Design and simulation of hydraulic driven disc harrow

-

摘要:目的

针对长江中下游地区土壤黏重板结、秸秆量大和土壤含水率波动大的作业情况,设计一种液压驱动式圆盘耙。

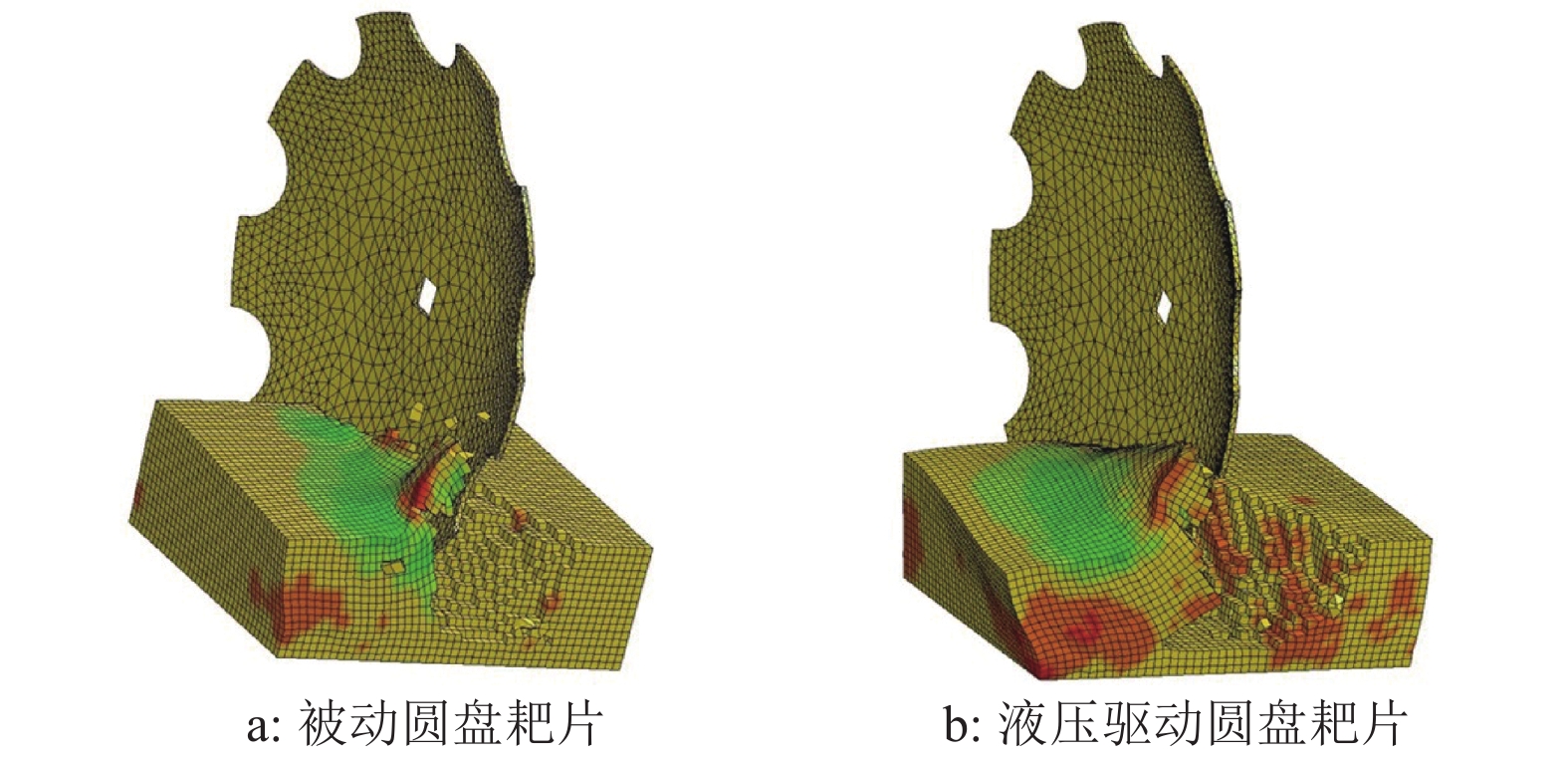

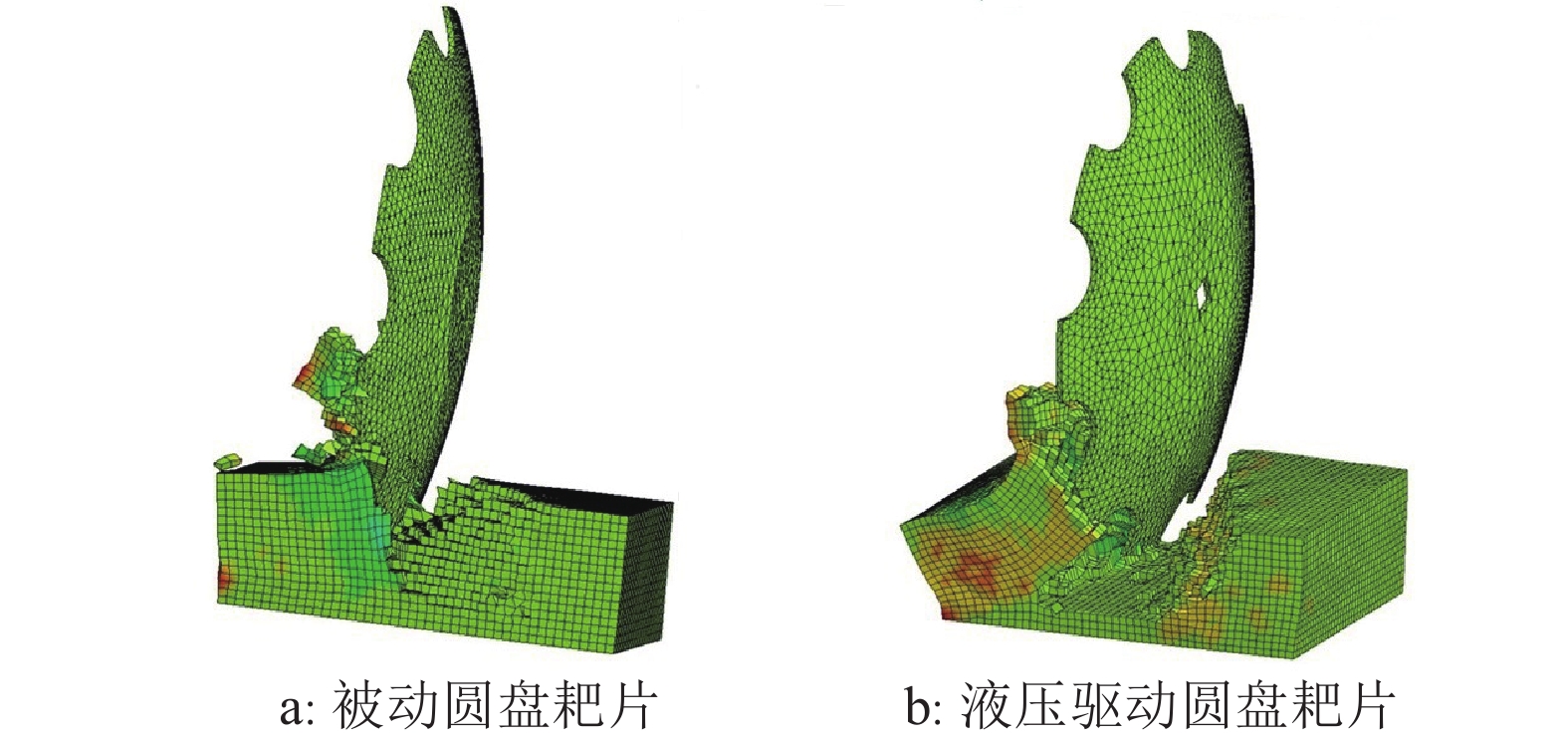

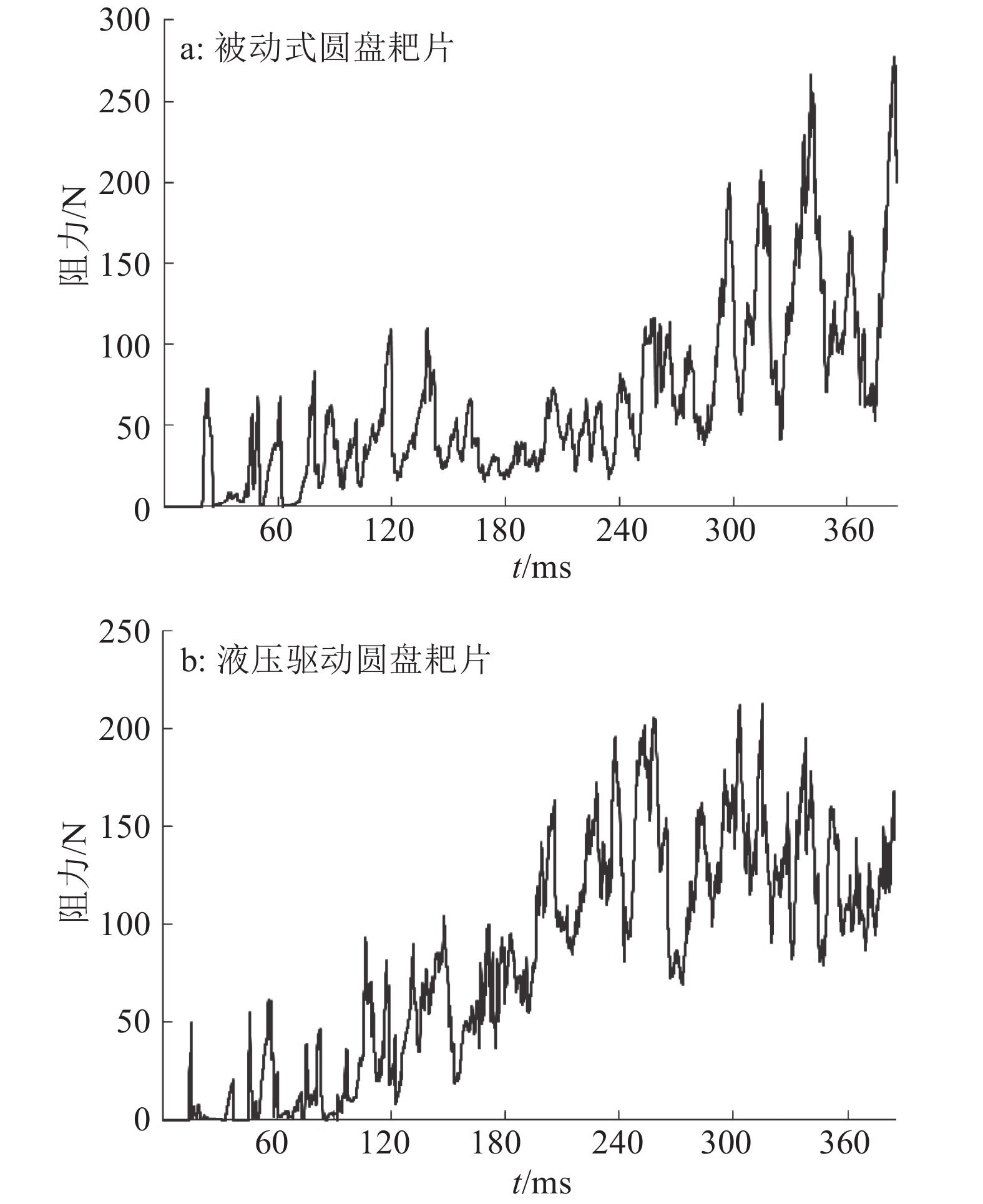

方法分析确定圆盘耙结构和作业参数及液压驱动系统的设计,依据机组前进速度确定圆盘耙组转速;分析得出缺口圆盘耙片的运动轨迹及满足功能要求的耙片临界偏角;基于ANSYS/LS-DYNA对圆盘耙片切削土壤过程进行有限元仿真分析。

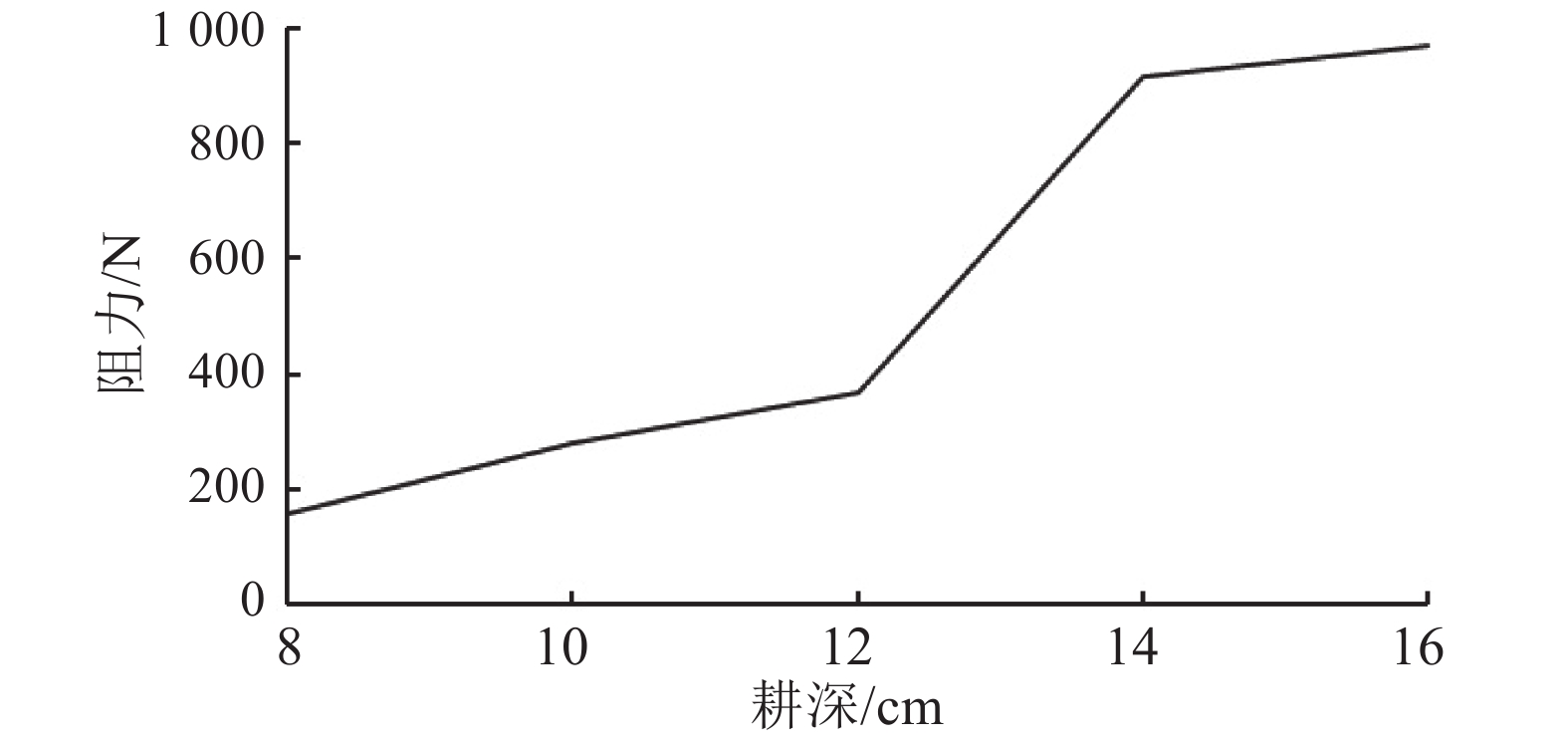

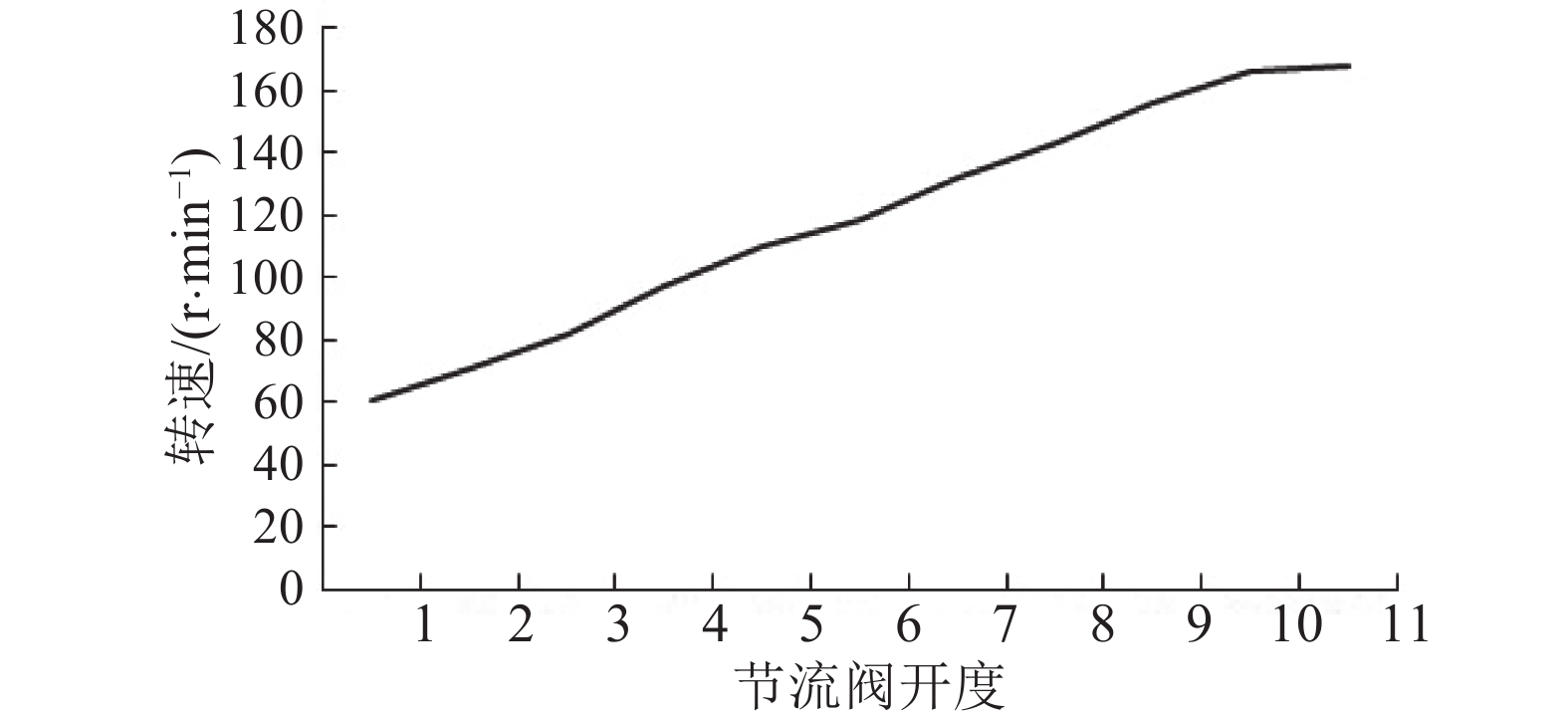

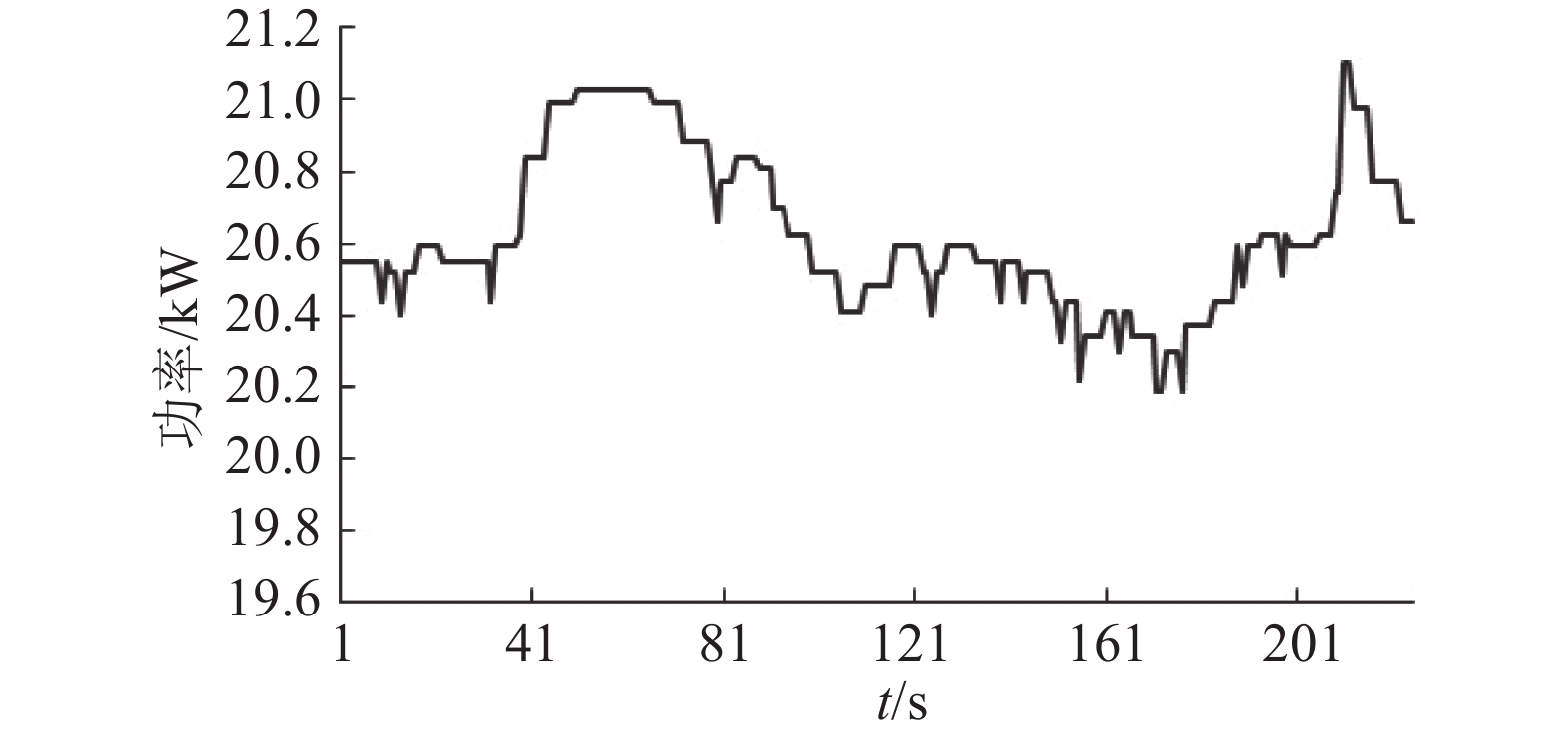

结果圆盘耙组转速为60~168 r·min–1,耙片临界偏角为23°。仿真结果表明:圆盘耙片刃口切削土壤其耕作阻力呈周期性变化,随切削土壤深度的增加耕作阻力逐渐变大,后趋于稳定;对比被动圆盘耙片与液压驱动圆盘耙片作业效果,液压驱动圆盘耙片抛翻土量大,耕深稳定。田间试验表明:液压驱动式圆盘耙耕深为85~120 mm,耕深稳定性变异系数为9.6%。

结论液压驱动圆盘耙组作业效果达到设计要求。

Abstract:ObjectiveTo design a hydraulic driven disc harrow, and to use it under the working conditions of the middle-lower Yangtze plain with sticky and sealing soil, large amount of rice straws and fluctuating soil moisture content.

MethodThe structure and operation parameters of the disc harrow were analyzed and the hydraulic driven system was designed. The rotary speed ranges of the hydraulic motor were determined according to the forward speed of the system. The motion trajectory of the notched disc was analyzed and the critical angle of the disc was determined. The process that the disc cutting the soil was analyzed using the finite element simulation method based on ANSYS/LS-DYNA.

ResultThe rotary speed of hydraulic motor ranged from 60 to 168 r·min–1. The critical angle of the disc was 23°. The simulation results showed that the resistance of soil cutting by the disc changed periodically, increased gradually as soil depth increased and then became stable. Compared with a negative disc, the hydraulic driven notched disc could rotate more soil and its tillage depth was more stable. Field experiment showed that the tillage depth for the hydraulic driven notched disc was 85–120 mm and the coefficient of variation for stability in tillage depth was 9.6%.

ConclusionThe hydraulic driven disc harrow meets the design requirements.

-

Keywords:

- agricultural machinery /

- disc harrow /

- hydraulic drive /

- finite element method /

- notched disc

-

N和P是植物生长最主要的限制元素,N是植物的蛋白质、核酸、叶绿素和许多次生代谢产物中的重要成分,在光合过程的酶活性中起着至关重要的作用,P在植物代谢中起着核心作用。外源增施氮、磷肥,能改变土壤中的氮磷结构比例,调控植物应对环境的生长策略,进而影响植物生长[1]。不同植物对养分的需求以及不同土壤的特定肥力指标并不相同[2]。有研究表明,增加施肥后植物的生长效率和酶活性也增加[3-4],而有些研究者发现生长效率在很大程度上不受营养元素添加的影响[5-6],且适宜的施肥配方往往因树种或者无性系而异[7-8]。因此,很有必要针对特定树种开展施肥配方研究。

西南桦Betula alnoides是我国热带、亚热带地区优良的乡土阔叶树种,它生长快、材质优,有较高的经济价值,其林分具有优良的生态特性,如涵养水源、维持生物多样性和固定碳素等,当前种植面积已逾15万hm2。随着西南桦种植业迅速发展,对容器苗数量和质量的要求不断提高。育苗容器基质中的养分含量往往无法满足苗木的生长发育所需,因此通过科学施肥补充苗木营养需求已成为国内外育苗管理的一项重要研究内容。目前,西南桦苗木施肥的研究主要集中在营养元素的种类、最佳施肥量和施肥方法等方面[9-15]。研究认为,适量地添加N、P会增加西南桦幼苗生长量,但现有对西南桦开展的配方施肥研究报道较少,且多见于N或P的单独作用。鉴于此,本文以4个西南桦无性系组培苗为研究对象,通过设置N、P添加试验,阐明西南桦无性系对不同施肥处理的响应差异,揭示西南桦无性系适宜的施肥配方,为西南桦育苗施肥策略提供理论依据。

1. 材料与方法

1.1 试验区概况

试验地点位于广西友谊关森林生态系统国家定位观测研究站中国林业科学研究院热带林业实验中心站点,地理位置为22°05′00″N,106°48′12″E,该地属于南亚热带季风气候,年平均气温21.5 ℃,≥10 ℃积温约6 000~7 600 ℃,年均降水量1 400 mm,相对湿度80%~84%。

1.2 试验设计

2017年10月—2018年1月在热带林业实验中心苗圃温室内开展氮磷施肥对西南桦无性系幼苗生长及叶片N、P含量影响的试验。

参试的4个西南桦无性系为A5、BY-1、FB4、FB4+,其组培苗来自热带林业实验中心苗圃,平均高度约为4 cm。氮肥为尿素,w(N)≥46.4%,设置3个单株施N水平(0、200、400 mg)。磷肥为钙镁磷肥,w(P2O5)≥18%,设置3个单株施P水平(0、70、140 mg)。为防止苗木缺素,按照每株332 mg施入K肥,钾肥为氯化钾(K2O质量分数≥60%)。采用完全随机区组设计,共9个组合处理,具体见表1,每个小区25株,3次重复(区组),共计2 700株。

表 1 西南桦无性系苗木单株施肥处理Table 1. Fertilization treatment for per seedling of Betula alnoides clone处理编号

No. of treatment施N量/mg

N application amount施P量/mg

P application amount施K量/mg

K application amount1(CK) 0 0 332 2 0 70 332 3 0 140 332 4 200 0 332 5 200 70 332 6 200 140 332 7 400 0 332 8 400 70 332 9 400 140 332 移苗前将黄心土、炭化树皮、沤制锯末、沤制树皮按体积比1︰1︰3︰6充分混合,做为基质装入12 cm(直径)×15 cm(高)的无纺布袋,置于塑料盘中。育苗基质pH为6.14,全N、全P、全K和有机质质量分数分别为4.24、0.70、3.18和29.97 g/kg。磷肥作为基肥一次性施入基质中,移苗后1个月,开始追施氮肥和钾肥,每周施肥1次,共10次。每隔2周移动1次苗盘,以减小边际效应对试验结果的影响。

1.3 生长及养分含量测定

试验结束时,统计每个小区幼苗的存活率,测定所有幼苗的苗高、地径、分枝数等。每个小区分别选取5株标准西南桦无性系幼苗,用于生物量、叶面积和叶片养分含量的测定。用去离子水将苗木冲洗干净,并分为根、枝和叶3部分取样。吸干叶片表面水分,应用Microtek Scan Maker 9700XL扫描仪获取叶片图像,叶面积计算采用Chen等[16]的方法。将根、枝和叶部分分别放入烘箱内,65 ℃条件下烘48 h至恒质量,测定各部分的干物质量。将烘干称质量后的叶片样品粉碎,过筛后用于叶片养分含量的测定。植株样品用浓H2SO4-H2O2消煮,全N、全P含量分别用扩散法和钼锑抗比色法测定。

1.4 数据分析

利用SPSS 19.0软件一般线性模型对西南桦幼苗生长和叶片养分含量指标进行方差分析和Duncan’ s多重比较分析,用Sigmaplot 10.0软件绘图。

2. 结果与分析

2.1 西南桦无性系幼苗生长表现

不同施肥处理下的西南桦无性系幼苗生长情况见表2。方差分析表明:不同施肥处理对西南桦无性系幼苗的苗高、地径、生物量、根冠比、分枝数和叶面积影响极显著(P<0.01);4个无性系的生长指标(地径除外)均差异不显著(P>0.05);施肥处理和无性系的交互作用除对生物量和叶面积无显著影响外,其他生长指标均差异极显著。

表 2 不同施肥处理下的西南桦无性系苗木生长表现1)Table 2. Growth performance of Betula alnoides clone seedlings in different fertilization treatments项目

Item编号

Number苗高/cm

Seedling height地径/mm

Root collar diameter生物量/g

Biomass根冠比

Ratio of root to shoot分枝数

Branch number叶面积/cm2

Leaf area处理

Treatment1(CK) 10.01±1.33e 1.17±0.34c 0.24±0.04c 0.39±0.07a 0.87±0.62c 73.59±14.77c 2 10.80±1.79de 1.26±0.34c 0.27±0.06c 0.37±0.15a 1.66±0.89bc 84.54±21.02c 3 11.07±1.77d 1.39±0.33c 0.31±0.08c 0.38±0.07a 2.11±1.54b 98.36±23.34c 4 16.61±0.50abc 2.07±0.27ab 0.86±0.17b 0.27±0.10b 6.78±0.84a 364.97±85.89ab 5 17.43±0.49a 2.24±0.29a 1.10±0.19a 0.18±0.02d 7.07±0.27a 409.39±94.00a 6 17.07±1.36ab 2.10±0.32ab 0.97±0.26ab 0.21±0.04bcd 6.88±1.45a 399.57±87.38a 7 15.92±0.76c 1.90±0.33b 0.89±0.12b 0.26±0.08bc 6.58±0.93a 317.79±81.23b 8 16.36±0.80bc 2.00±0.27ab 0.98±0.18ab 0.20±0.02cd 6.51±1.15a 354.25±107.68ab 9 16.15±0.74bc 2.03±0.24ab 0.89±0.18b 0.23±0.05bcd 6.17±0.75a 347.78±123.73ab 无性系

CloneA5 14.77±3.19a 1.59±0.42c 0.69±0.36a 0.28±0.10a 5.42±3.07a 257.15±148.43a FB4 14.80±2.32a 1.85±0.33ab 0.69±0.30a 0.29±0.10a 5.12±1.93a 279.42±151.72a FB4+ 14.81±2.89a 1.81±0.47bc 0.81±0.44a 0.24±0.09a 4.90±2.60a 305.94±186.45a BY-1 14.02±3.82a 2.01±0.59a 0.70±0.34a 0.30±0.13a 4.39±2.87a 246.47±134.38a 变异来源

Source of variance处理 Treatment 114.19** 39.06** 58.06** 17.99** 126.47** 33.05** 无性系 Clone 0.42 4.00** 0.72 1.76 0.65 0.53 处理×无性系

Treatment×Clone2.27** 2.46** 0.70 2.09** 2.60** 0.31 1)同一项目同列数据后的不同小写字母表示差异显著(P<0.05,Duncan′s法);“**”表示差异达0.01显著水平(双因素方差分析)

1) Different lowercase letters in the same column of the same item indicated significant differences(P<0.05,Duncan′s test);“**” indicated significances at 0.01 level(Two-way ANOVA)施肥处理的西南桦无性系幼苗各生长指标(除根冠比外)均高于CK处理。其中,处理5的苗高、地径、生物量、分枝数和叶面积生长表现最优。多重比较发现,处理5和处理4、6的苗高差异不显著,3个处理的苗高均显著高于其他处理,是CK处理的1.66~1.74倍;处理5和处理4、6、8、9的地径、叶面积差异不显著,比CK处理分别提高了70.94%~91.45%和372.59%~456.31%;处理5和处理4、6、7、8、9的分枝数差异不显著,是CK处理的8.13倍;处理5和处理6、8的生物量差异不显著,是CK处理的近4.58倍。不同施肥处理西南桦幼苗根冠比表现为CK处理最大,与处理2和3无显著差异,但均显著高于其他处理。

无性系间比较,除地径外,4个无性系各生长指标均无显著性差异,但无性系FB4+的苗高、生物量和叶面积均略高于其他3个无性系,BY-1的地径和根冠比大于其他3个无性系。

2.2 西南桦无性系幼苗叶片养分状况

由表3可知,施肥处理对西南桦无性系幼苗叶片的N、P含量的影响均达到极显著水平(P<0.01),无性系对叶片养分含量的影响均未达到显著水平,且不存在明显的无性系和施肥处理的交互作用。

表 3 不同施肥处理对西南桦无性系苗木叶片养分含量的影响1)Table 3. Effects of different fertilization treatments on leaf nutrient contents of Betula alnoides clone seedings项目 Item 编号 Number w/(g·kg−1) N P 处理 Treatment 1(CK) 21.42±2.66c 1.49±0.39c 2 22.08±3.07c 1.76±0.41bc 3 22.47±3.08c 1.94±0.49ab 4 30.06±3.05b 1.84±0.25ab 5 30.33±2.58b 2.00±0.23a 6 28.69±2.57b 2.17±0.34a 7 30.55±3.00ab 1.81±0.23ab 8 32.63±1.35a 1.86±0.28ab 9 30.08±2.08b 1.98±0.2ab 无性系 Clone A5 28.20±4.65a 1.86±1.12a FB4 28.15±4.68a 1.86±0.90a FB4+ 28.64±5.06a 1.94±1.07a BY-1 27.07±5.06a 1.81±1.70a 变异来源 Source of variance 处理 Treatment 32.96** 3.44** 无性系 Clone 1.82 0.62 处理×无性系 Treatment×Clone 1.05 0.63 1)同一项目同列数据后的不同小写字母表示差异显著(P<0.05,Duncan′s法);“**”表示差异达0.01显著水平(双因素方差分析)

1) Different lowercase letters in the same column of the same item indicated significant differences(P<0.05,Duncan′s test); “**” indicated significances at 0.01 level(Two-way ANOVA)不同施肥处理叶片N含量均高于CK处理,其中,处理8的叶片N含量最高,比其他处理增加了6.80%~52.33%。多重比较进一步发现,单施氮肥(处理4和7)或氮磷肥混施(处理5、6、8和9)的西南桦幼苗叶片N含量与CK相比显著提高,单施磷肥的处理2和3对叶片N含量无显著影响。与CK相比,各施肥处理显著影响了西南桦苗木叶片P含量,其中,处理6的叶片P含量最高,是其他处理的1.09~1.46倍。无性系间比较,无性系FB4+的叶片N、P含量高于其他3个无性系,但差异不显著。

2.3 西南桦无性系幼苗单株生物量与叶片养分的相关性

通过绘制西南桦无性系幼苗叶片的N、P含量及其比值与生物量的散点图,及对叶片的N、P含量及其比值与生物量的统计分析表明,叶片N、P含量及其比值与生物量均符合抛物线关系,且呈显著的正相关关系(P<0.000 1,图1)。从拟合的一元二次抛物线方程可以看出,西南桦幼苗生物量与叶片N/P质量比的相关性最大(R=0.844 0),其次是叶片N含量(R=0.713 6),叶片P含量与幼苗生物量的相关性最小(R=0.406 2)。不同施肥处理相比,西南桦幼苗生物量在处理5最大,而在处理6略有降低,结合生物量与叶片N/P质量比的变化规律图(图1C),推测处理5的叶片N/P质量比约为15,这可能是影响西南桦生长的N/P限制比例。

3. 讨论与结论

N、P缺乏对植物产生负面影响[17-18]。本研究中,施肥处理的西南桦无性系幼苗的苗高、地径、生物量、叶面积和分枝数均高于对照,其中,处理5(每株施N 200 mg、施P 70 mg)的生长表现最好,这与以往研究者[13,15,19-21]认为适量地添加氮磷肥能促进林木生长的研究结论一致。然而,Gotore等[6]研究表明,单施氮肥对树木生长有负面影响;Rothstein[22]研究表明,与未施肥的对照处理相比,单独或组合添加常量营养元素处理均未促进北美短叶松Pinus banksiana 的生长。其原因可能在于林木不同生长阶段对施肥的需求不同或干旱胁迫等立地条件限制了林木对施肥的响应。此外,添加氮磷肥能否促进植物生长与幼苗所生长的基质养分有关。基质养分趋于饱和状态时,施肥不一定能促进幼苗的生长。如Santiago等[23]研究表明,高施N未促进巴拿马中部巴罗科罗拉多自然保护区吉加特半岛的5种最常见热带树种幼苗的生长,与研究地土壤N养分已趋于饱和有关。

叶片的养分含量已被认为是反映林分生长和土壤肥力的重要指标[24]。植物体内某种元素含量会随着该种元素的添加而明显增加,但对于其他含量稳定的元素可能使其含量降低,即产生稀释效应[25]。本研究结果表明,叶片的N、P含量随着氮、磷肥的添加而增加,支持了Chen等[12]、彭少麟[25]和严正兵等[26]的结论;单施氮肥或磷肥,西南桦无性系幼苗叶片N、P含量增加,但与对照差异不显著,这一结果在前人对刨花楠Machilus pauhoi的相关研究中也得到证实[27]。植物叶片N/P质量比反映植物生长的环境养分供应状况,被广泛应用于植物的营养限制诊断。研究认为,较低的N/P质量比说明植物受N限制,较高的N/P质量比说明植物受P限制。刘洋等[28]根据巨桉Eucalyptus grandis生物量与N/P质量比的变化规律,认为叶片N/P质量比<15时,巨桉生长受N含量限制。本研究中,西南桦无性系幼苗生物量在处理5施肥条件下最大,而在处理6(每株施N 200 mg、施P 140 mg)条件下略有降低,结合生物量与叶片N/P质量比的变化规律,推测叶片N/P质量比约为15可能是影响西南桦无性系生长的N/P质量比限制比例。

对于同一树种,其生长对施肥的响应往往因种质材料而异。如韦如萍等[8]对低P胁迫下杉木Cunninghamia lanceolate无性系根系形态进行研究,发现杉木的根系形态指标随施P水平的变化呈极显著的基因型效应差异;宋平等[29]研究表明,马尾松Pinus massoniana无性系幼苗的根系对不同N、P处理水平的形态反应差异显著;赵燕等[30]研究亦表明,在相同施肥处理条件下,不同系号毛白杨Populus tomentosa苗木的响应不尽一致。本研究中,西南桦不同无性系幼苗的生长表现和叶片养分状况对施肥的响应亦存在差异,但无性系间的差异不显著,与上述研究结果一致。

-

-

[1] 章秀福, 王丹英, 符冠富, 等. 南方稻田保护性耕作的研究进展与研究对策[J]. 土壤通报, 2006, 37(2): 346-351. [2] 谷子寒, 王元元, 帅泽宇, 等. 土壤耕作方式对水稻产量形成特性的影响初探[J]. 作物研究, 2017(2): 103-109. [3] 贾洪雷, 陈忠亮, 刘昭辰, 等. 耕整联合作业工艺及配套机具的研究[J]. 农业机械学报, 2001, 32(5): 40-43. [4] 朱瑞祥, 李成鑫, 程阳, 等. 被动式圆盘刀作业性能优化试验[J]. 农业工程学报, 2014, 30(18): 47-54. [5] 王金武, 张成亮, 许春林, 等. 联合整地机平整部件参数优化[J]. 农业机械学报, 2013, 44(2): 34-37. [6] 曹肆林, 王序俭, 王敏, 等. 1LZ系列联合整地机的设计与试验[J]. 西北农业学报, 2012, 21(5): 202-206. [7] 周勇, 余水生, 夏俊芳. 水田高茬秸秆还田耕整机设计与试验[J]. 农业机械学报, 2012, 43(8): 46-49. [8] 张欣悦, 李连豪, 汪春, 等. 1GSZ-350型灭茬旋耕联合整地机的设计与试验[J]. 农业工程学报, 2009, 25(5): 73-77. [9] 赵长海, 赵蛾, 朱雅林, 等. 稻田土壤的特点及耕整[J]. 天津农林科技, 2012(3): 32-35. [10] 张胜雄,方文熙. 驱动式圆盘犁在南方水田的适应性[J]. 粮油加工与食品机械, 1993(1): 24-27. [11] 郑侃, 何进, 王庆杰, 等. 联合整地作业机具的研究现状[J]. 农机化研究, 2016(1): 257-263. [12] 张孝安. 农业机械设计手册[M]. 北京: 中国农业科学技术出版社, 2007. [13] 刘辉. 基于LS-DYNA的旱地旋耕刀工作机理研究[D]. 重庆: 西南大学, 2012. [14] 夏俊芳, 贺小伟, 余水生, 等. 基于 ANSYS/LS-DYNA 的螺旋刀辊土壤切削有限元模拟[J]. 农业工程学报, 2013, 29(10): 34-41. [15] 张建, 王颖, 王淑红, 等. 基于 LS-DYNA 的油菜单圆盘开沟器切削茎秆土壤动态仿真[J]. 云南农业大学学报(自然科学), 2015, 30(6): 941-945. [16] ABO-ELNOR M, HAMILTON R, BOYLE J T. 3D Dynamic analysis of soil-tool interaction using the finite element method[J]. J Terramechanics, 2003, 40(1): 51-62.

[17] 齐龙, 梁仲维, 马旭, 等. 耙压式除草轮与水田土壤作用的流固耦合仿真分析及验证[J]. 农业工程学报, 2015, 31(5): 29-37. [18] ABDUL M M, MIKLÓS N. Tillage tool design by the finite element method: Part 1: Finite element modelling of soil plastic behaviour[J]. J Agr Eng Res, 1999, 72(1): 37-51.

[19] ABDUL M M, MIKLÓS N, HELMUT S, et al. Tillage tool design by the finite element method: Part 2: Experimental validation of the finite element results with soil bin test[J]. J Agr Eng Res, 1999, 72(1): 53-58.

[20] 张青松, 肖文立, 廖庆喜, 等. 油菜直播机深浅旋组合式种床整备装置的设计与试验[J]. 华中农业大学学报, 2016, 35(4): 121-128.

下载:

下载: