In-situ synthesis and anti-mold property of nano-copper of the heat-treated wood

-

摘要:目的

提高热处理木材的防霉变性能,为扩大高温热处理木材的使用范围提供技术支撑。

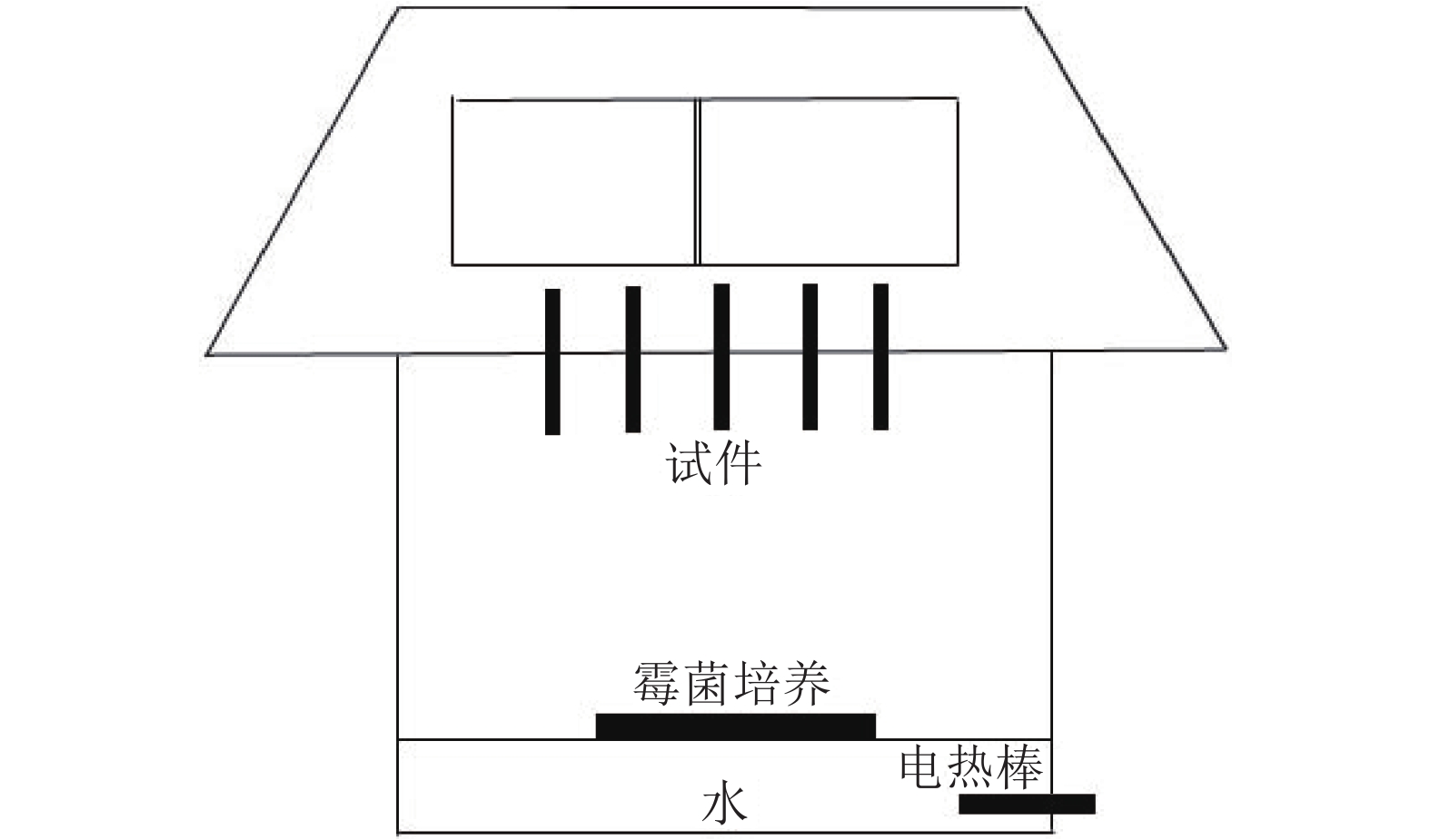

方法依据液相还原反应原理,以含铜浸渍液加压处理马尾松Pinus massoniana木材,运用木材热处理技术,获得热处理木材,依据改良的霉变箱法测试该材料的防霉变效力。

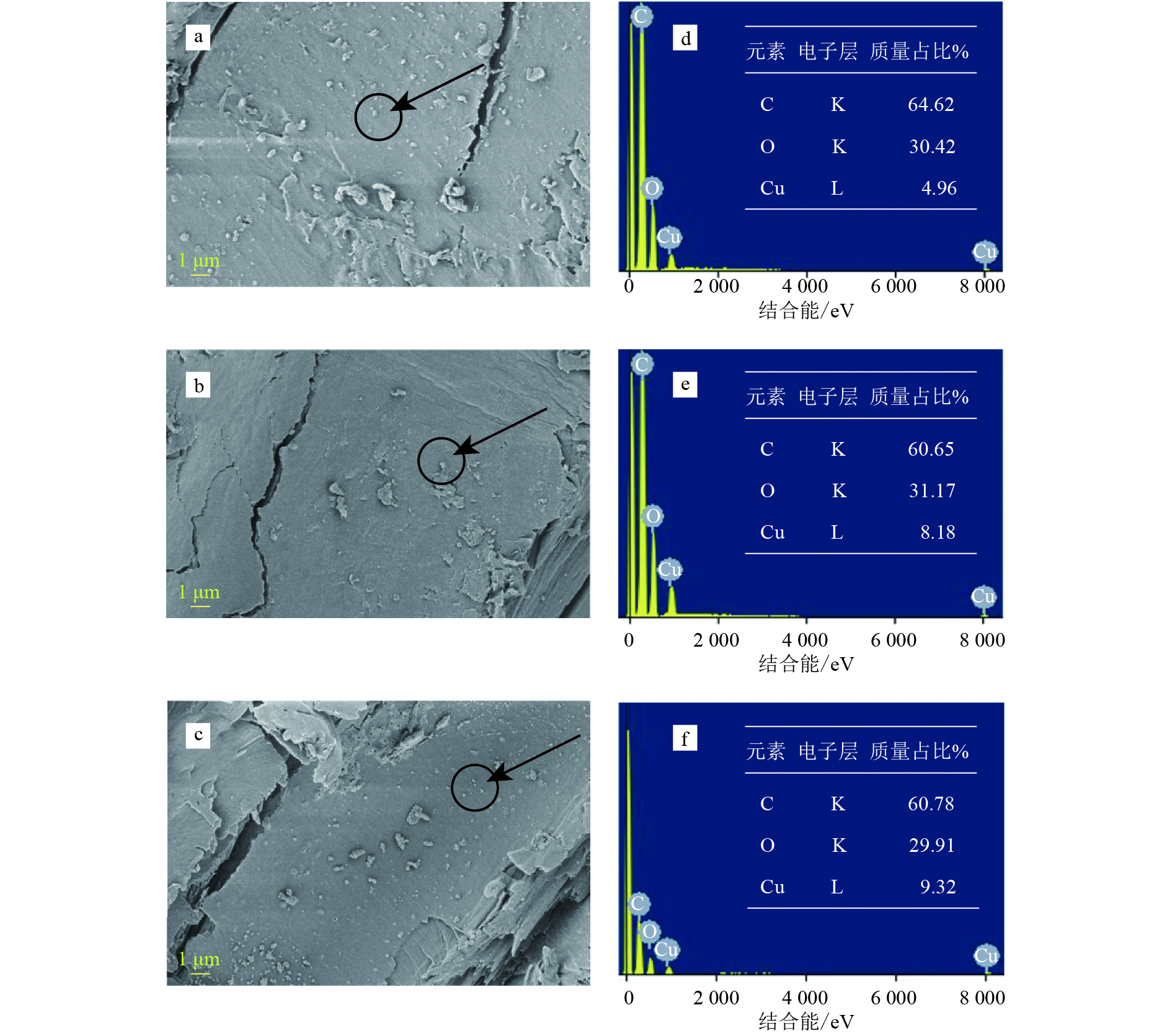

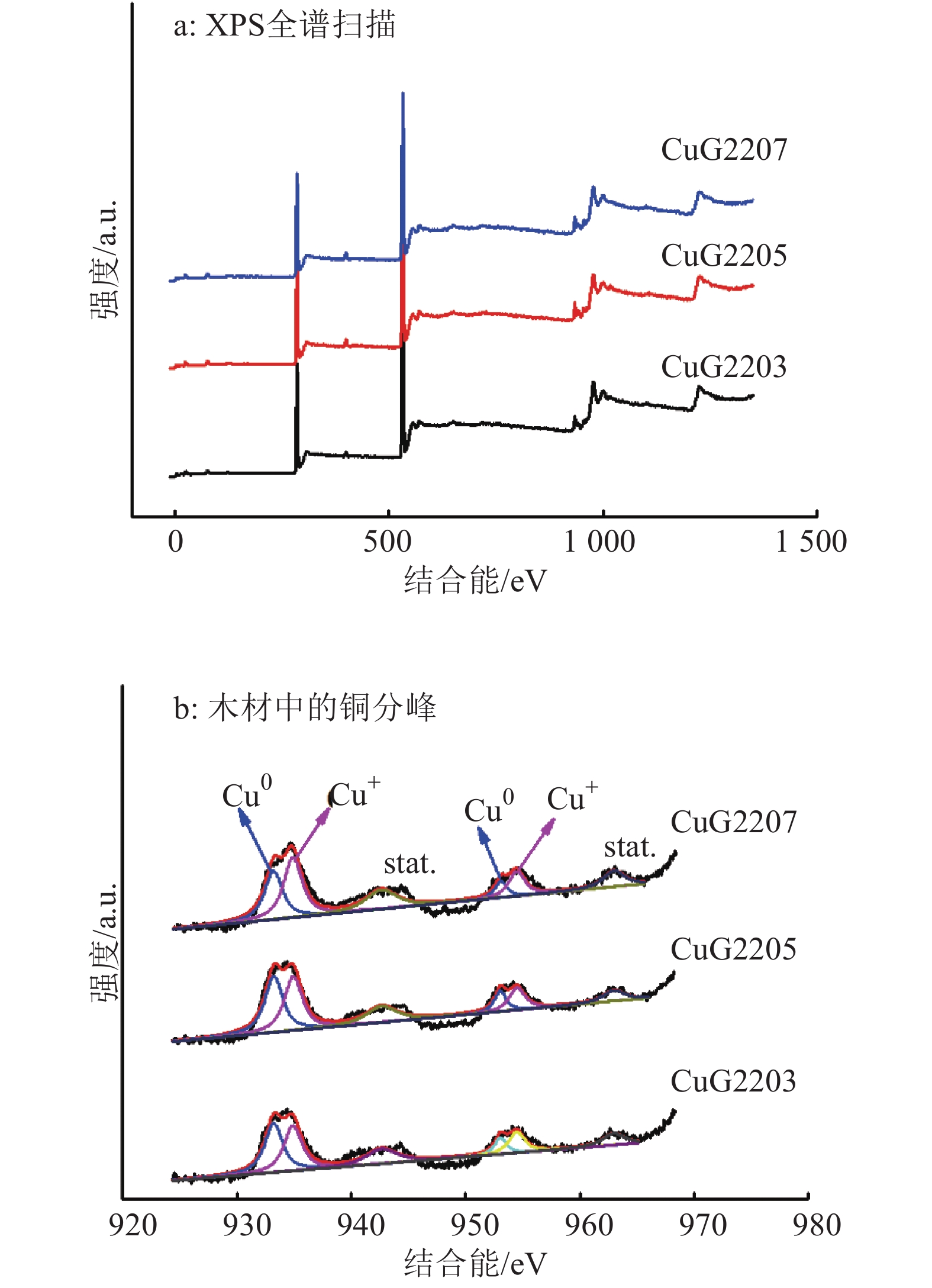

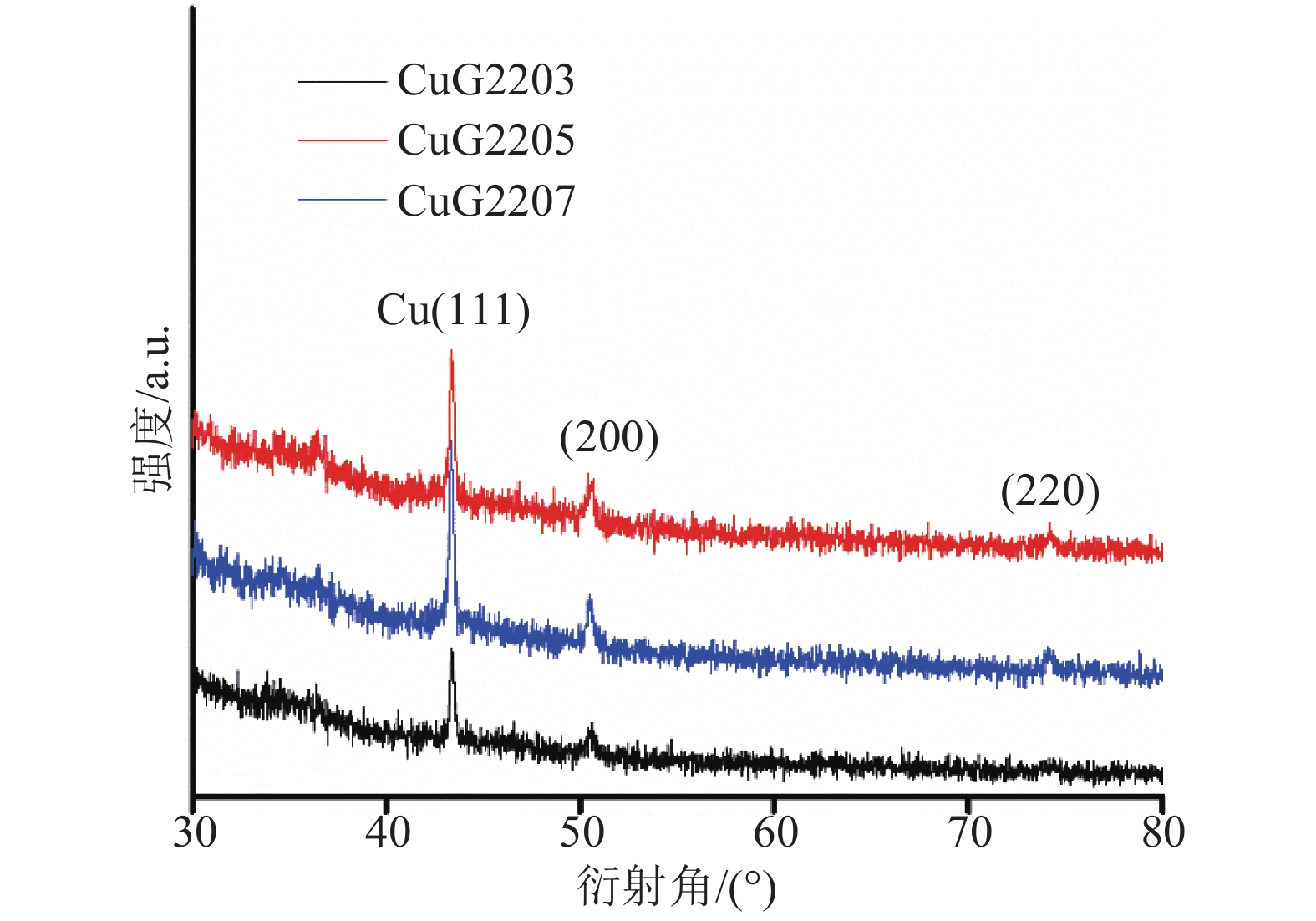

结果对照组马尾松经高温220 ℃、3 h以上热处理之后,木材的防霉效力为20%以下;同等条件下,含铜马尾松热处理材防霉效力达90%以上。扫描电镜(SEM)与能谱(EDS)、X射线光电子能谱(XPS)和X射线衍射(XRD)表征含铜马尾松热处理木材内生成了纳米铜。

结论含铜热处理木材受热原位生成的100 nm铜能够极大地提高木材的防霉变效力。

Abstract:ObjectiveTo improve the anti-mold property of heat-treated wood and provide a technical support for expanding the use range of heat-treated wood.

MethodThe Pinus massoniana wood was dipped in copper impregnated liquid with pressure according to liquid reduction reaction principle. The heat-treated wood was obtained by heat treatment technics, and anti-mold property of the wood was tested by modified mold culture box test method.

ResultThe control group of P. massoniana wood was treated more than 3 hours at 220 ℃ and the mold-resistance effectiveness was lower than 20%. Under the same heat treatment condition, the mold-resistance effectiveness of P. massoniana wood which was impregnated in copper solution was more than 90%. The data of scanning electron microscope (SEM), energy disperse spectroscopy (EDS), X-ray photoelectron spectroscopy (XPS) and X-ray diffraction (XRD) showed that nano-copper was generated in copper-contained P. massoniana heat-treated wood.

ConclusionThe 100 nm copper produced in situ by heat treatment of copper-contained wood can greatly improve anti-mold property of wood.

-

Keywords:

- wood /

- heat treatment /

- anti-mold /

- nano-copper /

- copper-contained compound

-

-

表 1 不同处理方式的马尾松材的防霉变效力

Table 1 Mold-resistance effectiveness of Pinus massoniana wood processed in different methods

样品

编号1)处理方式 平均霉

变等级防霉效

力/%CuG浸渍2) θ热处理/℃ t/h CK – 4.00 0 N-3 – 220 3 3.75 6.25 N-5 – 220 5 3.33 16.75 N-7 – 220 7 3.67 8.25 CuG2203 + 220 3 0.25 93.75 CuG2205 + 220 5 0.08 97.92 CuG2207 + 220 7 0.33 91.67 1) CK为对照材,N为经热处理的对照材,CuG为经热处理的浸渍材;2) +表示经过CuG浸渍处理,–表示未处理 -

[1] MILITZ H. Heat treatment technologies in Europe: Scientific background and technological state-of-art[C]//International Research Group on Wood Preservation. Enhancing the durability of lumber and engineered wood products. Kissimmee, FL, USA: Forest Products Society, 2002: 11-13.

[2] MILITZ H, TJEERDSMA B. Heat treatment of wood by the PLATO-process[C]//Northwest Regional Educational Laboratory. Proceedings of special seminar of COST action E22. France: Antibes, 2001.

[3] XIE Y J, LIU Y X, SUN Y X. Heat-treated wood and its development in Europe[J]. J Forest Res, 2002, 13(3): 224-230.

[4] VERNOIS M. Heat treatment of wood in France-state of the art[C]//Northwest Regional Educational Laboratory. Proceedings of special seminar of COST action E22. France: Antibes, 2001.

[5] RAPP A O, SAILER M. Oil heat treatment of wood in Germany-state of the art[C]//Northwest Regional Educational Laboratory. Proceedings of special seminar of COST action E22. France: Antibes, 2001.

[6] VIITANIEMI P, JÄMSÄ S. Puun modifiointi lämpökäsittelyllä (Modification of wood with heat-treatment)[M]. Espoo: VTT Julkaisuja–Publikationer, 1996: 814.

[7] 朱昆, 程康华, 李慧明, 等. 热处理改性木材的性能分析Ⅲ: 热处理材的防霉性能[J]. 木材工业, 2010, 24(1): 42-44. [8] 顾炼百, 丁涛, 吕斌, 等. 压力蒸汽热处理木材生物耐久性的研究[J]. 林产工业, 2010, 37(5): 6-9. [9] SIVONEN H, NUOPPONEN M, MAUNU S L, et al. Carbon-thirteen cross-polarization magic angle spinning nuclear magnetic resonance and fourier transform infrared studies of thermally modified wood exposed to brown and soft rot fungi[J]. Appl Spectrosc, 2003, 57(3): 266-273.

[10] THEANDER O, BJURMAN J, BOUTELJE J B. Increase in the content of low-molecular carbohydrates at lumber surfaces during drying and correlations with nitrogen content, yellowing and mould growth[J]. Wood Sci Technol, 1993, 27(5): 381-389.

[11] KARTAL S N, GREEN Ⅲ F, CLAUSEN C A. Do the unique properties of nanometals affect leachability or efficacy against fungi and termites?[J]. Int Biodeterior Biodegrad, 2009, 63(4): 490-495.

[12] 于洪枫, 孙芳, 王学文, 等. 低温液相法制备铜及氧化亚铜[J]. 哈尔滨师范大学自然科学学报, 2015, 31(5): 73-75. [13] 张文凤, 阎玺庆, 王治华, 等. 花状纳米铜的制备及抗菌性能[J]. 功能材料, 2013, 44(15): 2156-2161. [14] SASTRY A B S, AMANCHI R B K, PRASAD C S R L, et al. Large-scale green synthesis of Cu nanoparticles[J]. Environ Chem Lett, 2013, 11(2): 183-187.

[15] WU C W, MOSHER B P, ZENG T F. One-step green route to narrowly dispersed copper nanocrystals[J]. J Nanopart Res, 2006, 8(6): 965-969.

[16] JAIN S, JAIN A, KACHHAWAH P, et al. Synthesis and size control of copper nanoparticles and their catalytic application[J]. Frans Nonferrous Met Soc China, 2015, 25(12): 3995-4000.

[17] YU Y, DU F P, YU J C, et al. One-dimensional shape-controlled preparation of porous Cu2O nano-whiskers by using CTAB as a template[J]. J Solid State Chem, 2004, 177(12): 4640-4647.

[18] LIU Q M, ZHOU D B, YAMAMORO Y Y, et al. Effects of reaction parameters on preparation of Cu nanoparticles via aqueous solution reduction method with NaBH4[J]. Trans Nonferrous Met Soc China, 2012, 22(2): 2991-2996.

[19] KHANNA P K, GAIKWAD S, ADHYAPAK P V, et al. Synthesis and characterization of copper nanoparticles[J]. Mater Lett, 2007, 61(25): 4711-4714.

[20] 杨瑞卿, 樊金串. 聚乙二醇体系中含铜化合物液相热解法制备纳米铜粉[J]. 材料导报, 2014, 28(14): 88-90. [21] 全国木材标准化技术委员会. 防霉剂对木材霉菌及变色菌防治效力的试验方法: GB/T 18261—2013[S]. 北京: 中国标准出版社, 2014. [22] 杜晓凤, 刘雅, 连崑. 新型纳米铜/碳复合材料抗菌性能与机理的研究[C]//全国卫生产业企业管理协会抗菌产业分会. 2016年抗菌科学与技术论坛论文集. 苏州: 全国卫生产业企业管理协会抗菌产业分会, 2016. [23] 黄荣凤, 吕建雄, 曹永建, 等. 高温热处理对毛白杨木材化学成分含量的影响[J]. 北京林业大学学报, 2010, 32(3): 155-160. [24] 黄玉莹. 稻草的水热碳化研究[D]. 长沙: 湖南大学, 2012. [25] USMAN M S, EI ZOWALATY M E, SHAMELI K, et al. Synthesis, characterization, and antimicrobial properties of copper nanoparticles[J]. Int J Nanomed, 2013, 8: 4467-4479.

[26] DING X C, MENESES M B, ALBUKHARI S M, et al. Comparing leaching of different copper oxide nanoparticles and ammoniacal copper salt from wood[J]. Macromol Mater Eng, 2013, 298(12): 1335-1343.

[27] 许晓滨. 可得然胶/纳米铜复合材料的制备及抗菌研究[D]. 武汉: 武汉理工大学, 2013. [28] MUHCU D, TERZI E, KARTAL S N, et al. Biological performance, water absorption, and swelling of wood treated with nano-particles combined with the application of Paraloid B72®[J]. J Forest Res, 2017, 28(2): 381-394.

[29] MANTANIS G, TERZI E, KARTAL S N, et al. Evaluation of mold, decay and termite resistance of pine wood treated with zinc- and copper-based nanocompounds[J]. Int Biodeterior Biodegrad, 2014, 90(4): 140-144.

[30] CIVARDIC, SCHWARZE F W M R, WICK P. Micronized copper wood preservatives: An efficiency and potential health risk assessment for copper-based nanoparticles[J]. Environ Pollut, 2015, 200: 126-132.

[31] MONDAL K K, MANI C. Investigation of the antibacterial properties of nanocopper against Xanthomonas axonopodis pv. punicae, the incitant of pomegranate bacterial blight[J]. Ann Microbiol, 2012, 62(2): 889-893.

[32] SEDIGHI A, MONTAZER M, HEMMATINEJAD N. Copper nanoparticles on bleached cotton fabric: In situ synthesis and characterization[J]. Cellulose, 2014, 21(3): 2119-2132.

[33] KRYŠTOF D, PAVEL U, MARIE Š, et al. Affordable, green, and facile synthesis of copper nanoparticles stabilized by environmentally friendly surfactants[J]. Metall Mater Trans : B, 2015, 46(4): 2529-2533.

[34] RAFFI M, MEHRWAN S, BHATTI T M, et al. Investigations into the antibacterial behavior of copper nanoparticles against Escherichia coli[J]. Ann Microbiol, 2010, 60(1): 75-80.

下载:

下载: