Parameter optimization of automatic grading and monomeric delivery device of litchi

-

摘要:目的

开发荔枝自动分级设备。

方法设计自动单体排序输送装置,对其进行排序输送试验,分析装置不同的工作和结构参数对荔枝卡果次数和空穴率的影响,同时,建立回归及组合模型,并对各影响因素进行综合优化。

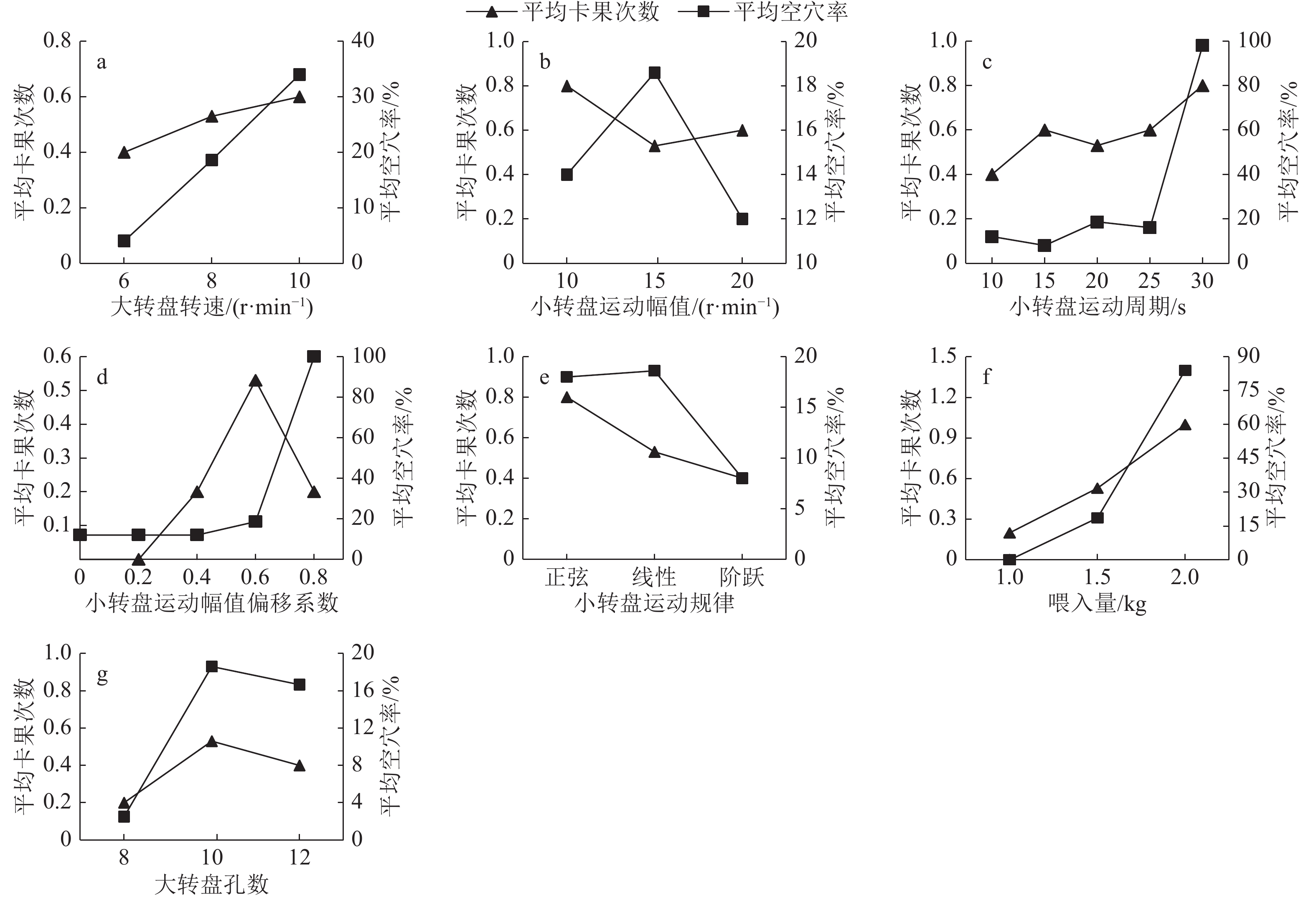

结果荔枝卡果次数和空穴率都随着大转盘转速、小转盘运动周期和喂入量的增大而增多,荔枝卡果次数和空穴率都随大转盘孔数的增多先增多后减少,空穴率随着小转盘运动幅值偏移系数的增大而增大;影响荔枝卡果次数和空穴率的最主要因素是喂入量,其次是大转盘转速和小转盘运动幅值偏移系数。回归组合模型求解得到的最优参数组合优于基于正交试验水平值的综合平衡最优参数组合和独立回归模型得到的最优参数组合;输送装置最优参数组合为大转盘转速7.35 r·min–1、小转盘运动幅值为14.30 r·min–1、小转盘运动周期16.93 s、小转盘运动幅值偏移系数0.33、小转盘运动规律以线性变化、喂入量1.31 kg、大转盘孔数10个,此时,荔枝卡果0次、空穴率为6%。

结论研究可为荔枝自动分级单体排序装置的设计提供参考。

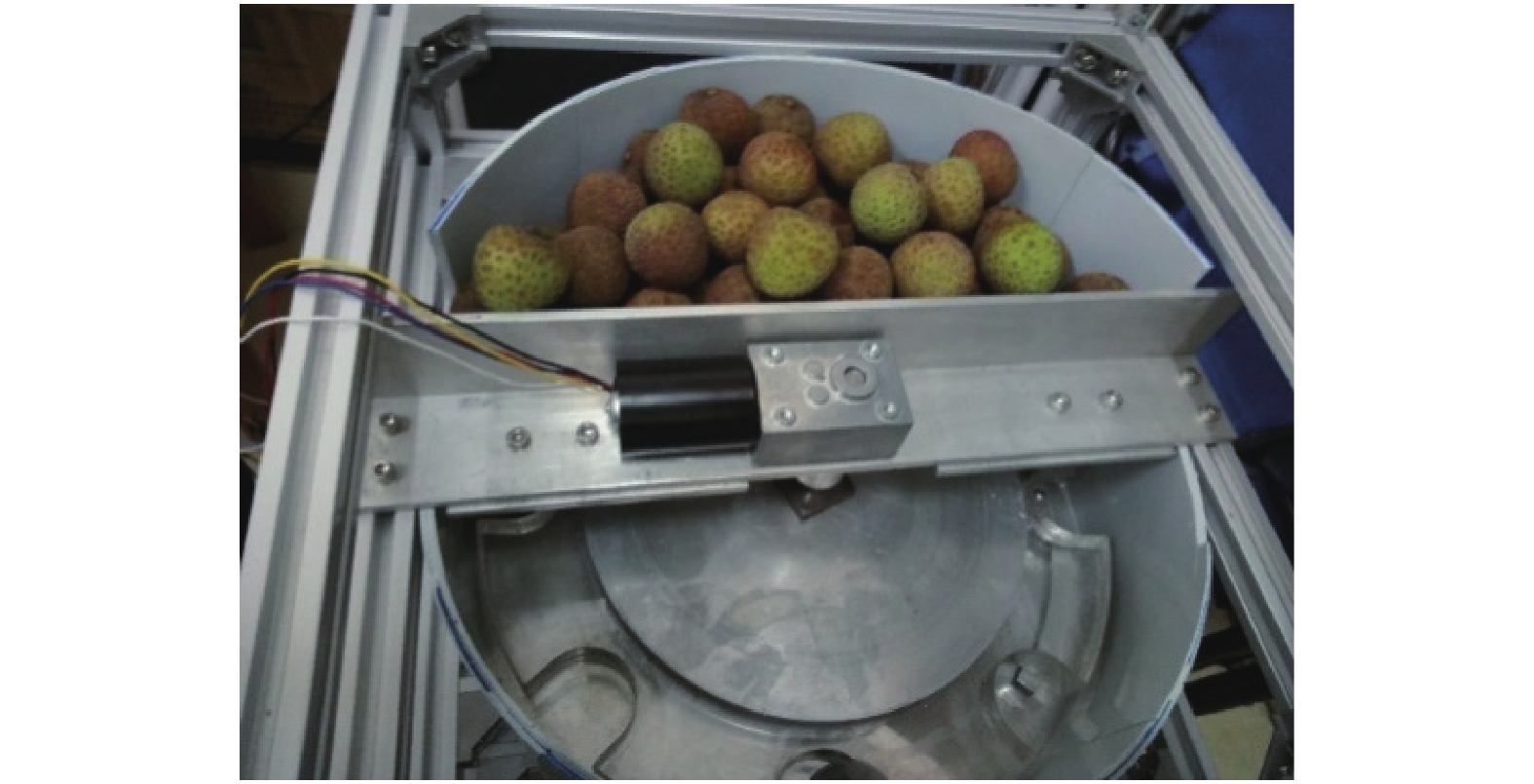

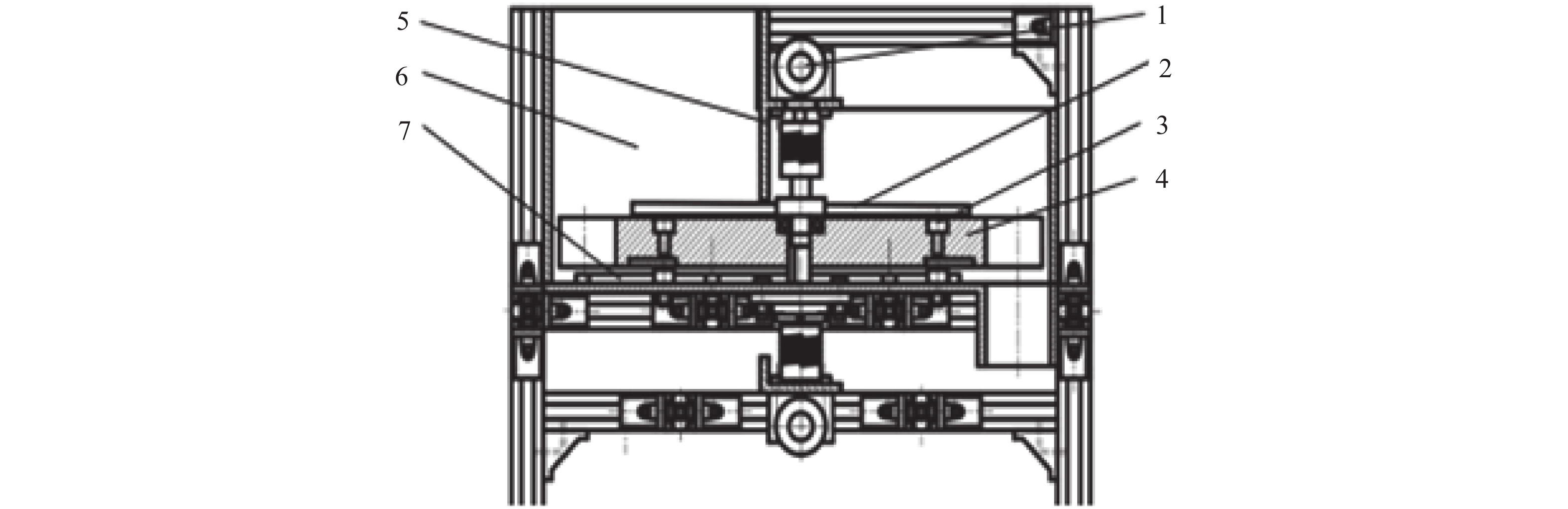

Abstract:ObjectiveTo develop an automatic grading machine of litchi.

MethodAn automatic monomeric delivery device was designed and a delivery experiment was performed. The influences of different working and structural parameters on the stuck frequency and cavity rate of litchi were analyzed. Regression and combined models were established. Influencing factors were optimized comprehensively.

ResultBoth stuck frequency and cavity rate increased with the rotation speed of big turnable, the cycle length of small turnable and the feeding volume increasing. Both stuck frequency and cavity rate increased firstly and then decreased with the number of holes of big turnable increasing. The cavity rate also increased with the offset coefficient of amplitude of small turnable increasing. The major factor influencing the stuck frequency and cavity rate was the feeding volume, followed by the rotation speed of big turnable, then the offset coefficient of amplitude of small turnable. The optimial parameter combination from the combined regression model was better than those from the orthogonal experiment and the independent regression model. The optimial parameters of the delivery device were as follows: the rotation speed of big turnable was 7.35 r·min–1, the rotation amplitude of small turnable was 14.30 r·min–1, the cycle length of small turnable was 16.93 s, the offset coefficient of amplitude of small turnable was 0.33, the rotation motion of small turnable changed linearly, the feeding volume was 1.31 kg and the number of holes of big turnable was 10. Based on this combination, the stuck frequency was 0 and the cavity rate was 6%.

ConclusionThe results can provide references for the designation of automatic grading and monomeric delivery device of litchi.

-

Keywords:

- litchi /

- automatic grading /

- monomeric delivery device /

- parameter optimization /

- stuck frequency /

- cavity rate

-

-

表 1 单因素试验的因素与水平

Table 1 Factors and levels of single factor test

水平 因素 大转盘转速

(A)/(r·min–1)小转盘运动幅值

(B)/(r·min–1)小转盘运动

周期(C)/s小转盘运动幅值

偏移系数(D)小转盘运动

规律(E)喂入量

(F)/kg大转盘

孔数(G)1 6 10 10 0 正弦 1.00 8 2 8 15 15 0.20 线性 1.50 10 3 10 20 20 0.40 阶跃 2.00 12 4 25 0.60 5 30 0.80 表 2 正交试验的因素与水平

Table 2 Factors and levels of orthogonal test

水平 因素 大转盘转速

(A)/(r·min–1)小转盘运动幅值

(B)/(r·min–1)小转盘运动

周期(C)/s小转盘运动幅值

偏移系数(D)小转盘运动

规律(E)喂入量

(F)/kg大转盘

孔数(G)1 6 10 10 0 正弦 1.00 8 2 8 15 20 0.4 线性 1.50 10 3 10 20 25 0.8 阶跃 2.00 12 表 3 正交试验结果及极差分析

Table 3 Orthogonal test results and range analysis

序号 因素1) 卡果

次数空穴率/

%A B C D E F G 1 1 1 1 1 1 1 1 0 8.38 2 1 2 3 3 1 2 1 0.33 2.88 3 3 2 1 2 3 1 3 0.67 2.75 4 3 1 2 3 3 3 3 1.33 44.42 5 1 1 2 1 3 2 2 0 13.30 6 2 1 2 2 3 1 1 0.33 0 7 2 2 3 1 1 1 3 0 8.33 8 2 3 1 3 2 1 2 0 20.00 9 2 2 1 1 3 2 1 0.67 25.00 10 1 3 1 2 2 2 3 0 8.33 11 1 2 2 3 2 1 3 0.33 5.58 12 1 1 3 1 2 3 3 1.00 33.33 13 3 1 1 3 1 2 2 0.50 25.00 14 2 3 3 3 3 3 1 1.67 100.00 15 2 1 1 2 1 3 3 1.33 19.42 16 1 3 2 2 1 3 1 0.67 16.63 17 3 2 2 2 2 2 1 0.67 20.88 18 2 1 3 2 2 2 2 0.33 13.30 19 1 3 3 2 3 1 2 0 6.70 20 3 3 1 1 2 3 1 1.00 16.63 21 3 3 2 1 1 1 2 0.67 13.30 22 2 2 2 1 2 3 2 0.33 16.70 23 3 2 3 2 1 3 2 2.33 43.30 24 3 3 3 1 3 2 3 0.33 13.92 25 2 3 2 3 1 2 3 0.33 38.92 26 1 2 1 3 3 3 2 0.67 23.30 27 3 1 3 3 2 1 1 0.33 4.13 卡果次数 K1 1.00 1.72 1.61 1.33 2.05 0.78 1.89 K2 1.66 2.00 1.55 2.11 1.33 1.05 1.61 K3 2.61 1.53 2.10 1.83 1.89 3.44 1.77 极差(R) 1.61 0.44 0.55 0.78 0.72 2.67 0.28 空穴率/% K1 39.48 53.76 49.60 49.63 58.71 23.06 64.83 K2 80.56 49.57 56.57 43.77 46.29 53.84 58.30 K3 61.44 78.14 75.29 88.07 76.46 104.57 58.33 极差(R) 41.08 28.57 25.69 44.31 30.17 81.52 6.53 1)A:大转盘转速;B:小转盘运动幅值;C:小转盘运动周期;D:小转盘运动幅值偏移系数;E:小转盘运动规律;F:喂入量;G:大转盘孔数 表 4 虚拟变量的设置与赋值

Table 4 Setting and assigning of virtual variables

小转盘运动规律(E) 虚拟变量赋值 x5a x5b 正弦 0 1 线性 1 0 阶跃 0 0 表 5 参数优化试验结果

Table 5 Experimental results of parameter optimization

最优参数组合 卡果次数 空穴率% 正交最优 0.3 9 η最优 0 10 r最优 0.2 10 y最优 0 6 -

[1] 张灵光. 农产品质量分级标准是增强市场竞争力的基础[J]. 中国标准化, 2007(10): 59-62. [2] 孙宝霞, 汤林越, 何志良, 等. 基于机器视觉的采后荔枝表皮微损伤实时检测[J]. 农业机械学报, 2016, 47(7): 35-41. [3] 梁健, 梁材. 荔枝保鲜分级处理工艺及设备[J]. 现代农业装备, 2008(7): 61-63. [4] 蒙必胜, 梁兆新, 朱其崇. 链板式间距可调果类分选机的原理及设计[J]. 农产品加工, 2004(8): 35-37. [5] 李嘉威, 陈燕, 王佳盛, 等. 荔枝自动分级机的设计研究[J]. 农产品加工, 2017(12): 29-30. [6] 王松磊, 刘民法, 何建国, 等. 红枣自动快速无损检测分级机研究[J]. 农业机械学报, 2014, 45(9): 79-83. [7] 刘启全. 基于线阵相机的哈密瓜分级机改进设计与试验研究[D]. 乌鲁木齐: 新疆农业大学, 2016. [8] 杜宏伟, 邓立苗, 熊凯, 等. 基于计算机视觉的胡萝卜外观品质分级系统与装备[J]. 农机化研究, 2015, 37(1): 196-200. [9] VAN DER SCHOOT J. Orienting mechanism for orienting fruit, for example: US5078258A[P]. 1992-01-07.

[10] UKADA M. Automatic slope fruit feeding machine used with a fruit grading machine: US5613595A[P]. 1995-04-19.

[11] FONT R O. Fruit feeder for squeezer machines: US5957043[P]. 1982-09-27.

[12] SOPER J L, FREE D R. Screw feeder for proportioning machine: WO1999023019A1[P]. 1999-05-14.

[13] 刘向东, 王学农, 王春耀, 等. 鲜杏单体排序间隔输送装置的设计与试验[J]. 农业工程学报, 2016, 32(12): 31-38. [14] 左兴健, 武广伟. 猕猴桃自动分级设备设计与试验[J]. 农业机械学报, 2014, 45(S1): 287-295. [15] 赵广华, 李鹏飞, 陆奎荣, 等. 智能化苹果品质实时分选系统[J]. 中国科技信息, 2010(19): 123-124.

下载:

下载: