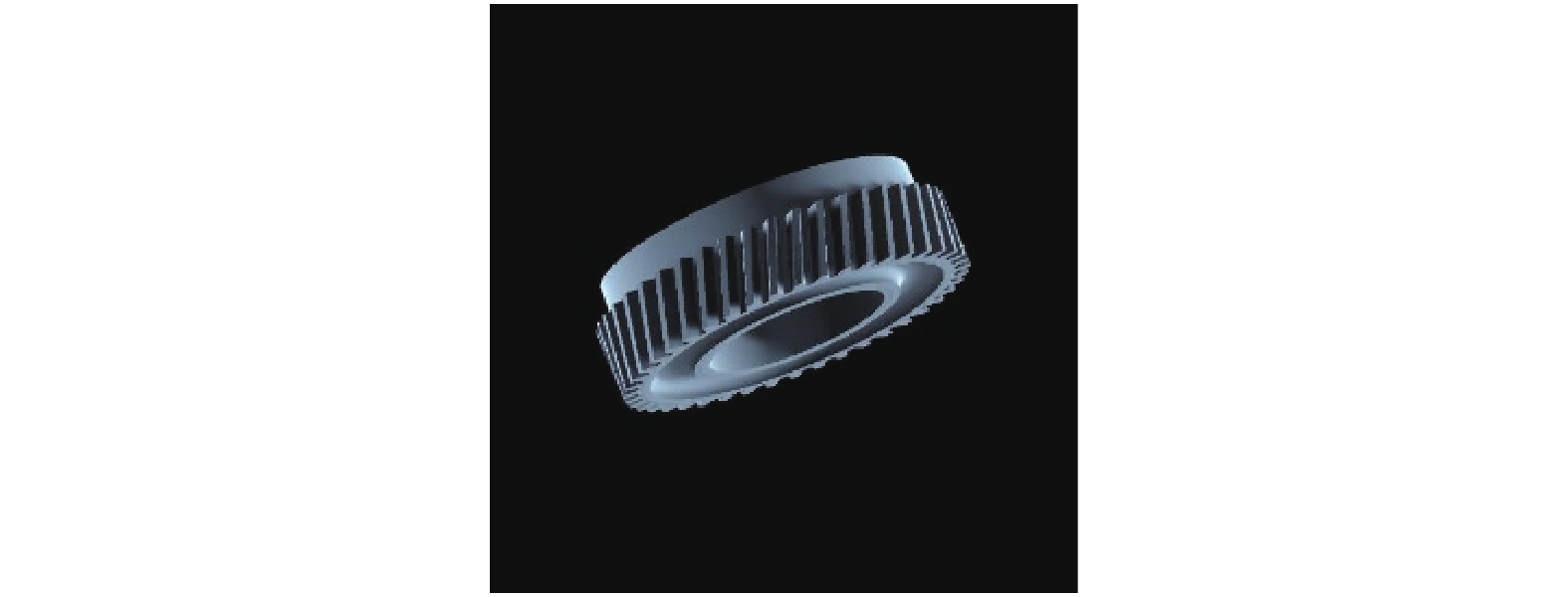

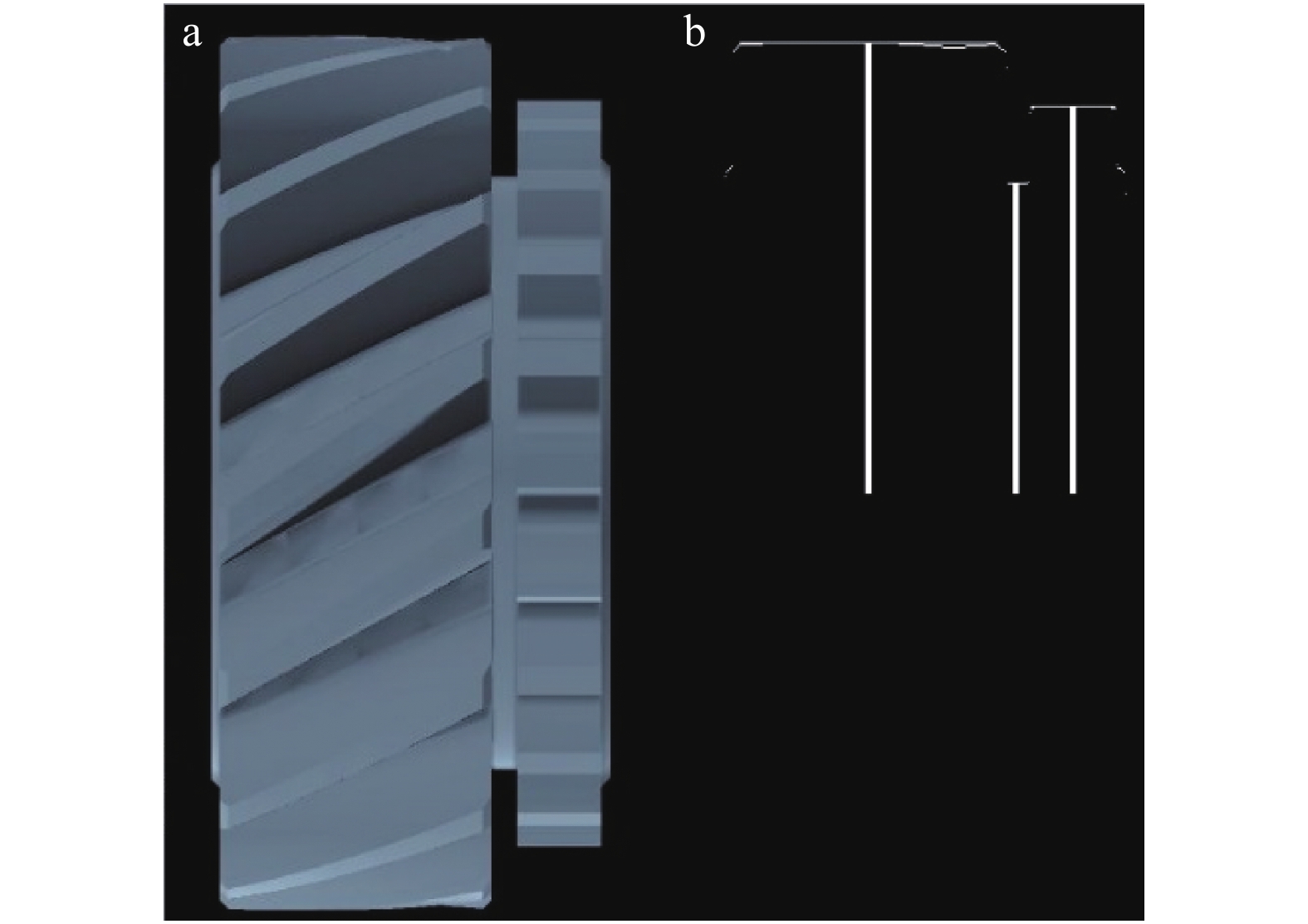

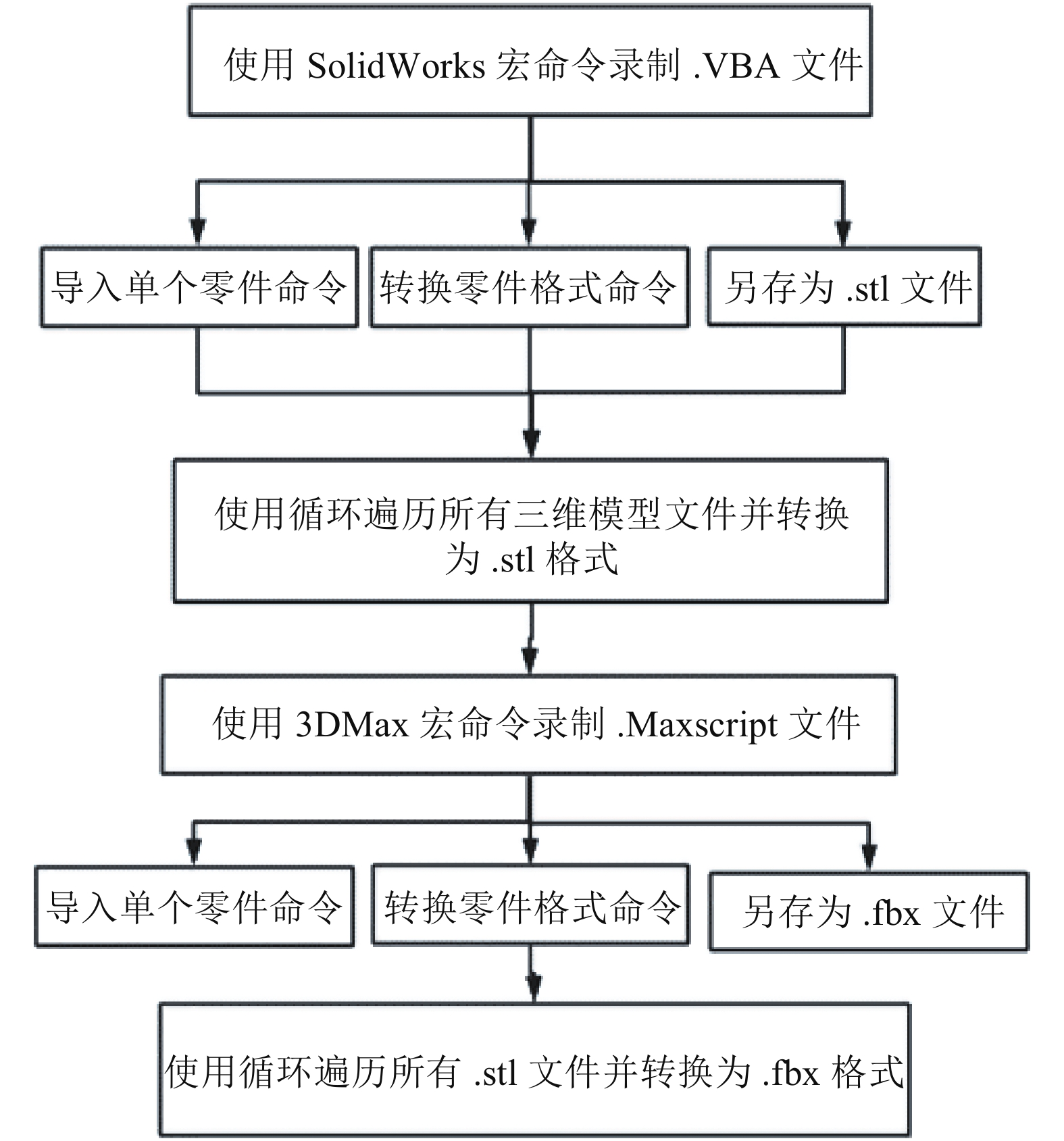

方法以批量农机部件为样本对象,设计批量预处理算法及改进采样相关算法,通过构建三维模型样本的图片数据集,训练人工智能分类检测网络,从图片中分类并检测相关参数,实现自动构建碰撞体功能。

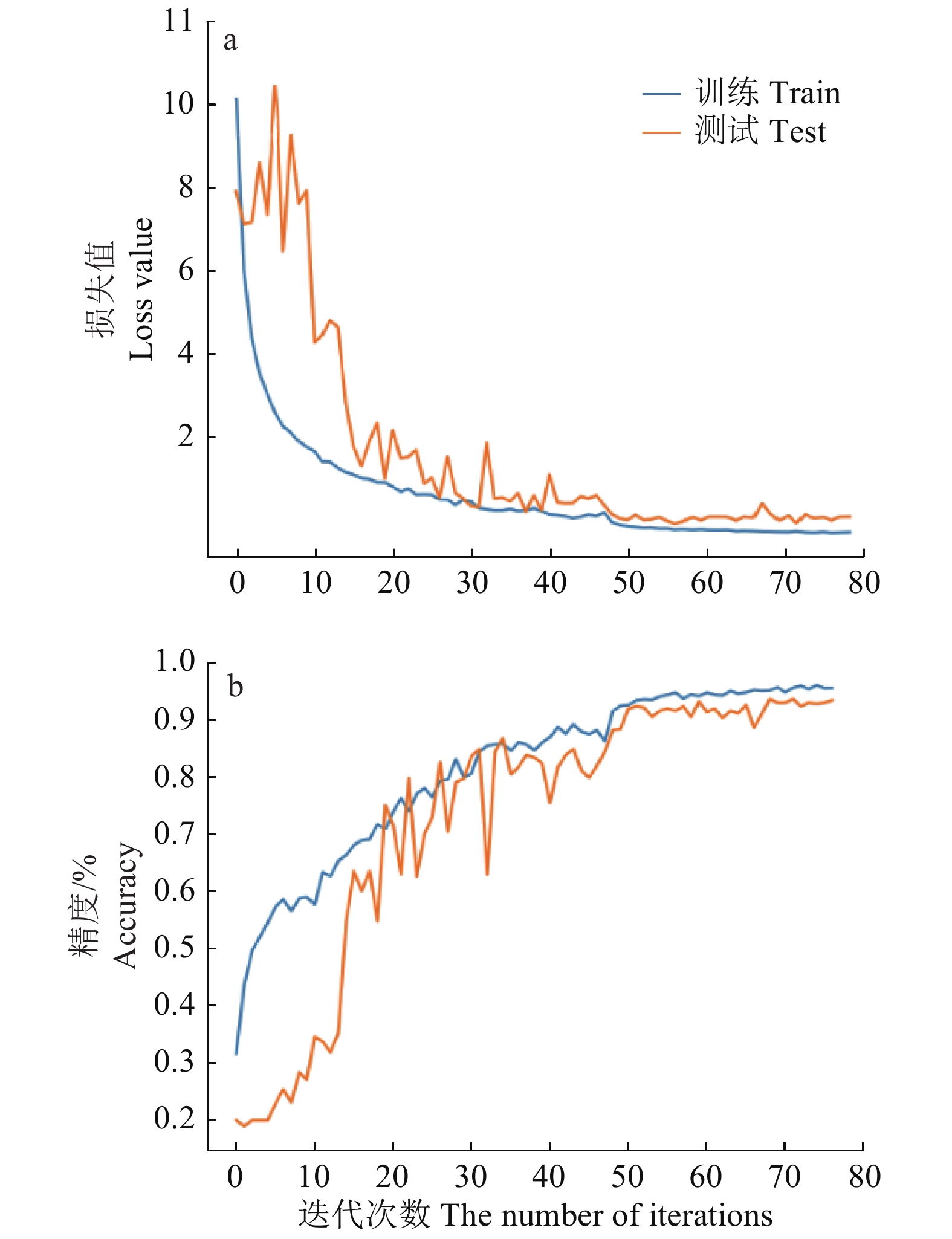

结果经过优化算法处理训练得到的分类检测网络从图片分类零件种类的精度在98%以上,从图片检测零件各项碰撞体构建参数的精度在98%以上;未经优化处理训练的网络不收敛。

结论本研究方法可以有效提升人工智能分类检测网络的识别精度及训练效率,结合碰撞体参数化构建程序,可提升碰撞体建模精度。

Abstract:ObjectiveVirtual assembly can save production cost and improve the production efficiency of mechanical parts in industry. Due to the lack of the function of automatically creating collision body, the existing virtual reality engine can not completely restore the physical properties in the actual assembly process. Universaly building mechanical part grid entity is the important approach for improving practicability, accuracy and universality of virtual assembly.

MethodThe batch preprocessing algorithm and the improved sampling algorithm were designed for the batch agricultural machinery parts sampling. The image data set of three-dimensional model sample was constructed to train the artificial intelligence classification detection network, which can classify and detect the relevant parameters from the image samples, and realize the function of automatic construction of collision body.

ResultThe accuracy of the classification network trained by the optimized algorithm was more than 98% for the classification of parts from pictures, and more than 98% for the construction parameters of collision bodies from pictures. However, the network without optimized training did not converge.

ConclusionThis method can effectively improve the recognition accuracy and training efficiency of the artificial intelligence classification detection network, and improve the modeling accuracy of the collision body by combining with the collision body parameterization construction program.

-

Keywords:

- virtual assembly /

- artificial intelligence /

- collision body /

- batching /

- data set

-

-

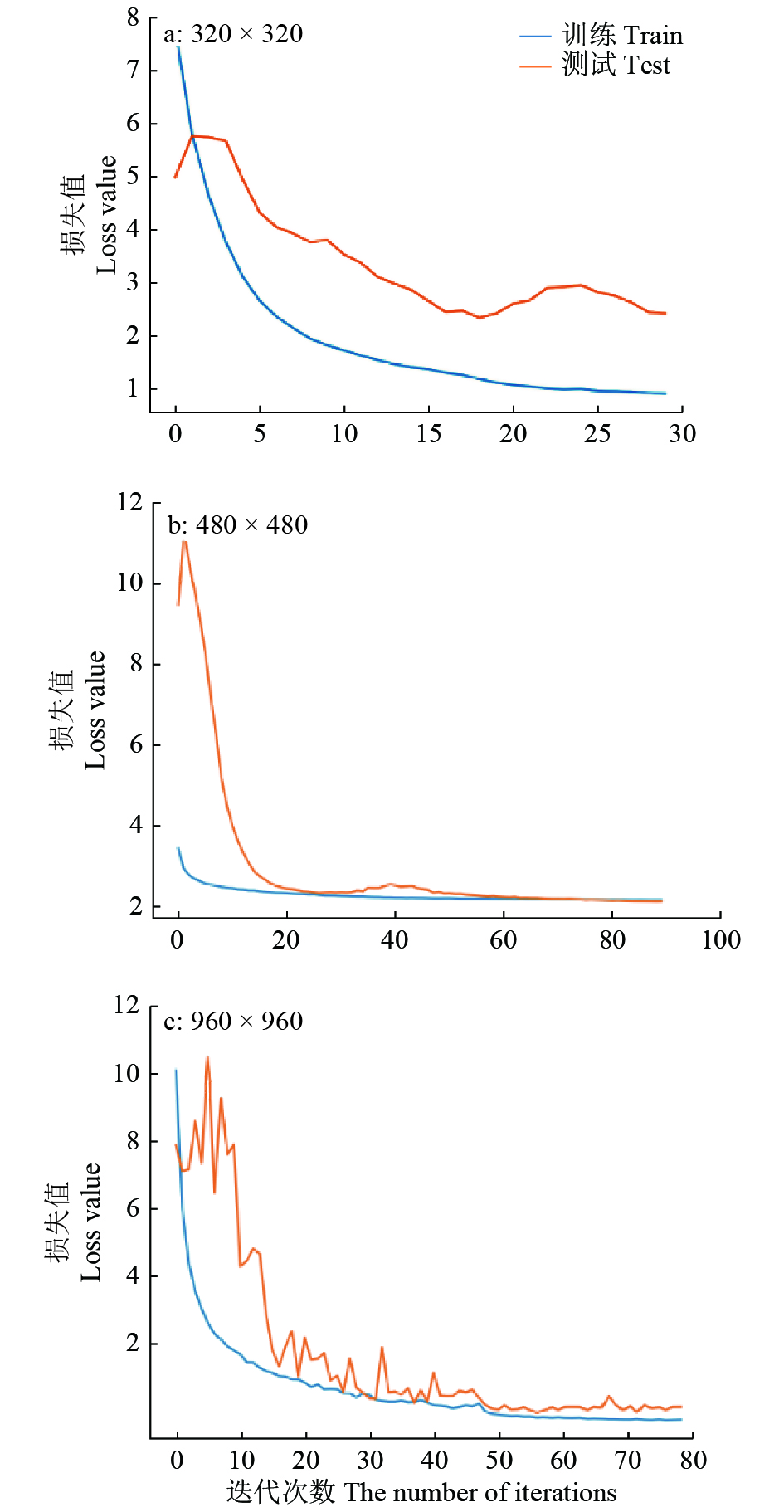

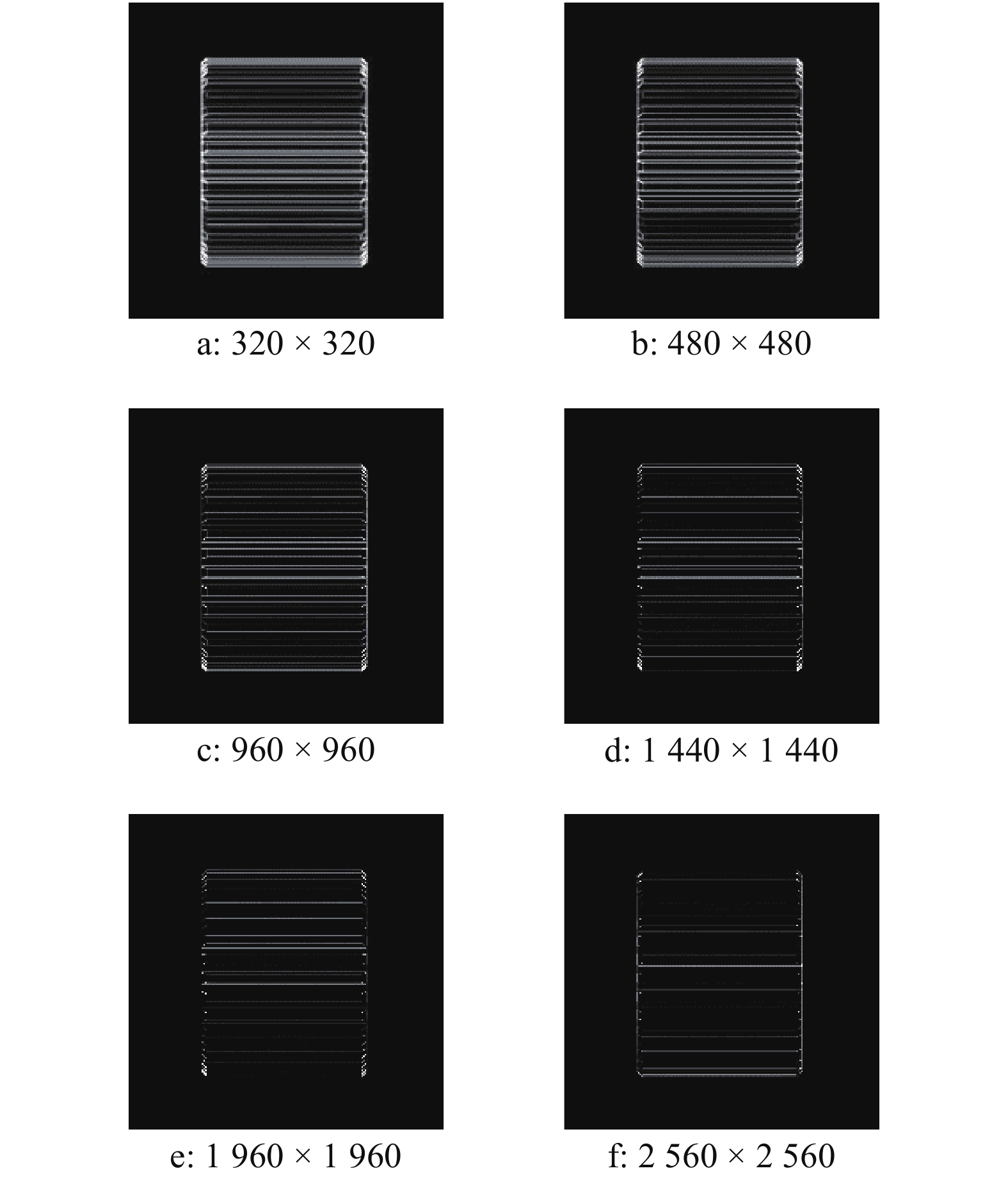

表 1 不同分辨率的训练数据

Table 1 Training data with different resolutions

分辨率

Resolution迭代次数

The number of iterations损失值

Loss value320 × 320 28 2.87 480 × 480 86 2.05 960 × 960 77 0.33 1 440 × 1 440 显存不足

Insufficient memory无

None1 960 × 1 960 显存不足

Insufficient memory无

None2 560 × 2 560 显存不足

Insufficient memory无

None表 2 部分检测数据

Table 2 Part of the test data

处理1)

Treatment检测精度/%

Accuracy损失值

Loss

value迭代次数

The number

of iterations结果

ResultBCD 62.92 0.91 22 不收敛

MisconvergenceACD 60.98 0.90 17 不收敛

MisconvergenceABD 91.87 0.30 56 收敛

ConvergenceABC 88.13 0.39 49 收敛

ConvergenceABCD 98.54 0.33 77 收敛

Convergence空白对照

Blank control23.13 2.25 8 不收敛

Misconvergence1) A:坐标转换,B:尺寸归一化,C:采样空间优化,D:随机采样

1) A: Coordinate transformation, B: Size normalization, C: Sampling space optimization, D: Random sampling表 3 部分三维模型检测数据

Table 3 Partial inspection data of 3D model

样本名称

Sample

name实际齿顶圆

半径/mm

Actural

outside radius检测齿顶圆

半径/mm

Detected

outside radius相对误差/%

Relative

errorgear_ (27) 32.00 31.58 1.3 gear_ (28) 136.00 133.42 1.9 gear_ (29) 56.00 55.27 1.3 gear_ (30) 72.00 70.99 1.4 gear_ (31) 72.00 71.01 1.4 gear_ (32) 36.00 35.53 1.3 -

[1] 邹湘军, 孙健, 何汉武, 等. 虚拟现实技术的演变发展与展望[J]. 系统仿真学报, 2004(9): 1905-1909. doi: 10.3969/j.issn.1004-731X.2004.09.015 [2] 陈燕, 曾泽钦, 王杰, 等. 收获机虚拟环境模型与仿真平台构建[J]. 农业机械学报, 2019, 50(7): 159-166. doi: 10.6041/j.issn.1000-1298.2019.07.016 [3] 邹湘军, 孙健, 何汉武. 虚拟环境下的生产线三维动态仿真及其建模[J]. 组合机床与自动化加工技术, 2004(4): 29-31. doi: 10.3969/j.issn.1001-2265.2004.04.012 [4] SHAO N, DING X, LIU J. Tolerance analysis of spur gears based on skin model shapes and a boundary element method[J]. Mechanism and Machine Theory, 2020, 144: 103658. doi: 10.1016/j.mechmachtheory.2019.103658.

[5] 朱忠祥, 陈莉, 李山山, 等. 基于虚拟现实的联合收获机底盘虚拟装配关键技术[J]. 农业机械学报, 2013, 44(S2): 262-267. [6] 林木, 张永春, 单丽君. 基于强化学习和虚拟现实技术的机械仿真教学系统研究[J]. 中国设备工程, 2020(22): 228-229. doi: 10.3969/j.issn.1671-0711.2020.22.132 [7] 刘伟良, 王红军, 邹湘军, 等. 基于知识的变速箱齿轮虚拟设计研究[J]. 华南农业大学学报, 2020, 41(4): 120-126. doi: 10.7671/j.issn.1001-411X.201912024 [8] 万华明, 杨丽, 邹湘军, 等. 基于VR技术的几何建模与优化[J]. 苏州科技学院学报(自然科学版), 2009, 26(4): 20-24. [9] 李承恩, 邹湘军, 曾泽钦, 等. 基于虚拟碰撞体的弧齿锥齿轮网格实体构建算法[J]. 系统仿真学报, 2021, 33(4): 837-844. [10] LUO L, TANG Y, ZOU X, et al. Vision-based extraction of spatial information in grape clusters for harvesting robots[J]. Biosystems Engineering, 2016, 151: 90-104. doi: 10.1016/j.biosystemseng.2016.08.026

[11] TANG Y, CHEN M, WANG C, et al. Recognition and localization methods for vision-based fruit picking robots: A review[J]. Frontiers in Plant Science, 2020, 11: 510. doi: 10.3389/fpls.2020.00510.

[12] TANG Y, LI L, WANG C, et al. Real-time detection of surface deformation and strain in recycled aggregate concrete-filled steel tubular columns via four-ocular vision[J]. Robotics and Computer-Integrated Manufacturing, 2019, 59: 36-46. doi: 10.1016/j.rcim.2019.03.001

[13] ZHUANG C, MIAO T, LIU J, et al. The connotation of digital twin, and the construction and application method of shop-floor digital twin[J]. Robotics and Computer-Integrated Manufacturing, 2021, 68: 102075. doi: 10.1016/j.rcim.2020.102075.

[14] 陈燕, 王佳盛, 曾泽钦, 等. 大视场下荔枝采摘机器人的视觉预定位方法[J]. 农业工程学报, 2019, 35(23): 48-54. doi: 10.11975/j.issn.1002-6819.2019.23.006 [15] 邹湘军, 孙健, 何汉武, 等. 虚拟环境中多Agent决策的冲突证据合成研究[J]. 系统仿真学报, 2006(4): 1010-1014. doi: 10.3969/j.issn.1004-731X.2006.04.050 [16] 吴烽云, 张坡, 邹湘军, 等. 基于复杂部件虚拟装配的智能决策行为[J]. 自动化与信息工程, 2019, 40(5): 1-5. doi: 10.3969/j.issn.1674-2605.2019.05.001 [17] ZOU X, HE H, WU Y, et al. Automatic 3D point cloud registration algorithm based on triangle similarity ratio consistency[J]. IET Image Processing, 2020, 14(14): 3314-3323.

[18] 高伟, 王昱霖, 宋笑迎, 等. 基于虚拟现实技术下深度学习环境的构建研究[J]. 软件, 2019, 40(5): 42-46. doi: 10.3969/j.issn.1003-6970.2019.05.009 [19] 梁锋, 钟建强, 罗培锋, 等. CATIA VBA二次开发在装配中批量搜索零件的应用[J]. 汽车实用技术, 2021, 46(1): 32-35. [20] 齐江飞, 戈北京, 范颖超, 等. Inventor图纸编号和名称批量自动更改方法研究与应用[J]. 科技创新与应用, 2020(4): 167-169. [21] 赵仁兵, 刘金科. 基于Unigraphics NX二次开发功能的批量后置软件[J]. 机械制造, 2020, 58(11): 53-58. doi: 10.3969/j.issn.1000-4998.2020.11.016 [22] 郭鹏, 张新艳, 余建波. 基于深度强化学习与有限元仿真集成的拉深成形控制[J]. 机械工程学报, 2020, 56(20): 47-58. [23] 康文利, 周学辉. 虚拟装配快速碰撞干涉检验算法的研究[J]. 机械工程与自动化, 2010(4): 53-55. doi: 10.3969/j.issn.1672-6413.2010.04.019 [24] 张炫, 杨艳. 基于改进随机霍夫变换的直线提取算法[J]. 信息技术, 2017(12): 6-9. [25] 张天煜, 冯华君, 徐之海, 等. 基于强边缘宽度直方图的图像清晰度指标[J]. 浙江大学学报(工学版), 2014, 48(2): 312-320.

下载:

下载: