Calibration of discrete element model parameters for maize kernel based on response surface methodology

-

摘要:目的

离散元法普遍用于模拟农业物料在农业生产过程中的运动状态。离散元模拟的准确度取决于所使用的离散元参数,对颗粒离散元参数进行标定,为其在仿真试验中的应用提供可靠基础。

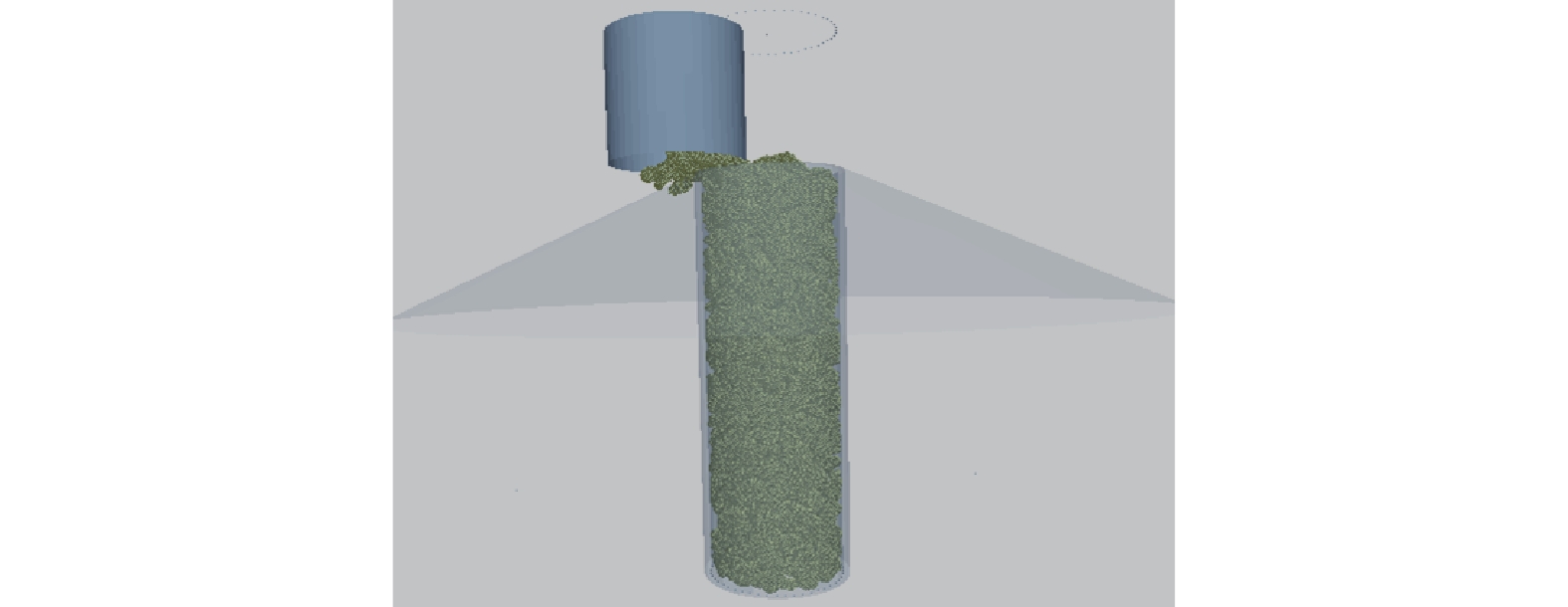

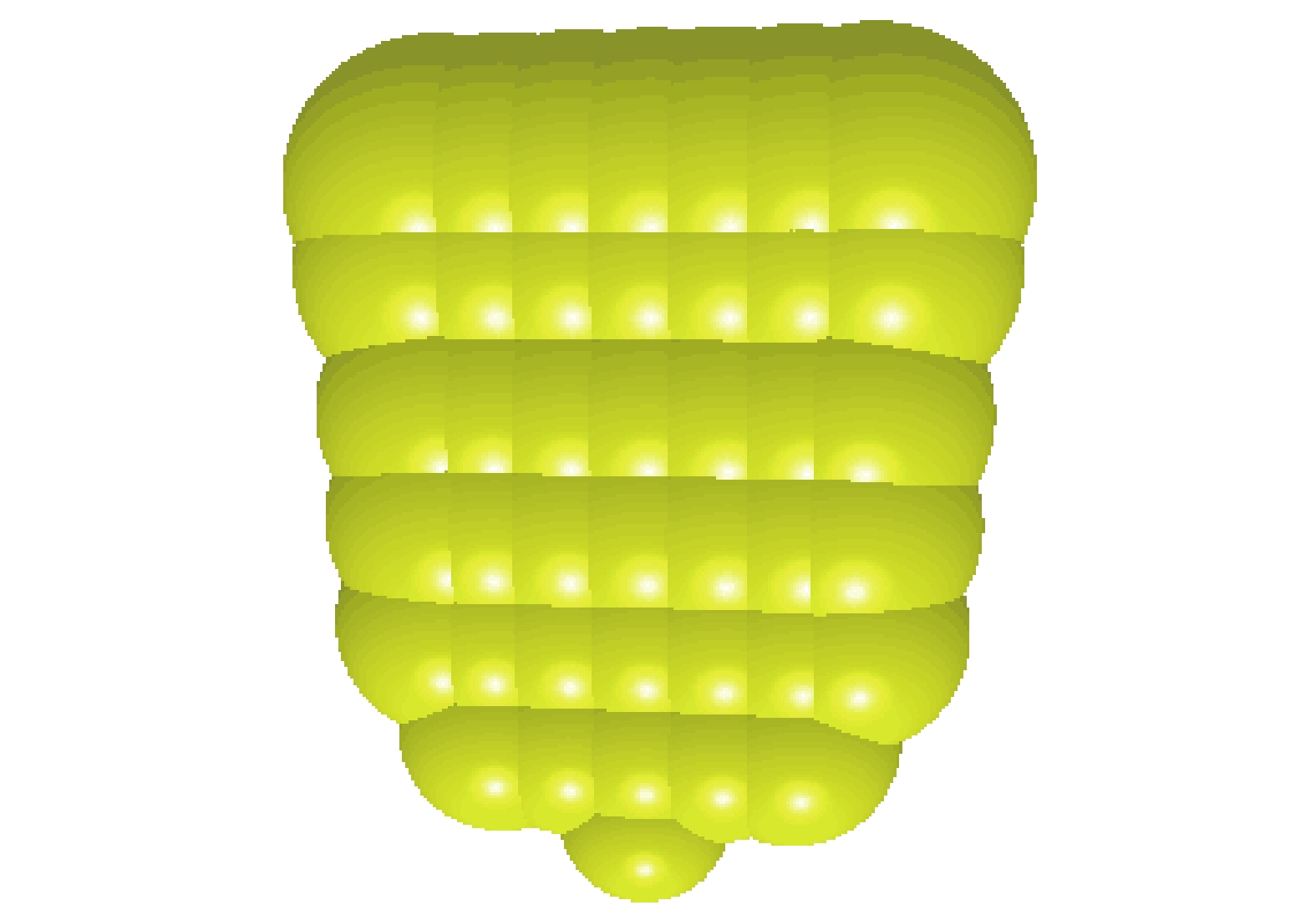

方法以玉米籽粒为研究对象,以堆积角为响应值,将采用不同参数组合的仿真试验结果与实体试验结果对比,提出一种基于响应面法的离散元参数标定方法。采用Plackett-Burman试验对玉米籽粒离散元参数进行显著性检验,筛选对响应值影响显著的因素;根据最陡爬坡试验确定显著性因素的最佳水平范围;采用中心组合设计进行3因素5水平响应面优化试验。

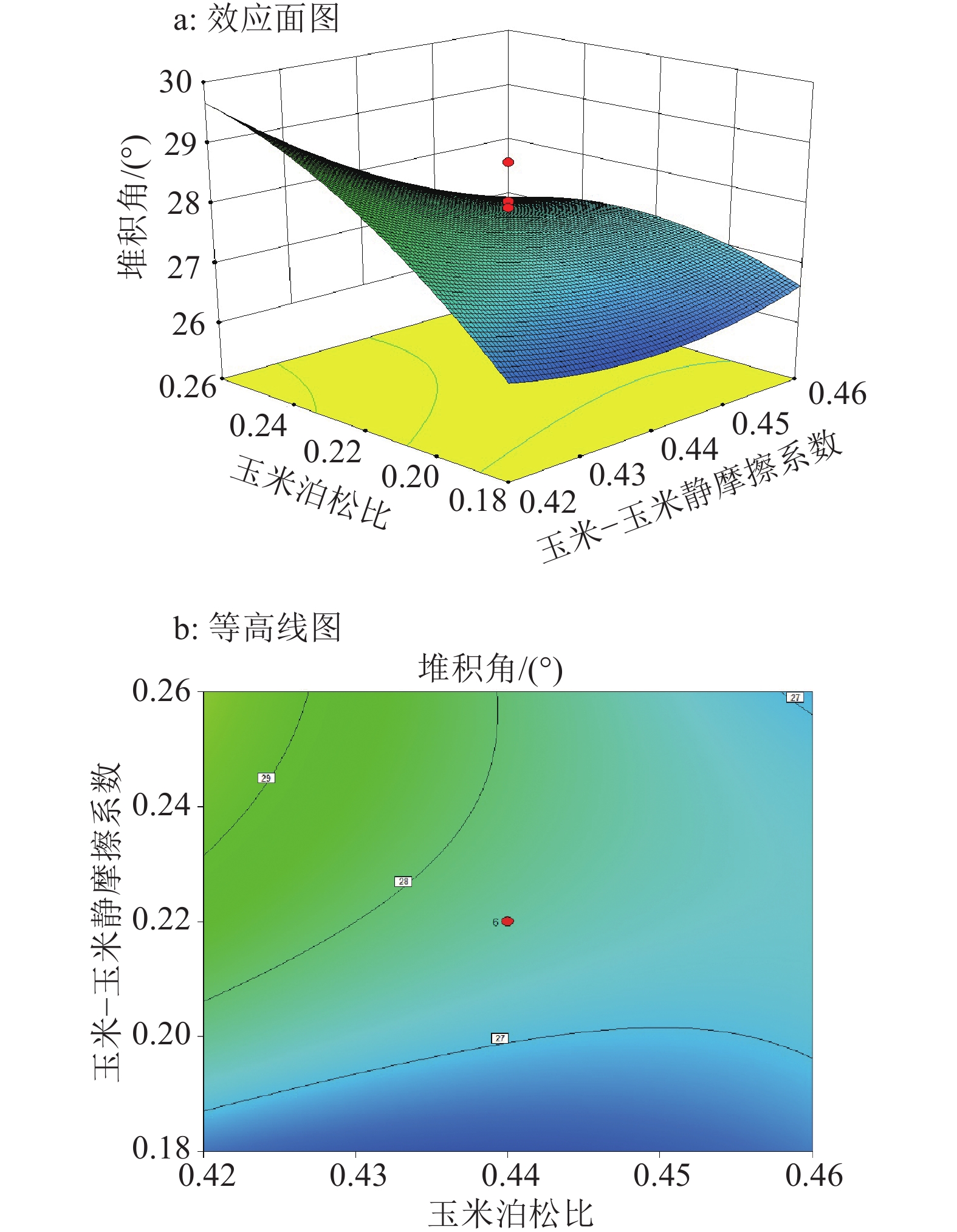

结果玉米泊松比与玉米–玉米静摩擦系数交互作用显著,得到玉米籽粒离散元参数最佳组合为玉米泊松比0.438、玉米–玉米静摩擦系数0.182、玉米–玉米滚动摩擦系数0.051。采用标定好的参数进行仿真试验得到堆积角平均值为26.89°,接近实体试验的堆积角值。

结论基于响应面法的玉米籽粒离散元参数标定方法是可行的,可以提高玉米籽粒离散元仿真试验的准确性。

Abstract:ObjectiveThe discrete element method (DEM) is commonly used in simulating the motion states of agricultural materials in agricultural production process. The accuracy of discrete element simulation depends on the parameters used in simulation process. In this study, we calibrated DEM parameters to provide a reliable basis for the application of DEM in simulation experiment.

MethodUsing maize kernel as object and repose angle as response value, the discrete element calibration method based on response surface methodology was proposed after the comparison of simulation experiment results adopting different parameter combinations with prototype experiment results. Plackett-Burman experiment was performed to test the significance of discrete element parameters and screen the parameters that significantly influenced response value. Then the steepest ascent experiment was used to ascertain the optimum value ranges of significant parameters. Finally, central composite designs were used to design response surface modifying experiments consisting of three factors and five levels.

ResultCorn Poisson's ratio and corn-corn static friction coefficient interacted significantly with each other. The best parameter combination was corn Poisson's ratio 0.438, corn-corn static friction coefficient 0.182 and corn-corn static rolling coefficient 0.051. The simulation experiments were conducted using calibrated parameters above and the mean value of repose angle was 26.89°, approximately to the value in prototype experiment.

ConclusionThe discrete element parameter calibration method for maize kernel based on response surface methodology is feasible, and can improve the accuracy of maize kernel discrete element simulation test.

-

-

表 1 仿真参数设置

Table 1 The setting of simulation parameters

参数 数值 玉米泊松比 0.399~0.423 玉米弹性模量/MPa 138.3~409.5 玉米密度/(kg·m–3) 1 197 不锈钢泊松比 0.28 不锈钢弹性模量/MPa 75 000 不锈钢密度/(kg·m–3) 8 000 玉米–玉米恢复系数 0.182~0.284 玉米–不锈钢恢复系数 0.615~0.729 玉米–玉米静摩擦系数 0.231~0.342 玉米–不锈钢静摩擦系数 0.267~0.401 玉米–玉米滚动摩擦系数 0.054 5~0.078 2 玉米–不锈钢滚动摩擦系数 0.031 7~0.093 1 表 2 Plackett-Burman试验因素与水平1)

Table 2 Plackett-Burman experimental factors and levels

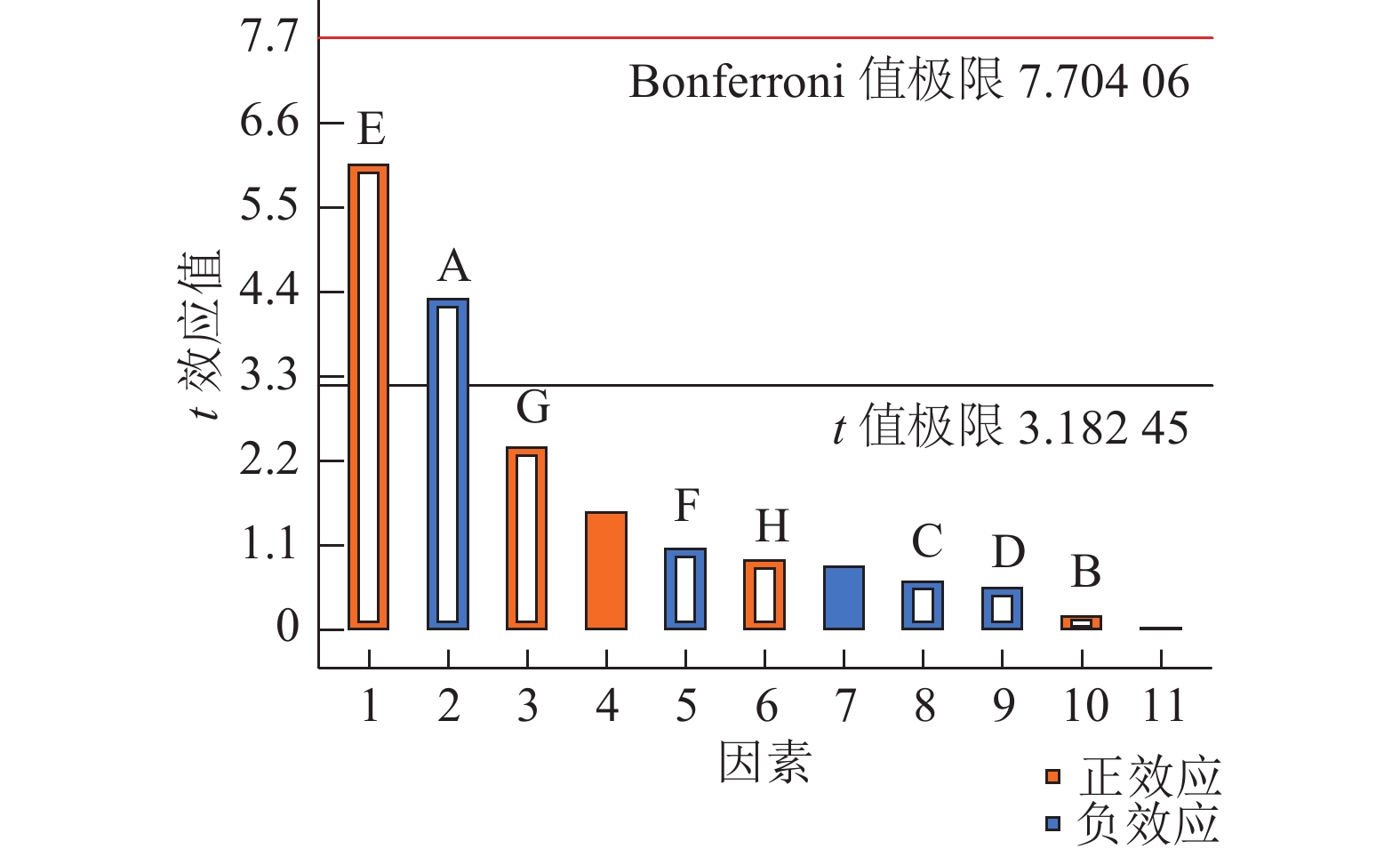

水平 因素 A B/MPa C D E F G H I1~I3 低水平(−1) 0.399 138.3 0.182 0.615 0.231 0.267 0.054 5 0.031 7 — 高水平(+1) 0.423 409.5 0.284 0.729 0.342 0.401 0.078 2 0.093 1 — 1)A:玉米泊松比;B:玉米弹性模量;C:玉米–玉米恢复系数;D:玉米–不锈钢恢复系数;E:玉米–玉米静摩擦系数;F:玉米–不锈钢静摩擦系数;G:玉米–玉米滚动摩擦系数;H:玉米–不锈钢滚动摩擦系数;I1~I3:虚拟变量 表 3 Plackett-Burman试验设计及结果1)

Table 3 Design and result of Plackett-Burman experiment

序号 因素 堆积角/(°) A B I1 C D I2 E F I3 G H 1 +1 +1 –1 –1 –1 +1 –1 +1 +1 –1 +1 26.52 2 +1 +1 –1 +1 +1 +1 –1 –1 –1 +1 –1 27.30 3 –1 +1 +1 +1 –1 –1 –1 +1 –1 +1 +1 31.45 4 +1 +1 +1 –1 –1 –1 +1 –1 +1 +1 –1 32.96 5 –1 –1 –1 +1 –1 +1 +1 –1 +1 +1 +1 34.17 6 –1 +1 +1 –1 +1 +1 +1 –1 –1 –1 +1 33.81 7 +1 –1 +1 +1 –1 +1 +1 +1 –1 –1 –1 29.96 8 +1 –1 +1 +1 +1 –1 –1 –1 +1 –1 +1 27.73 9 +1 –1 –1 –1 +1 –1 +1 +1 –1 +1 +1 31.53 10 –1 –1 –1 –1 –1 –1 –1 –1 –1 –1 –1 29.51 11 –1 –1 +1 –1 +1 +1 –1 +1 +1 +1 –1 30.40 12 –1 +1 –1 +1 +1 –1 +1 +1 +1 –1 –1 31.88 1)A:玉米泊松比;B:玉米弹性模量;I1:虚拟变量;C:玉米–玉米恢复系数;D:玉米–不锈钢恢复系数;I2:虚拟变量;E:玉米–玉米静摩擦系数;F:玉米–不锈钢静摩擦系数;G:玉米–玉米滚动摩擦系数;H:玉米–不锈钢滚动摩擦系数;I3:虚拟变量 表 4 Plackett-Burman试验方差分析1)

Table 4 Variance analysis of Plackett-Burman experiment

误差来源 均方和 F P A 19.335 8 18.533 0* 0.023 1 B 0.030 3 0.029 0 0.875 6 C 0.417 2 0.399 9 0.572 1 D 0.311 2 0.298 3 0.623 0 E 38.118 8 36.536 2** 0.009 1 F 1.167 2 1.118 7 0.367 8 G 5.869 5 5.625 8* 0.098 3 H 0.854 7 0.819 2 0.432 1 1)A:玉米泊松比;B:玉米弹性模量;C:玉米–玉米恢复系数;D:玉米–不锈钢恢复系数;E:玉米–玉米静摩擦系数;F:玉米–不锈钢静摩擦系数;G:玉米–玉米滚动摩擦系数;H:玉米–不锈钢滚动摩擦系数;“*”和“**”分别表示达0.1和0.01显著水平 表 5 最陡爬坡试验设计及结果1)

Table 5 Design and result of the steepest ascent experiment

处理 因素 堆积角/(°) 误差/

%玉米泊松比 玉米–玉米

静摩擦系数玉米–玉米

滚动摩擦系数1 0.46 0.18 0.042 25.53 2.97 2 0.44 0.22 0.050 26.49 0.21 3 0.42 0.26 0.058 28.45 8.08 4 0.40 0.30 0.066 31.51 17.99 5 0.38 0.34 0.074 31.31 19.31 6 0.36 0.38 0.082 32.71 29.94 表 6 中心组合设计试验设计及结果

Table 6 Design and result of central composite designs experiment

序号 玉米

泊松比玉米–玉米

静摩擦系数玉米–玉米

滚动摩擦系数堆积角/

(°)1 1 1 1 27.49 2 1 –1 1 27.75 3 0 0 0 26.77 4 0 0 0 26.49 5 0 0 0 27.39 6 1.682 0 0 27.83 7 0 0 0 27.96 8 –1 –1 –1 30.70 9 –1 –1 –1 30.13 10 0 0 –1.682 27.18 11 0 0 1.682 31.71 12 0 0 0 28.07 13 1 1 –1 25.83 14 0 0 0 28.71 15 0 1.682 0 25.80 16 1 –1 –1 27.35 17 –1.682 0 0 29.82 18 0 –1.682 0 27.21 19 –1 1 –1 25.83 20 –1 1 1 27.59 表 7 中心组合设计试验模型方差分析1)

Table 7 Variance analysis of model of central composite designs experiment

变异来源 自由度 均方 F P 模型 9 4.626 2 5.652 7** 0.006 1 A 1 6.169 7 7.538 8* 0.020 6 E 1 9.805 8 11.981 7** 0.006 1 G 1 10.554 7 12.896 8* 0.004 9 AE 1 3.951 6 4.828 4 0.052 7 AG 1 0.007 7 0.009 4 0.924 9 EG 1 0.751 8 0.918 7 0.360 4 A2 1 1.731 6 2.115 8 0.176 4 E2 1 3.220 5 3.935 1 0.075 4 G2 1 4.642 9 5.673 2* 0.038 5 残差 10 0.818 4 拟失项 5 0.926 4 1.303 9 0.389 0 纯误差 5 0.710 4 总和 19 1) A、E、G分别为玉米泊松比、玉米–玉米静摩擦系数和玉米–玉米滚动摩擦系数;“*”和“**”分别表示达0.05 和0.01显著水平 表 8 中心组合设计优化模型方差分析1)

Table 8 Variance analysis of modified model of central composite designs

变异来源 自由度 均方 F P 模型 7 5.839 5 7.835 2** 0.001 1 A 1 6.169 7 8.278 3* 0.013 9 E 1 9.805 8 13.157 1* 0.003 5 G 1 10.554 7 14.161 9* 0.002 7 AE 1 3.951 6 5.302 0* 0.040 0 A2 1 1.731 6 2.323 4 0.153 4 E2 1 3.220 5 4.321 1 0.059 8 G2 1 4.642 9 6.229 7* 0.028 1 残差 12 0.745 3 拟失项 7 0.770 2 1.084 1 0.481 5 纯误差 5 0.710 4 总和 19 1) A、E、G分别为玉米泊松比、玉米–玉米静摩擦系数和玉米–玉米滚动摩擦系数;“*”和“**”分别表示达0.05和0.01显著水平 -

[1] 王国强, 郝万军, 王继新. 离散单元法及其在EDEM上的实践[M]. 西安: 西北工业大学出版社, 2010. [2] 胡国明. 颗粒系统的离散元素法分析仿真: 离散元素法的工业应用与EDEM软件简介[M]. 武汉: 武汉理工大学出版社, 2010. [3] MA Z, LI Y, XU L, et al. Dispersion and migration of agricultural particles in a variable-amplitude screen box based on the discrete element method[J]. Comput Electron Agr, 2017, 142, Part A: 173-180.

[4] 张涛, 刘飞, 赵满全, 等. 基于离散元的排种器排种室内玉米种群运动规律[J]. 农业工程学报, 2016, 32(22): 27-35. [5] BOAC J M, AMBROSE R P K, CASADA M E, et al. Applications of discrete element method in modeling of grain postharvest operations[J]. Food Eng Rev, 2014, 6(4): 128-149.

[6] LENAERTS B, AERTSEN T, TIJSKENS E, et al. Simulation of grain-straw separation by Discrete Element Modeling with bendable straw particles[J]. Comput Electron Agr, 2014, 101: 24-33.

[7] 纪玉杰, 薛宏达, 李成华. 玉米精密排种器工作过程的离散元仿真分析[J]. 计算机仿真, 2013, 30(3): 393-397. [8] SARNAVI H J, MOHAMMADI A N, MOTLAGH A M, et al. DEM model of wheat grains in storage considering the effect of moisture content in direct shear test[J]. Res J Appl Sci Eng Technol, 2013, 5(3): 829-841.

[9] RACKL M, HANLEY K J. A methodical calibration procedure for discrete element models[J]. Powder Technol, 2017, 307: 73-83.

[10] COETZEE C J. Review: Calibration of the discrete element method[J]. Powder Technol, 2017, 310: 104-142.

[11] COETZEE C J, ELS D N J. Calibration of granular material parameters for DEM modelling and numerical verification by blade–granular material interaction[J]. J Terramechanics, 2009, 46(1): 15-26.

[12] WANG L, ZHOU W, DING Z, et al. Experimental determination of parameter effects on the coefficient of restitution of differently shaped maize in three-dimensions[J]. Powder Technol, 2015, 284: 187-194.

[13] GRIMA A P, WYPYCH P W. Investigation into calibration of discrete element model parameters for scale-up and validation of particle–structure interactions under impact conditions[J]. Powder Technol, 2011, 212(1): 198-209.

[14] COETZEE C J, ELS D N J. Calibration of discrete element parameters and the modelling of silo discharge and bucket filling[J]. Comput Electron Agr, 2009, 65(2): 198-212.

[15] 张荔, 李文辉, 杨胜强. 滚磨光整加工中磨料颗粒堆积角的离散元参数标定[J]. 中国科技论文, 2016, 11(16): 1821-1825. [16] 冯俊小, 林佳, 李十中, 等. 秸秆固态发酵回转筒内颗粒混合状态离散元参数标定[J]. 农业机械学报, 2015, 46(3): 208-213. [17] 张锐, 韩佃雷, 吉巧丽, 等. 离散元模拟中沙土参数标定方法研究[J]. 农业机械学报, 2017, 48(3): 49-56. [18] 武涛, 黄伟凤, 陈学深, 等. 考虑颗粒间黏结力的黏性土壤离散元模型参数标定[J]. 华南农业大学学报, 2017, 38(3): 93-98. [19] COETZEE C J. Calibration of the discrete element method and the effect of particle shape[J]. Powder Technol, 2016, 297: 50-70.

[20] PASHA M, HARE C, GHADIRI M, et al. Effect of particle shape on flow in discrete element method simulation of a rotary batch seed coater[J]. Powder Technol, 2016, 296: 29-36.

[21] MARKAUSKAS D, RAMÍREZ-GÓMEZ Á, KAČIANAUSKAS R, et al. Maize grain shape approaches for DEM modelling[J]. Comput Electron Agr, 2015, 118: 247-258.

[22] GUO Z, CHEN X, LIU H, et al. Theoretical and experimental investigation on angle of repose of biomass–coal blends[J]. Fuel, 2014, 116(15): 131-139.

[23] 吴爱祥, 孙业志, 刘湘平. 散体动力学理论及其应用[M]. 北京: 冶金工业出版社, 2002. [24] 贾富国, 韩燕龙, 刘扬, 等. 稻谷颗粒物料堆积角模拟预测方法[J]. 农业工程学报, 2014(11): 254-260. [25] GRIMA A P, WYPYCH P W. Development and validation of calibration methods for discrete element modelling[J]. Granul Matter, 2011, 13(2): 127-132.

[26] 周文秀. 玉米籽粒的物理力学特性研究[D]. 哈尔滨: 东北农业大学, 2015. [27] 崔涛, 刘佳, 杨丽, 等. 基于高速摄像的玉米种子滚动摩擦特性试验与仿真[J]. 农业工程学报, 2013, 29(15): 34-41. [28] DAI F, ZHAO W Y, HAN Z S, et al. Experiment on Poisson's ratio determination about corn kernel[C]// Trans Tech Publications Ltd. Advanced Materials Research. Switzerland: Trans Tech Publications Ltd., 2013: 799-802.

[29] 杨明芳. 基于离散元法的玉米排种器的数字化设计方法研究[D]. 长春: 吉林大学, 2009. [30] COŞKUN M B, YALҪIN N B, ÖZARSLAN C. Physical properties of sweet corn seed (Zea mays saccharata Sturt.)[J]. J Food Eng, 2006, 74(4): 523-528.

下载:

下载: